What is a HEPA filter: operating principles and unobvious facts

Welcome to the blog of the company Tion Smart microclimate . The topic of the article is HEPA filters.

These are highly efficient filters, the main purpose of which is to remove fine particles from the air, including PM2.5 and PM10 (with a diameter of less than 2.5 and 10 microns, respectively). HEPA is not a brand or a brand, but a class of filters, which is determined by international and national standards EN 1822-1: 2009 and GOST R EN 1822-1-2010.

Let's look at the HEPA filter "from an arm's length", tell you about the principle of its operation and the main effects due to which particles are deposited on the filter.

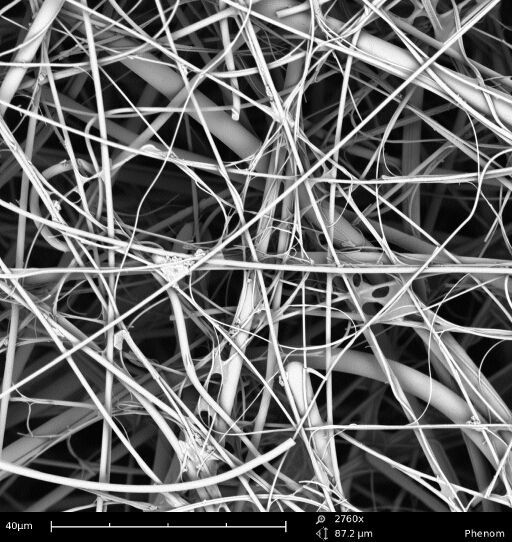

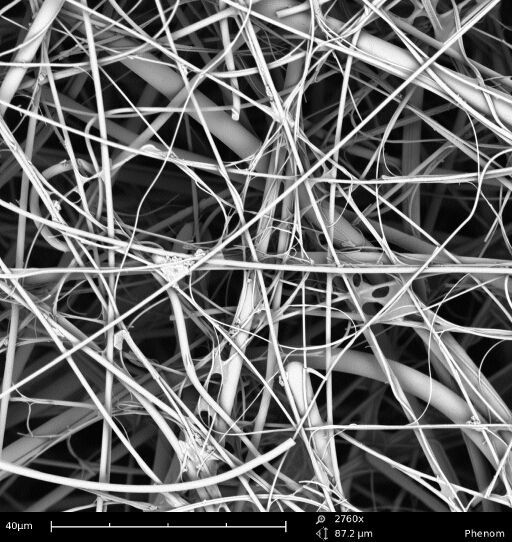

The basis of any HEPA filter is randomly located fibers of different thicknesses, approximately 0.5-5 microns. The distance between the fibers is about 5-50 microns. The diameter of the fine particles is within a few microns or even several fractions of a micron. The question arises: how does a filter with such large pores trap such small particles?

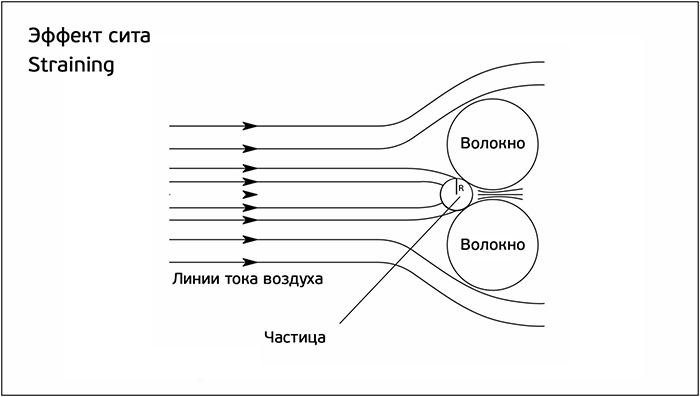

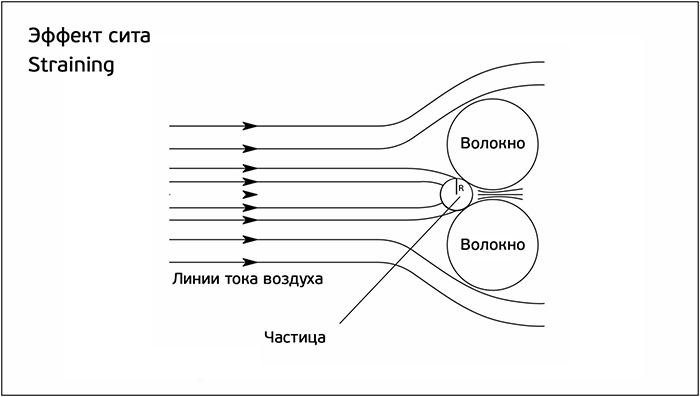

Usually we imagine a filter in the form of a fishing net or net: if the filtered object is larger than the cell, it gets stuck. This mechanism is called the straining effect. It works for particles whose diameter exceeds the pore size in the filter. On a simplified model, the sieve effect looks like this:

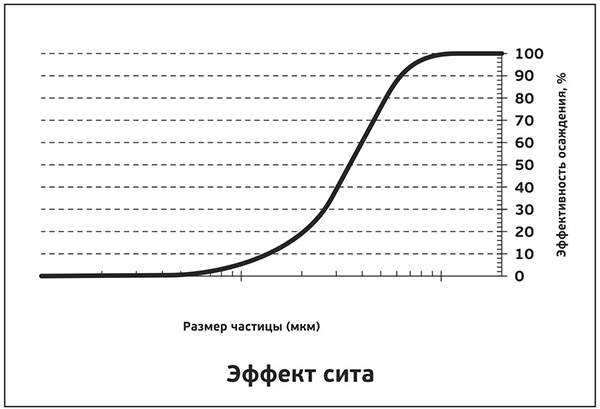

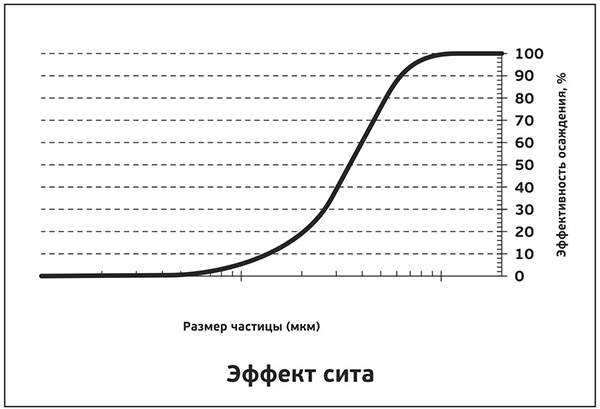

The filter fibers are presented in the form of cylinders located across the air stream. The flow itself is considered irrotational. The particle model is a ball with a radius R. If 2R is greater than the distance between the fibers, the particle gets stuck in the filter. The larger the particle, the more likely it is to get stuck in the fibers. Therefore, for large particles, the sieve effect works better:

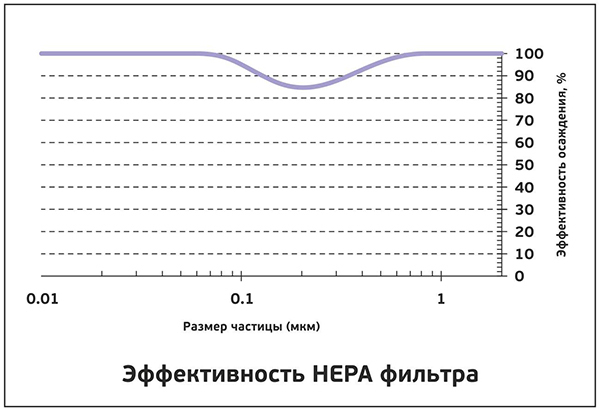

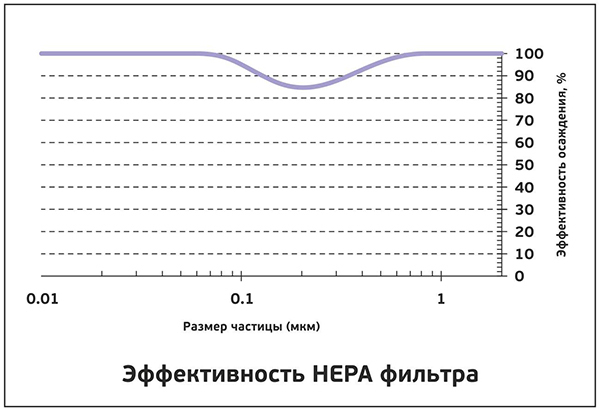

There is no reference to specific sizes on the graph, since filters with different fiber thicknesses and different packing densities will delay different fractions of particles. The shape of the curve will be about the same, but it can “float” on a horizontal scale. For example, for a class G coarse filter, the curve will be located to the right than for a class F fine filter. In the HEPA filters, a sieve effect is also observed. And if HEPA worked only on this mechanism, then the curve of its effectiveness would look approximately the same. However, in reality it looks very different:

The graph shows that the HEPA filter delays particles of any size. And if effective filtering of large particles (about 5 microns and more) occurs by the sieve mechanism, then the filtration of fine fractions (of the order of 1-0.01 microns) has a different nature.

The main difference between HEPA and coarse and fine filters is that the particle does not need to get stuck in the fibers to filter. If the speck of dust just touched the filter material, this is already sufficient for effective deposition. This is due to two processes: adhesion and autohesion.

Adhesion is the interaction of dust with a settling surface, in our case, with HEPA fibers. Due to adhesion, a first layer of dust appears on clean fibers.

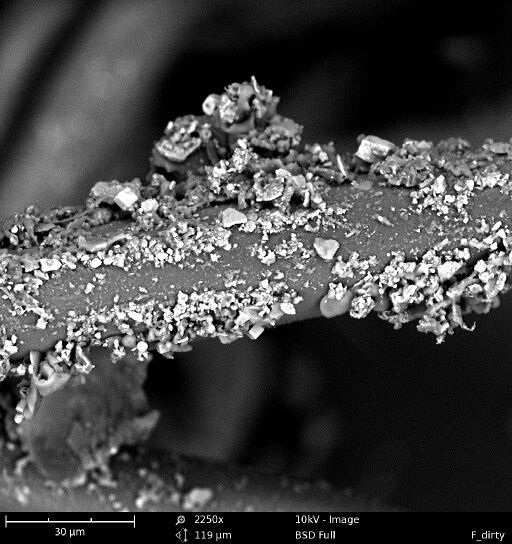

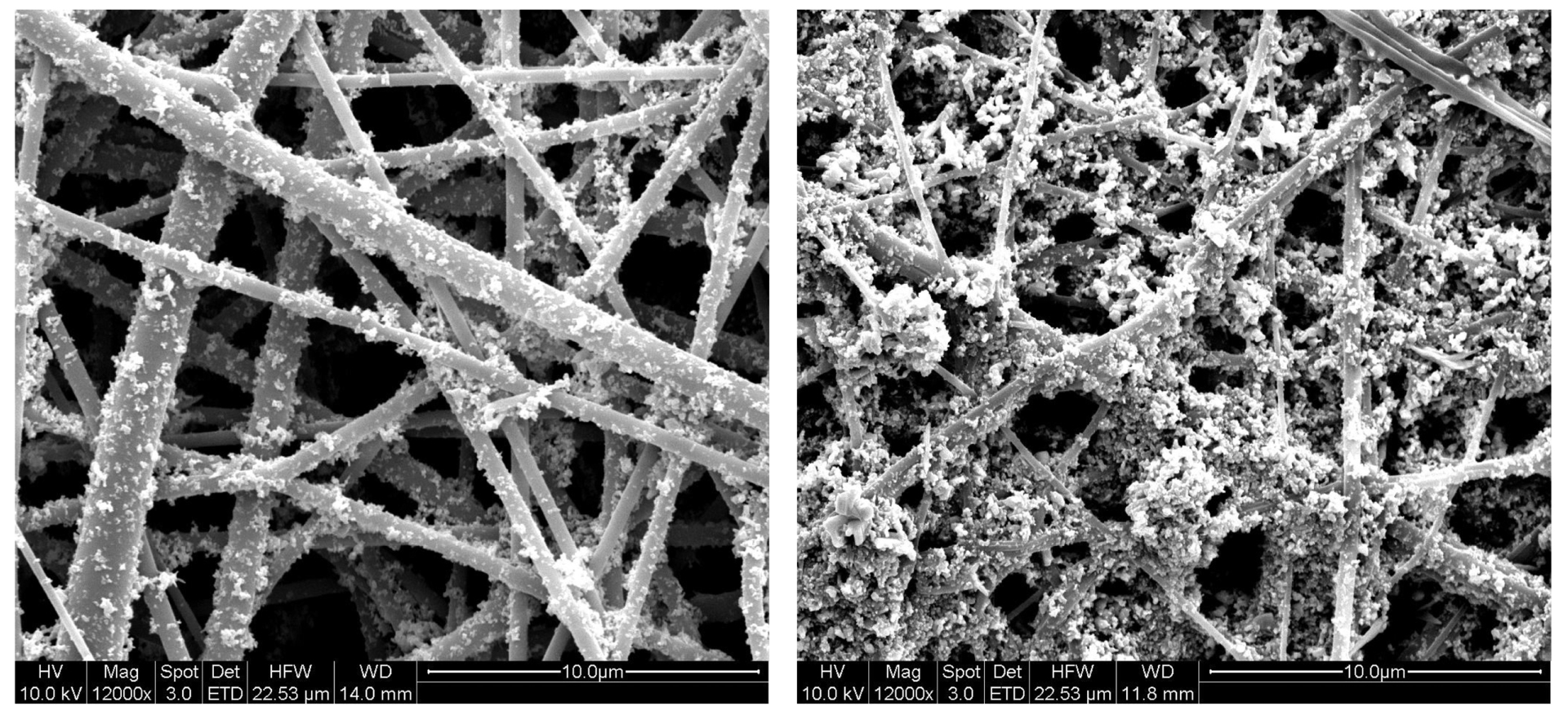

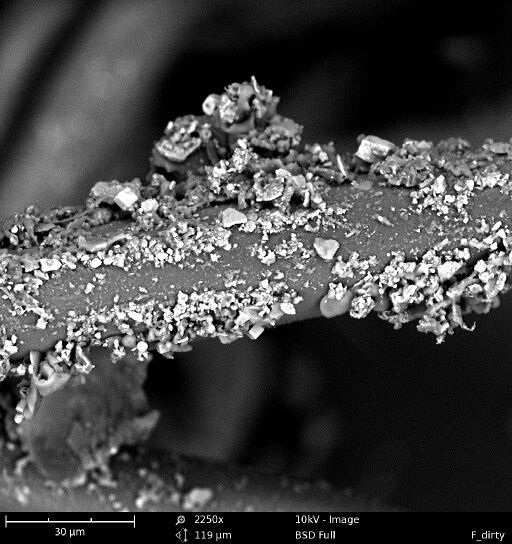

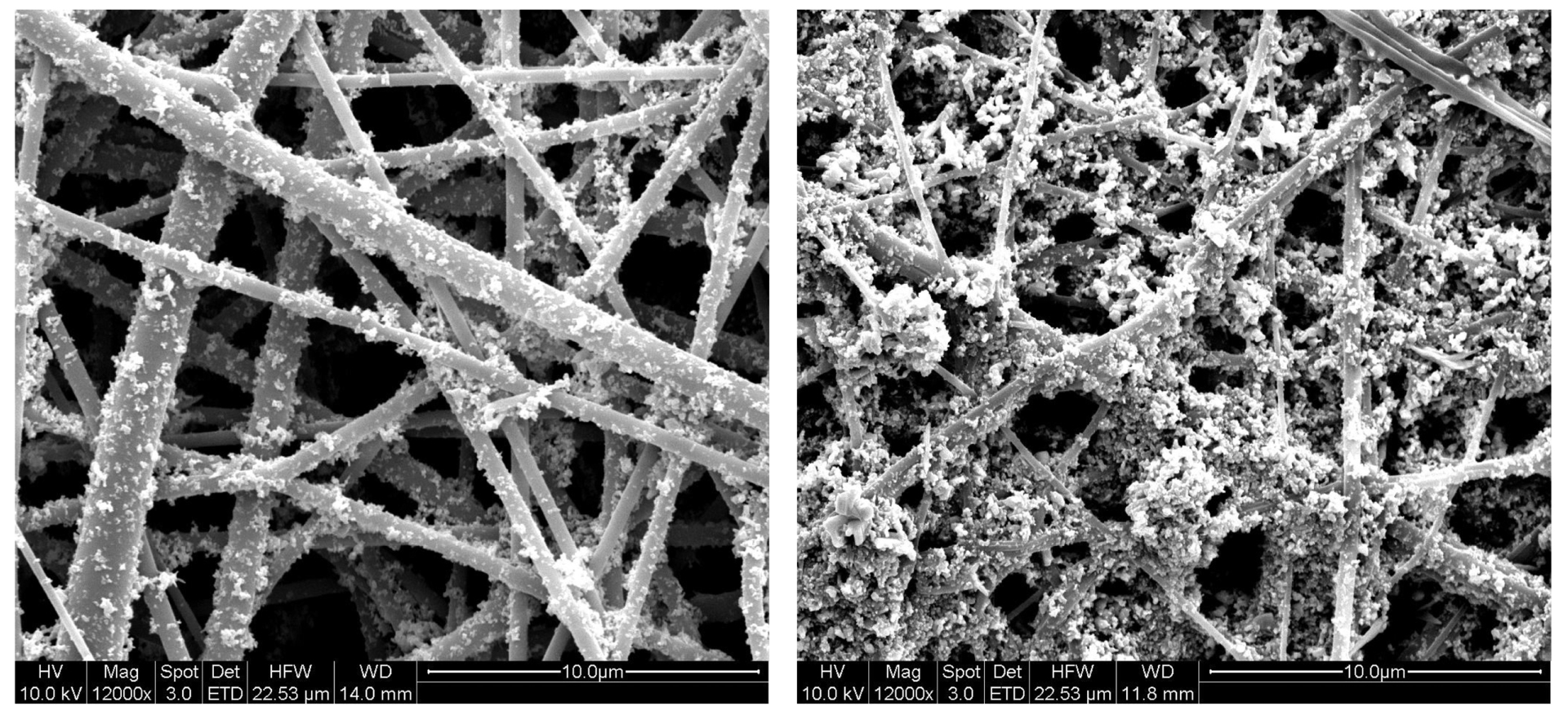

Autohesion, or stickiness, is the interaction of dust particles with each other. Due to the autogenous interaction, the particles continue to overlap each other, forming multilayer conglomerates on the fibers. They look like this:

The nature of adhesion and autohesion is in the molecular interaction of particles with each other and with fibers (Van der Waals forces). These forces appear at a distance of one to several hundred particle diameters. For the smallest particles, the attraction to the fiber and the dust layer is so great that the particles settle in the HEPA filter almost forever . The numbers confirm this: for particles less than 10 microns, the tensile strength of the dust layer is more than 600 Pa.

So, due to the attractive forces, the particle sticks to the HEPA filter fiber almost tightly, just touch its surface. This explains the retention of particles on the filter, but there is still no answer to the question:

As we found out, the sieve effect has nothing to do with it - the smallest particles fly freely through the pores. Other mechanisms operate in HEPA filters.

Any particle is held in the air stream, and if there are no forces in the filter that deflect the particle from the air flow line towards the fiber, then there will be no deposition. As a result, the particle will slip through the filter along with the flow. Therefore, the question “How do particles touch the fiber?” Can be rephrased: “How do particles leave the air stream?” And the answer to it will be different, depending on the size and mass of the particle.

The smallest particles (with a diameter of less than 0.1 microns) have a small mass and are constantly in chaotic Brownian motion. Their trajectory constantly fluctuates relative to the air flow line. During oscillations, the particle exits the stream, touches the fiber and settles. This is the effect of diffusion :

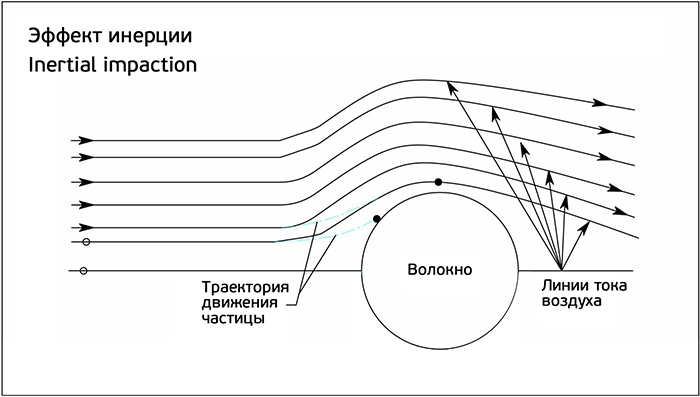

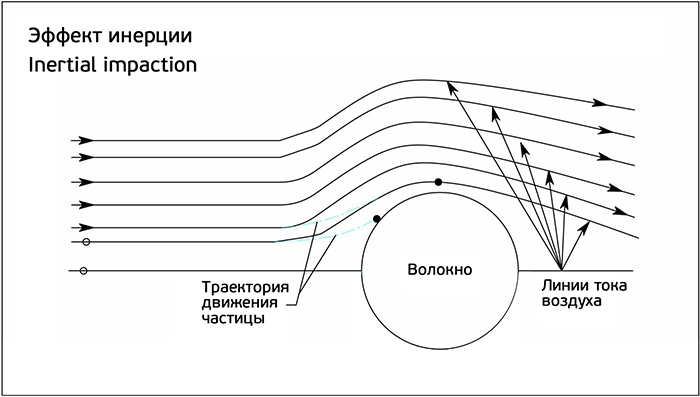

Larger particles (with a diameter greater than 0.3 microns) weigh more, so their oscillations relative to the streamline are less or absent altogether. Such particles are deposited by a different mechanism. The model shows that the air flow lines are bent near the fiber, enveloping the obstacle. Large and heavy particles due to inertia exit the air stream, collide with the fiber and settle. This is the effect of inertia :

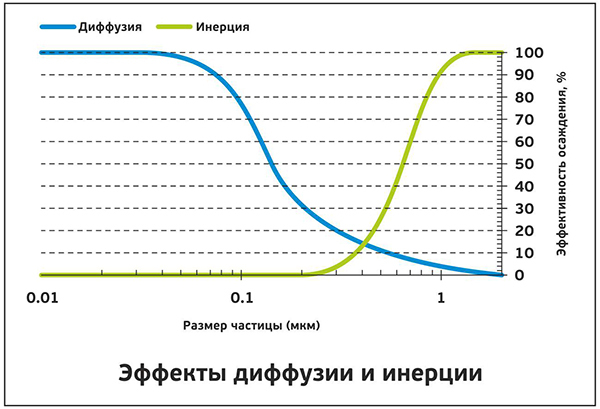

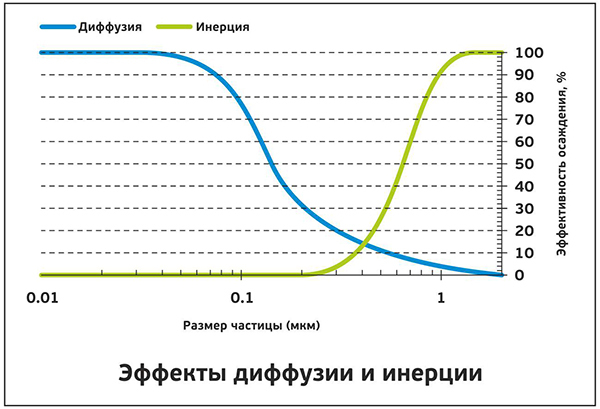

Diffusion and inertial effects complement each other: one is responsible for filtering the smallest particles, the other for larger ones:

It is most difficult to plant particles with an “intermediate” size on the fiber. Their inertia is still not large enough, and diffusion is already working weakly, since the fluctuations of their trajectory relative to the streamline are no longer so strong. Therefore, such particles are more likely to remain in the stream and bend the fibers along with the air. They are called particles with maximum penetration, Most Penetrating Particle Size (MPPS). And for their deposition, the last mechanism is of greatest importance - the engagement effect :

The meshing effect works when the particle approaches the surface of the fiber at a distance of its radius. Such a touch is enough to precipitate it. This mechanism works not only for MPPS. It is universal and works for particles of any size. Dust particles can remain in the air stream, make diffusion oscillations relative to the streamline, or fly out of the stream due to inertia - in any case, if the particle touches the fiber, it settles.

The effectiveness of this mechanism depends on the particle size. The larger the particle, the more likely it will touch the fiber. In this, the engagement effect is similar to the sieve effect, therefore the graph is almost the same (of course, with reference to a different range of particles):

In fact, in the HEPA filter, all mechanisms act simultaneously on the particle, therefore, the total efficiency of the HEPA filter is equal to the sum of the contributions of each effect:

η total = η sieves + η engagement + η inertia + η diffusion

If HEPA is constantly sprayed with aerosol with large particles, the filter life is significantly reduced. This is due to the effect of the sieve: large particles quickly clog the filter and reduce its permeability. To avoid the effect of a sieve, one or more lower-grade prefilters are installed in front of the HEPA filter: G and / or F. They protect the HEPA from premature clogging. If the prefilters are installed, then HEPA works strictly "in the specialty" - filtering fine particles. Thus, three effects remain:

η total = η engagement + η inertia + η diffusion

If we add up all three efficiency graphs for each mechanism, we get the very curve of the overall HEPA filter efficiency that we showed at the beginning of the article:

As we see in the MPPS range (from about 0.1 to 0.3 μm), the overall efficiency of the HEPA filter "Falls into the pit." And it is MPPS that measures overall performance. A HEPA filter of class H10 (according to the new E10 nomenclature) works with an efficiency of more than 85%, and a filter of class H11 (E11) - more than 95%. This means that 95 of 100 MPPS particles are deposited in the E11 HEPA filter. In this case, the remaining particles are deposited with a probability of almost 100%, but the final efficiency is usually indicated by MPPS, 95%.

The effectiveness of HEPA depends not only on the size of the filtered particles, but also on the parameters of the filter itself:

The thinner the fibers and the denser they are packed, the larger the area of their contact with the particles. And the better the fibers “catch”, the more effective the deposition. If the material from which the filter is made has a high conductivity, then the fibers can be charged in the air stream. In this case, between the fibers and particles, electrostatic attraction forces (Coulomb forces) arise. They further increase the efficiency of the HEPA filter. We will not consider this effect in more detail here; we will talk about electrostatic deposition in another article.

When particles are deposited, the distance between the fibers decreases:

As a result, the fiber area increases, and a paradoxical fact is associated with this: over time, the effectiveness of HEPA does not decrease, but increases. On the other hand, with pollution, the filter permeability decreases, its resistance increases, the pressure drop across the filter increases, and, as a result, the performance of the device in which it is installed decreases. If the filter is completely clogged and the device performance drops to almost zero, the only way out is to replace the filter. The frequency of replacement depends on the filter capacity. This indicator determines how much dust HEPA can precipitate before the pressure drop across it becomes critical.

Now that we have an idea of the HEPA filter, let’s collect the points of how it works:

We will also collect in one place all the unobvious facts about the HEPA filter:

That's all for now: we talked about the principles of precipitation and retention of fine dust in HEPA filters. If you have any questions, we will be happy to answer them in the comments.

See also:

Hunting for stuffy air: how much CO2 in Moscow?

Microclimate against influenza: how to kill the virus with ventilation and a humidifier

Photos of HEPA filters are taken from here and from here .

These are highly efficient filters, the main purpose of which is to remove fine particles from the air, including PM2.5 and PM10 (with a diameter of less than 2.5 and 10 microns, respectively). HEPA is not a brand or a brand, but a class of filters, which is determined by international and national standards EN 1822-1: 2009 and GOST R EN 1822-1-2010.

Let's look at the HEPA filter "from an arm's length", tell you about the principle of its operation and the main effects due to which particles are deposited on the filter.

The basis of any HEPA filter is randomly located fibers of different thicknesses, approximately 0.5-5 microns. The distance between the fibers is about 5-50 microns. The diameter of the fine particles is within a few microns or even several fractions of a micron. The question arises: how does a filter with such large pores trap such small particles?

Usually we imagine a filter in the form of a fishing net or net: if the filtered object is larger than the cell, it gets stuck. This mechanism is called the straining effect. It works for particles whose diameter exceeds the pore size in the filter. On a simplified model, the sieve effect looks like this:

The filter fibers are presented in the form of cylinders located across the air stream. The flow itself is considered irrotational. The particle model is a ball with a radius R. If 2R is greater than the distance between the fibers, the particle gets stuck in the filter. The larger the particle, the more likely it is to get stuck in the fibers. Therefore, for large particles, the sieve effect works better:

There is no reference to specific sizes on the graph, since filters with different fiber thicknesses and different packing densities will delay different fractions of particles. The shape of the curve will be about the same, but it can “float” on a horizontal scale. For example, for a class G coarse filter, the curve will be located to the right than for a class F fine filter. In the HEPA filters, a sieve effect is also observed. And if HEPA worked only on this mechanism, then the curve of its effectiveness would look approximately the same. However, in reality it looks very different:

The graph shows that the HEPA filter delays particles of any size. And if effective filtering of large particles (about 5 microns and more) occurs by the sieve mechanism, then the filtration of fine fractions (of the order of 1-0.01 microns) has a different nature.

How does the HEPA filter “catch” fine dust?

The main difference between HEPA and coarse and fine filters is that the particle does not need to get stuck in the fibers to filter. If the speck of dust just touched the filter material, this is already sufficient for effective deposition. This is due to two processes: adhesion and autohesion.

Adhesion is the interaction of dust with a settling surface, in our case, with HEPA fibers. Due to adhesion, a first layer of dust appears on clean fibers.

Autohesion, or stickiness, is the interaction of dust particles with each other. Due to the autogenous interaction, the particles continue to overlap each other, forming multilayer conglomerates on the fibers. They look like this:

The nature of adhesion and autohesion is in the molecular interaction of particles with each other and with fibers (Van der Waals forces). These forces appear at a distance of one to several hundred particle diameters. For the smallest particles, the attraction to the fiber and the dust layer is so great that the particles settle in the HEPA filter almost forever . The numbers confirm this: for particles less than 10 microns, the tensile strength of the dust layer is more than 600 Pa.

So, due to the attractive forces, the particle sticks to the HEPA filter fiber almost tightly, just touch its surface. This explains the retention of particles on the filter, but there is still no answer to the question:

How do the smallest particles touch the fiber of the HEPA filter?

As we found out, the sieve effect has nothing to do with it - the smallest particles fly freely through the pores. Other mechanisms operate in HEPA filters.

Any particle is held in the air stream, and if there are no forces in the filter that deflect the particle from the air flow line towards the fiber, then there will be no deposition. As a result, the particle will slip through the filter along with the flow. Therefore, the question “How do particles touch the fiber?” Can be rephrased: “How do particles leave the air stream?” And the answer to it will be different, depending on the size and mass of the particle.

The smallest particles (with a diameter of less than 0.1 microns) have a small mass and are constantly in chaotic Brownian motion. Their trajectory constantly fluctuates relative to the air flow line. During oscillations, the particle exits the stream, touches the fiber and settles. This is the effect of diffusion :

Larger particles (with a diameter greater than 0.3 microns) weigh more, so their oscillations relative to the streamline are less or absent altogether. Such particles are deposited by a different mechanism. The model shows that the air flow lines are bent near the fiber, enveloping the obstacle. Large and heavy particles due to inertia exit the air stream, collide with the fiber and settle. This is the effect of inertia :

Diffusion and inertial effects complement each other: one is responsible for filtering the smallest particles, the other for larger ones:

It is most difficult to plant particles with an “intermediate” size on the fiber. Their inertia is still not large enough, and diffusion is already working weakly, since the fluctuations of their trajectory relative to the streamline are no longer so strong. Therefore, such particles are more likely to remain in the stream and bend the fibers along with the air. They are called particles with maximum penetration, Most Penetrating Particle Size (MPPS). And for their deposition, the last mechanism is of greatest importance - the engagement effect :

The meshing effect works when the particle approaches the surface of the fiber at a distance of its radius. Such a touch is enough to precipitate it. This mechanism works not only for MPPS. It is universal and works for particles of any size. Dust particles can remain in the air stream, make diffusion oscillations relative to the streamline, or fly out of the stream due to inertia - in any case, if the particle touches the fiber, it settles.

The effectiveness of this mechanism depends on the particle size. The larger the particle, the more likely it will touch the fiber. In this, the engagement effect is similar to the sieve effect, therefore the graph is almost the same (of course, with reference to a different range of particles):

In fact, in the HEPA filter, all mechanisms act simultaneously on the particle, therefore, the total efficiency of the HEPA filter is equal to the sum of the contributions of each effect:

η total = η sieves + η engagement + η inertia + η diffusion

If HEPA is constantly sprayed with aerosol with large particles, the filter life is significantly reduced. This is due to the effect of the sieve: large particles quickly clog the filter and reduce its permeability. To avoid the effect of a sieve, one or more lower-grade prefilters are installed in front of the HEPA filter: G and / or F. They protect the HEPA from premature clogging. If the prefilters are installed, then HEPA works strictly "in the specialty" - filtering fine particles. Thus, three effects remain:

η total = η engagement + η inertia + η diffusion

If we add up all three efficiency graphs for each mechanism, we get the very curve of the overall HEPA filter efficiency that we showed at the beginning of the article:

As we see in the MPPS range (from about 0.1 to 0.3 μm), the overall efficiency of the HEPA filter "Falls into the pit." And it is MPPS that measures overall performance. A HEPA filter of class H10 (according to the new E10 nomenclature) works with an efficiency of more than 85%, and a filter of class H11 (E11) - more than 95%. This means that 95 of 100 MPPS particles are deposited in the E11 HEPA filter. In this case, the remaining particles are deposited with a probability of almost 100%, but the final efficiency is usually indicated by MPPS, 95%.

What determines the effectiveness of the HEPA filter?

The effectiveness of HEPA depends not only on the size of the filtered particles, but also on the parameters of the filter itself:

- The diameter of the fibers in the HEPA filter

- Fiber packing density

- Fiber material

The thinner the fibers and the denser they are packed, the larger the area of their contact with the particles. And the better the fibers “catch”, the more effective the deposition. If the material from which the filter is made has a high conductivity, then the fibers can be charged in the air stream. In this case, between the fibers and particles, electrostatic attraction forces (Coulomb forces) arise. They further increase the efficiency of the HEPA filter. We will not consider this effect in more detail here; we will talk about electrostatic deposition in another article.

When particles are deposited, the distance between the fibers decreases:

As a result, the fiber area increases, and a paradoxical fact is associated with this: over time, the effectiveness of HEPA does not decrease, but increases. On the other hand, with pollution, the filter permeability decreases, its resistance increases, the pressure drop across the filter increases, and, as a result, the performance of the device in which it is installed decreases. If the filter is completely clogged and the device performance drops to almost zero, the only way out is to replace the filter. The frequency of replacement depends on the filter capacity. This indicator determines how much dust HEPA can precipitate before the pressure drop across it becomes critical.

Now that we have an idea of the HEPA filter, let’s collect the points of how it works:

- The air stream with dust particles of different sizes, from 10 microns and less, enters the filter

- Large particles leave the air stream due to the inertia effect, small particles due to the diffusion effect

- All particles that come out of the stream and touch the fiber settle on the filter

- Particles are firmly held on the fiber due to attractive forces (van der Waals)

We will also collect in one place all the unobvious facts about the HEPA filter:

- HEPA filter can trap particles of all sizes

- Dust lingers in the HEPA filter almost forever. Vacuuming HEPA is useless - just change it.

- Over time, the efficiency of the HEPA filter only grows.

That's all for now: we talked about the principles of precipitation and retention of fine dust in HEPA filters. If you have any questions, we will be happy to answer them in the comments.

See also:

Hunting for stuffy air: how much CO2 in Moscow?

Microclimate against influenza: how to kill the virus with ventilation and a humidifier

Photos of HEPA filters are taken from here and from here .