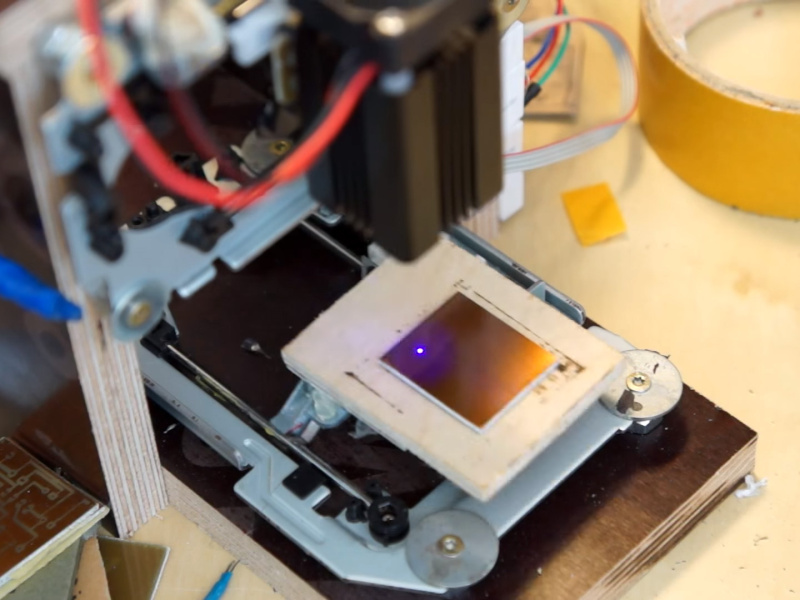

Laser engraver based on parts of CD-ROM drives and Arduino mega

A YouTube user with the nickname NeumiElektronik used old CD-ROM drives (servos and some other parts), a 150 mW and 405 nm laser diode and Arduino mega to create a laser engraver. The central platform moves under the control of the Arduino, and the laser burns out on the surface the details of the circuit and patterns set by the master. In this case, the most interesting option for using such a mechanism is the creation of printed circuit boards with a photoresist.

The laser removes portions of the film, and the pattern is then etched in an ordinary solution. The result is an almost perfect small circuit board. The author of the project reports that he spent about $ 61 on everything about everything. He took all the other parts from his storerooms or simply found. The engraver works with materials such as paper, leather, plastic, wood, foam. To work with each type of material, you need to set the exposure time for the laser.

Managing software Neumi wrote on his own, wishing to study the very concept of a laser engraver. The software sends raster scans to the Arduino mega, and only then Arduino controls the laser itself and the drives of the mechanical platform. The entire source package and device diagram are available on GitHub. The author himself says that there is nothing complicated for a person who is at least a little versed in electronics.

Caustic soda is used to wash the photoresist (they say you can even use the Mole pipe cleaner, which includes NaOH), and sodium persulfate is used to etch the circuit board itself. All this is shown in the video, and the further use of the board created using this system is also shown.

The mechanism works with a working area of 32 * 32 mm. Resolution - 100 pixels per cm. Complete processing of such an area takes 10 minutes. This is not a record at all, but pretty good, plus if you take into account the cost of the system, its advantages become quite obvious.