5 features of metal powders for 3D printing

One of the important advantages of 3D printing technology with metals is the ability to create a product from almost any alloy. In addition to standard metals, there is a wide range of special alloys - unique high-tech materials that are produced for specific tasks of the customer.

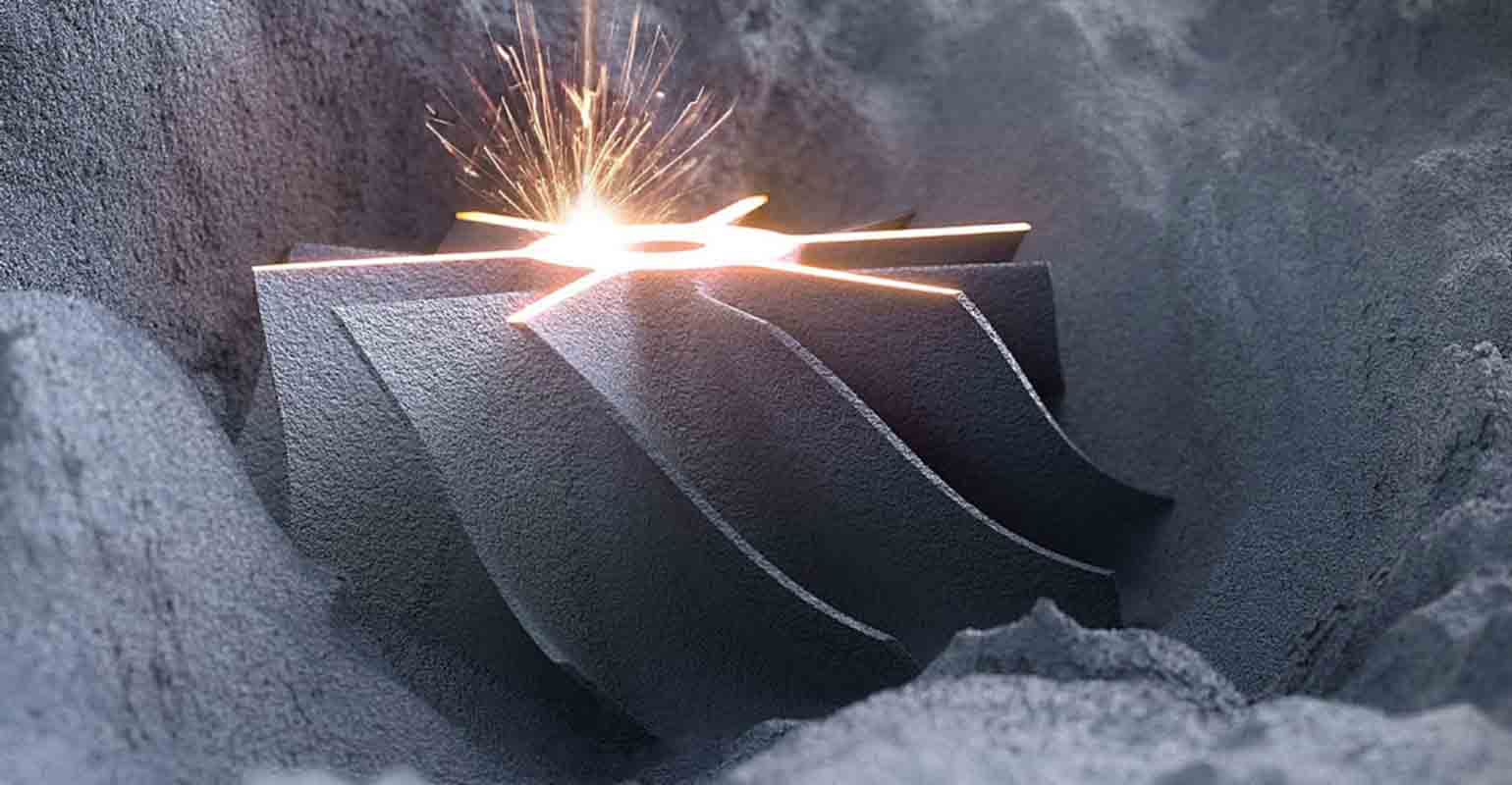

The most advanced and popular of 3D printing technologies with metals is selective laser melting (SLM / DMP). It consists in sequential layer-by-layer fusion of metal powders using high-power radiation from a ytterbium laser.

The technology is patented by the leaders of the 3D industry - SLM Solutions and 3D Systems. Depending on their functionality and tasks, metal 3D printers of these manufacturers can be used both as production machines for serial production and as laboratory units with flexible settings and the ability to quickly change materials for 3D printing.

Equipment:

SLM Solutions (SLM technology): SLM 125, SLM 280, SLM 500, SLM 800;

3D Systems (DMP technology): ProX DMP 100, ProX DMP 200, ProX DMP 300, ProX DMP 320, DMP 8500.

The main advantages of 3D printing with metals:

- high density: 1.5 times higher than when casting;

- the ability to create miniature and geometrically complex objects and other unique forms in the form of closed bionic structures;

- a wide selection of metal alloys, both standard and special;

- reduction of production cycles and accelerated output of finished products.

Scopes of application:

- aerospace industry;

- engineering;

- automotive industry ;

- oil and gas industry;

- electronics;

- the medicine;

- food industry;

- research and experimental work in design bureaus, scientific and educational centers.

Types of metals used in additive manufacturing

Modern additive technologies involve the use of about twenty tested and ready-to-use materials, including instrumental, stainless, heat-resistant alloys, aluminum and titanium alloys, medical cobalt-chromium and titanium.

Since there are a lot of metals, and each of them has certain properties, one metal can be replaced by another based on technological problems. For example, if a titanium alloy must be used in the technological chain, then the technologist will be able to choose one of the many titanium alloys with the properties that are needed for the production of a particular product.

- Stainless alloys: 17-4PH, AISI 410, AISI 304L, AISI 316L, AISI 904L

This category includes complex alloyed steels with a chromium content of at least 12%. Chromium oxide forms a corrosion-resistant film on the metal surface, which can be destroyed by mechanical damage or chemical media, but is restored as a result of reaction with oxygen. Corrosion-proof alloys are used in the manufacture of valves for hydraulic presses, valves for cracking plants, springs, welded equipment operating in aggressive environments, and products used at high temperatures (+ 550 ... 800 ° C). - Tool alloys: 1.2343, 1.2367, 1.2709

The main purpose of tool alloys is the manufacture of various types of tools (cutting, measuring, stamping, etc.), tabs in molds during hot deformation of structural steels and non-ferrous alloys in large-scale production, molds for casting under pressure alloys of aluminum, zinc and magnesium. These alloys contain at least 0.7% carbon and have increased hardness, wear resistance, toughness, thermal conductivity and hardenability. - Nickel alloys: Inconel 625, Inconel 718

Nickel has the ability to dissolve many other metals, while maintaining ductility, so there are many nickel alloys. For example, in combination with chromium, they are widely used in aircraft engines, from which they make working and nozzle blades, turbine rotor disks, combustion chamber parts , etc. The most heat-resistant are nickel-base cast alloys, which withstand temperatures up to + 1100 ° C for hundreds and thousands of hours at high static and dynamic loads. - Cobalt-chromium: CoCr

CoCr is a high-quality cobalt-chromium alloy for model casting that meets modern technical requirements. Due to its excellent mechanical properties, it is well suited for the manufacture of cases of complex geometry in electronics, food production, aircraft, rocket and mechanical engineering, as well as clasp prostheses. - Non-ferrous metals: CuSn6

CuSn6 is an alloy of copper and 6% tin, which has high heat-conducting properties and corrosion resistance and is ideal for creating unique cooling systems . - Aluminum Alloys: AlSi12

These are the cheapest foundry alloys. Their advantages include high corrosion resistance, fluidity, electrical and thermal conductivity. In industry, they are used, as a rule, for the manufacture of large-sized thin-walled castings of complex shape. - Titanium alloys: Ti6Al4V, Ti6Al7Nb

Ti6Al4V is the most common titanium alloy with excellent mechanical properties. It is considered the strongest and toughest titanium alloy; it is characterized by a particularly high processing complexity. It has a density of 4500 kg / m³ and a tensile strength of more than 900 MPa. Ti6Al4V provides undeniable advantages in terms of weight reduction in industries such as aerospace, automotive and shipbuilding. These metals are used, in particular, in the manufacture of inserts in molds, turbine blades, combustion chambers, as well as products designed to work at high temperatures (up to + 1100 ° C).

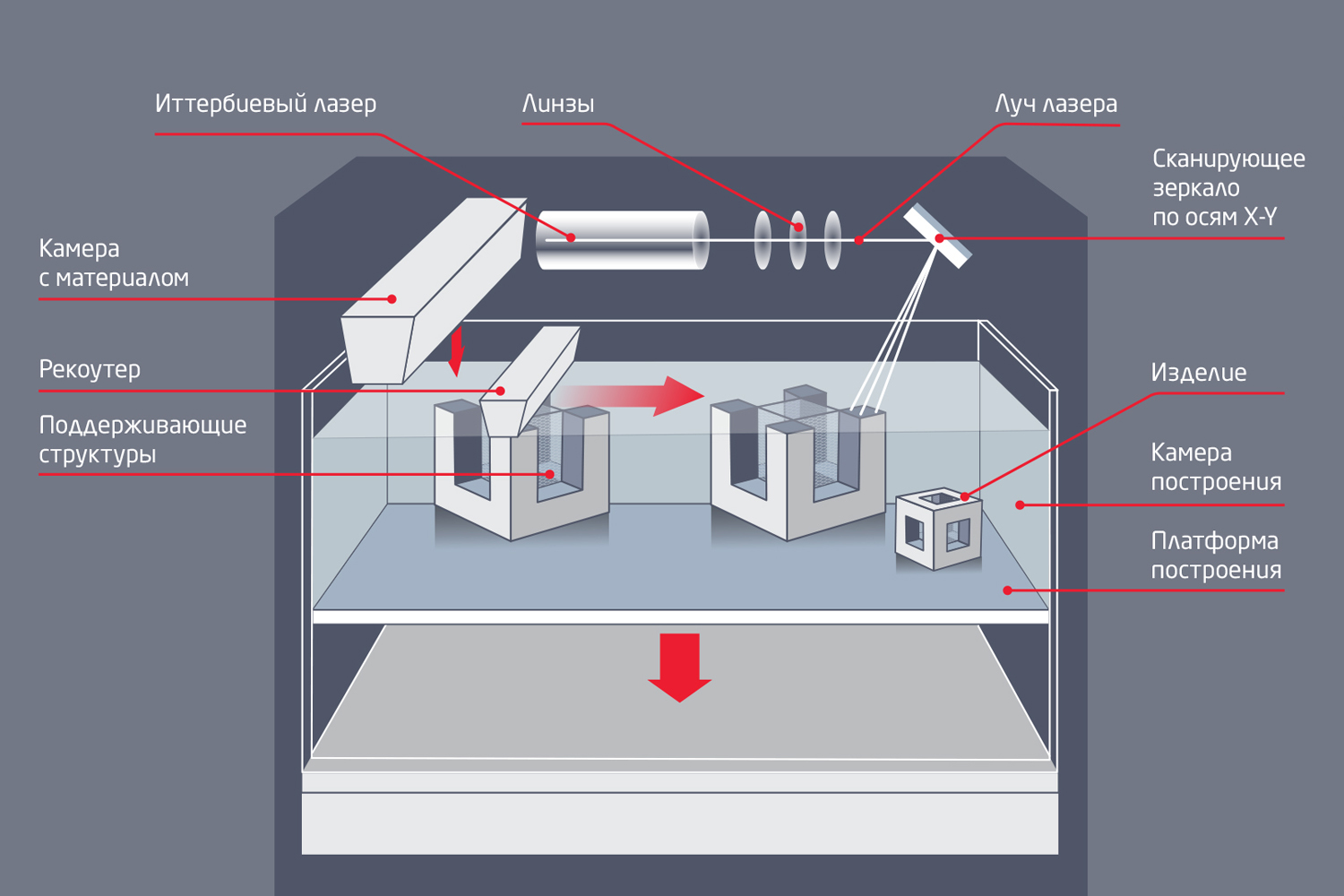

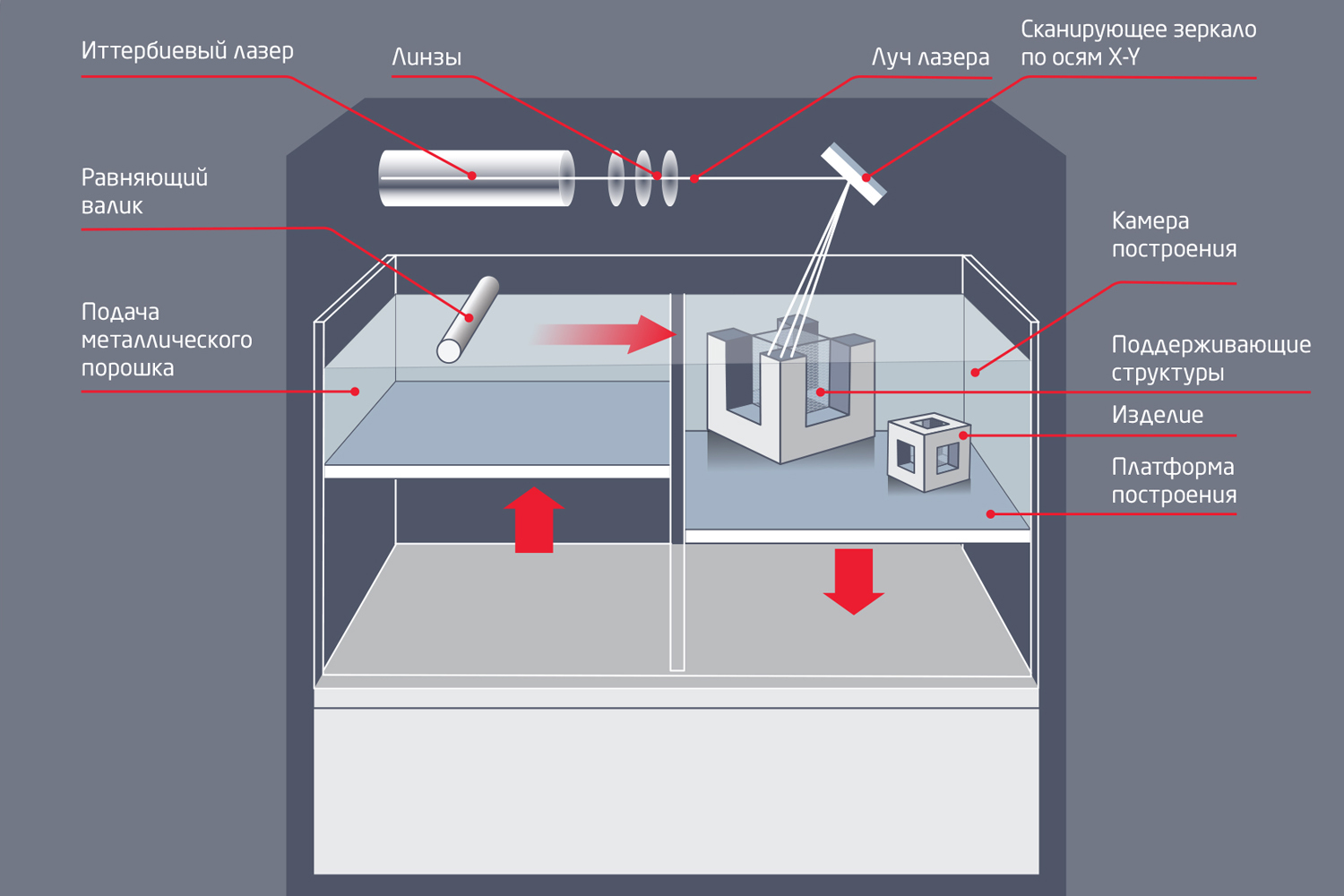

Installation Diagrams for SLM Solutions (above) and 3D Systems (below)

Features of metal powders

- Metal for additive plants is produced in the form of finely divided spherical granules with a grain size of 4 to 80 microns. This indicator determines the thickness of the object to be grown in the additive plant. When creating a powder, the size and composition of the grain are set , since it is necessary to observe a certain percentage of large and small grains. In this way, the fluidity of the metal is determined, which is checked using a Hall device (funnel with a calibrated hole). If the grain has too small a fraction, the metal will not flow through the funnel and, accordingly, will be poorly fed to the construction table, and this directly affects the uniformity of the layers obtained and the quality of the grown product.

- Each company producing this type of 3D printer has its own flow requirements , depending on the principle of applying the material to the construction platform. In additive installations of SLM Solutions (SLM technology), metal is fed to the desktop from above, from a feeder (chamber with material), and transported by a rekouter. In this case, fluidity is very important for the powder to flow from the feeder to the recauter and the layers to be applied properly. 3D Systems (DMP technology) uses a slightly different principle of operation: the container with the powder rises slightly, with the help of a roller it is transferred to the construction table, then the container is lowered. Due to this design, the flow indicators are not critical (see product design diagrams in the figures).

- Different metals require different heat treatments , and sometimes specially heated platforms are used for this. During the construction process, when the metal is melted, a large amount of heat is generated, which must be removed. The role of radiators that remove heat is performed by the supports used in the construction of products. In some cases, the part itself without supports is welded to the desktop, as to a radiator.

- The structure of metal products obtained in an additive manner depends on both the construction technology and the equipment settings. Leading manufacturers achieved a metal density of about 99.9% of theoretical. Along with selective laser melting, there are less efficient, already obsolete technologies similar to the SLS method, which provide lower density.

- The internal structure of the metal is fine-grained. If in the future we are going to compact the part, that is, physically affect it, we must take into account that it is much more difficult to compress a small grain than a large one. But at the same time, we are very close to rolling metal - i.e. to metal that has already been densified. The density of products printed on a 3D printer is 10-15% lower than during rental, but about 50% higher than that of cast metals.

Security Considerations for 3D Metal Printers

As you know, metals that enter the human body in microscopic doses are useful. In macro doses, they carry a health hazard - it is very easy to get metal poisoning, and in addition, the powders are explosive. When the dispersion of the powder is from 4 microns, it penetrates through the pores of the skin, respiratory system, vision, etc. In this regard, when working on metal 3D printers, you must strictly follow safety precautions. For this, protective workwear is provided - a suit, gloves and shoes. Additive machines, as a rule, are equipped with a vacuum cleaner to remove the main powder, however, even after its use, some suspension of metals remains.

Manufacturers strive to improve safety conditions, and now there is a tendency to create so-called closed cycles in additive manufacturing, i.e. completely tight rooms, beyond which the powder does not fall. The operator works in special clothing, which is then disposed of.

3D metal printing potential

So, we found out that modern technologies make it possible to obtain powder for 3D printing with metal with certain properties for solving specific production problems. And since almost any metal can be sprayed, the range of metal materials for 3D printers is extremely wide.

Achievements of metallurgy are fully implemented in additive manufacturing, allowing the use of unique alloys for the manufacture of geometrically complex products of increased accuracy, density and repeatability. At the same time, the introduction of metal additive plants has also constraining factors, the main one of which is the high cost of powders.

3D printing with metals has serious potential for increasing production efficiency in many industries and is used by an increasing number of companies and research organizations. An example for the global industry is shown by such industry leaders as General Electric , Airbus, Boeing, Michelin, who have already moved from the manufacture of single metal products to serial additive manufacturing.