Dreams of a big silly carrier

Remember the bike about developing a space pen ? Yes, it is not based on real events, but it very clearly illustrates the idea that a simple solution can be better than a complex one. The missile, built on the principle of "Big Dumb Booster" ("Big Dumb Booster") is not in the range of "smart-stupid", but rather, "simple-complex." Our usual launch vehicles grew out of military ballistic missiles, and their design was more important than cost. But, if we are going to explore the Cosmos, then we need a lot of rockets, and complex former military rockets become too expensive. But what if you try to make a rocket relatively simple, but economically viable?

Briefly about other methods

In previous publications, the series told about other ideas to facilitate access to space:

reusable . The rocket is expensive, the fuel is cheap, let's use the rocket repeatedly. If everything were so simple, then Space Shuttles would fly now in tens and hundreds a year. Reusable systems are very dependent on the time and money involved in preparing for the return flight, and here the shuttles lost the economic competition to disposable carriers . Now Elon Musk is engaged in reusability, but he still has a long way to go in this direction - there have not been a single flight of reused Dragon or Falcon, not to mention regular reuse in order to be able to evaluate cost-effectiveness.

Air start. The idea of launching a launch vehicle from a flying aircraft was proposed in many projects . However, to date, only Pegasus lightweight LVs use this design. Of the notable projects under development - the construction of the Stratolaunch project carrier aircraft for a heavier rocket is underway.

Single Stage To Orbit . The idea of a reusable spaceplane starting from an airfield, going out into space and coming back. The Skylon project is known, but there has not been any noticeable news on it lately.

Rocket-free space launch . Space elevator, loop Lofstroma, space fountains and so on and so forth. They write about this often, for example, a fresh review, so I didn’t do mine (or do you think it's worth it?), but things are still there. Similar technologies have three huge disadvantages:

- Almost all projects require materials and technologies that mankind still cannot do.

- The cost of such a structure is truly cosmic, and it will be built for a long time.

- Problems with calculating the payback period and the inability to operate a partially finished structure to confirm the concept.

First monster

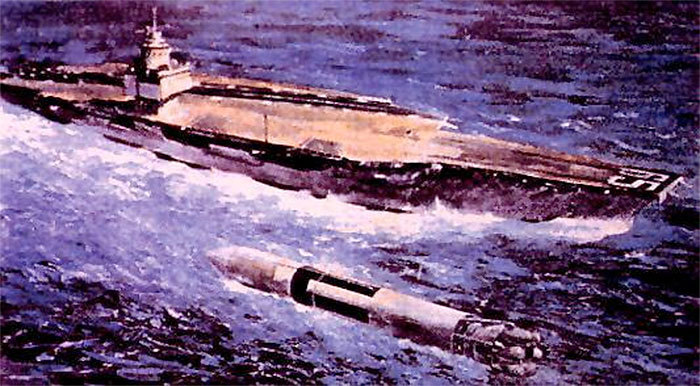

In 1962, Aerojet engineer Robert Truax proposed the Sea Dragon project. The two-stage launch vehicle was to have a height of 150 m, a diameter of 23 m and a total weight of 18,000 tons. The missile was assembled in the port, then it was fueled with kerosene - the first stage fuel and nitrogen - the gas of the boost tanks. Then the rocket should have been towed afloat to the launch site. The supply ship (it was proposed to use an atomic aircraft carrier) decomposed water into hydrogen and oxygen by electrolysis. Fuel tanks of the second stage were filled with liquid hydrogen, and oxidizer tanks of both stages were filled with oxygen. After refueling, the first stage ballast tanks were filled with water, and the rocket became vertical in the water. The launch was made from a partially submerged position, it was expected that Sea Dragon would be able to bring about 500 tons into low Earth orbit.

A single engine of the first stage created a thrust of 36,000 tons, but did not present any particular technical complexity - the pressure in the combustion chamber did not exceed 20 atmospheres, and the fuel was supplied without complex turbo pumps, pressurized boost gas (the so-called displacement feed). The second-stage engine had a thrust of “only” 6,350 tons, and the pressure in the combustion chamber was only 7 atmospheres. For comparison, the pressure in the combustion chambers of modern rocket engines reaches 255 atm (RD-191). The hull of the rocket was made of alloy steel with a thickness of 7 mm and was no more complicated than the hull of a submarine in production. In fact, the rocket was supposed to be produced at the shipyard. The project was reviewed by Todd Shipyards, which considered it feasible. Economic and engineering calculations have been confirmed by TRW, it was already a question of buying a section of the coast under the spaceport, but NASA's budget began to be reduced. Due to a lack of funds, the entire advanced development department that was involved in Sea Dragon and manned flight projects to Mars was closed. And Aerojet could not allocate funds for the development of such a cyclopean project on its own.

Near-soared OTRAG

Lutz Kaiser could be known for more than thirty years as the first private rocket builder. Senger's apprentice, Lutz founded OTRAG (Orbital Transport and Missiles) and convinced Werner von Braun and Kurt Debus to join the team after they retired from NASA. The idea of the new launch vehicle was to use simple blocks that were to be mass-produced and therefore very cheap.

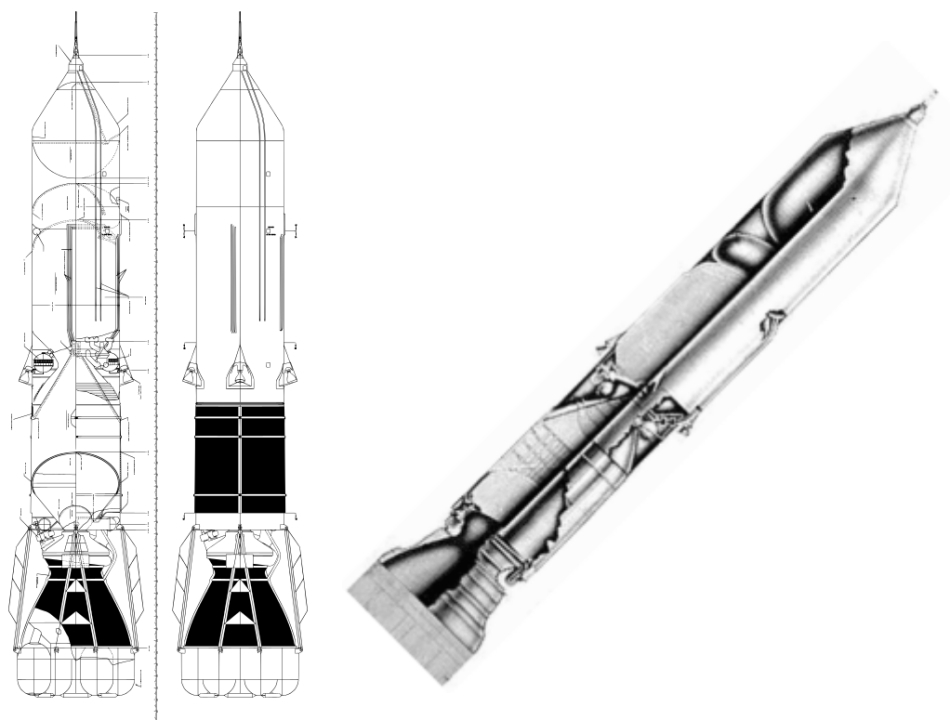

One CRPU (Common Rocket Propulsion Unit - “standard rocket block”) was a pipe 16 m long and 23 cm in diameter. The block housed fuel tanks (kerosene), an oxidizer (nitrogen tetroxide and nitric acid in equal proportions), boost (compressed air ) The tanks were separated by flat bulkheads. A simple engine with ablation heat protection nozzle and a thrust of 2.5 tons, valves, batteries and electronics was installed below.

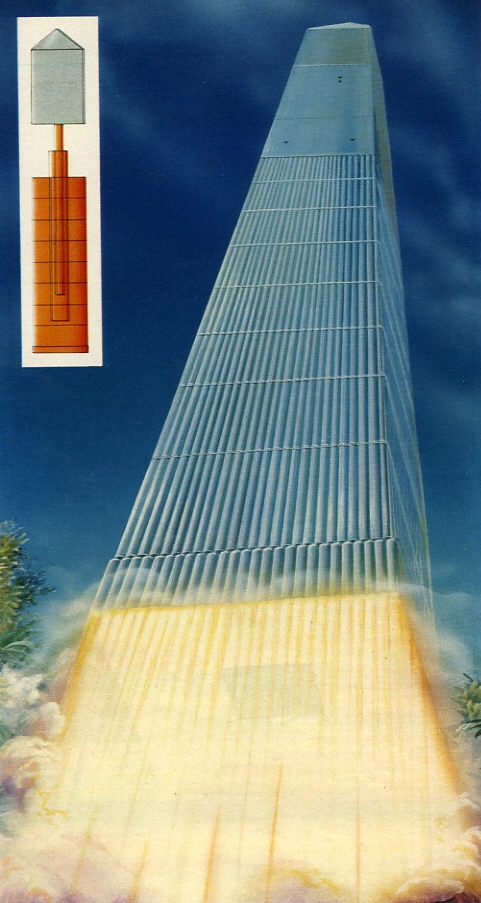

A feature of the design of the rocket was the batch installation of steps. First, the blocks worked from the outside of the package, then the inside. According to calculations, for the launch of one ton into orbit, three steps were needed, out of 4, 12 and 48 blocks. The batch layout led to the fact that the rocket was relatively short and wide, and, in theory, could launch large and wide satellites. To launch heavier loads, you just had to take more blocks. From the point of view of the familiar criterion for the ratio of the payload and the starting mass, the rocket turned out to be ineffective - in order to put 8 tons into orbit (a little more than the modern Soyuz), a rocket with an initial mass of 800 tons was needed (more than two times heavier than the Soyuz) . In order to get 128 tons, a monster with an initial mass of 12,800 tons was required (four times heavier than Saturn V, outputting about the same). OTRAG was supposed to win due to economic efficiency. The mass production of structurally simple blocks, tens of thousands a year, was supposed to make them very cheap.

Six engines at the test bench.

CRPU automated production line. OTRAG

super heavy launch launch.

In 1975, OTRAG signed a contract with Zaire to build a cosmodrome in the province of Katanga (now the territory of Congo). From the point of view of physics, everything was logical - the cosmodrome was near the equator, in a place convenient for astronautics. The first flights of test four-block missiles began in 1977.

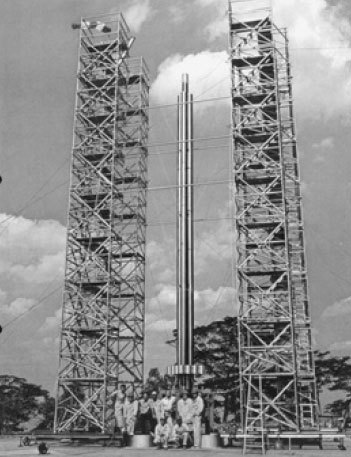

Rocket on the launch pad.

Test run. One engine did not turn on.

A unique video of the visit of some high Zaire authorities and that unsuccessful launch:

Problems began when politics intervened. First, developed countries feared that OTRAG missiles would be used for military purposes. Yes, they would be extremely ineffective in such a role, but to the underdeveloped countries of Africa, any missile is better than nothing. Secondly, developed countries did not want an economic competitor to their launch vehicles. The USSR, the USA and France jointly launched a campaign to discredit OTRAG in the media and began to exert political pressure on Zaire. In 1979, OTRAG was forced to leave the country. Tests in West Germany were extremely difficult for political reasons, and in 1981 the company built a testing ground in an even worse place - Libya. In 1982, West Germany joined the treaty on the non-proliferation of rocket technology, and the transportation of blocks produced in Germany to Libya became impossible. Despite promises, Muammar Gaddafi immediately confiscated the test site, and Libyan engineers tried to continue the project. Fortunately (because it was clearly a ballistic missile development program,look at the launcher ), nothing came of them, and the project was stopped completely. During the tests, about six thousand tests were conducted at the test bench and about one and a half dozen suborbital flights in a single-stage four-block configuration. Between 1975 and 1987, the OTRAG project cost about $ 200 million.

Big dumb carrier today

Lutz Kaiser is alive and quite actively communicates with privateers of the “new wave” - Armadillo Aerospace John Carmack and others. Interorbital Systems is developing a Neptune rocket of the same layout:

And Armadillo Aerospace wanted to make a very similar Stig rocket and use it as a geophysical one:

Dramatic accident:

Of the notable projects, it is also worth noting the HEAT-1X , which also simplified the design by replacing the LRE with a hybrid engine using a liquid oxygen / polyurethane fuel pair. Unfortunately, the HEAT-1X crashed in one of the tests; the new version of the TM-65 Tordenskjold burned out during bench tests. Now the Copenhagen Suborbitals are making a new rocket.

In 2006, the Aquarius project of Space Systems / Loral participated in the COTS contest (cargo delivery to the ISS by a private company), but lost. A feature of the project was the use of an oxygen / hydrogen fuel pair, which is quite difficult for a “simple” rocket, and only one step to put 1 ton of cargo into orbit.

In Russia, the idea of a "big stupid carrier" is being implemented by the Taimyr projectfrom the company "Lin Industrial". Low-voltage engines, non-cryogenic fuel components, a modular batch layout - all this should minimize the cost of starting. The heavier Adler and Aldan use the Soyuz RD-108 first-stage engine and steering chambers from it, I suspect, for the same reasons - the engine already exists and has been mass-produced for a long time.

Curiously, sometimes Russian launch vehicles as a whole are referred to the BDB concept. For example, the Soyuz launch vehicle uses engines that are not at the limit of the capabilities of modern technology. But it is very reliable, mass-produced, relatively cheap and therefore extremely successful. But, since our missiles were not developed specifically as simple and as cheap as possible, the question of the applicability of the BDB concept to them remains debatable.

Future

As for the future, it seems to me that this path is potentially very promising, and I have two arguments:

Argument from technology

A modern rocket engine is a very complicated thing . A lot of parts of complex shape made from special high-strength materials using complex manufacturing processes with very small tolerances for accuracy - all this cannot be cheap. Now imagine a rocket engine, which is printed on a 3D printer and specially designed to be simple. Yes, it will not be effective from the point of view of physics, it will not have record indicators for the pressure in the combustion chamber, thrust or specific impulse, but small-scale production of such engines can be very cost-effective. They also should not be reusable - at a certain level of technology it will be easier to re-melt and print them again than to try to sort and flaw them.

Argument from the history of technology

When has humanity truly mastered computers and microprocessors? When they began to appear at city dumps. In the 60s and 70s, powerful computers were relatively common and already influenced our lives. But for the next qualitative transition, even less powerful, but cheap and affordable personal computers were required. High technology is required for the production of microchips, but a single chip can now cost a penny.

The same situation can be found in other areas. Maxim's machine gun changed the battlefields, but the next qualitative step was the Kalashnikov assault rifle - with a less powerful cartridge and a smaller range of aimed fire, but technologically advanced for mass production conditions.

In aviation, jet engines made it possible to achieve first transonic, then supersonic speeds. But now high technology is used to reduce the cost of flight, and supersonic passenger liners have died out.

It seems to me that these analogies can be applied when trying to predict the future of rocket technology. The dialectic of the development of launch vehicles may be that high technology and ingenuity of people will be used to create "stupid" missiles.

List of sources used

The main source besides Wikipedia is Encyclopedia Astronautica .