How were the steam locomotives arranged?

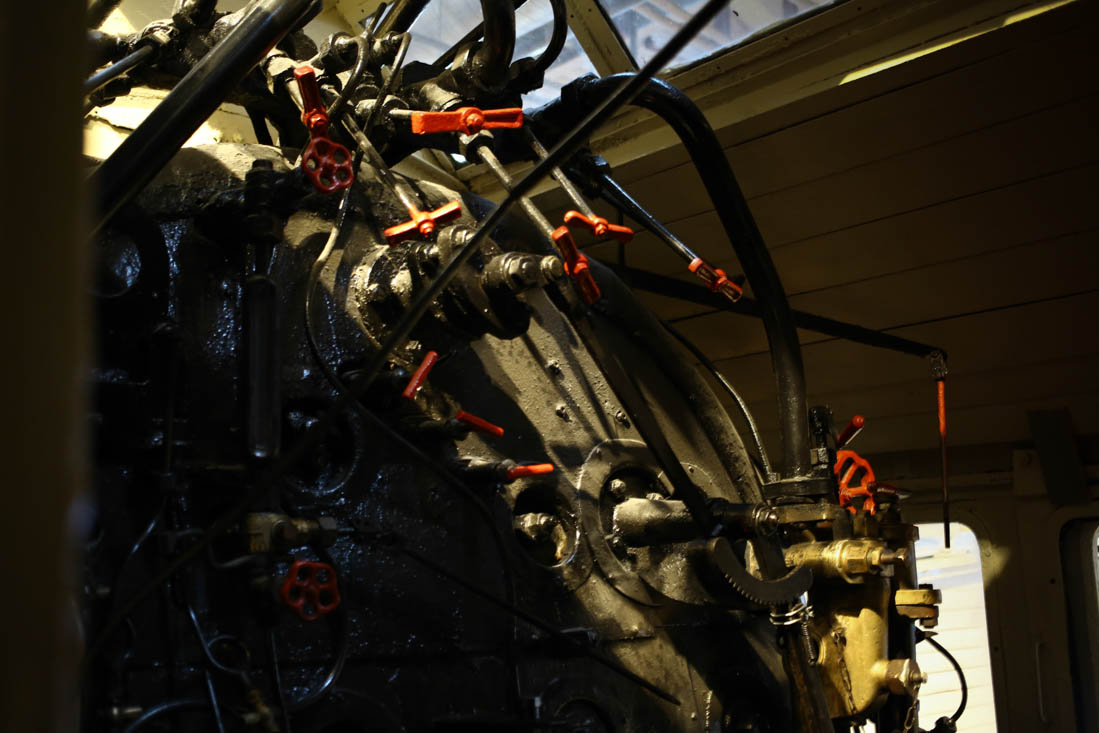

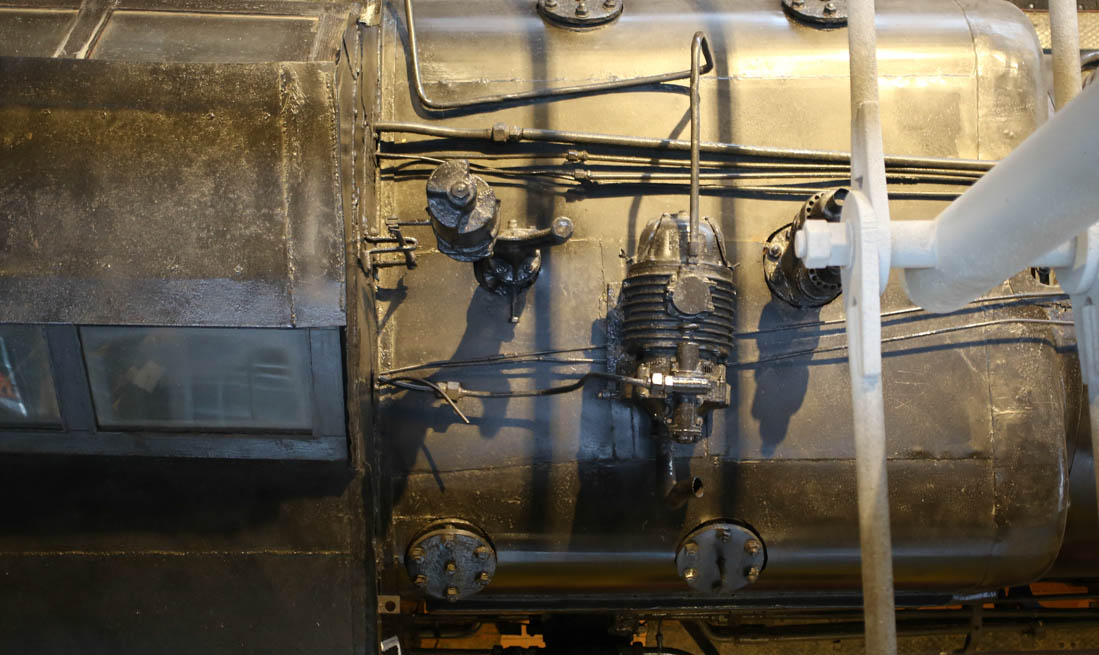

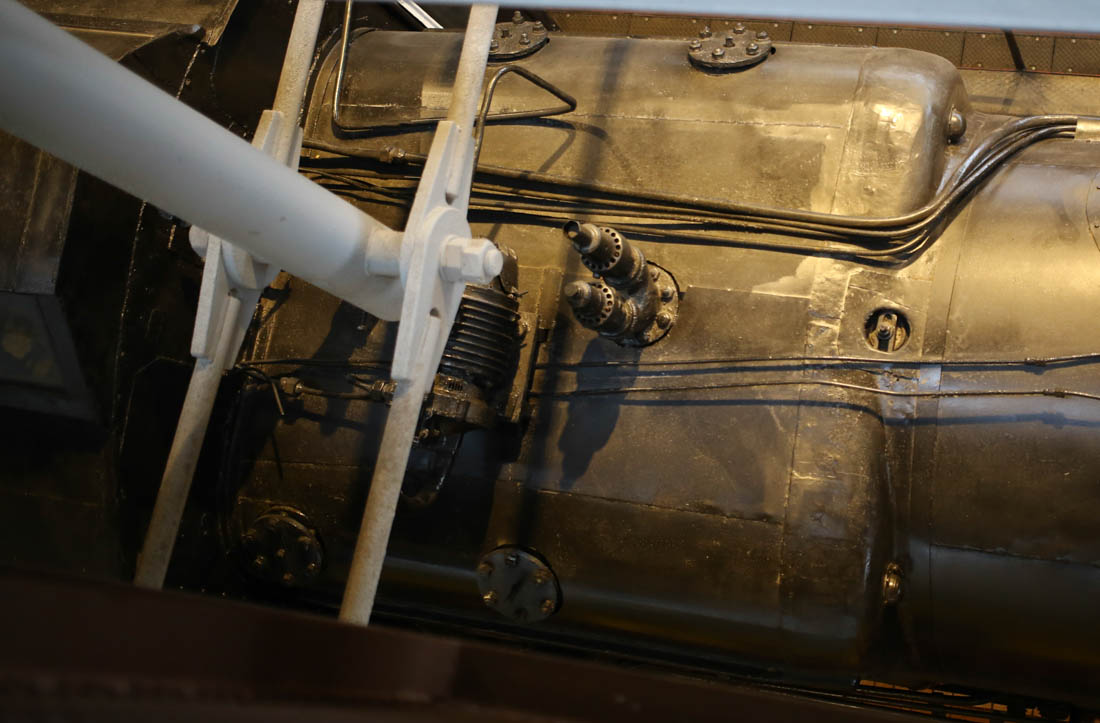

This is the cabin of the steam locomotive "Sergo Ordzhonikidze" (this is СО17-1137). A lot of tubes on top is a steam column, each pipe has its own pipe. And there are many consumers in a technically mature enough steam locomotive: two steam engines on the left and right for wheel movement, a whistle, a mechanical coal feeder, injectors for pumping water, an electric generator for lighting, a pump for the air line and so on.

Before electric lamps, kerosene lights were used right in front of the engine and acetylene chemical spotlights. Then, around the beginning of the twentieth century, luxury cars acquired electric light, and then the engine began to be lit with bright lamps, in particular, to see what was happening with the wheels and axles. Because the assistant to the driver sometimes needed to go on the go and knock the sledgehammer on the wings, as the snow began to clog and freeze in ice.

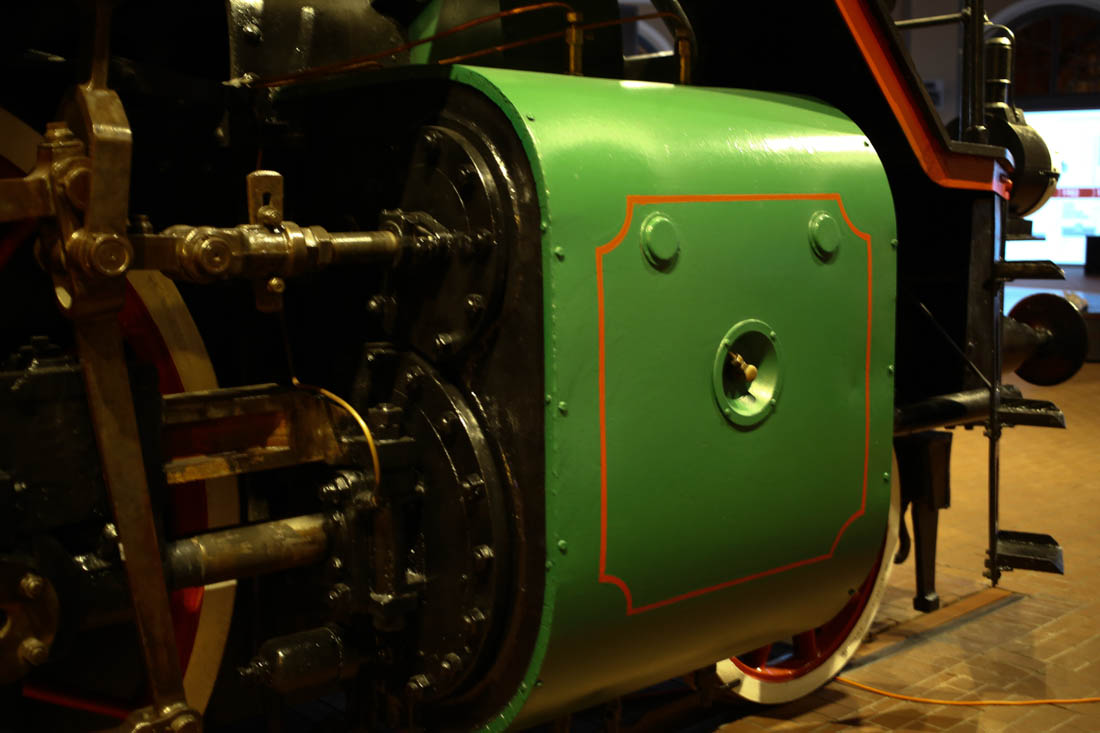

The domestic passenger locomotive differs from the freight one visually very easily. It looks elegant, colored (most often green or blue), it has large coupling wheels. Speed was important for the passenger, traction was important for the cargo, so the cargo wheels have less coupling wheels. And freight locomotives are usually black.

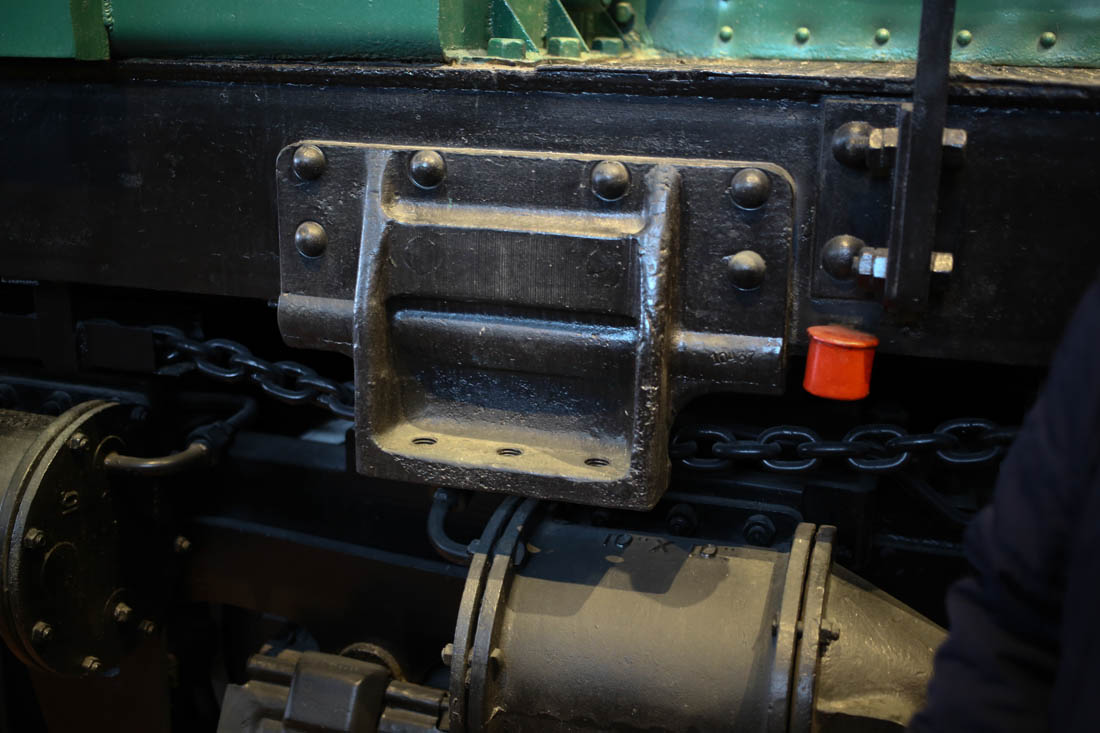

In front of the engine there is a small runner trolley, which has the ability to rotate relative to the main frame. Here it is right in front of the green steam engine:

It is needed so that the steam locomotive fits into the curves (it could turn easier).

Here is a steam engine, it converts steam energy into mechanical energy, driving wheels:

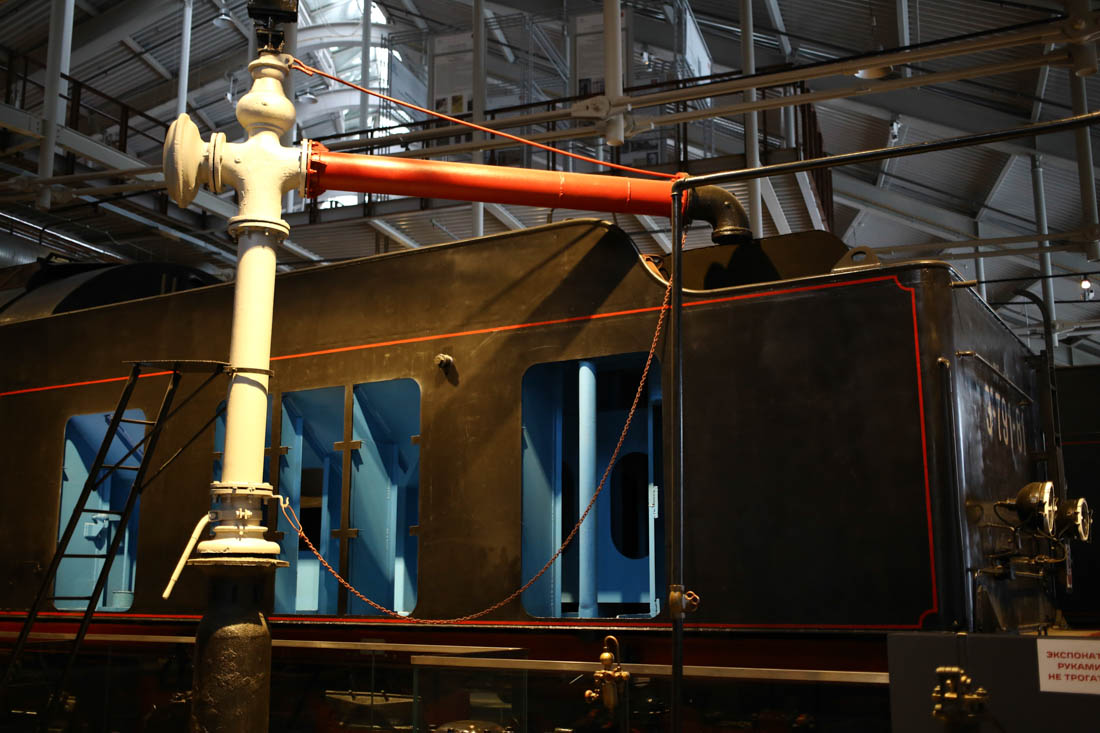

A tender car follows a steam locomotive, coal and water reserves are loaded there. Pay attention to the characteristic Russian counter-booth: it connects to the booth on the steam locomotive specifically to provide more comfortable working conditions for the steam locomotive crew in the winter.

Here is the basic structure of the steam locomotive (hereinafter we go around the Museum of Russian Railways in St. Petersburg). They made a wonderful stand with the anatomy of a steam locomotive:

For the steam locomotive to go, it is necessary to load coal (fuel), water (working fluid) and a brigade from the driver, assistant driver and stoker into it. So, with the help of a hydrocolumn, water was loaded through a special hatch in the tender:

Next, the team drowns the boiler and controls the train. Accordingly, a furnace, a boiler, a hood and a pipe stand out. Around the wheels are steam engines that make movement out of steam energy. Steam formation occurs inside the steam locomotive, then a couple of times the steam is driven along the contour of the tubes inside the device.

The steam locomotive almost up to the present had to be controlled very gently and accurately, and for this a high professionalism was needed. The fact is that any section of the path has inclines: descents and ascents. Wagons interact unevenly, and couplings between them break. The train may crumble, and it will end badly. Plus, you just need to take into account the huge inertia and be able to manage all this colossus. Therefore, there were two qualified people in the booth: the assistant, who knows how to heat the boiler, and the driver, who knows how to control the train and everything else.

Here is the driver’s workplace and his overview:

And here is the assistant with the door out: The

stoker, contrary to popular belief, did not drown, but simply fed coal to the bunker in a steam locomotive from a tender. It was usually a healthy man who knew how to work a lot with a shovel.

On this shovel, by the way, the assistants passed a secret exam to the drivers when they were admitted to the brigade. It was necessary to fry the fried eggs. To do this, it was necessary to melt the furnace evenly, throwing coal at the corners of the compartment, hold the shovel correctly, estimate the temperature in the compartment by the color of the parts and coal, and control the temperature of the shovel. If the scrambled eggs turned out to be burnt out or “with snot”, it was an unsuitable helper. If excellent, you could eat with water from the tanks. From this, where it says "Water is poisonous, you must not drink":

Despite the inscription, almost every engineer boiled and drank water from the tanks. But this was forbidden, because after loading the water into it, it was necessary to throw a few tablets of a descaler, which is not very healthy. This is so that the tubes inside the steam and water systems do not clog too quickly. Soft water was so appreciated that if there was a source near the railway, a station was immediately set up there, even if there was no settlement along the road. The average distance between the English stations is 20 kilometers, and between ours - 80. And this is because it is almost the limit of the steam locomotive without refueling.

This is a problem, and at least some solution was required. The first diesel locomotive was invented and assembled with us in order to solve some of the shortcomings of the locomotive system. Specifically, I really wanted to get away from dependence on water and simplify maneuvers at the stations. A shunting diesel locomotive is good because it does not need to be constantly heated: there is work — turned on the engine, no work — turned off. As a result, they tried to assemble a prototype and made this creation of a gloomy Russian genius - Щ-ЭЛ-1 of 1924:

Alas, he did not work long and did not spread widely. The prototype had too many problems associated with the fact that the steam gave instant feedback, and the internal combustion engine required a gearbox between the engine and the wheels. The gear shifting created hard shocks, and they could cause the clutch to break. An electric transmission system was needed, which led to such a design:

As a result, they refused from diesel locomotives for some time and began to conduct experiments immediately with electric motors. As you can guess, the batteries weren’t very good then, and therefore they were distributed only where trams could go. That is, freight trains for Moscow enterprises crawled on tram rails at night.

But, of course, steam locomotives became more and more obsolete. At some point, an incredibly beautiful and efficient steam engine was made in the USSR. Here he is, in the museum is the last steam engine of the P36 series. He has a four-digit number 0251, but they produced it exactly this much:

Because of this lampas he was nicknamed “General”.

And at about the same time, America removed steam locomotives from production, and at our XXth Party Congress Khrushchev decided to put locomotives on it too. So there was the TEZ - the killer of steam locomotives:

And these are deck mounts in order to put the locomotive in the USSR by sea. Both wagons (disassembled) and diesel locomotives were transported through Vladivostok.

Then there was a rich history of diesel locomotives of the USSR. Of the interesting things to note here are these exhibits:

Regular diesel bus AB 758 - Romanian. He walked 110 kilometers per hour, that is, not much faster than steam locomotives (steam locomotives could develop up to 120 km / h), but he did not stop to refuel with water.

Here on TE-6769 (T means the trophy equivalent of the fact that after T, that is, as close as possible to the E series) the sandbox is very clearly visible:

Bends from it lead to each wheel and end like this:

So the sand moves under the wheels for increased friction. This is necessary for emergency braking or icing tracks.

Under the wheels you can still clearly see the springs, highways and brakes:

But with the help of this device you could find out the speed of the engine:

The rotation speed was removed from the front axle, and then converted to linear velocity on the device.

There is also an interesting class of steam locomotives, these are the so-called steam locomotives-tanks. They differ from ordinary ones only in that they have coal and water on the engine itself, and not in the tender:

It is clear that the reserves there are not very large, but sometimes it’s really easier.

This tank has an excellent carbide flashlight. The top with a yellow-orange edge is an “American lantern”, and it is also an acetylene chemical searchlight. Water dripped into the carbide tank (the pressure of the water was manually regulated), it reacted, combustible gas was released, which then burned in the burner. It turned out a bright flame, which gave much more light than the "headlights on candles" below. By the way, the candle lights are removable so that you can inspect the engine. Later they began to make lighting. Here is a lamp of the CO series that illuminates the wheels:

And, returning to the workplace of the assistant driver of the CO, there is next to it - it will distribute, while small, just for such lamps:

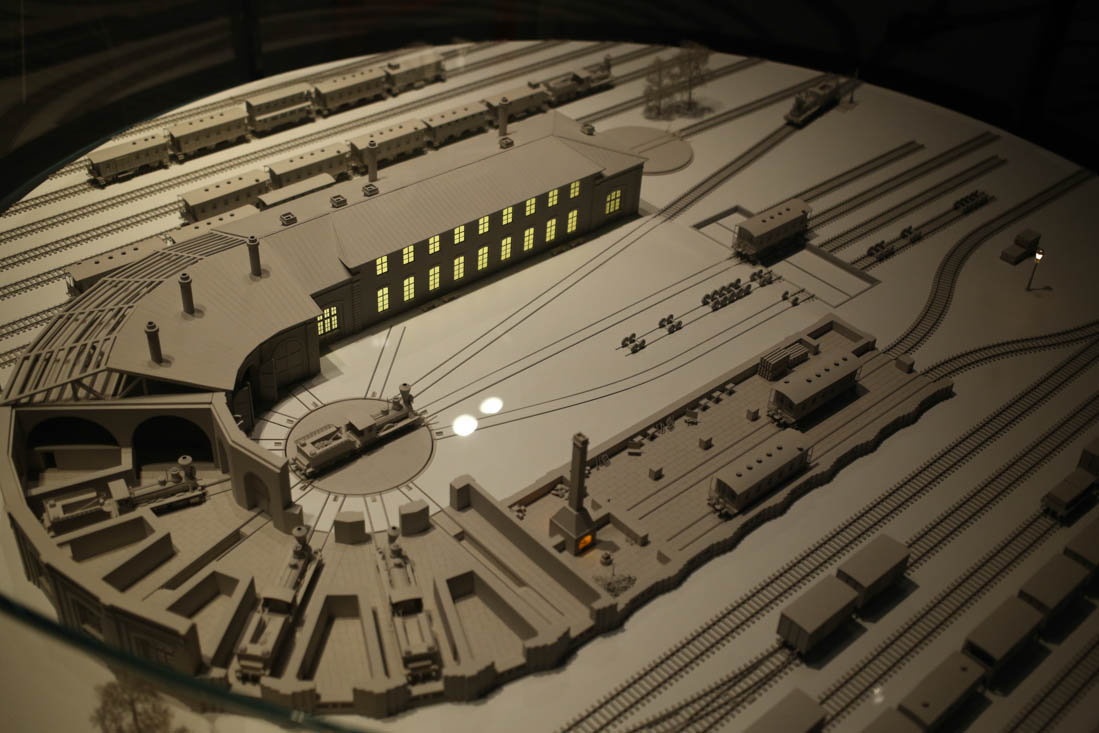

The design of the turntable is very interesting. Depots were then based on turntable architecture:

These steam locomotives in the museum were arranged exactly in such a circle, which is located in the center of the exposition (it used to be a functioning depot):

An alternative to such a circle is arrow triangles. But the circles, as you can see, were much more convenient, especially when they switched from manual turning to engines.

Now let's look at the locomotives from above. Here you can clearly see the auger for supplying coal from the tender:

Turbogenerator:

Safety valves (later they began to make three on more powerful steam locomotives, two here in case of failure of one):

On diesel locomotives, top and sides are also characteristic grilles for the refrigerator: since the engines were installed by the ships, they had to be cooled somehow so that they did not boil. In water it’s just (water), and on the railway up to a quarter of the locomotive is occupied by a refrigeration unit.

This is a reconstruction of the middle of the working day at the station: A

table with locomotives and team leaders is visible on the back. The brigades could be assigned to the locomotive (three brigades, one senior engineer) or change. The first method provided better service for the “native” locomotive, and the second - lower mileage, because the teams rested in a working depot and sometimes could not immediately go back.

And the last one. Steam engine with a large battery for steam, fuel-free. It was used in chemical plants where fire was banned:

The front end is a large tank for steam, in fact. The steam engine came to the boiler, refueled like this:

And went to the danger zone to work. The pair lasted for about two hours.

We have already talked a lot about the railroad, here are some more posts on this subject:

• A large FAQ about long-distance trains and unobvious rules

• Why do I need an old kind coal boiler in a car when there is power

? • How a long-distance passenger car is arranged

• How to assemble passenger cars trains

• The evolution of the railway carriage

• How the station works

• Different trains. Highly