What's inside? We disassemble the charger from the MacBook

Have you ever wondered what is inside the MacBook charger? The compact power supply has significantly more details than you would expect, including even a microprocessor. In this article, we will be able to disassemble the MacBook charger to see the numerous components hidden inside and find out how they interact with each other to safely deliver much-needed electricity to the computer.

Most consumer electronics, from your smartphone to your TV, use pulsed power supplies to convert AC power from a wall outlet to the low-voltage direct current used by electronic circuits. Switching power supplies or, more correctly, low-voltage power supplies - got their name from the fact that they turn on and off the power supply thousands of times per second. It is most effective for voltage conversion.

The main alternative to a switching power supply is a linear power supply, which is much simpler and converts overvoltage to heat. Due to this energy loss, the efficiency of a linear power supply is about 60%, compared to about 85% for a switching power supply. Linear power supplies use a bulky transformer that can weigh up to a kilogram or more, while switching power supplies can use tiny high-frequency transformers.

Now, such power sources are very cheap, but this has not always been the case. In 1950, switching power supplies were complex and expensive, used in aerospace and satellite technologies, which needed a light and compact power source. By the beginning of the 70s, new high-voltage transistors and other technological improvements made sources much cheaper and they were widely used in computers. The introduction of single-chip controllers in 1976 made power converters even simpler, smaller, and cheaper.

Apple's use of switching power supplies began in 1977, when chief engineer Rod Holt designed the switching power supply for the Apple II.

According to Steve Jobs:

This is a wonderful quote, but it is not entirely true. The revolution of power sources occurred much earlier. Robert Boschert (Robert Boschert), began selling switching power supplies in 1974 for everyone and everything, from printers and computers to the F-14 fighter. Apple's design was similar to earlier devices and other computers did not use Rod Holt's design. However, Apple makes extensive use of switching power supplies and pushes the boundaries of charger design with compact, stylish, and advanced chargers.

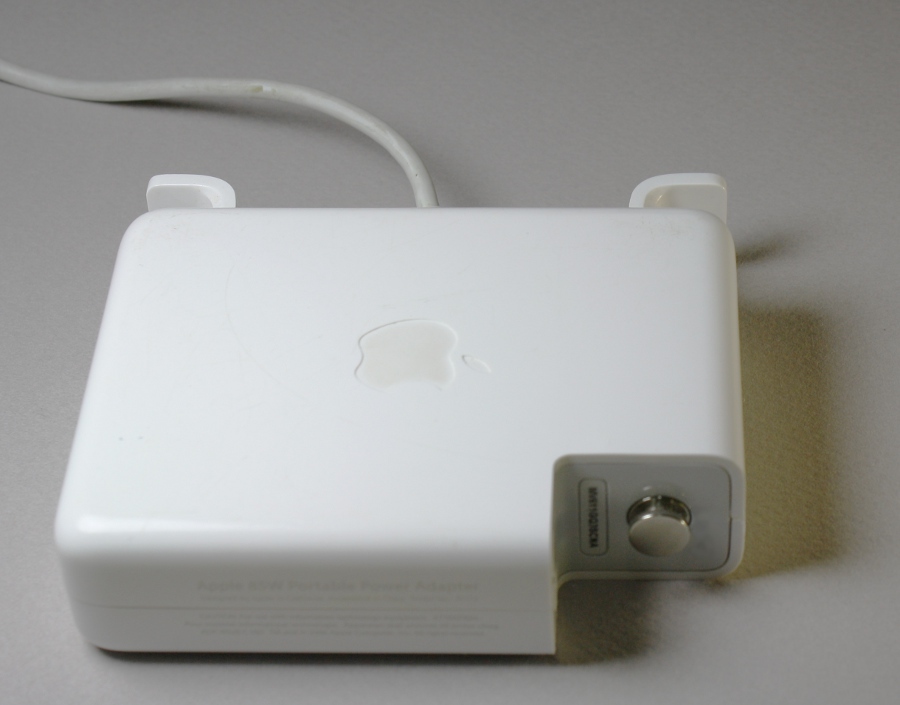

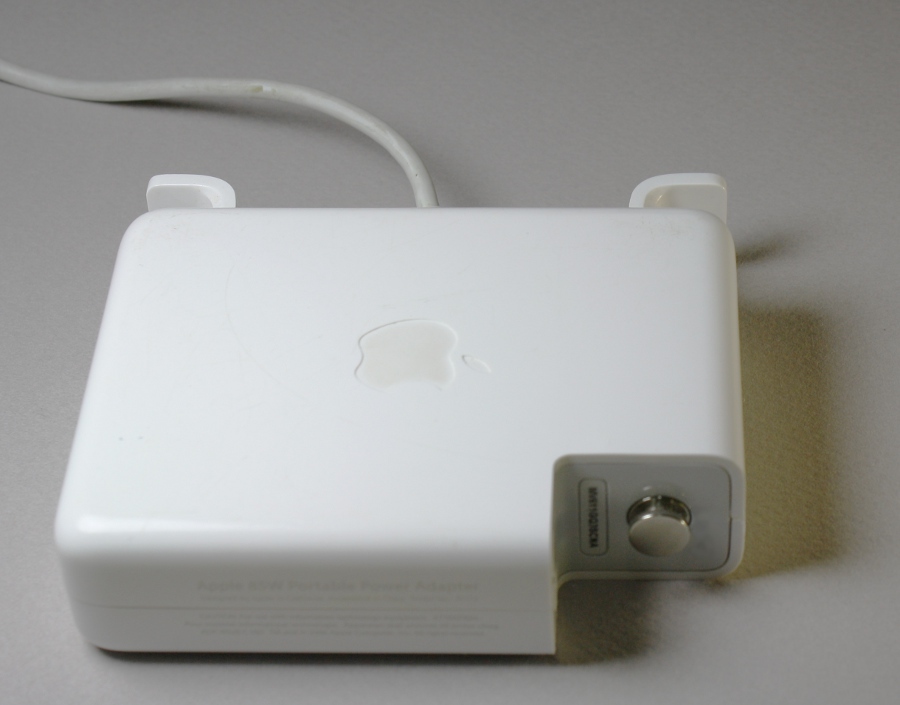

For analysis, we took the Macbook 85W charger model A1172, the dimensions of which are small enough to fit in the palm of your hand. The figure below shows several features that can help distinguish the original charger from fakes. A bitten apple on the case is an integral attribute (what everyone knows about), but there is a detail that does not always attract attention. Original chargers must always have a serial number located under the ground contact.

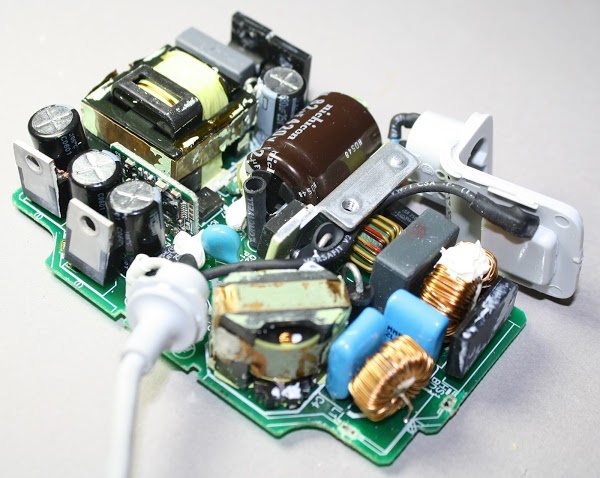

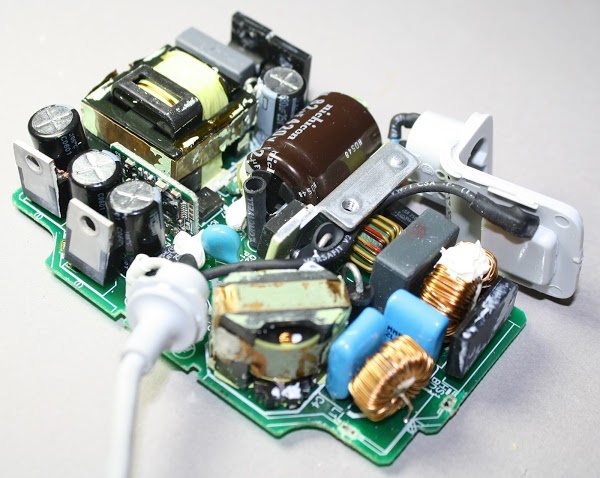

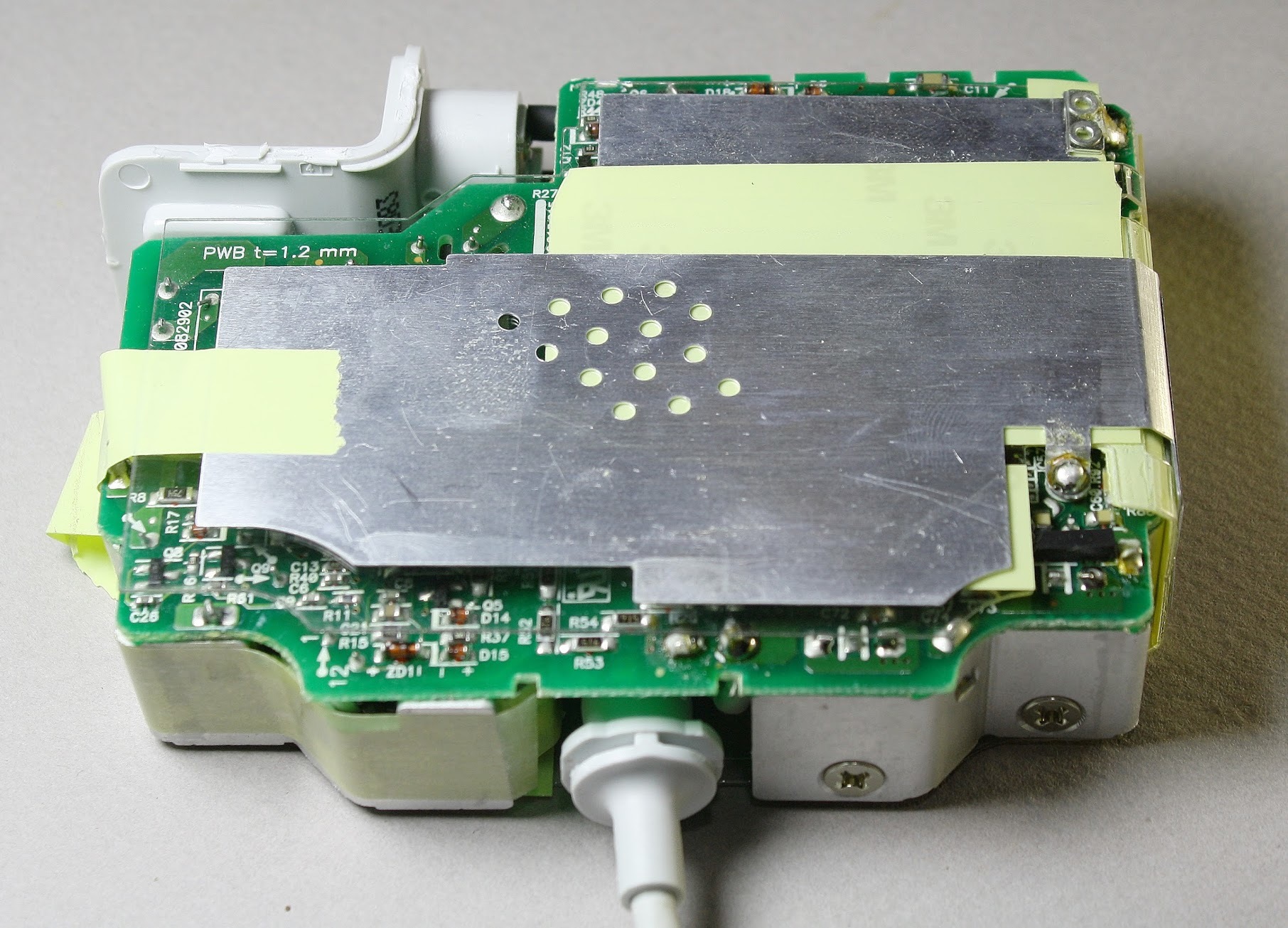

As strange as it sounds, the best way to open the charge is to use a chisel or something similar and add a little brute force to it. Apple initially opposed anyone opening their products and inspecting the "insides." Removing the plastic case, you can immediately see the metal radiators. They help cool powerful semiconductors placed inside the charger.

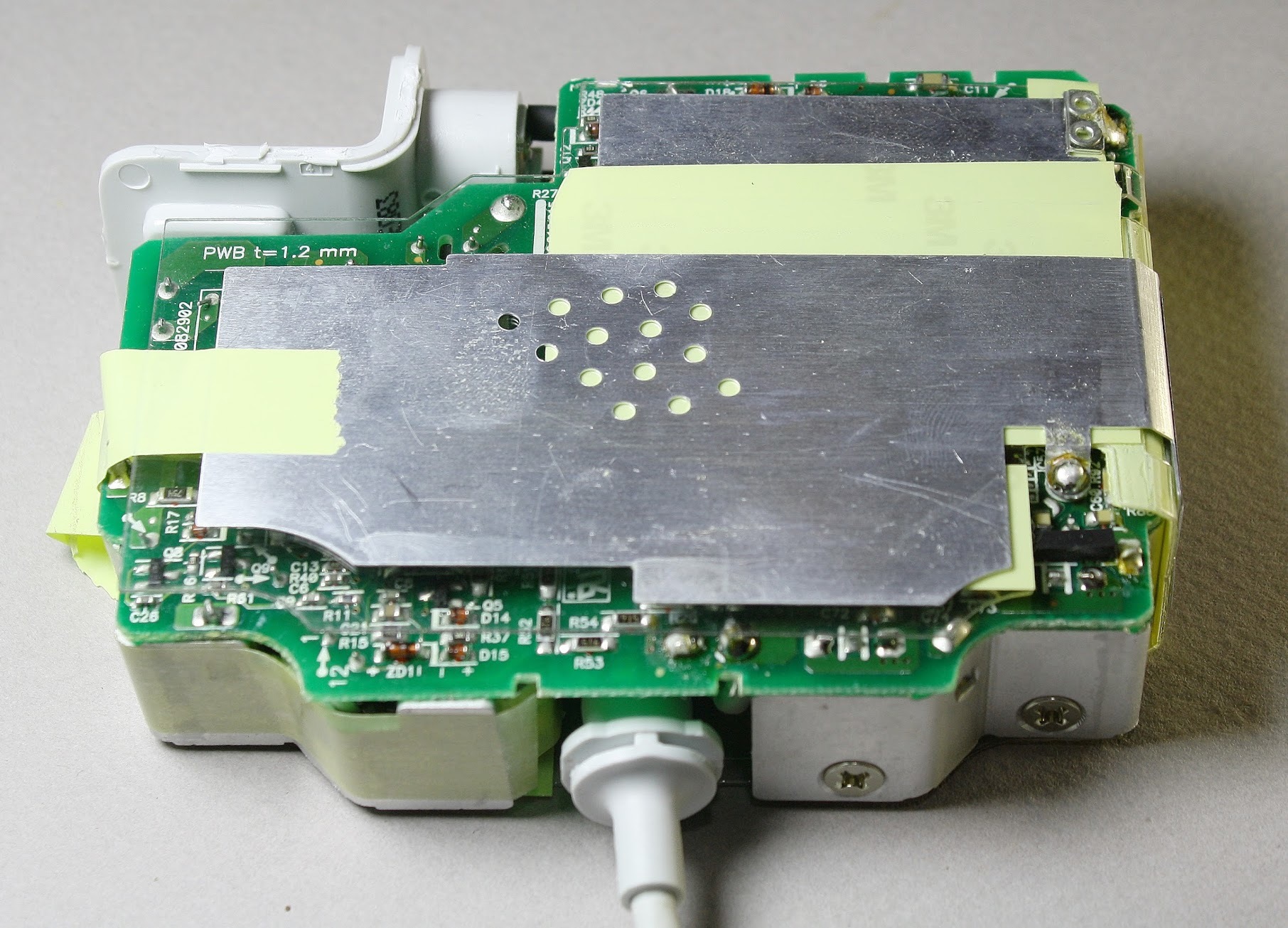

On the back of the charger you can see the circuit board. Some tiny components are visible, but most of the circuitry is hidden under metal radiators fastened with yellow electrical tape.

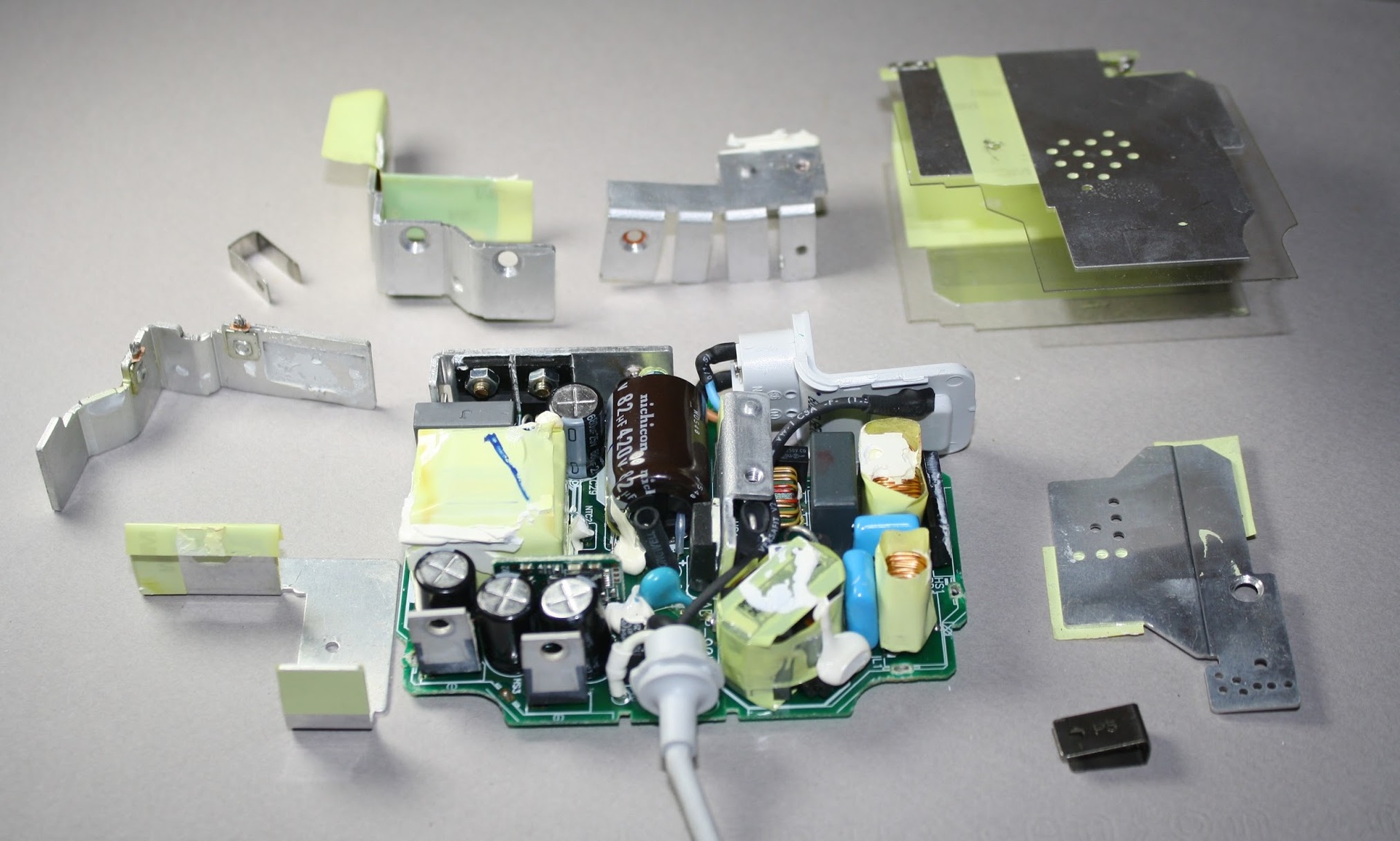

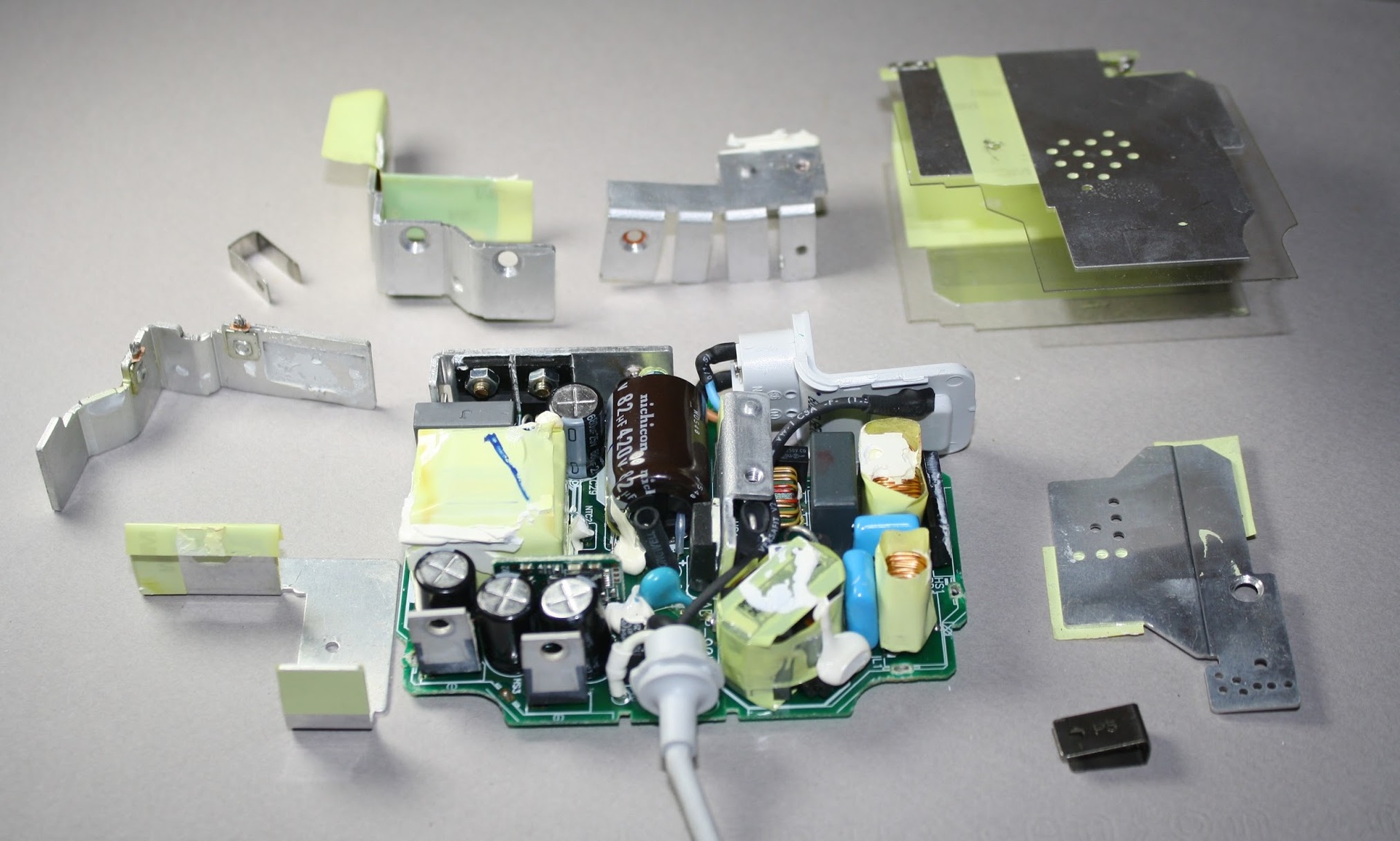

We looked at the radiators and that's enough. To see all the details of the device, of course you need to remove the radiators. Significantly more components are hidden under these metal parts than might be expected from a small block.

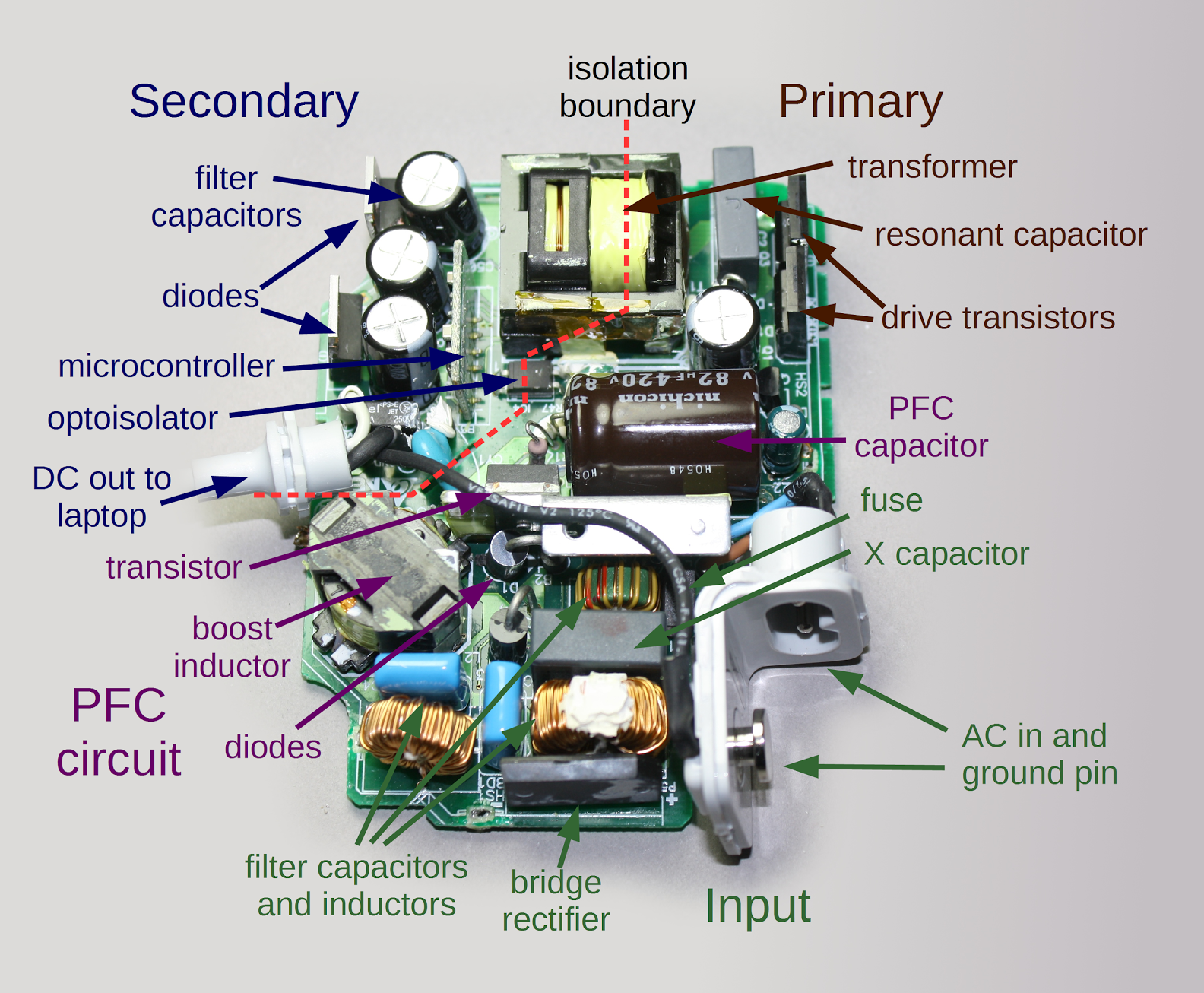

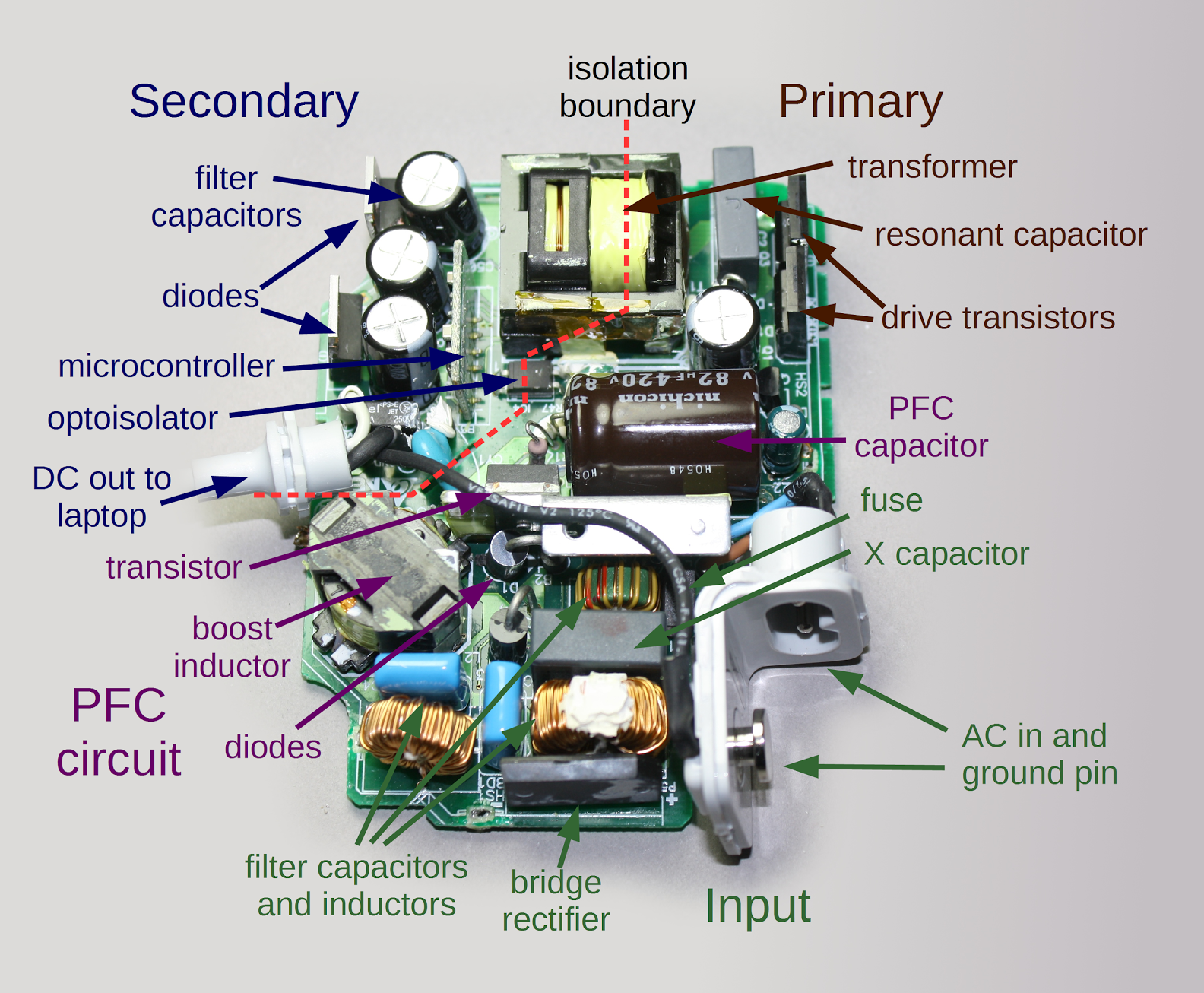

The image below shows the main components of the charger. AC power is supplied to the charger and is already converted there to direct current. The PFC (Power Factor Correction) scheme improves efficiency by providing a stable load on the AC line. According to feasible functions, it is possible to divide the board into two parts: high-voltage and low-voltage. The high-voltage part of the board together with the components placed on it is designed to lower the high-voltage constant voltage and transfer it to the transformer. The low-voltage part receives a constant low-voltage voltage from the transformer and displays a constant voltage of the required level to the laptop. Below we will consider these schemes in more detail.

Alternating voltage is supplied to the charger through a removable plug of the network cable. A big advantage of switching power supplies is their ability to operate over a wide range of incoming voltages. By simply changing the plug, the charger can be used in any region of the world, from European 240 volts at 50 hertz to North American 120 volts at a frequency of 60 hertz. Capacitors, filters and inductors at the input stage prevent interference from leaving the charger through the power lines. The bridge rectifier contains four diodes that convert AC power to direct current.

Watch this video for a more visual demonstration of how a bridge rectifier works.

The next step in the operation of the charger is the power factor correction circuit, marked in purple. One of the problems with simple chargers is that they only get charged in a small part of the AC cycle. When this is done by a single device, there are no particular problems, but when there are thousands of them, this creates problems for energy companies. That is why the rules require that chargers use the power factor correction technique (they use energy more evenly). You might expect that a poor power factor is caused by the transmission of switched power, which quickly turns on and off, but that is not a problem. The problem arises due to the nonlinear diode bridge, which charges the input capacitor only at the peaks of the AC signal. The idea of PFC is to use a DC boost converter before switching power. Thus, the sine wave of the output current is proportional to the waveform of the alternating current.

The PFC circuit uses a power transistor to accurately chop up the AC input tens of thousands of times per second. Contrary to expectations, this makes the load on the AC line smoother. The two largest components in the charger are an inductor and a PFC capacitor, which help increase the DC voltage to 380 volts. The charger uses the MC33368 chip to run the PFC.

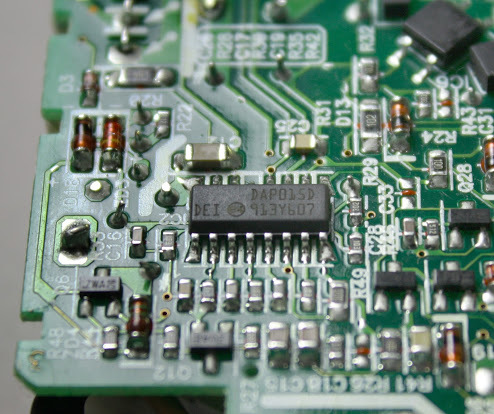

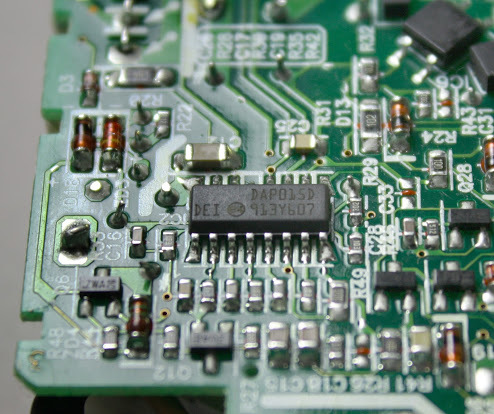

The high voltage circuit is the heart of the charger. It receives a high DC voltage from the PFC circuit, grinds it, and feeds it into a transformer to generate a low voltage output signal from the charger (16.5-18.5 volts). The charger uses an advanced resonant controller, which allows the system to operate at a very high frequency of up to 500 kilohertz. A higher frequency allows the use of more compact components inside the charger. The chip shown below controls the power supply.

SMPS controller - L6599 high-voltage resonant controller; for some reason labeled DAP015D. It uses a half-bridge resonant topology; in a half-bridge circuit, two transistors control the power through the converter. Common switching power supplies use a PWM (Pulse Width Modulation) controller that adjusts the input time. L6599 corrects the frequency of the pulse rather than its pulse. Both transistors turn on alternately for 50% of the time. When the frequency increases above the resonant frequency, the power drops, so the frequency control regulates the output voltage.

Two transistors alternately turn on and off to reduce the input voltage. The converter and capacitor resonate at the same frequency, smoothing the interrupted input into the sine wave.

The second half of the circuit generates the output of the charger. It receives power from the converter and, using diodes, converts it into direct current. Filter capacitors smooth out the voltage that comes from the charger through the cable.

The most important role of the low voltage parts of the charger is to keep the dangerous high voltage inside the charger to avoid a potentially dangerous shock to the end device. The insulating gap, marked with a red dotted line in the image above, indicates the separation between the main high-voltage part and the low-voltage part of the device. Both sides are separated from each other at a distance of about 6 mm.

The transformer transfers power between the primary and secondary devices using magnetic fields, instead of a direct electrical connection. The wire in the transformer has triple insulation for safety. Cheap chargers are usually stingy with insulation. This poses a security risk. Opto-isolation uses an internal light beam to transmit a feedback signal between the low-voltage and high-voltage parts of the charger. The control chip in the high-voltage part of the device uses a feedback signal to adjust the switching frequency to keep the output voltage stable.

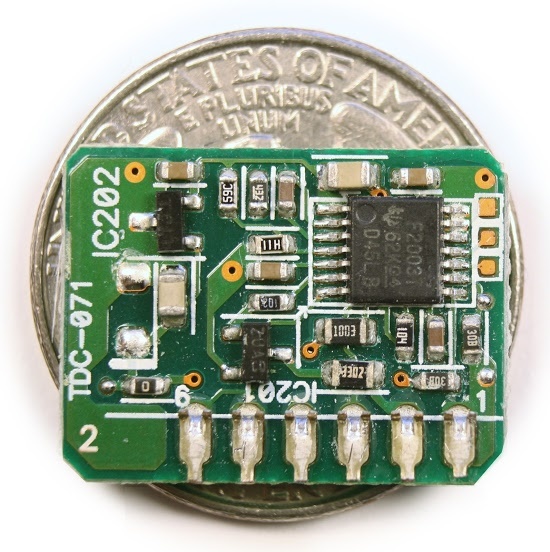

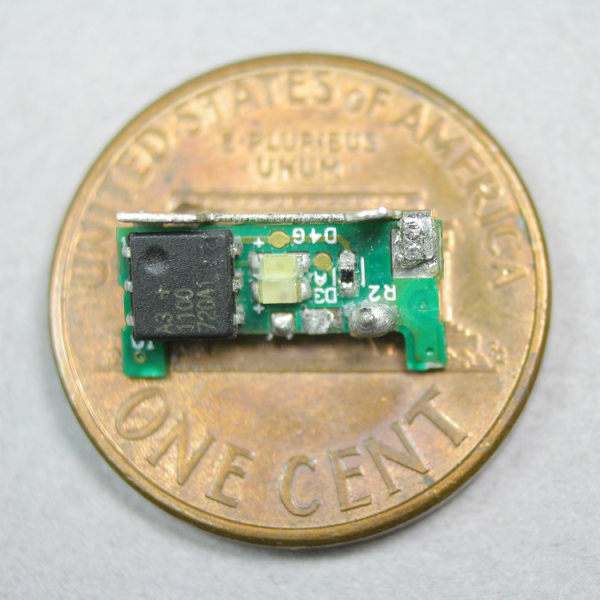

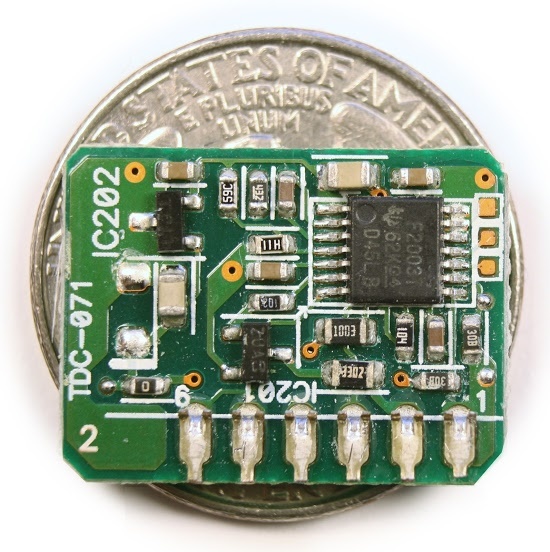

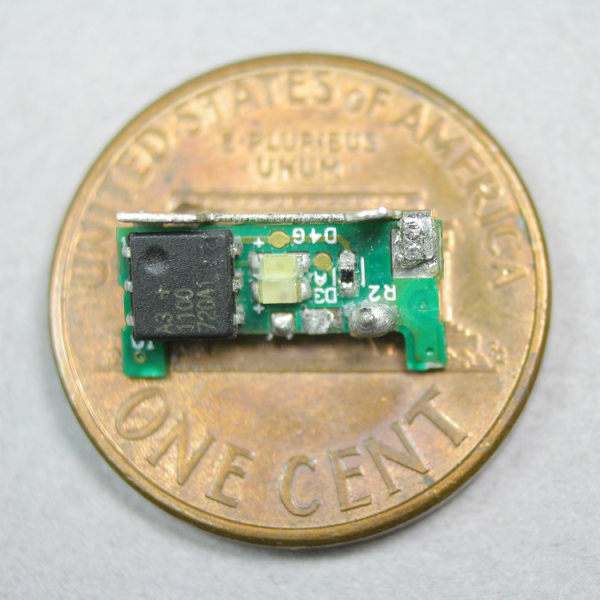

An unexpected component of the charger is a miniature circuit board with a microcontroller, which can be seen in our diagram above. This 16-bit processor constantly monitors the voltage of the charger and amperage. It enables transmission when the charger is connected to the MacBook and disables transmission when the charger is disconnected. Disconnecting the charger occurs if there is any problem. This Texas Instruments MSP430 microcontroller is about the same power as the processor inside the first original Macintosh. The processor in the charger is a low power microcontroller with 1 KB of flash memory and only 128 bytes of RAM. It includes a high-precision 16-bit analog-to-digital converter.

The 68,000 microprocessor from the original Apple Macintosh and the 430 microcontrollers in the charger are not comparable, as they have different designs and instruction sets. But for a rough comparison: 68000 is a 16/32 bit processor operating at a frequency of 7.8 MHz, while the MSP430 is a 16 bit processor operating at a frequency of 16 MHz. The MSP430 is designed for low power consumption and uses approximately 1% of the power supply from 68,000.

The gold-plated pads on the right are used to program the chip during production. A 60-watt MacBook charger uses the MSP430 processor, but an 85-watt charger uses a general-purpose processor, which must be additionally flashed. It is programmed with a Spy-Bi-Wire interface, which is a two-wire version of the TI standard JTAG interface. After programming, the safety fuse in the chip is destroyed to prevent it from reading or changing the firmware.

The three-pin chip on the left (IC202) reduces the 16.5 volts of the charger to 3.3 volts required by the processor. The voltage on the processor is provided not by a standard voltage regulator, but by means of the LT1460, which delivers 3.3 volts with an exceptionally high accuracy of 0.075%.

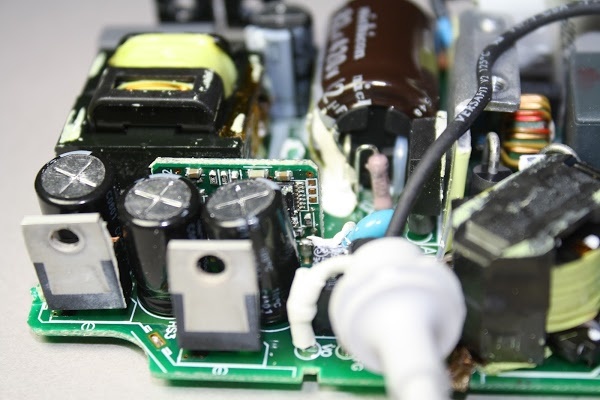

By flipping the charger on the circuit board, you can see dozens of tiny components. The PFC controller and power supply chip (SMPS) are the main integrated circuits that control the charger. The microcircuit of the reference voltage source is responsible for maintaining a stable voltage even when the temperature changes. The reference voltage source microcircuit is the TSM103 / A, which combines two operational amplifiers and a 2.5-volt link in a single-chip circuit. The properties of a semiconductor vary significantly depending on temperature, so maintaining a stable voltage is not an easy task.

These chips are surrounded by tiny resistors, capacitors, diodes, and other small components. MOS - output transistor, turns on and off the power at the output in accordance with the instructions of the microcontroller. To his left are resistors that measure the current transmitted to the laptop.

An isolation gap (marked in red) separates the high voltage from the low voltage output circuit for safety. The dashed red line shows the insulation boundary that separates the low voltage side from the high voltage side. Optocouplers send signals from the low-voltage side to the main device, disconnecting the charger if there is a problem.

A little bit about grounding. A 1KΩ grounding resistor connects the AC grounding terminal to the base at the output of the charger. Four 9.1MΩ resistors connect the internal DC base to the output base. Since they cross the boundary of isolation, safety is a problem. Their high stability avoids the danger of shock. Four resistors are not really necessary, but redundancy exists to ensure the safety and fault tolerance of the device. There is also a Y capacitor (680pF, 250V) between internal ground and output ground. A T5A fuse (5A) protects the ground output.

One reason to install a larger number of control components than usual on the charger is the variable output voltage. To give out 60 watts of voltage, the charger provides 16.5 volts with a resistance level of 3.6 ohms. To produce 85 watts, the potential rises to 18.5 volts and the resistance, respectively, is 4.6 ohms. This allows the charger to be compatible with laptops that require different voltages. When the current potential increases above 3.6 amperes, the circuit gradually increases the output voltage. The charger is urgently turned off when the voltage reaches 90 watts.

The control scheme is quite complex. The output voltage is controlled by an operational amplifier in the TSM103 / A chip, which compares it with the reference voltage generated by the same chip. This amplifier sends a feedback signal through an optocoupler to the SMPS control chip on the high voltage side. If the voltage is too high, the feedback signal lowers the voltage and vice versa. This is a fairly simple part, but where the voltage rises from 16.5 volts to 18.5 volts, things get more complicated.

The output current creates a voltage across resistors with a tiny resistance of 0.005Ω each - they look more like wires than resistors. The operational amplifier in the TSM103 / A chip amplifies this voltage. This signal goes to the tiny operational amplifier TS321, which triggers the build-up when the signal matches 4.1A. This signal enters the previously described control circuit, increasing the output voltage. The current signal is also included in the tiny comparator TS391, which sends the signal to the high-voltage device through another optocoupler to reduce the output voltage. This is a protection circuit if the current level becomes too high. There are several places on the circuit board where resistors with zero resistance (i.e. jumpers) can be installed to change the gain of the operational amplifier.

The Magsafe magnetic plug that connects to the Macbook is more complex than it might seem at first glance. It has five spring-loaded pins (known as Pogo pins) for connecting to a computer, as well as two power contacts, two ground pins. The middle pin is a connection for transferring data to a computer.

Inside, Magsafe is a miniature chip that tells the laptop the serial number, type and power of the charger. The laptop uses this data to determine the originality of the charger. The chip also controls the LED indicator to visually determine the status. The laptop does not receive data directly from the charger, but only through the chip inside Magsafe.

You may have noticed that when you connect the charger to the laptop, it takes one to two seconds before the LED sensor triggers. During this time, a complex interaction occurs between the Magsafe plug, the charger and the Macbook itself.

When the charger is disconnected from the laptop, the output transistor blocks the output voltage. If you measure the voltage from a MacBook charger, you'll find about 6 volts instead of the 16.5 volts you were hoping to see. The reason is the output is turned off, and you measure the voltage through the bypass resistor just below the output transistor. When the Magsafe plug is connected to the Macbook, it begins to access low voltage. The microcontroller in the charger detects this and within a few seconds turns on the power supply. During this time, the laptop manages to get all the necessary information about the charger from the chip inside Magsafe. If everything is fine, the laptop starts to consume power from the charger and sends a signal to the LED indicator. When the Magsafe plug is disconnected from the laptop,

The logical question arises - why is the Apple charger so complicated? Other laptop chargers simply provide 16 volts and when connected to a computer, they immediately supply voltage. The main reason is security concerns to ensure that no voltage is applied until the pins are firmly attached to the laptop. This minimizes the risk of sparks or electric arcs when connecting the Magsafe plug.

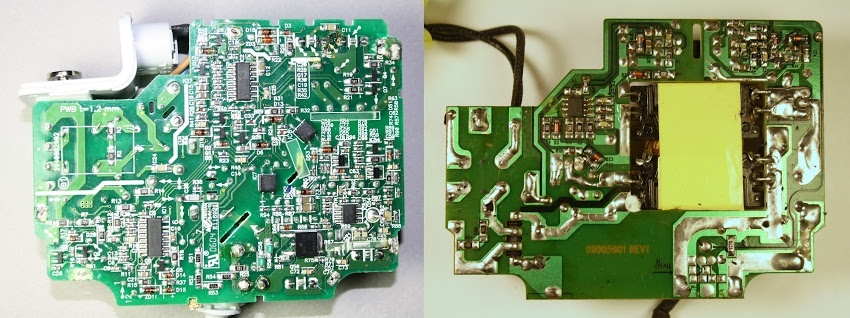

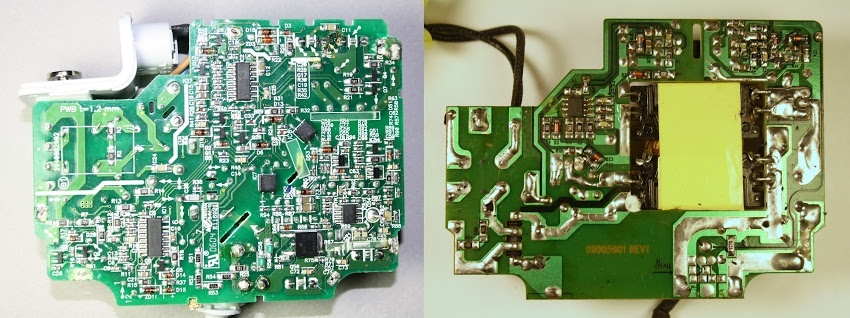

The original Macbook 85W charger costs $ 79. But for $ 14 you can buy a charge on eBay, outwardly similar to the original. So what do you get for an extra $ 65? Let's compare the copy of the charger with the original. From the outside, the charger looks exactly like Apple's original 85W. Except that the Apple logo itself is missing. But if you look inside, the differences become apparent. The photos below show a genuine Apple charger on the left and a copy on the right.

A copy of the charger has two times less parts than the original and the place on the circuit board is simply empty. While the genuine Apple charger is packed with components, its copy is not designed for more filtering and regulation, and it lacks a PFC circuit. The transformer in the copy of the charger (a large yellow rectangle) is much larger in size of the original model. The higher frequency of Apple's Advanced Resonance Converter allows for a smaller transformer.

Turning the charger over and examining the circuit board, you can see a more complex circuit of the original charger. A copy has only one control IC (in the upper left corner). Since the PFC circuit is completely thrown away. In addition, the charging clone is less difficult to manage and does not have grounding. You understand what this threatens.

It is worth noting that a copy of the charger uses the Fairchild FAN7602 green PWM controller chip, which is more advanced than you might expect. I think most expected to see something like a simple transistor generator. And in addition to the copies, unlike the original, a single-sided printed circuit board is used.

In fact, a copy of the charger is better quality than you might expect, compared to the terrible copies of the chargers for the iPad and iPhone. A copy of the charge for the MacBook does not reduce all possible components and uses a moderately complex circuit. This charger also places a slight emphasis on safety. Component isolation and separation of high and low voltage sections are applied, with the exception of one dangerous error, which you will see below. The capacitor Y (blue) was installed crookedly and dangerously close to the optocoupler contact on the high voltage side, creating a risk of electric shock.

The irony is that despite the complexity and attention to detail, the Apple MacBook charger is not a trouble-free device. On the Internet you can find a lot of different photos of burned, damaged and simply idle charges. The most vulnerable part of the original charger is precisely the wire in the area of the Magsafe plug. The cable is rather flimsy and it quickly frays, which leads to damage, burnout or simply breaking. Apple provides detailed instructions on how to avoid cable damage, rather than just providing a more powerful cable. As a result of the review on the Apple website, the charger received only 1.5 stars out of 5 possible.

MacBook chargers may also stop working due to internal issues. The photos above and below show burn marks inside Apple's failed charge. It’s impossible to say exactly what exactly caused the fire. Due to a short circuit, half of the components and a good part of the printed circuit board burned out. At the bottom of the photo, charred silicone insulation for mounting the board.

As you can see, Apple’s charger has a more advanced design than copies and has additional security features. However, a genuine charger costs $ 65 more and I doubt that additional components cost more than $ 10 - $ 15. Most of the cost of the charger goes into the net profit of the company. According to estimates, the cost of the iPhone 45% is the company's net profit. Chargers probably bring even more money. Apple's original price should be significantly lower. The device has many tiny components of resistors, capacitors and transistors, the price of which varies in the region of one cent. Large semiconductors, capacitors and inductors naturally cost significantly more, but for example, the 16-bit MSP430 processor costs only $ 0.45. Apple explains the high cost not only with the costs of marketing and so on, but also with the high costs of the development of a particular charger model. BookPractical Switching Power Supply Design estimates 9 months of work time for designing and improving power supplies in the region of $ 200,000. The company sells about 20 million MacBooks per year. If you invest the development cost in the cost of the device, it will be only 1 cent. Even if the cost of designing and developing chargers from Apple is 10 times higher, the price will not exceed 10 cents. Despite all this, I do not recommend you save your money by purchasing analogues of a charger and risking your laptop and even health.

Users are not often interested in what is inside the charger. But there are a lot of interesting things. In appearance, simple charging uses advanced technology, including power factor correction and a resonant power supply, to produce 85 watts of power in a compact module. The Macbook Charger is an impressive piece of engineering. At the same time, its copies strive to reduce the cost of everything that is possible to the maximum. This is of course economical, but also a danger to you and your laptop.

Most consumer electronics, from your smartphone to your TV, use pulsed power supplies to convert AC power from a wall outlet to the low-voltage direct current used by electronic circuits. Switching power supplies or, more correctly, low-voltage power supplies - got their name from the fact that they turn on and off the power supply thousands of times per second. It is most effective for voltage conversion.

The main alternative to a switching power supply is a linear power supply, which is much simpler and converts overvoltage to heat. Due to this energy loss, the efficiency of a linear power supply is about 60%, compared to about 85% for a switching power supply. Linear power supplies use a bulky transformer that can weigh up to a kilogram or more, while switching power supplies can use tiny high-frequency transformers.

Now, such power sources are very cheap, but this has not always been the case. In 1950, switching power supplies were complex and expensive, used in aerospace and satellite technologies, which needed a light and compact power source. By the beginning of the 70s, new high-voltage transistors and other technological improvements made sources much cheaper and they were widely used in computers. The introduction of single-chip controllers in 1976 made power converters even simpler, smaller, and cheaper.

Apple's use of switching power supplies began in 1977, when chief engineer Rod Holt designed the switching power supply for the Apple II.

According to Steve Jobs:

This switching power supply was as revolutionary as the logic of the Apple II. Rod did not receive much recognition in the pages of history, but he deserved it. Each computer now uses switching power supplies, and they are all similar in structure to that invented by Holt.

This is a wonderful quote, but it is not entirely true. The revolution of power sources occurred much earlier. Robert Boschert (Robert Boschert), began selling switching power supplies in 1974 for everyone and everything, from printers and computers to the F-14 fighter. Apple's design was similar to earlier devices and other computers did not use Rod Holt's design. However, Apple makes extensive use of switching power supplies and pushes the boundaries of charger design with compact, stylish, and advanced chargers.

What's inside?

For analysis, we took the Macbook 85W charger model A1172, the dimensions of which are small enough to fit in the palm of your hand. The figure below shows several features that can help distinguish the original charger from fakes. A bitten apple on the case is an integral attribute (what everyone knows about), but there is a detail that does not always attract attention. Original chargers must always have a serial number located under the ground contact.

As strange as it sounds, the best way to open the charge is to use a chisel or something similar and add a little brute force to it. Apple initially opposed anyone opening their products and inspecting the "insides." Removing the plastic case, you can immediately see the metal radiators. They help cool powerful semiconductors placed inside the charger.

On the back of the charger you can see the circuit board. Some tiny components are visible, but most of the circuitry is hidden under metal radiators fastened with yellow electrical tape.

We looked at the radiators and that's enough. To see all the details of the device, of course you need to remove the radiators. Significantly more components are hidden under these metal parts than might be expected from a small block.

The image below shows the main components of the charger. AC power is supplied to the charger and is already converted there to direct current. The PFC (Power Factor Correction) scheme improves efficiency by providing a stable load on the AC line. According to feasible functions, it is possible to divide the board into two parts: high-voltage and low-voltage. The high-voltage part of the board together with the components placed on it is designed to lower the high-voltage constant voltage and transfer it to the transformer. The low-voltage part receives a constant low-voltage voltage from the transformer and displays a constant voltage of the required level to the laptop. Below we will consider these schemes in more detail.

AC input to charger

Alternating voltage is supplied to the charger through a removable plug of the network cable. A big advantage of switching power supplies is their ability to operate over a wide range of incoming voltages. By simply changing the plug, the charger can be used in any region of the world, from European 240 volts at 50 hertz to North American 120 volts at a frequency of 60 hertz. Capacitors, filters and inductors at the input stage prevent interference from leaving the charger through the power lines. The bridge rectifier contains four diodes that convert AC power to direct current.

Watch this video for a more visual demonstration of how a bridge rectifier works.

PFC: smoothing power consumption

The next step in the operation of the charger is the power factor correction circuit, marked in purple. One of the problems with simple chargers is that they only get charged in a small part of the AC cycle. When this is done by a single device, there are no particular problems, but when there are thousands of them, this creates problems for energy companies. That is why the rules require that chargers use the power factor correction technique (they use energy more evenly). You might expect that a poor power factor is caused by the transmission of switched power, which quickly turns on and off, but that is not a problem. The problem arises due to the nonlinear diode bridge, which charges the input capacitor only at the peaks of the AC signal. The idea of PFC is to use a DC boost converter before switching power. Thus, the sine wave of the output current is proportional to the waveform of the alternating current.

The PFC circuit uses a power transistor to accurately chop up the AC input tens of thousands of times per second. Contrary to expectations, this makes the load on the AC line smoother. The two largest components in the charger are an inductor and a PFC capacitor, which help increase the DC voltage to 380 volts. The charger uses the MC33368 chip to run the PFC.

Primary power conversion

The high voltage circuit is the heart of the charger. It receives a high DC voltage from the PFC circuit, grinds it, and feeds it into a transformer to generate a low voltage output signal from the charger (16.5-18.5 volts). The charger uses an advanced resonant controller, which allows the system to operate at a very high frequency of up to 500 kilohertz. A higher frequency allows the use of more compact components inside the charger. The chip shown below controls the power supply.

SMPS controller - L6599 high-voltage resonant controller; for some reason labeled DAP015D. It uses a half-bridge resonant topology; in a half-bridge circuit, two transistors control the power through the converter. Common switching power supplies use a PWM (Pulse Width Modulation) controller that adjusts the input time. L6599 corrects the frequency of the pulse rather than its pulse. Both transistors turn on alternately for 50% of the time. When the frequency increases above the resonant frequency, the power drops, so the frequency control regulates the output voltage.

Two transistors alternately turn on and off to reduce the input voltage. The converter and capacitor resonate at the same frequency, smoothing the interrupted input into the sine wave.

Secondary power conversion

The second half of the circuit generates the output of the charger. It receives power from the converter and, using diodes, converts it into direct current. Filter capacitors smooth out the voltage that comes from the charger through the cable.

The most important role of the low voltage parts of the charger is to keep the dangerous high voltage inside the charger to avoid a potentially dangerous shock to the end device. The insulating gap, marked with a red dotted line in the image above, indicates the separation between the main high-voltage part and the low-voltage part of the device. Both sides are separated from each other at a distance of about 6 mm.

The transformer transfers power between the primary and secondary devices using magnetic fields, instead of a direct electrical connection. The wire in the transformer has triple insulation for safety. Cheap chargers are usually stingy with insulation. This poses a security risk. Opto-isolation uses an internal light beam to transmit a feedback signal between the low-voltage and high-voltage parts of the charger. The control chip in the high-voltage part of the device uses a feedback signal to adjust the switching frequency to keep the output voltage stable.

Powerful microprocessor inside the charger

An unexpected component of the charger is a miniature circuit board with a microcontroller, which can be seen in our diagram above. This 16-bit processor constantly monitors the voltage of the charger and amperage. It enables transmission when the charger is connected to the MacBook and disables transmission when the charger is disconnected. Disconnecting the charger occurs if there is any problem. This Texas Instruments MSP430 microcontroller is about the same power as the processor inside the first original Macintosh. The processor in the charger is a low power microcontroller with 1 KB of flash memory and only 128 bytes of RAM. It includes a high-precision 16-bit analog-to-digital converter.

The 68,000 microprocessor from the original Apple Macintosh and the 430 microcontrollers in the charger are not comparable, as they have different designs and instruction sets. But for a rough comparison: 68000 is a 16/32 bit processor operating at a frequency of 7.8 MHz, while the MSP430 is a 16 bit processor operating at a frequency of 16 MHz. The MSP430 is designed for low power consumption and uses approximately 1% of the power supply from 68,000.

The gold-plated pads on the right are used to program the chip during production. A 60-watt MacBook charger uses the MSP430 processor, but an 85-watt charger uses a general-purpose processor, which must be additionally flashed. It is programmed with a Spy-Bi-Wire interface, which is a two-wire version of the TI standard JTAG interface. After programming, the safety fuse in the chip is destroyed to prevent it from reading or changing the firmware.

The three-pin chip on the left (IC202) reduces the 16.5 volts of the charger to 3.3 volts required by the processor. The voltage on the processor is provided not by a standard voltage regulator, but by means of the LT1460, which delivers 3.3 volts with an exceptionally high accuracy of 0.075%.

Many tiny components on the underside of the charger

By flipping the charger on the circuit board, you can see dozens of tiny components. The PFC controller and power supply chip (SMPS) are the main integrated circuits that control the charger. The microcircuit of the reference voltage source is responsible for maintaining a stable voltage even when the temperature changes. The reference voltage source microcircuit is the TSM103 / A, which combines two operational amplifiers and a 2.5-volt link in a single-chip circuit. The properties of a semiconductor vary significantly depending on temperature, so maintaining a stable voltage is not an easy task.

These chips are surrounded by tiny resistors, capacitors, diodes, and other small components. MOS - output transistor, turns on and off the power at the output in accordance with the instructions of the microcontroller. To his left are resistors that measure the current transmitted to the laptop.

An isolation gap (marked in red) separates the high voltage from the low voltage output circuit for safety. The dashed red line shows the insulation boundary that separates the low voltage side from the high voltage side. Optocouplers send signals from the low-voltage side to the main device, disconnecting the charger if there is a problem.

A little bit about grounding. A 1KΩ grounding resistor connects the AC grounding terminal to the base at the output of the charger. Four 9.1MΩ resistors connect the internal DC base to the output base. Since they cross the boundary of isolation, safety is a problem. Their high stability avoids the danger of shock. Four resistors are not really necessary, but redundancy exists to ensure the safety and fault tolerance of the device. There is also a Y capacitor (680pF, 250V) between internal ground and output ground. A T5A fuse (5A) protects the ground output.

One reason to install a larger number of control components than usual on the charger is the variable output voltage. To give out 60 watts of voltage, the charger provides 16.5 volts with a resistance level of 3.6 ohms. To produce 85 watts, the potential rises to 18.5 volts and the resistance, respectively, is 4.6 ohms. This allows the charger to be compatible with laptops that require different voltages. When the current potential increases above 3.6 amperes, the circuit gradually increases the output voltage. The charger is urgently turned off when the voltage reaches 90 watts.

The control scheme is quite complex. The output voltage is controlled by an operational amplifier in the TSM103 / A chip, which compares it with the reference voltage generated by the same chip. This amplifier sends a feedback signal through an optocoupler to the SMPS control chip on the high voltage side. If the voltage is too high, the feedback signal lowers the voltage and vice versa. This is a fairly simple part, but where the voltage rises from 16.5 volts to 18.5 volts, things get more complicated.

The output current creates a voltage across resistors with a tiny resistance of 0.005Ω each - they look more like wires than resistors. The operational amplifier in the TSM103 / A chip amplifies this voltage. This signal goes to the tiny operational amplifier TS321, which triggers the build-up when the signal matches 4.1A. This signal enters the previously described control circuit, increasing the output voltage. The current signal is also included in the tiny comparator TS391, which sends the signal to the high-voltage device through another optocoupler to reduce the output voltage. This is a protection circuit if the current level becomes too high. There are several places on the circuit board where resistors with zero resistance (i.e. jumpers) can be installed to change the gain of the operational amplifier.

Magsafe plug

The Magsafe magnetic plug that connects to the Macbook is more complex than it might seem at first glance. It has five spring-loaded pins (known as Pogo pins) for connecting to a computer, as well as two power contacts, two ground pins. The middle pin is a connection for transferring data to a computer.

Inside, Magsafe is a miniature chip that tells the laptop the serial number, type and power of the charger. The laptop uses this data to determine the originality of the charger. The chip also controls the LED indicator to visually determine the status. The laptop does not receive data directly from the charger, but only through the chip inside Magsafe.

Use charger

You may have noticed that when you connect the charger to the laptop, it takes one to two seconds before the LED sensor triggers. During this time, a complex interaction occurs between the Magsafe plug, the charger and the Macbook itself.

When the charger is disconnected from the laptop, the output transistor blocks the output voltage. If you measure the voltage from a MacBook charger, you'll find about 6 volts instead of the 16.5 volts you were hoping to see. The reason is the output is turned off, and you measure the voltage through the bypass resistor just below the output transistor. When the Magsafe plug is connected to the Macbook, it begins to access low voltage. The microcontroller in the charger detects this and within a few seconds turns on the power supply. During this time, the laptop manages to get all the necessary information about the charger from the chip inside Magsafe. If everything is fine, the laptop starts to consume power from the charger and sends a signal to the LED indicator. When the Magsafe plug is disconnected from the laptop,

The logical question arises - why is the Apple charger so complicated? Other laptop chargers simply provide 16 volts and when connected to a computer, they immediately supply voltage. The main reason is security concerns to ensure that no voltage is applied until the pins are firmly attached to the laptop. This minimizes the risk of sparks or electric arcs when connecting the Magsafe plug.

Why you should not use cheap chargers

The original Macbook 85W charger costs $ 79. But for $ 14 you can buy a charge on eBay, outwardly similar to the original. So what do you get for an extra $ 65? Let's compare the copy of the charger with the original. From the outside, the charger looks exactly like Apple's original 85W. Except that the Apple logo itself is missing. But if you look inside, the differences become apparent. The photos below show a genuine Apple charger on the left and a copy on the right.

A copy of the charger has two times less parts than the original and the place on the circuit board is simply empty. While the genuine Apple charger is packed with components, its copy is not designed for more filtering and regulation, and it lacks a PFC circuit. The transformer in the copy of the charger (a large yellow rectangle) is much larger in size of the original model. The higher frequency of Apple's Advanced Resonance Converter allows for a smaller transformer.

Turning the charger over and examining the circuit board, you can see a more complex circuit of the original charger. A copy has only one control IC (in the upper left corner). Since the PFC circuit is completely thrown away. In addition, the charging clone is less difficult to manage and does not have grounding. You understand what this threatens.

It is worth noting that a copy of the charger uses the Fairchild FAN7602 green PWM controller chip, which is more advanced than you might expect. I think most expected to see something like a simple transistor generator. And in addition to the copies, unlike the original, a single-sided printed circuit board is used.

In fact, a copy of the charger is better quality than you might expect, compared to the terrible copies of the chargers for the iPad and iPhone. A copy of the charge for the MacBook does not reduce all possible components and uses a moderately complex circuit. This charger also places a slight emphasis on safety. Component isolation and separation of high and low voltage sections are applied, with the exception of one dangerous error, which you will see below. The capacitor Y (blue) was installed crookedly and dangerously close to the optocoupler contact on the high voltage side, creating a risk of electric shock.

Apple Original Issues

The irony is that despite the complexity and attention to detail, the Apple MacBook charger is not a trouble-free device. On the Internet you can find a lot of different photos of burned, damaged and simply idle charges. The most vulnerable part of the original charger is precisely the wire in the area of the Magsafe plug. The cable is rather flimsy and it quickly frays, which leads to damage, burnout or simply breaking. Apple provides detailed instructions on how to avoid cable damage, rather than just providing a more powerful cable. As a result of the review on the Apple website, the charger received only 1.5 stars out of 5 possible.

MacBook chargers may also stop working due to internal issues. The photos above and below show burn marks inside Apple's failed charge. It’s impossible to say exactly what exactly caused the fire. Due to a short circuit, half of the components and a good part of the printed circuit board burned out. At the bottom of the photo, charred silicone insulation for mounting the board.

Why are original chargers so expensive?

As you can see, Apple’s charger has a more advanced design than copies and has additional security features. However, a genuine charger costs $ 65 more and I doubt that additional components cost more than $ 10 - $ 15. Most of the cost of the charger goes into the net profit of the company. According to estimates, the cost of the iPhone 45% is the company's net profit. Chargers probably bring even more money. Apple's original price should be significantly lower. The device has many tiny components of resistors, capacitors and transistors, the price of which varies in the region of one cent. Large semiconductors, capacitors and inductors naturally cost significantly more, but for example, the 16-bit MSP430 processor costs only $ 0.45. Apple explains the high cost not only with the costs of marketing and so on, but also with the high costs of the development of a particular charger model. BookPractical Switching Power Supply Design estimates 9 months of work time for designing and improving power supplies in the region of $ 200,000. The company sells about 20 million MacBooks per year. If you invest the development cost in the cost of the device, it will be only 1 cent. Even if the cost of designing and developing chargers from Apple is 10 times higher, the price will not exceed 10 cents. Despite all this, I do not recommend you save your money by purchasing analogues of a charger and risking your laptop and even health.

| Component | Price |

|---|---|

| MSP430F2003 processor | $ 0.45 |

| MC33368D PFC chip | $ 0.50 |

| L6599 controller | $ 1.62 |

| LT1460 3.3V | $ 1.46 |

| TSM103 / A | $ 0.16 |

| 2x P11NM60AFP 11A 60V MOSFET | $ 2.00 |

| 3x Vishay Optocoupler | $ 0.48 |

| 2x 630V 0.47uF Film Capacitor | $ 0.88 |

| 4x 25V 680uF Electrolytic Capacitor | $ 0.12 |

| 420V 82uF Electrolytic Capacitor | $ 0.93 |

| polypropylene capacitor X2 | $ 0.17 |

| 3x toroidal inductor | $ 0.75 |

| 4A 600V diode bridge | $ 0.40 |

| 2x Schottky Semiconductor Diode 60V, 15A | $ 0.80 |

| 20NC603 MOSFET | $ 1.57 |

| transformer | $ 1.50 |

| PFC inductor | $ 1.50 |

And for the rest

Users are not often interested in what is inside the charger. But there are a lot of interesting things. In appearance, simple charging uses advanced technology, including power factor correction and a resonant power supply, to produce 85 watts of power in a compact module. The Macbook Charger is an impressive piece of engineering. At the same time, its copies strive to reduce the cost of everything that is possible to the maximum. This is of course economical, but also a danger to you and your laptop.