Why specifically doused the plane before departure, and what will happen if this is not done?

In my last post, there was some liberty regarding the procedure for removing ice and protecting the aircraft from ice. triplebanana corrected this in the comments, and then we began to understand this issue in detail. Fortunately, Yuri Vladimirovich Filatov helped, who assembled one of the first jet blowing machines for Aeroflot, bought the first Elephants, and generally has 40 years experience in this field. Now he teaches at the Aviation Executive Training Center, Aeroflot School and GOSNIIGA and works at A-Group, which I already talked about.

It all started with the fact that a long time ago in the USSR there was a water-jetting machine - in fact, the usual city “watering gun", which was run by the "Arctic" or "Arctic-200" squad. And there was a TZ-22 tanker (22 tons), which was filled with hot water in the boiler room and which went to the plane to wash off the snow from it. There were panicles and mops with scrapers, with which fighters in boots with steel horseshoes walked on the IL-76 wing and shot down the ice.

The procedure closest to modernity was as follows: the modified Ural A-96 with a retractable cradle approached the board. A man with a hose climbed into it, made a couple of turns around the cradle's fence (because the hose is heavy and slippery) and watered the plane from the tip - a metal tube flattened with a hammer. Regional airports in the North sometimes still do this, because it works in stable cold weather. But for situations of freezing rain, heavy snow and temperature jumps of about minus 5 Celsius, other measures are already needed so that the plane does not accumulate ice between the exit from the hangar and take-off.

Why do you need to pour water on a plane?

There are two types of dousing: for cleaning and for protection. They are called, respectively, deasing and anti-aising.

Snow and ice stick to the plane while they are on the ground. For example, a few centimeters of snow may fall over the night between flights. The following consequences are possible:

- This will increase the weight of the aircraft.

- It will change the shape and smoothness of the surface of the vessel, which may affect its aerodynamic qualities.

- It can block or restrict moving elements (mechanization).

- And finally, if during the take-off from the wing during the vibration solid fragments fly off, they can damage the tail or fall into the engines (if they are arranged behind the wings).

Ice falling on the blades of a rotating fan or engine compressor can lead to damage and surging of the engine (in other words, it will stall and fail to restart). There have been such cases in the history of aviation.

Therefore, it would be good to clear the plane of all that is stuck. Sometimes it’s enough to clean the existing layer and not cover the surface of the vessel with anything else.

At temperatures up to minus 7 (now according to the standard already up to 0 and above) this was done with hot water. At temperatures below - the composition of the "Arctic". The "Arctic" in different concentrations was used both for cleaning and for protection against new formations. Now, instead of it, several different types of liquid are used.

Now imagine that you just cleared the plane, but it stands in the rain or wet snow. It is necessary to protect it from the formation of new “crusts”. To do this, use another liquid that will create a film for about 10–20 minutes, and then fly off from the hull at takeoff at a speed of 180 kilometers per hour. A clean, fresh airplane will take off calmly and safely.

If the plane is not cleaned, then it cannot be taken off. Therefore, the alternative is not to fly in difficult weather conditions. That is, in the case of Russia - in fact, do not fly at all in winter.

Creations of the gloomy Russian genius

Remember the period when the country adopted the most rationalizing approach? So, one of the problems was aircraft engines, which, after exhausting their resources, were removed from aircraft. But the engines themselves could work, just their smooth operation was guaranteed by fewer nines. Most often two, sometimes one. So, these engines had to be used somehow. Imagine the joy of a Soviet engineer who was asked to somehow apply these things. And preferably peacefully.

For example, the TVZ set a record for the speed of the train (at the same time cutting off a section of the track and scattering gravel behind the laboratory car), something like this appeared fire engines for extinguishing fires with a jet, machines for cleaning quarries and mines from gas contamination.

And in the morning at Sheremetyevo aircraft in the morning came on a plane and with the help of ladders scrapped everything manually. It is dangerous and hard. The IL-76 wing is more than 8 meters wide, slippery. Fastened with carabiners. Considering that then, according to the rules, it was specially trained personnel with access to aircraft (in fact, aviation mechanics), I really wanted to somehow optimize the procedure. And then AI-20 turboprop (an engine with An-12 without a propeller) fell into their hands as a source of a jet stream. We took a ZIL-130 with a lifting body on the “scissors”, put the engine in a swinging fork and put the operator.

This thing perfectly blew the aircraft! True, during operation it turned out that the engine, let's say, is somewhat underestimated. In addition to ice, he perfectly cleared the plane of various protruding parts. At least he could, if brought closer. Only Tupolev gave official permission for such a procedure, having written detailed instructions on what is possible and what is not. GOSNIIGA took IL-18, pasted it with thermal sensors and blew it until they developed a technique. Recommendations came out, how many seconds to promote and where. The second feature of this particular unit was that the AI-20 does not have a very good venting system (releasing oil from air bubbles): when tilted, some of the oil fell into the exhaust nozzle. Boiling oil is quite difficult to wash off the board. And if you blow through the windows, then “silver” formed there - such a characteristic film, because of which I had to remove them and re-polish. As a result, with the existing methodology, the Riga plant began to produce these machines in series, but with a different engine. Another such wonderful unit was in Leningrad. They didn’t bother with the cradle, they just put the VK-1 in front of the plane, it blew exactly two times: to the right and to the left. And you could fly if the plane did not take down the pre-launch. Therefore, such experiments were carried out only with Tu-154 and heavier vehicles.

The M-701 engines (from training aircraft) went into the series, they turned out to be more compact and stable. Since we have a lot and often changed experiences with Copenhagen, we showed the invention to them. But they did not pass safety requirements, in addition, the auxiliary power unit (small jet engine) whistled too violently and disgustingly. But the Danes did not know about the fact that instead of headphones, you can insert light bulbs from a flashlight into your ears .

Similar cars with engines help to clean the snow strips. For example, it was the "Serpent Gorynych" TM-59.

We also tried to experiment with infrared emitters. Since it was the USSR, the “block of infrared lamps” should be read. It turned out that this radiation perfectly pierces both snow and ice, and further warms the wing. From the heating of the wing, the lower layer melts, but ice and ice slip off only at the edges of the wings, but not in the middle. Therefore, as a preliminary way to clean it is excellent (in the hangar before the plane rolls out). As a way to remove the frost - excellent. But for real winter conditions is not suitable. But a similar machine began to be used to remove thick layers of ice on concrete. ALMI-1 arrived with two jet engines. The power of one was used to power a huge square of lamps that shone directly on the ice. The second side blew this ice from the strip - it turned out that such huge pieces, sometimes the size of a passenger car, completely broke.

What are they cleaning now

The aerodynamics of new aircraft required new fluids. In 1988, the first Elephants cars were purchased for Sheremetyevo. Modern cars can work with different types of liquids, mix liquids inside, heat them on board and so on.

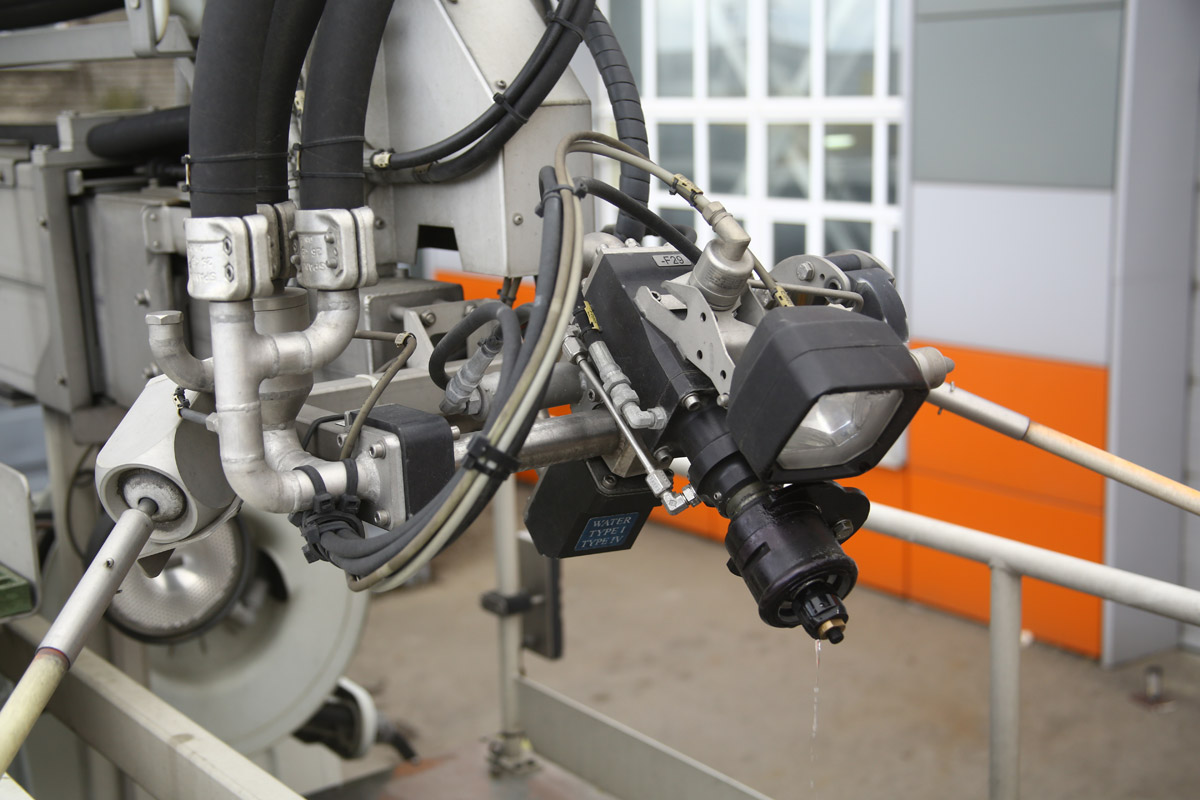

This is how the nozzle works:

Note that the spotlight is installed right next to it, that is, the operator can see specific areas and highlight the elements of the aircraft skin at an angle.

Appearance of the car.

The inside of the "Elephant."

Operator's cab and operator.

Deutz air-cooled diesel engine. Newer cars use the main engine of the car, since their power is now sufficient to support the operation of all systems. Under the steel casings on the right is the on-board electronics for controlling the systems.

A "counter" of water, more precisely, a liquid flow sensor in liters, which does not interfere. In case of deviations of the liquid composition during mixing, the automation changes the pressure. If the composition deviates by more than 3% in water content, then the machine stops working. Only Type-I PHL is mixed with water, and Type-IV is used in 100% concentration.

Boiler for 4 cubic meters of water and two tanks (rear) of 2 cubic meters of liquids. By standards, they are signed with the type of liquid, all sleeves are also signed.

Operator's cab in transport position.

The driver’s workplace, the block in the center controls the automation (in particular, heating compartments).

Maintenance plate.

Emergency Stop Buttons - Everywhere. In the center - a red 380 V power input for the operation of the machine's systems (warming up liquids) in the parking lot.

Tank inlets have different diameters.

Folded arrow.

The liquid is slippery, so many elements have additional friction coatings.

Raised arrow.

The boom raised and extended to the working position (maximum 10 meters, there are modifications of 13 meters).

The "mustache" at the end of the boom is the sensors for touching the surface of the aircraft; when they fire, the machine stops.

The cabin has wipers on all sides.

Workplace operator. Joysticks control the boom and nozzle.

Visible fluid flow.

“Dead Man's Pedal” - work is carried out only when you press it. If you remove the leg, the car stops.

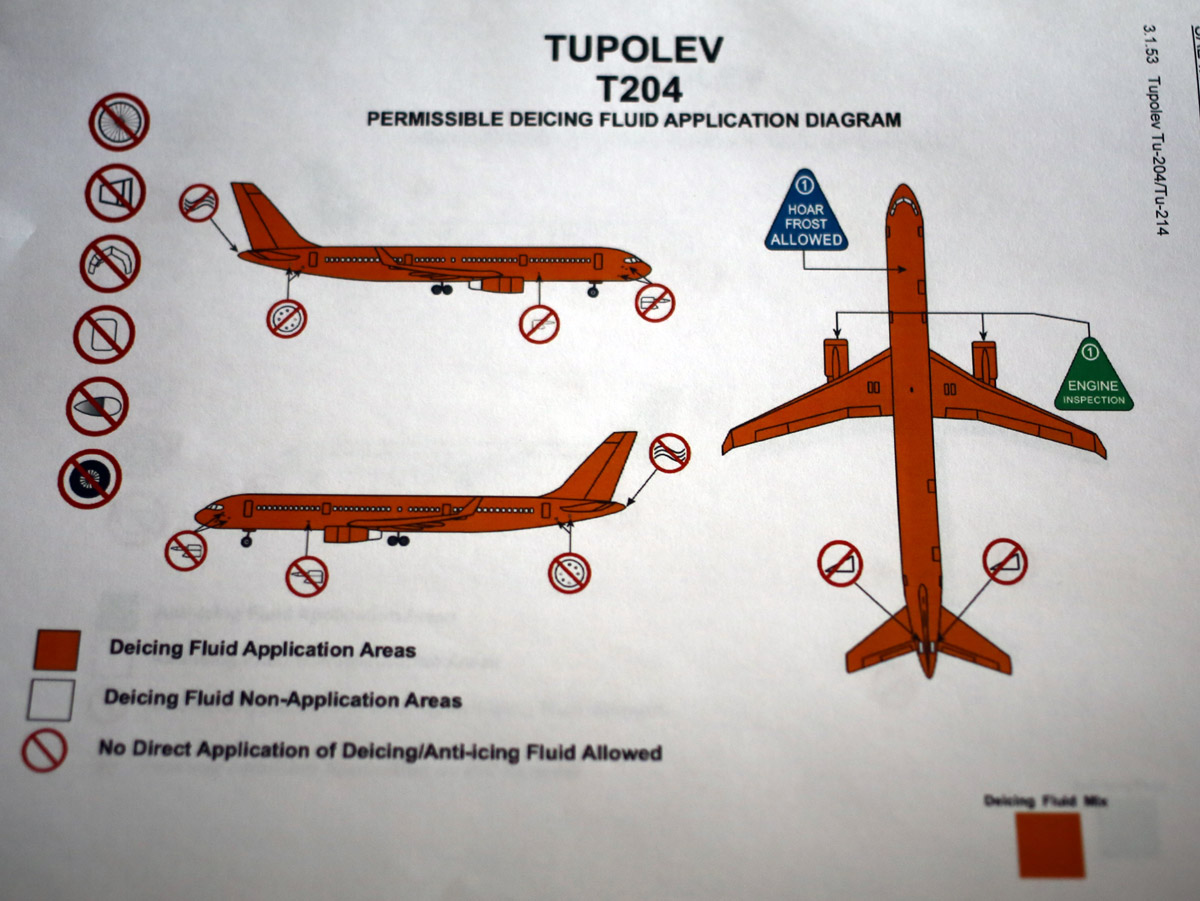

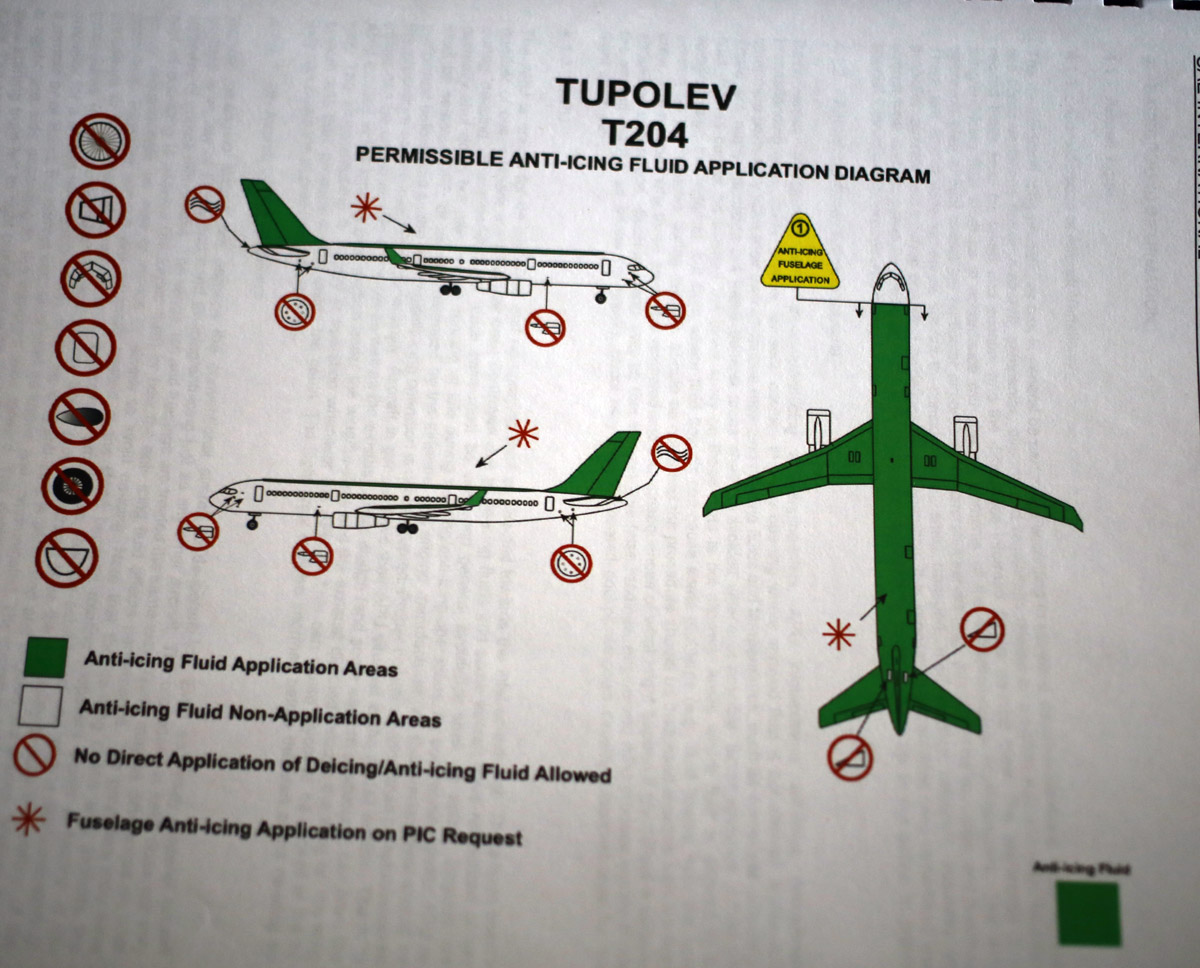

In practice, two types of liquids are used for SVO passenger flights: type-1 - for de-icing, and type-4 in different concentrations - for anti-aising. Type-3 is needed for a certain type of low-speed vessels, in which the speed of separation of the front strut from the runway is low.

Type-1 is glycol (there used to be propylene glycol, now longer ethylene glycol), 20% water and various additives: antifoam, anticorrosive (because glycols are aggressive), color (deysing “paints” the plane in red-orange, then “Paint” it with anti-aiing in green). Type-2 is a more complex variation for dilution in various concentrations.

Type-4 - 50% glycol and 50% water, the same additives, a thickener and another additive that reduces surface tension for uniform coating. Type-4 can be used in different concentrations. Conditionally, you can use a 50% Type-4 solution for deasing, and then 75% for anti-aising. Type-3 is also a thickened liquid, similar to Type-4, but with a lower shear moment. This is a non-Newtonian fluid that releases the wing at a certain speed. Type-4 does this at a speed of about 180 kilometers per hour, type-3 can and about 100.

By the way, about green. S7 airplanes have a different shade, and Yury Vladimirovich saw the intersection in color with liquid only once - when they dragged out of a snowdrift with a T-55 tank without a tower that rolled out of the Boeing 747 strip of Iraqi airlines. Since then nothing of the kind has come across.

It is ideal to place processing points directly next to the exit to the executive start near the end of the strip. This gives the shortest time from processing to take-off, and makes it environmentally friendly, since in one place it is easier to collect the remains of spilled liquid with the help of slopes of the coating and drainage, preventing the liquid from spilling over the platforms. But at most airports, infrastructure does not yet allow the location of watering points in this way. Dousing is done at the berths of the vessels and at the processing points between the berth and the start, in order to reduce the time between handling and departure.

Frankfurt and Tokyo have gantry cars. It works like this: the plane is taxiing under the gantry crane with nozzles, the operator types the vessel on the computer, the CNC rolls the processing program. It turned out that without a human eye - huge expenditures of fluids, low efficiency, sometimes ice remains. We tried to use video cameras, but then the recognition problem was solved poorly. With modern systems, opportunities should already be enough, but there are no ready-made projects yet. The operator knows how to look at indirect signs such as joints of sheets, gloss of rivets and so on.

Therefore, from the practical point of view, the IceWolf system in Denver is most interesting. At the executive start - columns at a wing span A-380. On the columns - the upper part of the "Elephant", telescopic arrows. There are operator cradles. In fact, this is a large "Elephant", dug in the ground, to which communications are connected and which has much more tanks (because Americans really like to work with ready-made mixtures, rather than interfering in place, and it is important for them to store somewhere that not used completely from premixes).

Now - FAQ

What is the protection of an airplane in flight?

Contrary to popular belief, in flight the aircraft should not be covered with liquid. In flight, to prevent ice formation, special rubber elements, hot air tracks, electric heaters or induction coils, “shaking” skin are used.

Why, then, is the plane being doused at obviously positive temperatures?

Because there is another feature - if this is an intermediate landing, then the fuel in the tanks on the wings cools down almost to the outboard temperature of the echelon and comes to the ground in the region of minus 40 degrees Celsius. That is, something can freeze from above on the wing, if you let the water "catch". There is confusion in words: often such ice is called fuel ice, but a similar term is used for ice that forms at high altitude inside a fuel tank.

With the engines turned on or off, is pouring done?

The protection time is measured from the first drop of liquid falling on the ship's hull. Therefore, you need to quickly process the aircraft (sometimes in 2, 3 or 4 cars under difficult weather conditions), and then start until the liquid is still “working”. When the engines are running, there is a danger of pouring liquid into the auxiliary power unit (IL-96, most Boeings, large Airbases have an air inlet near the vertical keel) or pass it through the engine: surging may occur. But most airlines have developed procedures where processing is done with the engines turned on to speed up the launch. A similar question is with moving elements: most protocols require processing with retracted mechanization, but there are companies that put mechanization in the take-off position before the flood.

In many countries of the world, the practice is adopted when processing is carried out with engines already running, which operate on low gas (that is, at idle). The plane at this moment is fully loaded, refueled, passengers are already on board, and the doors are completely battened down. In Russia, it is customary to first spray, and then start the engines.

Why is now ethylene glycol instead of propylene glycol in liquid?

Because two years ago, new tests in Quebec showed that for a number of conditions like ice rain, the protection time is very much reduced. According to the standards of the FAA (Federal Aviation Administration) and Canadian aviation authorities (these are the legislators in the world of anti-icing protection), the holding was almost halved. This required new compounds.

Is he not harmful?

And how! When processing at the rate of 1 liter per square meter of casing, 20% flows to the ground. Of the remaining 80%, a third flows at a distance from the executive start to 400 meters of run. Another third - from 400 to 1,200 meters. The last third is disrupted by such a characteristic aerosol that a visual effect is obtained as when a fighter penetrates a sound barrier. This aerosol flies far beyond the airport sewer. Part of the liquid from the strip is collected by the machine, but it's like pouring a bottle of vodka onto concrete: the tragedy of the inability to collect everything is familiar to many Russian people. Since the liquid is the choice of the airline (the PIC orders the type and method of processing), and the drainage is part of the airport, that is, some inconsistency is the responsibility. The correct option would be to build more complex sewage systems, but this is where the question arises: who will pay for it? Now 500 sorties a day, 200 liters on board.

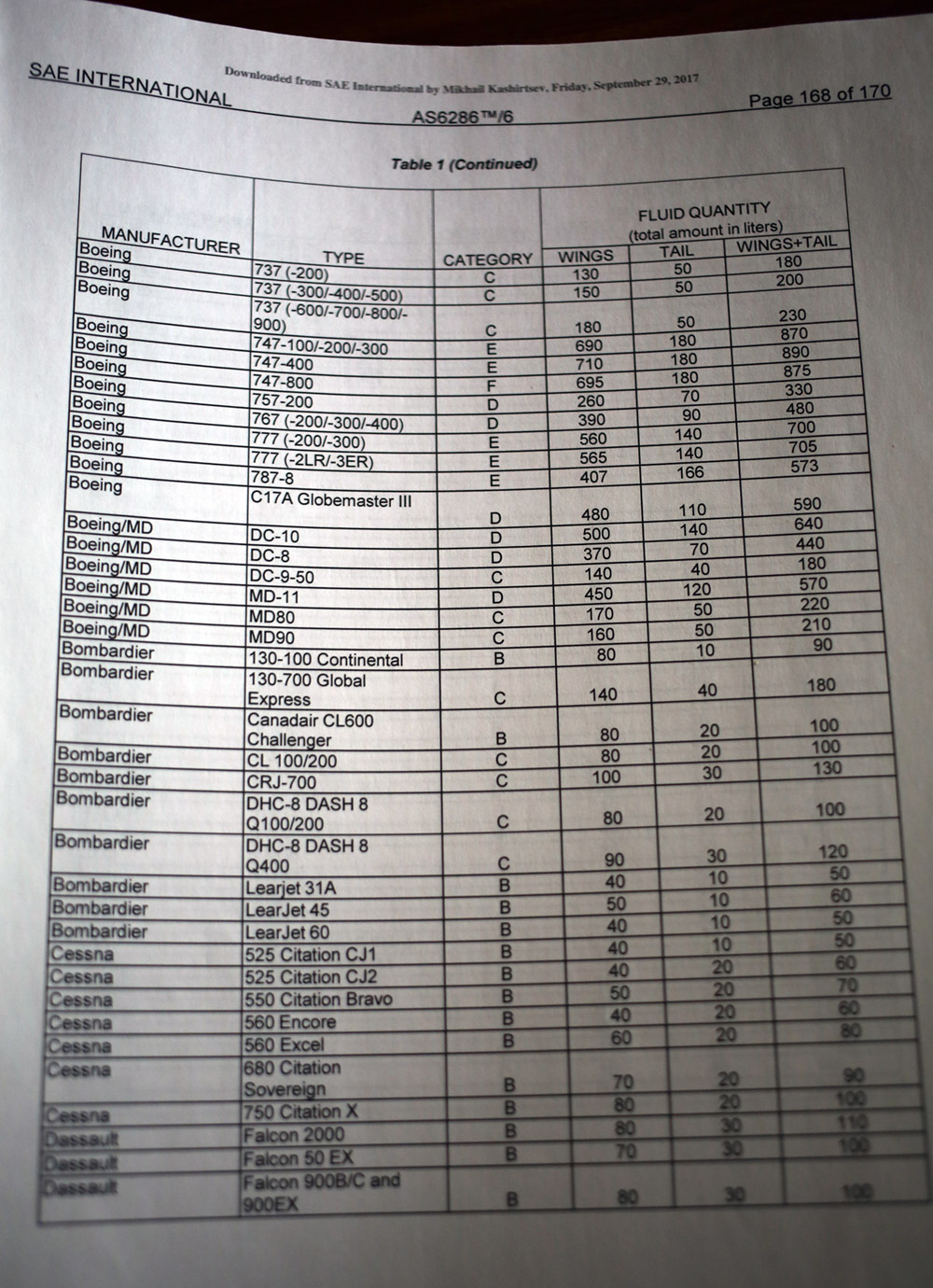

Here is an example of the amount of liquid (liter per square meter of skin after removing snow and ice):

Who produces the liquid?

Previously, it was purchased in Scotland (Kilfrost) and in Germany (Hoechst, later - Clariant). Now there are three companies in the Russian Federation. In the old days, during the Christmas period it was especially difficult: from Scotland, barrels of liquid were taken by ferry, then to Riga, then by car to Moscow. Customs officers put sticks in the wheels, but Yuri Vladimirovich then used the iron argument: “You and I are here only because planes fly. If they don’t fly, you and I are not needed here. ”

How long does it take to train the operator "Elephant"?

About 60 days, taking into account all admissions. Prior to this, secondary technical education and courses on the basis of Sheremetyevo are needed. The simplest category is the driver, then the operator, then the receiver (responsible for the finished result, in particular, touching the wing with his hand to check for transparent ice), trainer, teacher. The teacher is required to have not only a higher aviation education, but also experience in practical activities in the processing of ships. There is no machining with a scraper right now.

What are the pouring errors?

The main ones are:

- Liquid gets to where it does not need to get, for example, in the air intakes of the Ukrainian Armed Forces or in the aerodynamically “quiet” zones. And liquid types 2, 3 and 4 can lose moisture in them and become like a sponge, then it can increase in volume by several tens of times, collecting new moisture from the air, freeze and block mechanization.

- Inadequate deasing. It is almost impossible to make out the transparent ice on the wing: it does not visually differ from the gloss of the treated surface. Therefore, a mandatory operation is to touch the wing with your hand after a flood. There are no other methods of verification in practice yet. Scandinavian airlines are very afraid of transparent ice, in particular, they asked more experienced Russian colleagues to train their operators in the procedure of checking for transparent ice.

- Non-compliance with the pressure (the nozzle is placed too close to the surface of the vessel) - recently, flows at 90 degrees to the surface have been banned, plus there are norms of safe distances.

- When parallel processing by two machines - asymmetric fluid flow.

Many thanks to Yuri Vladimirovich Filatov and colleagues from A-Group for conducting the tour and assistance in creating materials.

And finally - a few photos from his archive. This is simultaneous processing by two machines:

This is why it is important to have headlights on the manipulator itself:

And from another perspective:

Our other posts on aviation: how business aviation works in Russia , FBO Sheremetyevo infrastructure , cargo flight , flight preparation for pilots , onboard history food and our rating of the “tastiest” airlines , by what rules a plane flies in Russia , the safety of air travel .