How to make the best rocket engines in the world

We continue the tour of the Khimki NPO Energomash. In the previous series, we visited their showroom , and now we will go through the enterprise itself.

Last time I was criticized for the loud epithet "best engines". I agree that it would be more correct to call "The best oxygen-kerosene engines ...", but I did not want to overload the headline. Maybe someone will disagree with such a clarification, but after the first report there was good news for Energomash - the American company Orbital Scienses ordered 60 RD-181 engines for its Antares rocket, after the Samara engines failed at the start . But this is a topic for a separate discussion, but for now we are moving forward to the workshops.

We must pay tribute to the organizers of the tour: all the shop managers were warned, waiting for the guests and were happy to talk about the contribution of their workshop to the creation of sophisticated engines.

First we moved to the test benches. This is a multi-storey building, which was inherited from the Soviet Union. And it is that "superweapon" that allows Energomash to create the most efficient oxygen-kerosene rocket engines.

An “old Vau-2” combustion chamber is installed in the “hallway” - in memory of how it all began.

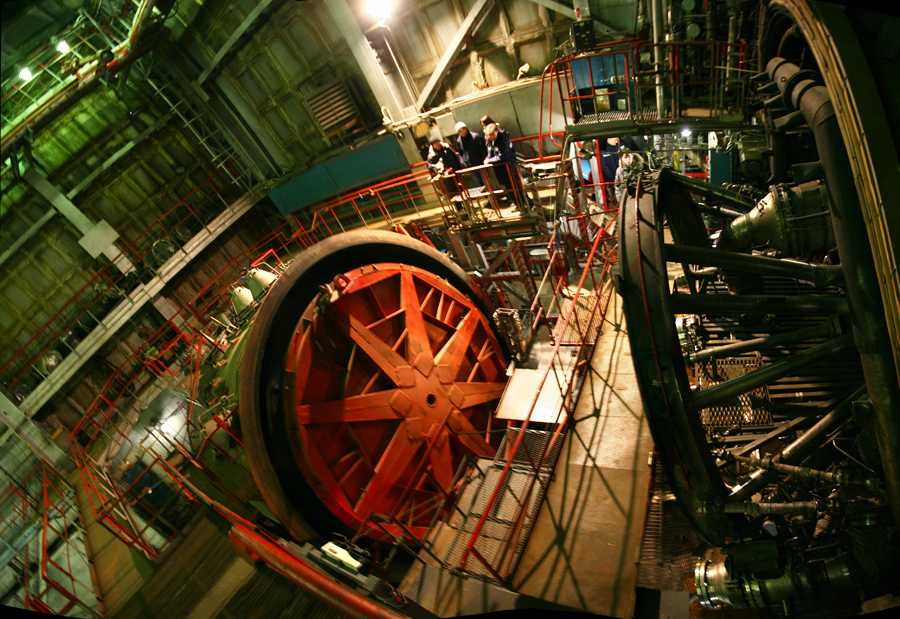

We rise by elevator and exit into a dark room, reminiscent of an ordinary factory workshop, but a giant bell of the stand occupies a third of the total volume.

When we arrived, there were no engines on the stand, and it was closed with a heavy plug.

Engineers talked about how it was created, how the world's most powerful RD-170 engines were tested on it, then remade under the RD-180 for an American order, and then under the RD-191 for the Angara.

And I looked at this cyclopean structure and thought about how good it was that it was possible to preserve it throughout the 90s, not to be cut into scrap metal, or simply not to leave to rot. Now the construction of such a structure would cost hundreds of millions of dollars, would turn into a long-term construction like Vostochny, overgrown with corruption scandals and environmental protests ... But none of this happened. The plant works, rockets fly, a test bench in business.

Here, on the NPO Energomash website, there was a good film about the RD-170, its production and testing:

Although offhand it is difficult to understand the interweaving of pipelines, but by the main functions of the stand you can understand what is needed there. An exhaustive illegal photo essay from the same place is known to many LJ users.

Oxygen-kerosene engines are being tested at the stand, so the entire infrastructure around it is created for this purpose. Kerosene and oxygen are supplied from the tanks, while a powerful fire stream is immediately mixed with colossal streams of water that dampen vibration and bind harmful combustion products at the chemical level. In case "something goes wrong", the automation stops access to fuel, and the network of nozzles fills the test chamber with non-combustible nitrogen, interrupting the possibility of uncontrolled ignition. Nitrogen is used to boost fuel and create operating modes similar to conditions in a rocket.

The system, apparently, is effective, if the engines exploded in it, then the consequences of the accidents left no traces.

After examining the stand, we get out onto the roof, where from the height of a ten-story building you can see two huge exhaust pipes of test benches, related buildings and the surroundings of Khimki.

When, in Soviet times, engines for Proton and military missiles were tested at the stands, the environmental situation in the vicinity was not the healthiest. In general, of course, it is surprising that engine tests on such toxic components were carried out so close to the largest city in the country. But the logic of those times is now difficult to understand, then everything was justified by work on the "nuclear shield of the country", therefore, they were not considered possible victims.

Now they are testing only oxygen-kerosene engines, and you can not worry about ecology. At the entrance to the test building, they even showed me a squirrel feeder - a symbol of the cleanliness of the surroundings. In general, during my stay on the test site, the word "ecology" sounded repeatedly - a painful question is evident for the employees of the enterprise, although I did not even ask it.

“Don’t take off to the right,” one of the enterprise’s technical staff asks me, pointing to the unfinished building, “They will say the ruins.”

The second explains:

- This is a new test building for reusable space systems. I saw how Americans are going to land ships on rocket engines? So we did it back in the eighties. It was built stands for testing landing rocket engines, but never completed ...

- Are you going to finish building?

- The enterprise has no money, and there is no order. Now only if you, young ones, take up such a task ...

In thoughts of lost opportunities, we move to the other side of the roof. From there, spherical containers for oxygen are visible, cylindrical ones for nitrogen, kerosene tanks are a little to the right, they weren’t in the frame.

Finally, we are moving forward to production.

The first program is a welding workshop. A young welder is preparing a machine tool. After a couple of minutes - he is already at work - a photo at the beginning of the text.

In the next room - an automatic welding machine. In the foreground, specialists are busy with work.

By the way, another observation about the age of employees. For other space enterprises, there is a problem of the lack of middle-aged specialists. Like, for example, the NGO Lavochkina. The problem comes from the 90s, when the most active left enterprises. Young people have come now, but they are only gaining experience, and are learning wisdom from those who still remember the storming of the Moon, Mars and Venus in the 70-80s.

At Energomash, the age gap is imperceptible. Apparently affected by the contract of the 90s for the supply of engines for the Atlas-V American space program. The order saved the enterprise from brain drain and hands in difficult times, although it became profitable only by 2012.

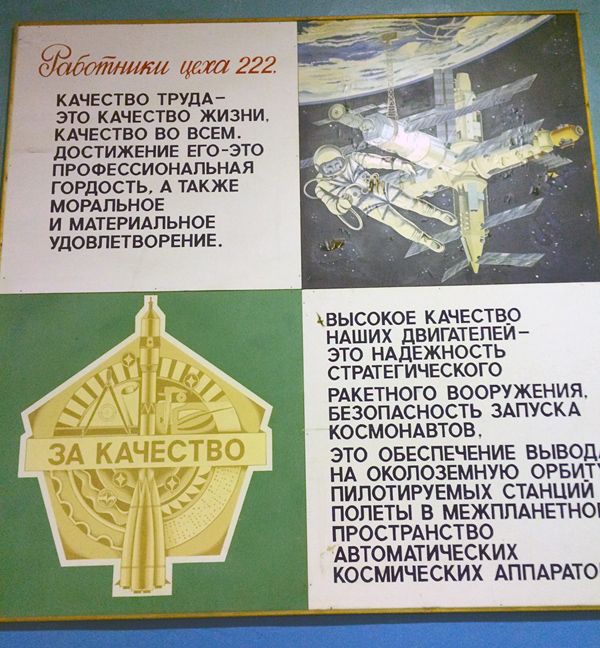

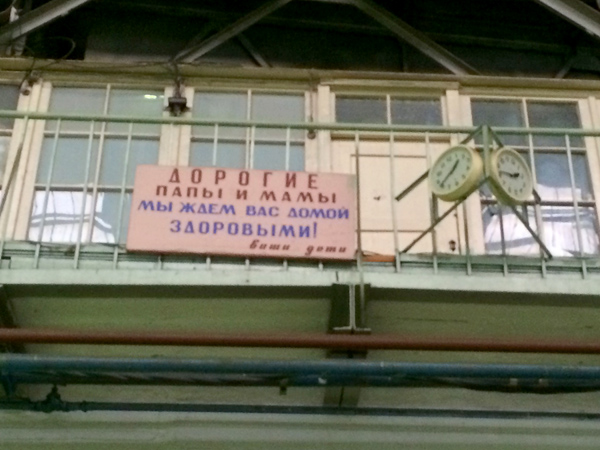

And the brains and hands in the enterprise, as well as in general in astronautics, are very important. In almost every workshop, posters reminiscent of the importance of product quality, the need for safety and accuracy.

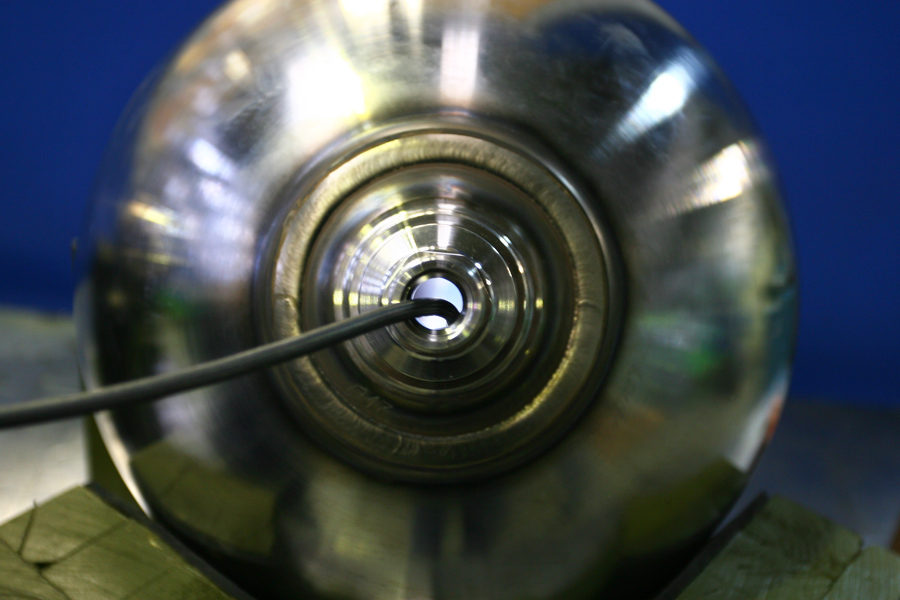

We go through different production lines. Here is the master Andrei checking the quality of the weld of titanium balloons:

Nearby are bellows joints that are familiar from the first part of the report. The unique design of Energomash is used both for mounting the combustion chamber to the swinging gimbal

and for individual piping connections.

We go to the blacksmith shop.

Yes, the most complicated engine design, with its micron tolerances, colossal loads and high manufacturing accuracy, grows out of these stainless steel blanks.

Here, under the roar of gas furnaces, it is processed by peppy blacksmiths, ...

... who handle hot-burning pood steel rings, like toys.

"Three rings - to the wise elves - for the goodness of their proud ..."

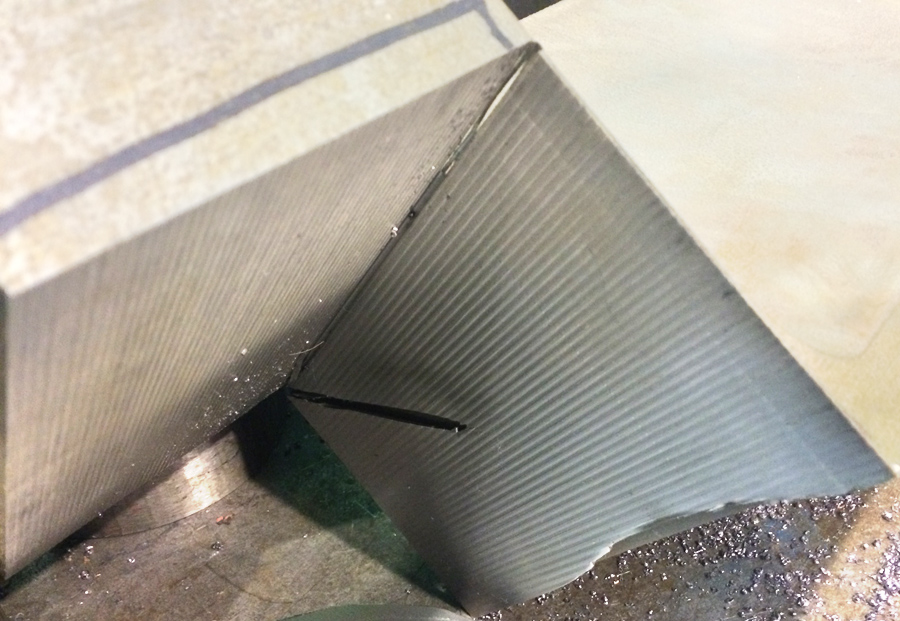

Then we move to the waterjet processing workshop.

A stream of water cuts steel no worse than Jedi swords.

A souvenir to the cosmoblogger from cosmohydro cutters.

We move further, look into the foundry. The casting itself is not shown, but the products are shown after casting. I did not understand the technology, so I can’t say why it looks like this, but it looks funny.

The next item in the program is the machining workshop.

They walk me past several creaking lathes of the Khrushchev era, and proudly demonstrate the orderly rows of automatic five-coordinate milling machines. It’s not interesting to take them off in the work, only vague contours of the devices and leaks of coolant are visible through the glass. But one shot opens and I rush there with the camera in my hands.

Oh, so this is our old friend - the rotor of the booster pump unit of the oxidizer. I can’t imagine how such a part was made in the 80s, when there was no modern technology. But the "Energy" flew the same ...

Go ahead.

Uh ... I don’t know what or who is behind the door ... My attendants were also unable to say.

But on the contrary, we are waiting for: Department of Metrology and Quality Control.

Elements of rocket engines are difficult not only to produce, but also to verify the accuracy of manufacture. Here they can.

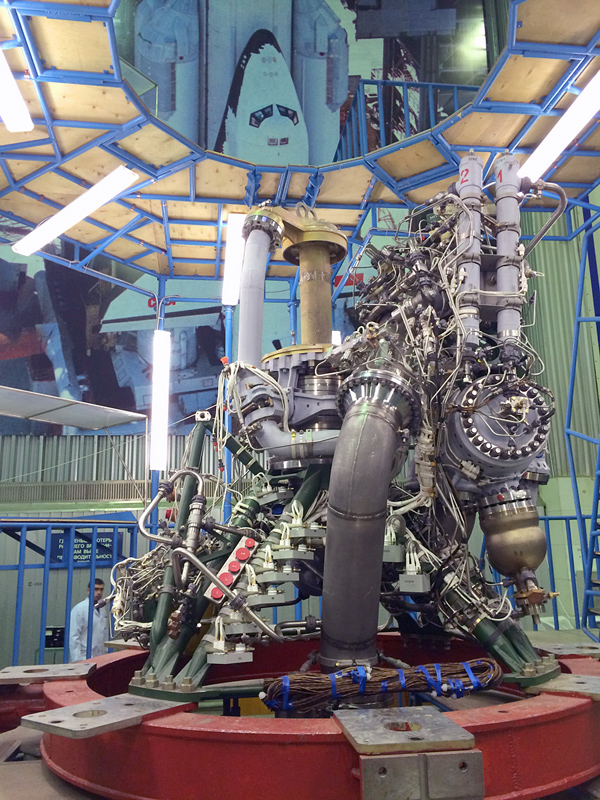

After all the stages of processing, fine-tuning and quality control, the parts fall into the huge final assembly shop. It is more difficult to get into it - additional passport control, bathrobes and shoe covers on shoes.

And at the entrance, Soviet space nostalgia rolls.

You can see right away - they remember here!

Even twisting a new unit for an American rocket, the energy workers do not forget that they also raised their native space.

I was going home, and the RD-191 for the Angara was going into space.

What to say in conclusion?

The plant is operating, and it has been loaded with business for years to the 20s. It’s bad that, due to the political games of the past year, the production of Soviet pride, the unrivaled RD-170, has practically stopped. It was used in Ukrainian Zeniths, but in the current situation there is little hope of continued joint production. There are difficulties with export RD-180s, on which half of the American astronautics flies on the United Launch Alliance Atlas-5 rockets - the order ends in 2018. They are not going to renew. Someone joked about trampolines. Now the Pentagon is ready to invest hundreds of millions of dollars to develop its own analogue, if only it does not depend on Russian products. True to the ULA shift cameOrbital Scienses with the Antares rocket and an order for RD-181 under the International Space Station supply program. NASA is not as important as the military. The years of peaceful cooperation in space were not in vain, but for the ISS they need much less.

There is also an order for RD-191 for the Russian Angara, but its volumes are completely dependent on the demand for the rocket. While the Proton flies, there is no reason to believe that the Angara will find work other than experimental launches.

Energomash is currently developing promising methane engines. This is the fuel of the future, it does not leave soot on the engine elements, which facilitates their repeated use. True, reusable missiles are not yet in the immediate Russian plans, but there is hope that, through the efforts of Elon Maskand SpaceX will gain insight, and awareness of the need for such missiles will come to Russia.

I express gratitude to the Department of Information Policy and Mass Media of the United Rocket and Space Corporation and the press service of NPO Energomash for their help in organizing the shootings .