The collective airliner rescue system has been created. This is not profitable - answer in airlines

Welcome to the iCover Blog Pages . For many, it may become a revelation that literally two days before the tragedy with the Russian airliner Airbus A-321 of MetroJet, following flight 9268 along the route “Sharm El Sheikh - St. Petersburg”, on October 29, the Street FX Motorsport & Graphics community published a video on Facebook pages demonstrating the collective rescue system for passengers in the crash of an aircraft, proposed by Ukrainian engineer Vladimir Tatarenko back in 2010.

Most likely, the minimum time difference between the release of the video and the crash of the plane south of the Egyptian city of El Arish at about 7 am on October 31 is just a coincidence. At the same time, this particular video, which gained almost 18.5 million views and more than 250,000 posts on November 10, 2015, clearly demonstrated the urgency of the collective safety problem for passengers on board the airliner.

In connection with the tragic events of the past days, we decided to devote our present material to the invention of V.N. Tatarenko, which, according to his author, if timely supported, would help minimize the number of victims of many flights over the past decade and a half.

Saving one person, you save the whole world. Confucius

Brief information: Vladimir Nikolaevich Tatarenko hails from near Krasnoyarsk. He graduated from the faculty of aircraft engineering at ISTU and then worked for some time in Irkutsk. By distribution, he got to the Kiev Aviation Plant, where for some time he worked as the head of a mechanical assembly shop, and after that as a leading engineer at the Research Institute of Aviation Technologies. He wrote a doctoral dissertation at the KPI. In total, Tatarenko has more than 100 patents and several books on aircraft construction. He participated in the creation of the heavy-load liner AN-225 “MRIYA” for which he was presented to the State Prize of the Ukrainian SSR in the field of science and technology.

The number of victims of car accidents, compared with the number of tragedies in the sky, is much larger. At the same time, the current level of search for ways and solutions to urgent problems of the safety of air passengers today remains extremely unsatisfactory.

A long-term study of existing rescue systems led the author of the invention to the disappointing conclusion: "... There are no truly effective systems for today. While the main emphasis is on improving the reliability of aircraft structures and duplicating their systems, people still remain in case of an accident on the plane and burn with it. On the other hand, most of the proposed systems for saving passengers require the destruction of the fuselage, the separation of the wings, etc. ... until the capsule is separated, which negates any th likelihood of restoration and future use of the aircraft. "

The only effective solution in such a situation here could be the complete removal of passengers and crew from the aircraft, Tatarenko said.

According to the inventor, the idea of creating an effective system of collective rescue of passengers excited the inventors in the first decades of the last century. The patent for one of such systems, “A device for rescuing passengers in an airplane accident”, was obtained back in 1923 by the Russian inventor of an airborne parachute parachute, Gleb Evgenievich Kotelnikov, but there were no technical capabilities to implement the project in those years.

An application for a patent under the number UA52936U “Aircraft with a device for rescuing passengers in an emergency” V. Tatarenko filed another October 9, 2010.

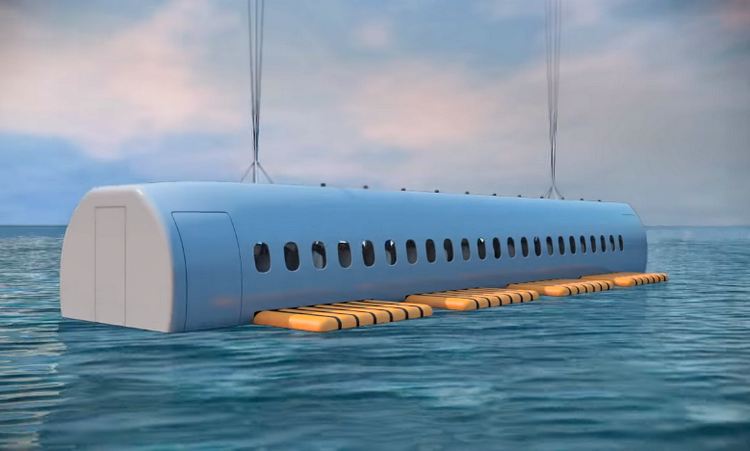

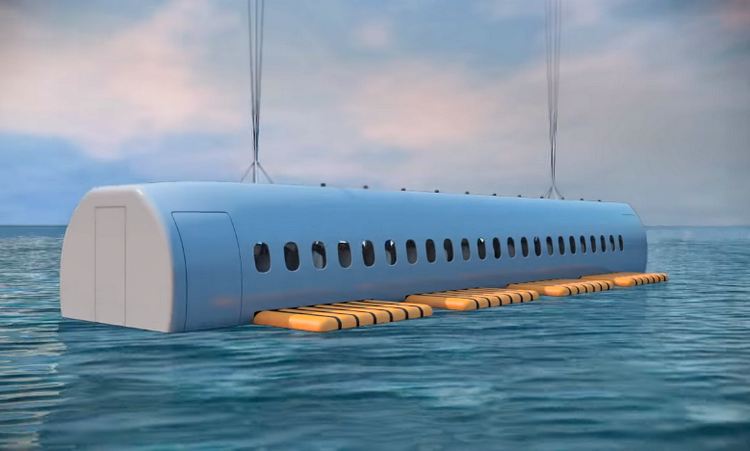

The system implemented by Tatarenko in the UA52936U patent, according to him, is based on time-tested reliable technical solutions. It makes it possible to evacuate all passengers and crew from an airplane in distress in the altitude range from several tens of meters to several kilometers, smooth descent and soft landing (splashdown) of the capsule, and ensuring the life of people up to the moment of detection by rescuers.

The capsule is attached to the fuselage via detachable automatic mounts. At the same time, all electrical, piping, kinematic and other connections at the separation sites are made self-disconnecting - using automatic couplings, electrical connectors, spool and other valves.

The descent of the capsule is ensured by the aerodynamic interaction of the parachutes with the incoming air flow under the influence of the capsule's own mass. The ability of the system to withdraw small and large parachute systems within 2-3 seconds and to ensure the evacuation of the capsule and its active self-braking, according to the aircraft designer, allows you to use the capabilities of the method at low altitudes - during takeoff and landing.

In a carbon fiber capsule, there are rows of seats for passengers and chairs for crew members, who, according to Tatarenko's plan, leaves the plane at the same time as passengers.

The Tatarenko project is an attempt to bring a fundamentally new aircraft to the market, taking into account strict technical, legal and commercial restrictions. In this case, in the case of the manufacture of the fuselage, wings and capsules of carbon fiber and modern high-strength materials, it becomes possible to maintain the total mass of the aircraft at the level of the mass of the basic configuration.

Aircraft design diagram: fuselage - 1, consisting of two upper (2) and lower (3) parts interconnected. The wings (4), tail unit (5), engines (6), and the cockpit (8) are attached to the upper part.

The upper part of the fuselage is made in the form of a rigid sealed thermally insulated body with a casing (9). The cross section of the upper part depends on the shape of the lower part of the fuselage (3) and can be a curved triangle (10) with convex or concave sides (Fig. 3) or a curved “Relo triangle” with all convex sides (Fig. 4). The section shown in (Fig. 5) is outlined by two curves, the upper of which is convex, and the lower one with one convex (12) and two concave (13) sections. In all proposed variants, the cross section of the upper part (2) of the fuselage is outlined along the contour of a closed curve, the shape of which can be different, depending on the implementation of the lower part (3).

The lower part (3) of the fuselage is made in the form of one, two, or more than two (Fig. 6) rigid (s), geometric (s), thermally insulated (s) body (s) 14, equipped with a contour lining 15 Each passenger compartment contains a passenger compartment (16) with seats (17), airtight doors in the front (18) and rear (not shown) ends of the compartment, compartments (19) for emergency parachutes (20) (shown in open form in Fig. 7.) located above, under the casing (15) and luggage compartments (21). Compartments (19) for parachutes are equipped with automatically opening hatches (not shown).

In its lower part, the container is equipped with compartments with hinged hatches, made with the possibility of their automatic opening to release the cylinders, automatically inflated with gas according to the altimeter signal. The latter will be required in a situation where the plane is in distress over a pond and the capsule is forced to splash down, or to provide a soft landing on the ground. For the same purpose, in its lower outer part, the container is equipped with small-sized soft-landing rocket engines, and the inside of the capsule provides additional individual safety options - inflatable life jackets and automatic safety belts for fixing the body at the time of landing or splashdown.

On-board automation and measuring equipment of the container in combination with its own on-board computer create the ability to control the capsule's orientation in space, descent speed, distance to the surface of the earth or water.

After landing (splashdown) of the capsule, life support is taken over by the life support system of passengers and crew.

The relative volume of space for passenger seats and transported goods is determined by the purpose of the aircraft, i.e. whether it is passenger, cargo-passenger or cargo. So, for example, in the lower part of the cargo compartment only a few seats for crew members can be installed, which they can take in case of an emergency. The rest of the space can be allocated for transported goods.

The zones of mutual adjacency of the bottom of the upper part (2) and the top of the lower part (3) of the fuselage body repeat the shape of each other. Means (25) were installed along the abutment surfaces for their rigid connection with each other, made with the possibility of emergency, on command from the pilot's cabin or from the ground, to disconnect these parts. These tools can have a different principle of action (mechanical, hydraulic, explosive, etc.) and are widely known at present.

Emergency evacuation of the capsule is carried out through the cargo hatch (26) in the rear lower part (3) of the fuselage. The doors of the cockpit (8) as a part of the upper part (2) of the fuselage and the door (s) of the body (s) (14) in the lower part (3) are located on the same level.

In the cockpit there is a device that, in the event of an emergency, allows you to generate a certain sequence of electrical commands that activate the rescue program. Evacuation commands in the necessary sequence can be given: by a pilot, on-board computer or from the ground.

Depending on the current situation, the Tatarenko system provides several options for action.

1. The current situation excludes the possibility of saving the aircraft.

In this case, all crew members occupy the reserved places (17) for them in the capsule, having previously given the command to operate automatic means (25), which ensure separation of the lower part (3) from the upper (2) with the subsequent extension and opening of the parachutes 20 and extension and blowing pontoons at the required distance from the landing surface.

2. If the possibility of saving the upper part (2) remains.

Crew members (with the exception of the first pilot who remains in the cockpit) go into the capsule. Separating the capsule can help improve the situation. Depending on the height of the aircraft at the time of evacuation, the nature and severity of the accident, the pilot may have some time to take control of the situation. In the case of preliminary evacuation of passengers in the lower part (3), those measures to save the aircraft can be implemented that, if they are present on board, are not allowed due to the increased risk. If all the measures taken to rescue the airliner were unsuccessful, then the pilot still has the opportunity to eject and save his life.

As we mentioned above, according to the inventor, an effective means of collective rescue of passengers has not yet been proposed for today. So, for example, one of such solutions was a plane with a wing with reinforcing stiffening panels, equipped with an inflatable balloon (US 3481569). However, this option can only be used for ultralight aircraft. Another solution is an aircraft with an additional wing with a single-layer skin, which is released from the fuselage in an accident (US 2193029). This option is useless if it is necessary to save the main aircraft. The method of separating the fuselage fragments from the wings and the plumage by means of directed explosions leaves the danger of depressurization or destruction of the rescue capsule with people. At the same time, the cost of aircraft maintenance increases significantly, which is explained by the need to maintain the integrity of pyro-bolts and charges and their regular verification. Another unaccounted risk factor is the detonation of cumulative charges with lightning.

A description of some other alternative systems, their limitations and disadvantages, as well as the invention of V. N. Tatarenko, can be found in more detail in the publication in the journal of the Islamic Republic of Ingushetia (Inventor and Rationalizer) No. 1 for 2014 (p. 5-15) .

The limitation of the Tatarenko system, provided that it is installed on existing models of airliners, is the ability to install only on those models that have space for the hatch through which the capsule is evacuated in the tail section. Alas, the existing Boeing or Airbus models fall out of this list. A serious advantage is the ability to quickly upgrade an aircraft that is in linear operation from passenger to cargo.

If there is a valid patent for the invention, the time required for the implementation of the first stage of the project will be about 4 years, of which half of this period should be allocated for development and testing, and from one and a half to two years for certification in ICAO for airworthiness. Tatarenko sees the next stage in the development of the project in the creation of fundamentally new models of aircraft equipped with capsules for collective rescue of passengers initially. In this case, the issue of “critical mass” of the aircraft is resolved automatically, since it is proposed to use light and durable modern materials when creating it. At the same time, the development of a safe airplane project with a pre-installed Tatarenko capsule will require very serious investments.

The chances that the project is being implemented in Ukraine are minimal. Tatarenko has already applied to the Ministry of Transport, but they replied that there is no money for this project. This is despite the fact that the estimated cost of the first stage - capsules, which can be integrated into existing aircraft models - is about $ 1,000,000, which is about 1-2% of the base cost of the airliner ($ 110,000,000 in the case of the Airbus A-321 model - author's comment).

The publication used photos of Olga Zakrevskaya

“I spoke with the heads of departments of OKB im. Antonova, their hands itch to do it, they say: "... yes, we would have developed it in two years ...". They have enough qualifications, technical readiness, experience. But money is needed, and today they are not in the OKB, ”says the inventor. The carrier companies, with the administration of which V.N. Tatarenko managed to discuss the invention, do not see any commercial sense in it ... Equipping existing liners (according to carriers) will inevitably reduce a large number of seats and, as a result, reduce actual profit. In addition, operating costs associated with the inevitable increase in fuel consumption due to the weighting of the aircraft structure are also growing. And, unfortunately, this is the point of view that is currently dominant.

“I asked the first persons of such companies: well, let the ticket turn out to be 15-30% more expensive - on which plane do you prefer to send your family and fly yourself - on a regular one or on one that you can safely escape from? But they answered me that they now have no security problems, ”the aircraft designer rightly regrets. We add that another source of project payback may be a reduction in the number and volume of insurance payments.

Judging by the thousands of comments on Facebook, judging by the thousands of comments on Facebook, the potential passengers themselves, who for the most part support this modernization, adhere to it that inspires hope that their opinion will be heard in the very near future.

Dear readers, we are always happy to meet and wait for you on the iCover blog pages! We will try our best to make the time spent with us useful. And, of course, do not forget to subscribe to our columns .

Our other articles and events

Most likely, the minimum time difference between the release of the video and the crash of the plane south of the Egyptian city of El Arish at about 7 am on October 31 is just a coincidence. At the same time, this particular video, which gained almost 18.5 million views and more than 250,000 posts on November 10, 2015, clearly demonstrated the urgency of the collective safety problem for passengers on board the airliner.

In connection with the tragic events of the past days, we decided to devote our present material to the invention of V.N. Tatarenko, which, according to his author, if timely supported, would help minimize the number of victims of many flights over the past decade and a half.

Saving one person, you save the whole world. Confucius

Brief information: Vladimir Nikolaevich Tatarenko hails from near Krasnoyarsk. He graduated from the faculty of aircraft engineering at ISTU and then worked for some time in Irkutsk. By distribution, he got to the Kiev Aviation Plant, where for some time he worked as the head of a mechanical assembly shop, and after that as a leading engineer at the Research Institute of Aviation Technologies. He wrote a doctoral dissertation at the KPI. In total, Tatarenko has more than 100 patents and several books on aircraft construction. He participated in the creation of the heavy-load liner AN-225 “MRIYA” for which he was presented to the State Prize of the Ukrainian SSR in the field of science and technology.

The number of victims of car accidents, compared with the number of tragedies in the sky, is much larger. At the same time, the current level of search for ways and solutions to urgent problems of the safety of air passengers today remains extremely unsatisfactory.

A long-term study of existing rescue systems led the author of the invention to the disappointing conclusion: "... There are no truly effective systems for today. While the main emphasis is on improving the reliability of aircraft structures and duplicating their systems, people still remain in case of an accident on the plane and burn with it. On the other hand, most of the proposed systems for saving passengers require the destruction of the fuselage, the separation of the wings, etc. ... until the capsule is separated, which negates any th likelihood of restoration and future use of the aircraft. "

The only effective solution in such a situation here could be the complete removal of passengers and crew from the aircraft, Tatarenko said.

The principle of the Tatarenko system

According to the inventor, the idea of creating an effective system of collective rescue of passengers excited the inventors in the first decades of the last century. The patent for one of such systems, “A device for rescuing passengers in an airplane accident”, was obtained back in 1923 by the Russian inventor of an airborne parachute parachute, Gleb Evgenievich Kotelnikov, but there were no technical capabilities to implement the project in those years.

An application for a patent under the number UA52936U “Aircraft with a device for rescuing passengers in an emergency” V. Tatarenko filed another October 9, 2010.

The system implemented by Tatarenko in the UA52936U patent, according to him, is based on time-tested reliable technical solutions. It makes it possible to evacuate all passengers and crew from an airplane in distress in the altitude range from several tens of meters to several kilometers, smooth descent and soft landing (splashdown) of the capsule, and ensuring the life of people up to the moment of detection by rescuers.

The capsule is attached to the fuselage via detachable automatic mounts. At the same time, all electrical, piping, kinematic and other connections at the separation sites are made self-disconnecting - using automatic couplings, electrical connectors, spool and other valves.

The descent of the capsule is ensured by the aerodynamic interaction of the parachutes with the incoming air flow under the influence of the capsule's own mass. The ability of the system to withdraw small and large parachute systems within 2-3 seconds and to ensure the evacuation of the capsule and its active self-braking, according to the aircraft designer, allows you to use the capabilities of the method at low altitudes - during takeoff and landing.

In a carbon fiber capsule, there are rows of seats for passengers and chairs for crew members, who, according to Tatarenko's plan, leaves the plane at the same time as passengers.

The Tatarenko project is an attempt to bring a fundamentally new aircraft to the market, taking into account strict technical, legal and commercial restrictions. In this case, in the case of the manufacture of the fuselage, wings and capsules of carbon fiber and modern high-strength materials, it becomes possible to maintain the total mass of the aircraft at the level of the mass of the basic configuration.

Aircraft design diagram: fuselage - 1, consisting of two upper (2) and lower (3) parts interconnected. The wings (4), tail unit (5), engines (6), and the cockpit (8) are attached to the upper part.

The upper part of the fuselage is made in the form of a rigid sealed thermally insulated body with a casing (9). The cross section of the upper part depends on the shape of the lower part of the fuselage (3) and can be a curved triangle (10) with convex or concave sides (Fig. 3) or a curved “Relo triangle” with all convex sides (Fig. 4). The section shown in (Fig. 5) is outlined by two curves, the upper of which is convex, and the lower one with one convex (12) and two concave (13) sections. In all proposed variants, the cross section of the upper part (2) of the fuselage is outlined along the contour of a closed curve, the shape of which can be different, depending on the implementation of the lower part (3).

The lower part (3) of the fuselage is made in the form of one, two, or more than two (Fig. 6) rigid (s), geometric (s), thermally insulated (s) body (s) 14, equipped with a contour lining 15 Each passenger compartment contains a passenger compartment (16) with seats (17), airtight doors in the front (18) and rear (not shown) ends of the compartment, compartments (19) for emergency parachutes (20) (shown in open form in Fig. 7.) located above, under the casing (15) and luggage compartments (21). Compartments (19) for parachutes are equipped with automatically opening hatches (not shown).

In its lower part, the container is equipped with compartments with hinged hatches, made with the possibility of their automatic opening to release the cylinders, automatically inflated with gas according to the altimeter signal. The latter will be required in a situation where the plane is in distress over a pond and the capsule is forced to splash down, or to provide a soft landing on the ground. For the same purpose, in its lower outer part, the container is equipped with small-sized soft-landing rocket engines, and the inside of the capsule provides additional individual safety options - inflatable life jackets and automatic safety belts for fixing the body at the time of landing or splashdown.

On-board automation and measuring equipment of the container in combination with its own on-board computer create the ability to control the capsule's orientation in space, descent speed, distance to the surface of the earth or water.

After landing (splashdown) of the capsule, life support is taken over by the life support system of passengers and crew.

The relative volume of space for passenger seats and transported goods is determined by the purpose of the aircraft, i.e. whether it is passenger, cargo-passenger or cargo. So, for example, in the lower part of the cargo compartment only a few seats for crew members can be installed, which they can take in case of an emergency. The rest of the space can be allocated for transported goods.

The zones of mutual adjacency of the bottom of the upper part (2) and the top of the lower part (3) of the fuselage body repeat the shape of each other. Means (25) were installed along the abutment surfaces for their rigid connection with each other, made with the possibility of emergency, on command from the pilot's cabin or from the ground, to disconnect these parts. These tools can have a different principle of action (mechanical, hydraulic, explosive, etc.) and are widely known at present.

Emergency evacuation of the capsule is carried out through the cargo hatch (26) in the rear lower part (3) of the fuselage. The doors of the cockpit (8) as a part of the upper part (2) of the fuselage and the door (s) of the body (s) (14) in the lower part (3) are located on the same level.

In the cockpit there is a device that, in the event of an emergency, allows you to generate a certain sequence of electrical commands that activate the rescue program. Evacuation commands in the necessary sequence can be given: by a pilot, on-board computer or from the ground.

Probable emergency scenarios

Depending on the current situation, the Tatarenko system provides several options for action.

1. The current situation excludes the possibility of saving the aircraft.

In this case, all crew members occupy the reserved places (17) for them in the capsule, having previously given the command to operate automatic means (25), which ensure separation of the lower part (3) from the upper (2) with the subsequent extension and opening of the parachutes 20 and extension and blowing pontoons at the required distance from the landing surface.

2. If the possibility of saving the upper part (2) remains.

Crew members (with the exception of the first pilot who remains in the cockpit) go into the capsule. Separating the capsule can help improve the situation. Depending on the height of the aircraft at the time of evacuation, the nature and severity of the accident, the pilot may have some time to take control of the situation. In the case of preliminary evacuation of passengers in the lower part (3), those measures to save the aircraft can be implemented that, if they are present on board, are not allowed due to the increased risk. If all the measures taken to rescue the airliner were unsuccessful, then the pilot still has the opportunity to eject and save his life.

Alternative solutions

As we mentioned above, according to the inventor, an effective means of collective rescue of passengers has not yet been proposed for today. So, for example, one of such solutions was a plane with a wing with reinforcing stiffening panels, equipped with an inflatable balloon (US 3481569). However, this option can only be used for ultralight aircraft. Another solution is an aircraft with an additional wing with a single-layer skin, which is released from the fuselage in an accident (US 2193029). This option is useless if it is necessary to save the main aircraft. The method of separating the fuselage fragments from the wings and the plumage by means of directed explosions leaves the danger of depressurization or destruction of the rescue capsule with people. At the same time, the cost of aircraft maintenance increases significantly, which is explained by the need to maintain the integrity of pyro-bolts and charges and their regular verification. Another unaccounted risk factor is the detonation of cumulative charges with lightning.

A description of some other alternative systems, their limitations and disadvantages, as well as the invention of V. N. Tatarenko, can be found in more detail in the publication in the journal of the Islamic Republic of Ingushetia (Inventor and Rationalizer) No. 1 for 2014 (p. 5-15) .

The limitation of the Tatarenko system, provided that it is installed on existing models of airliners, is the ability to install only on those models that have space for the hatch through which the capsule is evacuated in the tail section. Alas, the existing Boeing or Airbus models fall out of this list. A serious advantage is the ability to quickly upgrade an aircraft that is in linear operation from passenger to cargo.

Issue price

If there is a valid patent for the invention, the time required for the implementation of the first stage of the project will be about 4 years, of which half of this period should be allocated for development and testing, and from one and a half to two years for certification in ICAO for airworthiness. Tatarenko sees the next stage in the development of the project in the creation of fundamentally new models of aircraft equipped with capsules for collective rescue of passengers initially. In this case, the issue of “critical mass” of the aircraft is resolved automatically, since it is proposed to use light and durable modern materials when creating it. At the same time, the development of a safe airplane project with a pre-installed Tatarenko capsule will require very serious investments.

The chances that the project is being implemented in Ukraine are minimal. Tatarenko has already applied to the Ministry of Transport, but they replied that there is no money for this project. This is despite the fact that the estimated cost of the first stage - capsules, which can be integrated into existing aircraft models - is about $ 1,000,000, which is about 1-2% of the base cost of the airliner ($ 110,000,000 in the case of the Airbus A-321 model - author's comment).

The publication used photos of Olga Zakrevskaya

“I spoke with the heads of departments of OKB im. Antonova, their hands itch to do it, they say: "... yes, we would have developed it in two years ...". They have enough qualifications, technical readiness, experience. But money is needed, and today they are not in the OKB, ”says the inventor. The carrier companies, with the administration of which V.N. Tatarenko managed to discuss the invention, do not see any commercial sense in it ... Equipping existing liners (according to carriers) will inevitably reduce a large number of seats and, as a result, reduce actual profit. In addition, operating costs associated with the inevitable increase in fuel consumption due to the weighting of the aircraft structure are also growing. And, unfortunately, this is the point of view that is currently dominant.

“I asked the first persons of such companies: well, let the ticket turn out to be 15-30% more expensive - on which plane do you prefer to send your family and fly yourself - on a regular one or on one that you can safely escape from? But they answered me that they now have no security problems, ”the aircraft designer rightly regrets. We add that another source of project payback may be a reduction in the number and volume of insurance payments.

Judging by the thousands of comments on Facebook, judging by the thousands of comments on Facebook, the potential passengers themselves, who for the most part support this modernization, adhere to it that inspires hope that their opinion will be heard in the very near future.

Dear readers, we are always happy to meet and wait for you on the iCover blog pages! We will try our best to make the time spent with us useful. And, of course, do not forget to subscribe to our columns .

Our other articles and events