The use of 3D printing in cranioplasty

Hi Geektimes! I want to share my experience in using 3D modeling and printing in medicine, and more specifically in cranioplasty - plastic skull defects. Neurosurgeons from the regional hospital had the task of manufacturing a cranial implant for a patient with an extensive post-traumatic defect in the bones of the skull.

Typically, in such cases, a titanium implant is placed (which was expensive in our case), or a titanium mesh plate, or an implant is created from a biocompatible material. In this case, the surface of the defect was large enough, which limited the use of a titanium mesh (doctors had only standard-size and curvature meshes at the disposal of the doctors, and the trepanation defect significantly exceeded the standard-size meshes and had complex curvature with a transition to the base of the skull, so it could not even be closed two grids).

There was no full-time sculptor in the hospital staff, so it was not possible to sculpt an anatomically accurate model of the missing skull bone during the operation (as is usually done). Therefore, it was decided to manufacture a protacryl implant using a mold. The task was reduced to the manufacture of this very form.

The general procedure is as follows:

The patient underwent computed tomography of the head, which resulted in a set of images (sections) of the head over a certain distance (in our case, 1.25 mm).

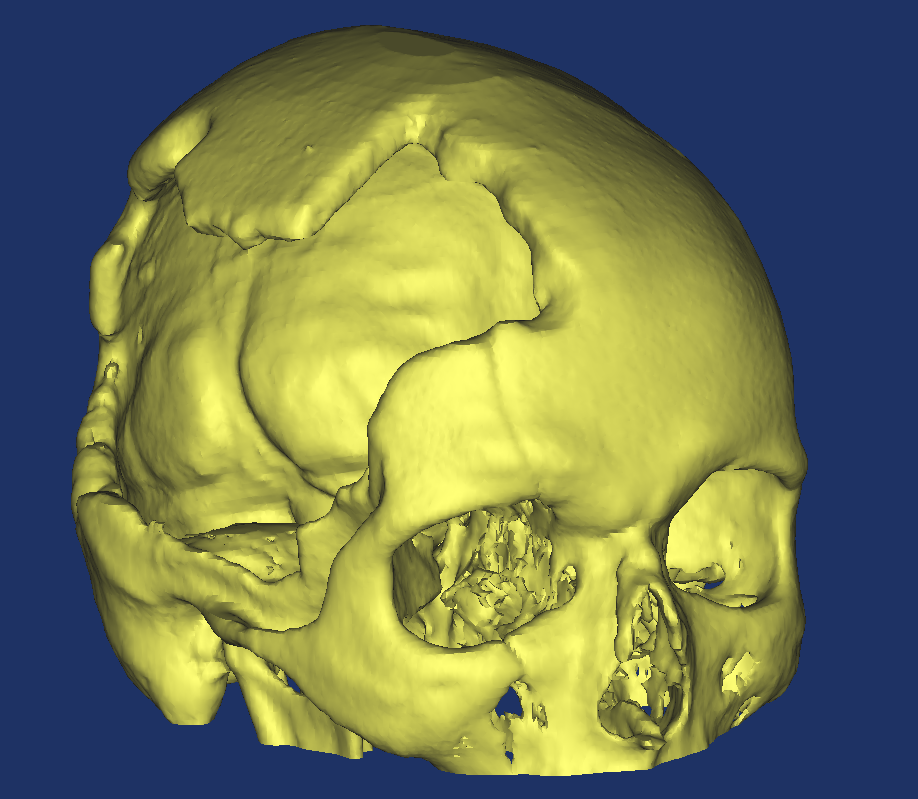

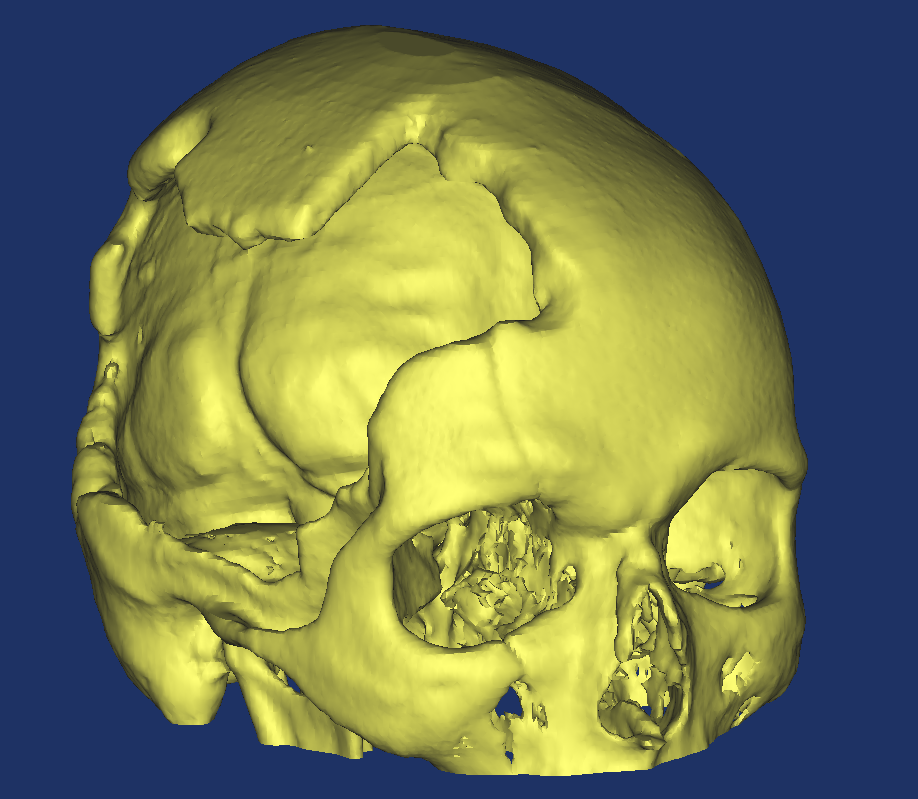

Based on this information, a three-dimensional model of skull bones was created. To do this, it is necessary to indicate to the program the sections of what density on the image will be used to build the model. Choosing different portions of brightness, you can create images of different types of tissues (bones, soft tissues, blood vessels, etc.). Programmatically, the transformation of a set of images into a 3d model is usually carried out using the marching cubes algorithm.

The original model was quite heavy and contained a number of defects, therefore, its refinement and optimization was required. As a result, not essential details were removed, but the model became much easier.

The main work was to create a model of the missing skull bones. Here CAD systems came to the rescue. When constructing it, the symmetry property of the human skull was used, as well as the indication of the defect boundary along the line of minimal surface curvature in order to smoothly pair the projected part with the rest of the skull.

After the part was modeled, the manufacture of the mold for the implant was not particularly difficult.

Half of the mold and the bone model itself (just in case) were printed on a 3d printer.

Experienced hands of a neurosurgeon make an implant using a mold.

Finally, a frame from the operation. Everything went well.

Main conclusions:

Typically, in such cases, a titanium implant is placed (which was expensive in our case), or a titanium mesh plate, or an implant is created from a biocompatible material. In this case, the surface of the defect was large enough, which limited the use of a titanium mesh (doctors had only standard-size and curvature meshes at the disposal of the doctors, and the trepanation defect significantly exceeded the standard-size meshes and had complex curvature with a transition to the base of the skull, so it could not even be closed two grids).

There was no full-time sculptor in the hospital staff, so it was not possible to sculpt an anatomically accurate model of the missing skull bone during the operation (as is usually done). Therefore, it was decided to manufacture a protacryl implant using a mold. The task was reduced to the manufacture of this very form.

The general procedure is as follows:

- Obtaining computed tomography (CT) data

- Convert CT data to a 3D model

- Refinement and optimization of the model

- Building an implant model

- Mold Design

- Mold making

- Production of the implant from a biocompatible material

- Implant sterilization

- Operation

The patient underwent computed tomography of the head, which resulted in a set of images (sections) of the head over a certain distance (in our case, 1.25 mm).

Based on this information, a three-dimensional model of skull bones was created. To do this, it is necessary to indicate to the program the sections of what density on the image will be used to build the model. Choosing different portions of brightness, you can create images of different types of tissues (bones, soft tissues, blood vessels, etc.). Programmatically, the transformation of a set of images into a 3d model is usually carried out using the marching cubes algorithm.

The original model was quite heavy and contained a number of defects, therefore, its refinement and optimization was required. As a result, not essential details were removed, but the model became much easier.

The main work was to create a model of the missing skull bones. Here CAD systems came to the rescue. When constructing it, the symmetry property of the human skull was used, as well as the indication of the defect boundary along the line of minimal surface curvature in order to smoothly pair the projected part with the rest of the skull.

After the part was modeled, the manufacture of the mold for the implant was not particularly difficult.

Half of the mold and the bone model itself (just in case) were printed on a 3d printer.

Experienced hands of a neurosurgeon make an implant using a mold.

Finally, a frame from the operation. Everything went well.

Not to look nervous!

Main conclusions:

- The designed form of the implant takes into account the anatomical features of the patient’s skull, which in this case is crucial for the recovery of the patient after a severe brain injury, and determines the further quality of his life.

- The time spent by the patient under anesthesia, the preparation and operation time (up to 1 hour instead of 2-3 hours) were significantly reduced, which has a significant economic effect.