Making Missing Keys for the Commodore 116 Rubber Keyboard

- Transfer

- Tutorial

From a translator: the article is very long, and it describes a lengthy, but quite ordinary repair of a brutally mocked Commodore 116 computer with restoration of printed tracks and soldering of missing components. An extraordinary is a method of manufacturing replicas of keys torn from a "rubber" keyboard. The method can also come in handy when repairing the original ZX Spectrum and modern flexible keyboards.

Before:

After:

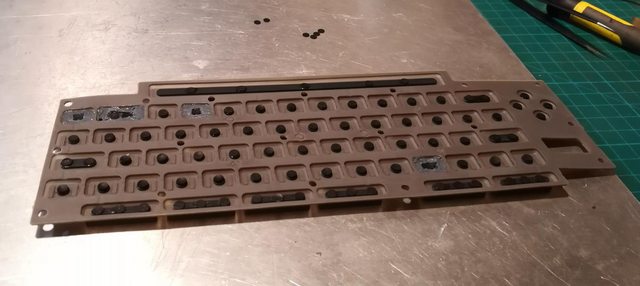

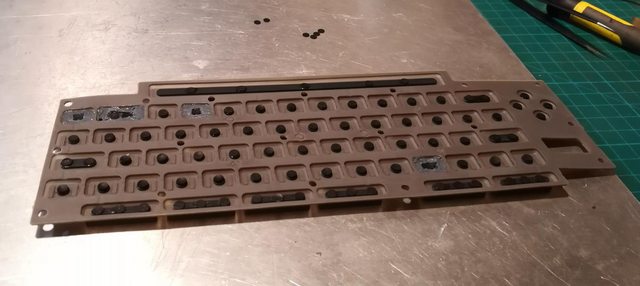

The board with keypad pads in Commodore 116 is held by plastic pins, which after assembly are fused with a soldering iron. If the keyboard needs repair, the melted parts of the pins are removed with wire cutters, metal racks are fused into the plastic instead. After repair and assembly of the keyboard they are bent. Everything would be fine, but the previous repairman heated the racks to too high a temperature, which made the plastic around black.

On the board there are traces of bullying with an emery cloth, and on a rubber sheet in conductive "heels" that have lost conductivity, brackets are inserted that first worked, but then also lost conductivity from corrosion.

But the most important thing is this. If all the tasks associated with repairing the board are familiar to the electronics engineer and are completely solvable, then here ...

But the author found a way out. On the reverse side, he sealed a rubber sheet with the keys of electrical tape.

I made a side out of a thick porous adhesive tape and glued it with a glue gun.

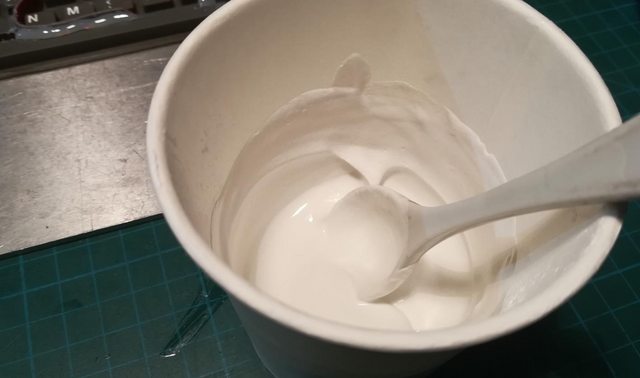

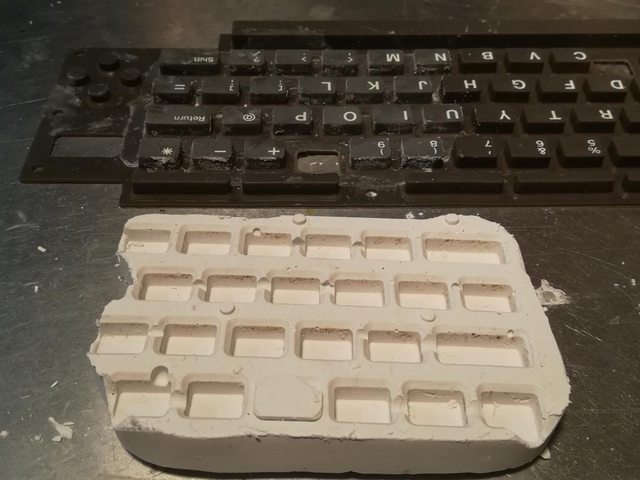

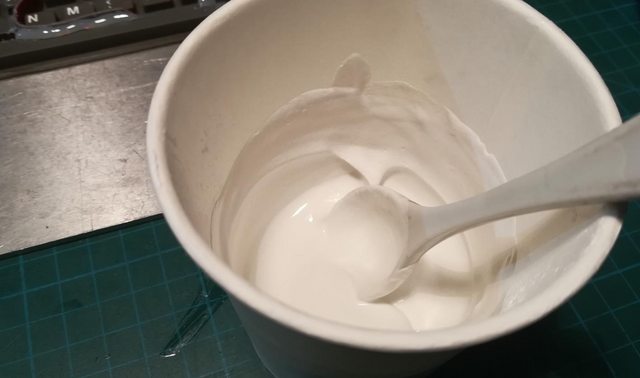

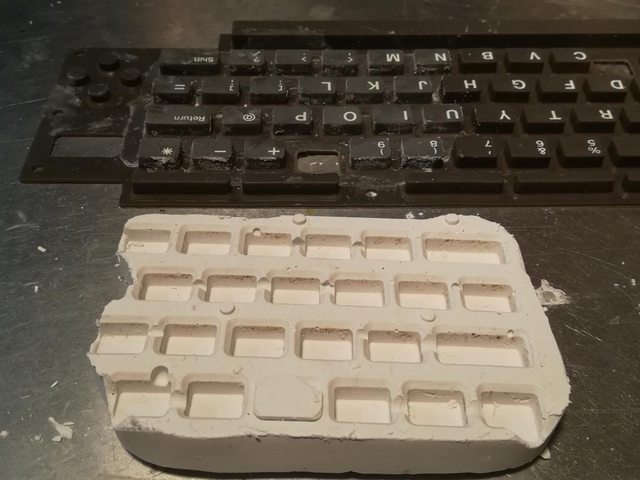

He prepared a cast and filled it.

When the gypsum hardened, it turned out that a section with a hole from a torn key fell outside the perimeter of the rim, and due to the incorrect filling method, a lot of air bubbles appeared. Also, the author forgot to clean the keys, and all the dirt from them transferred to the plaster.

What the wrong way of filling consisted of, and which is the correct one, the author does not specify, but the second attempt failed. Among other things, the side is redone so that the area with the hole from the torn key is outside.

A plaster mold with a side glued to a metal sheet.

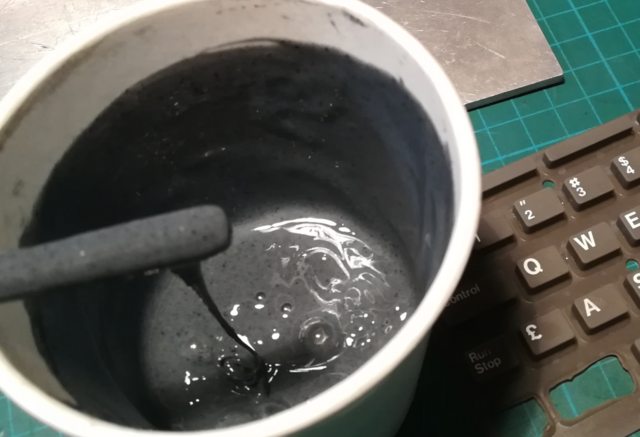

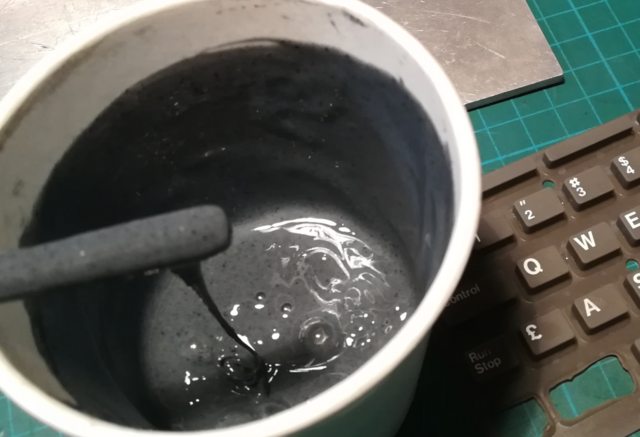

New keys will be made of molding silicone. The author turned out to be meticulous and decided to repeat the color of the original keys, for which he added charcoal to the grill first, then fluorescein. It didn’t work out very well, but then the author realized that meticulousness should have some kind of limit, otherwise you can experiment for a very long time, and poured silicone into the mold.

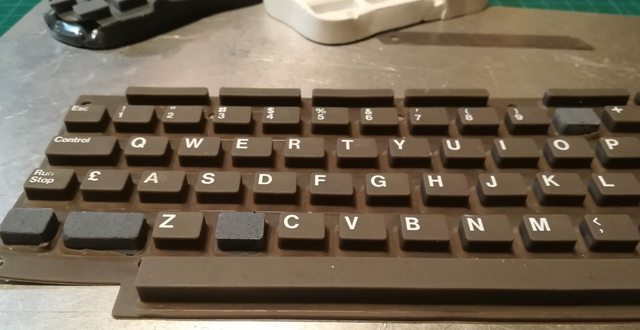

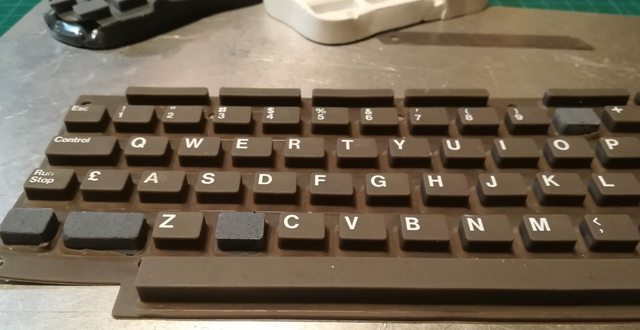

Here's what happened.

The keys are cut out (there are a lot of spare ones in case you need them suddenly) and put into place.

The brackets are removed, instead of them glued "patch" from the kit for the repair of remotes. Superglue did not work, the same silicone helped.

Glue the “patch” to the homemade keys, as we see, also happened. It is very important that the recesses on the back of the sheet are the same as the rest of the keys.

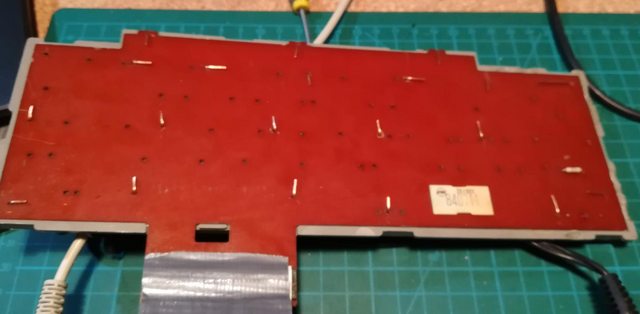

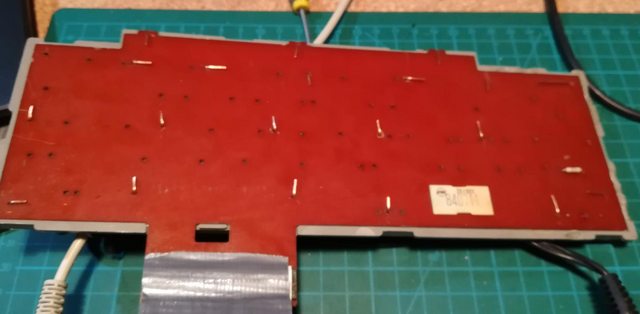

The board is also restored with sandpaper, but not the same as the previous repairman, but very small.

And again varnished in places where there are no sites.

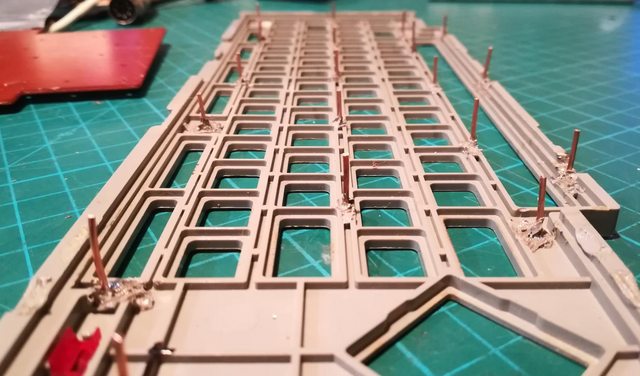

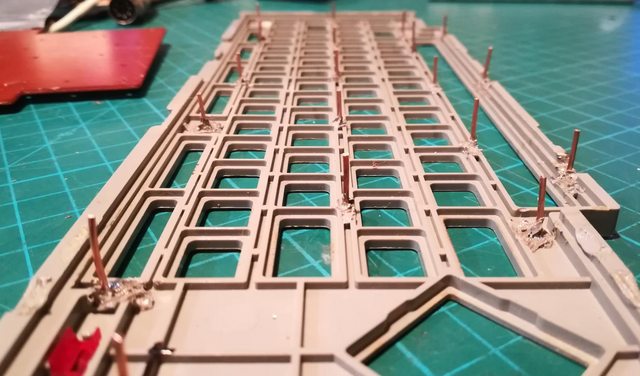

This is followed by loop repair and track restoration on the keyboard board, also quite ordinary. And new racks are soldered into plastic:

Now they are bent:

A little more work on the cable, and everything is assembled:

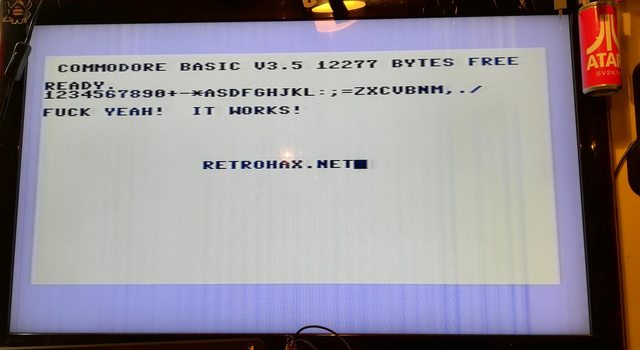

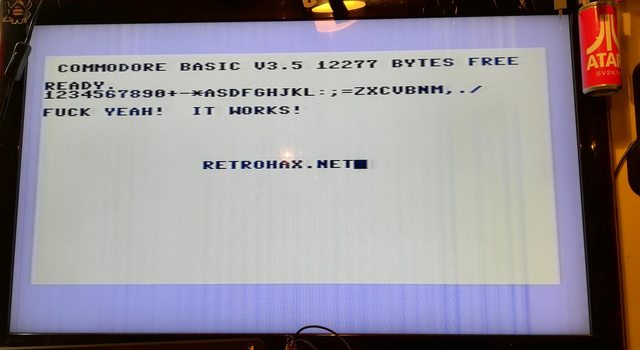

And it works:

PS Attention, when repairing the Commodore 116 it is important to change the thermal paste on the heat sink - just like in a modern (or not so) laptop.

You can try silkscreen printing to restore the writing on the keys, but even without it it turned out very nice and neat. And another Commodore 116 is back in service.

Before:

After:

The board with keypad pads in Commodore 116 is held by plastic pins, which after assembly are fused with a soldering iron. If the keyboard needs repair, the melted parts of the pins are removed with wire cutters, metal racks are fused into the plastic instead. After repair and assembly of the keyboard they are bent. Everything would be fine, but the previous repairman heated the racks to too high a temperature, which made the plastic around black.

On the board there are traces of bullying with an emery cloth, and on a rubber sheet in conductive "heels" that have lost conductivity, brackets are inserted that first worked, but then also lost conductivity from corrosion.

But the most important thing is this. If all the tasks associated with repairing the board are familiar to the electronics engineer and are completely solvable, then here ...

But the author found a way out. On the reverse side, he sealed a rubber sheet with the keys of electrical tape.

I made a side out of a thick porous adhesive tape and glued it with a glue gun.

He prepared a cast and filled it.

When the gypsum hardened, it turned out that a section with a hole from a torn key fell outside the perimeter of the rim, and due to the incorrect filling method, a lot of air bubbles appeared. Also, the author forgot to clean the keys, and all the dirt from them transferred to the plaster.

What the wrong way of filling consisted of, and which is the correct one, the author does not specify, but the second attempt failed. Among other things, the side is redone so that the area with the hole from the torn key is outside.

A plaster mold with a side glued to a metal sheet.

New keys will be made of molding silicone. The author turned out to be meticulous and decided to repeat the color of the original keys, for which he added charcoal to the grill first, then fluorescein. It didn’t work out very well, but then the author realized that meticulousness should have some kind of limit, otherwise you can experiment for a very long time, and poured silicone into the mold.

Here's what happened.

The keys are cut out (there are a lot of spare ones in case you need them suddenly) and put into place.

The brackets are removed, instead of them glued "patch" from the kit for the repair of remotes. Superglue did not work, the same silicone helped.

Glue the “patch” to the homemade keys, as we see, also happened. It is very important that the recesses on the back of the sheet are the same as the rest of the keys.

The board is also restored with sandpaper, but not the same as the previous repairman, but very small.

And again varnished in places where there are no sites.

This is followed by loop repair and track restoration on the keyboard board, also quite ordinary. And new racks are soldered into plastic:

Now they are bent:

A little more work on the cable, and everything is assembled:

And it works:

PS Attention, when repairing the Commodore 116 it is important to change the thermal paste on the heat sink - just like in a modern (or not so) laptop.

You can try silkscreen printing to restore the writing on the keys, but even without it it turned out very nice and neat. And another Commodore 116 is back in service.