We design a fire extinguishing pumping station

At the end of October, talking with the management, I get the task: “We need a series of articles on the practical application of nanoCAD VK and Heating programs . The task is set, go write. "

In thought, he did not notice how he reached his workplace. There are many projects on which you can write an article, but you want something fresher, something special. Such as to immediately show that you should not be afraid of domestic software, that it is not worse, and sometimes better than foreign. Correspondence with our user Vyacheslav Zatserkovny from Delta LLC catches your eye.

Here it is, the first article! Vyacheslav is one of the most interesting and curious users that I happened to encounter. His department designs fire safety systems for objects of commercial, warehouse, industrial use, and if you look more broadly, he develops any projects related to fire safety (AUPS, SOUE, OMK, ASPZ, SCS, MPB, AUPT, VPV).

Acquaintance with Vyacheslav began six months ago. From a phone call. Vyacheslav was interested in nanoCAD VK, there were many questions on the program, on its interaction with other solutions through the IFC format. The task for Vyacheslav was simple: to find software that allows you to calculate the fire extinguishing system, get the documentation and transfer the 3D model of the system to another program. I was interested not only in the projects carried out by Vyacheslav’s department, but also in the opportunity to test our BIM approach. The essence of the approach is that the designer works with the best solution in his field, and he can transfer all the results to his colleagues, subcontractors and customers using the DOC, DWG and IFC formats. The intended project was suitable for testing this approach as well as possible.

I rarely received fire extinguishing projects. At first glance, they may seem simple, but in fact there is a lot of work to calculate and select equipment. Due to the large distances, it is often necessary to coordinate the locations and heights of pipelines with subcontractors to avoid collisions.

It took two months to develop the program: the user studied its capabilities in his spare time from the main work. The basis was taken on a small previously completed project - now all of its stages, from the first steps to exporting a 3D model to another program, had to go to nanoCAD VK.

So, the project in nanoCAD VK to be! And from mid-summer, work began.

It would be cunning to say that everything went smoothly. There were enough problems, but Vyacheslav himself would better talk about this:

“I’ll try to tell as much as possible about the work on the project of the internal fire water supply system (ERW): and what difficulties I encountered, and how I solved them.

I understood the program on my own, I asked for help only in extreme cases. After switching to design in nanoCAD VK (from foreign CAD systems), there were no difficulties with orientation in the program. The interface is recognizable and intuitive.

They created the structure of the building, loaded a flat base (unfortunately, we did not have 3D architecture). We started laying the pipeline network and arranging the equipment. This is where the first problem arose: the situation with the equipment for ERW systems is not simple, I had to create new UGOs, search the Internet and download graphics for this equipment. Here, tangible support was provided by specialists from Nanosoft CJSC (Nikolay Suvorov) and ArcSoft Group of Companies (Arseny Smirnov).

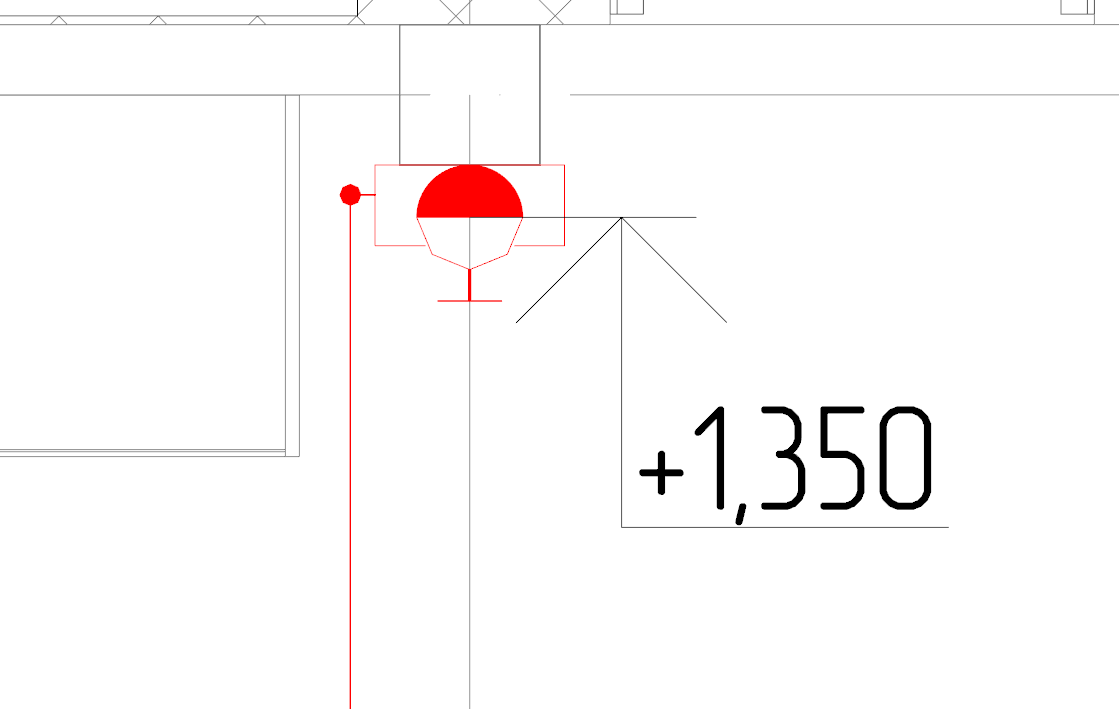

The program allows you to install a pressure gauge, but its installation is supposed to be directly on the pipe, as a measuring armature. I needed a pressure gauge on the nozzle. I had to create my own UGO.

Display in the plan of UGO elements

Next, it was necessary to find and partially work out the schedule, but in the end everything turned out as I wanted.

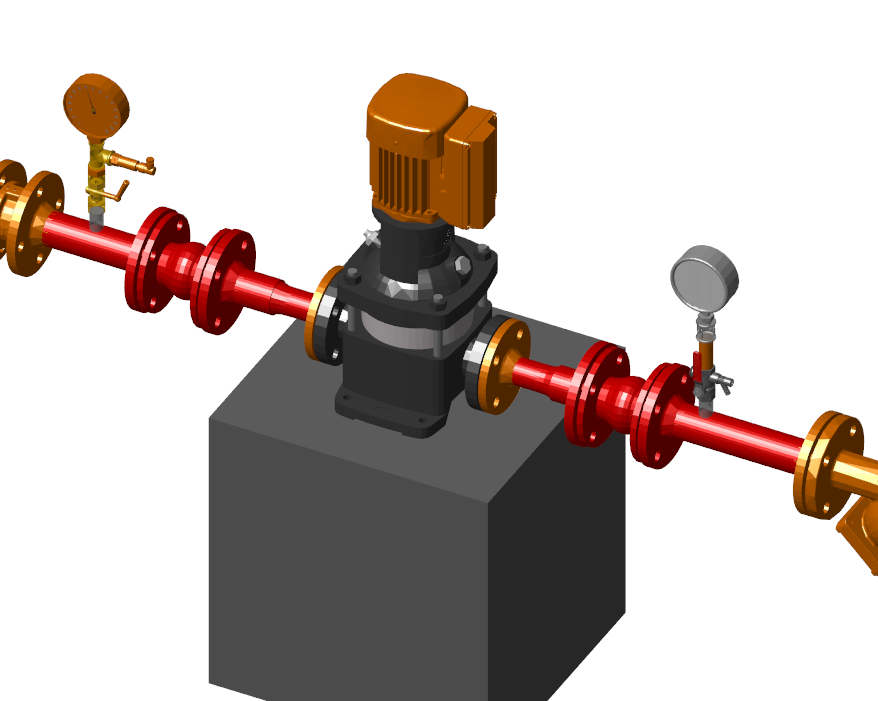

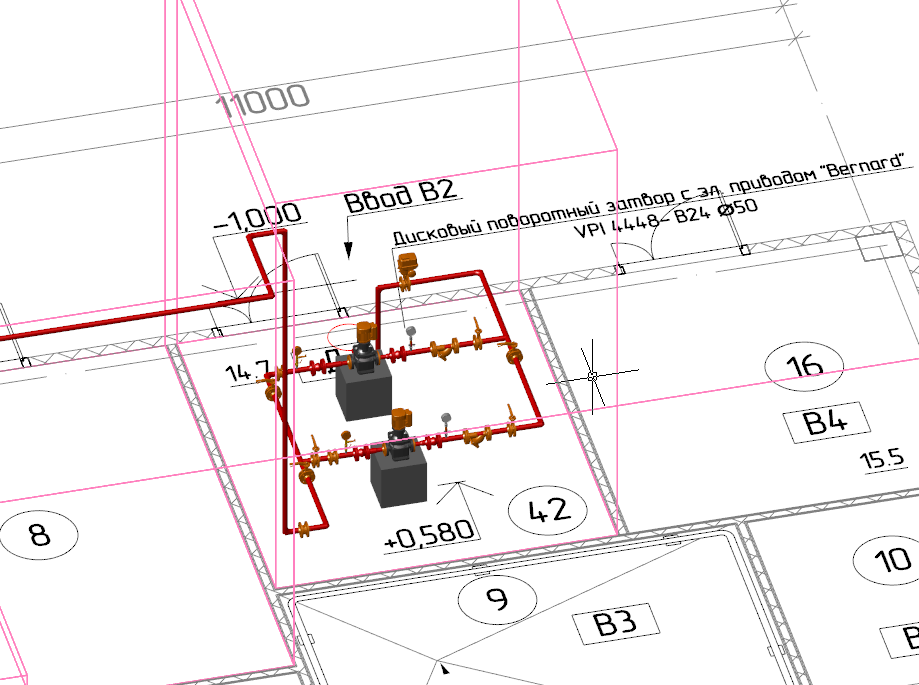

Displaying equipment in 3D

True, another complexity was discovered: in the database, the pressure gauge was set to DN 15 and during checks the program reported a diameter mismatch (the diameter of the pipe on which the pressure gauge was installed is DN 50). In a conversation with the developers, it turned out that the option to install the pipe was not taken into account. They accepted the comment, promised to fix it.

The next problem arose with the flanges of fittings and appliances. Since our fittings are flanged, it was necessary to install flanges on the pipeline. 90 percent of 3D-graphics - without response flanges, but in 3D it did not look, so the response flanges had to be added. How to do this, Nikolai Suvorov showed at the webinar "nanoCAD VK: working with 3D graphics". We used the proposed method. It turned out great, it only remained to add information to the database that now the fittings and devices are with mating flanges.

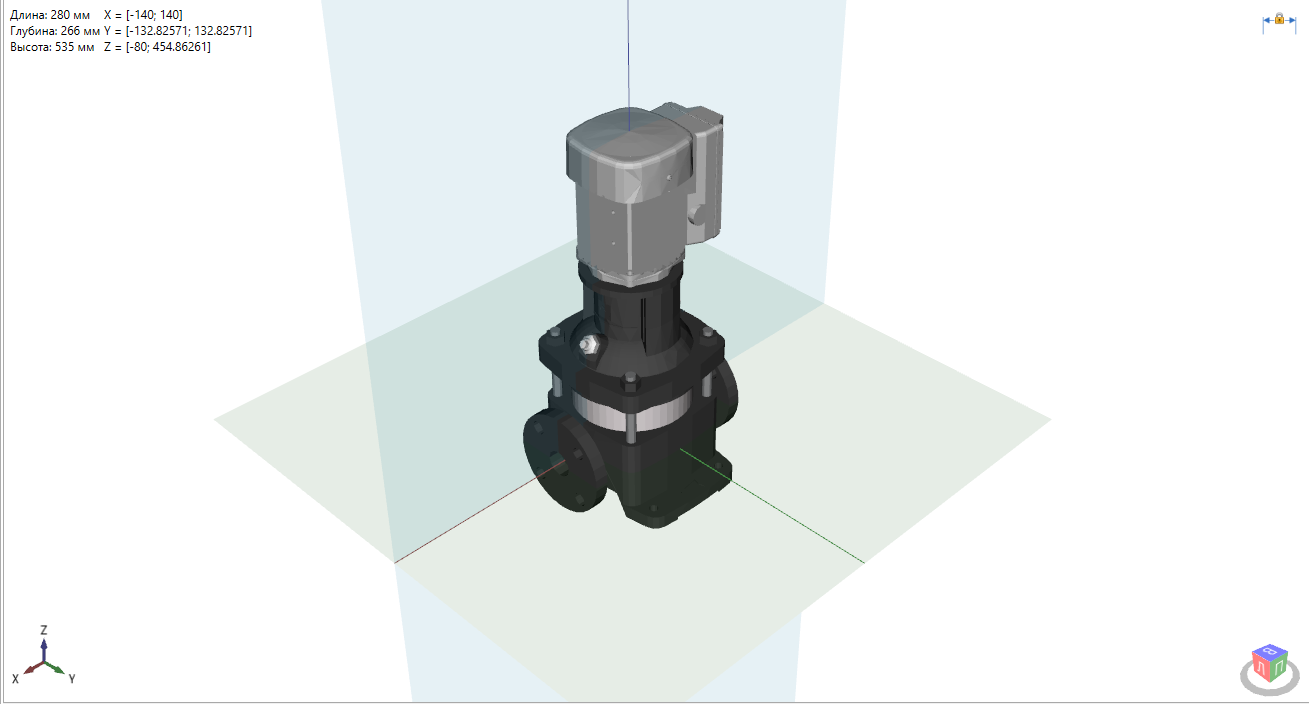

Displaying 3D-graphics in the database

It was also necessary to create a new UGO on a PC, with left and right connections. Well, the schedule - it was already the easiest.

Display in the plan

Independent creation of the equipment base is due to the fact that initially the schedule does not have all the necessary properties (dimensions, material, manufacturer, catalog number, accessories and accessories, equipment capacity, weight). All this information needs to be found and then entered into the database, which significantly increases the design time. It should also be noted that the customer wants to receive the most complete information about the equipment, which means that it will be necessary to work out the possibility of loading passports for this equipment when it is selected on the model. The situation could be fundamentally changed by the appearance of equipment databases from manufacturers, but, oddly enough, manufacturers are still not at all motivated to create such databases ...

After creating the model of the ERW system, the time has come for calculations. After checking the project for errors, we found that as an error (unconnected equipment) additional equipment that is not involved in the system is displayed. The required pressure exceeds the guaranteed pressure value, while the effect of the use of pressure boosting pumps is not taken into account in the calculation. The hydraulic calculation itself is losing its significance for the project, since it does not help to choose the right pumps for the fire fighting pump station. We solved the problem with the help of old Excel spreadsheets that we had previously considered. We hope that in the next version the developers will correct this annoying defect and nanoCAD VK will not only be able to help in choosing the diameter of the pipes, but will also take into account the pumping equipment.

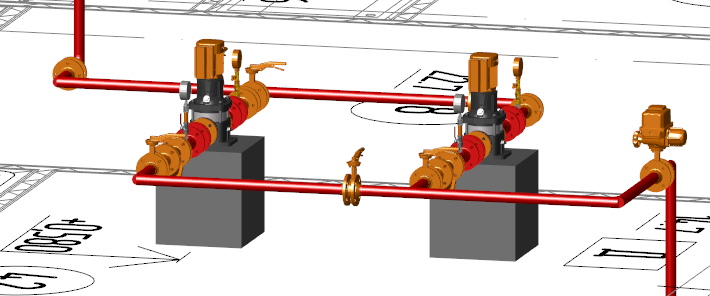

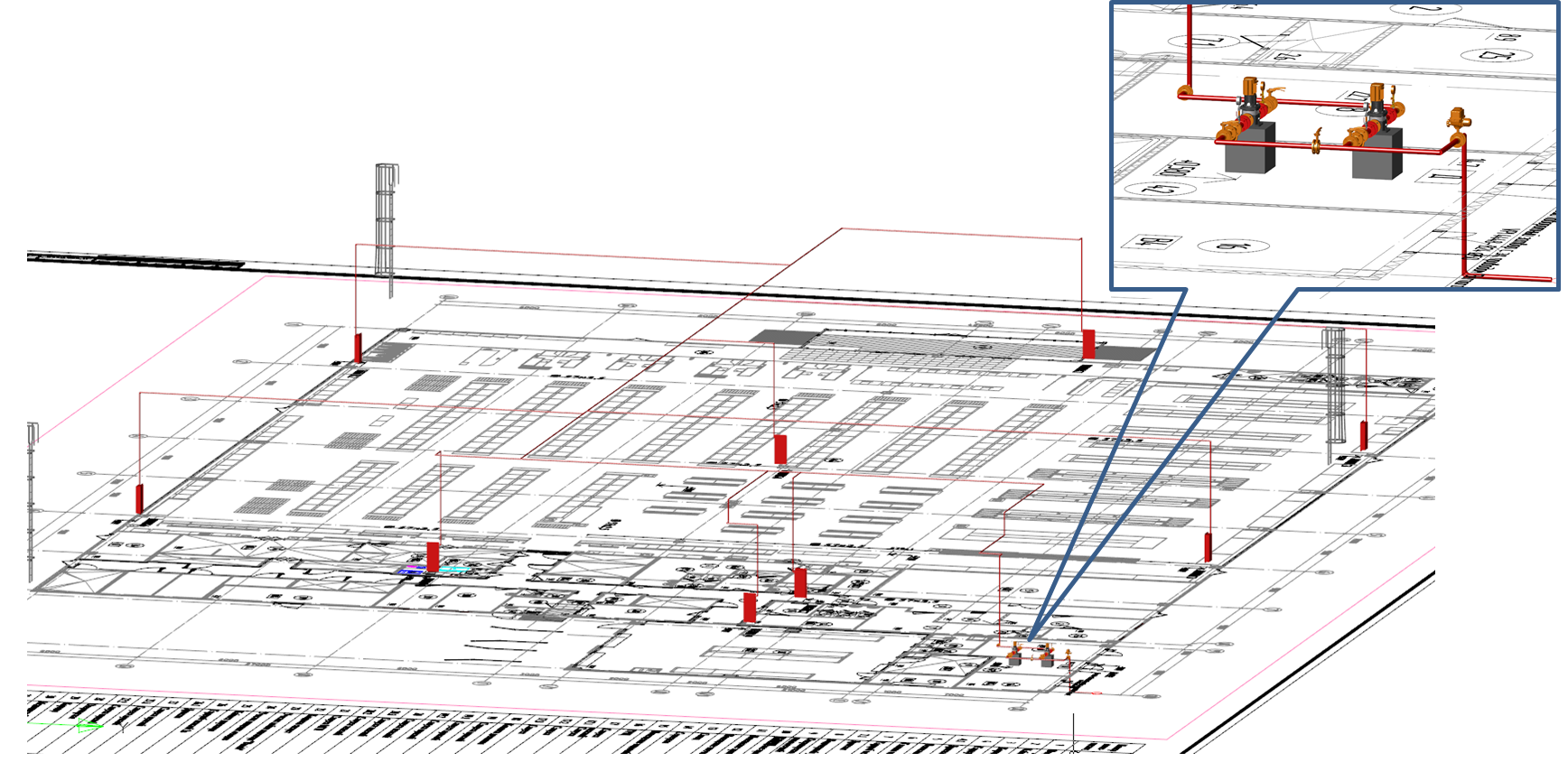

3D-model of a fire extinguishing pumping station

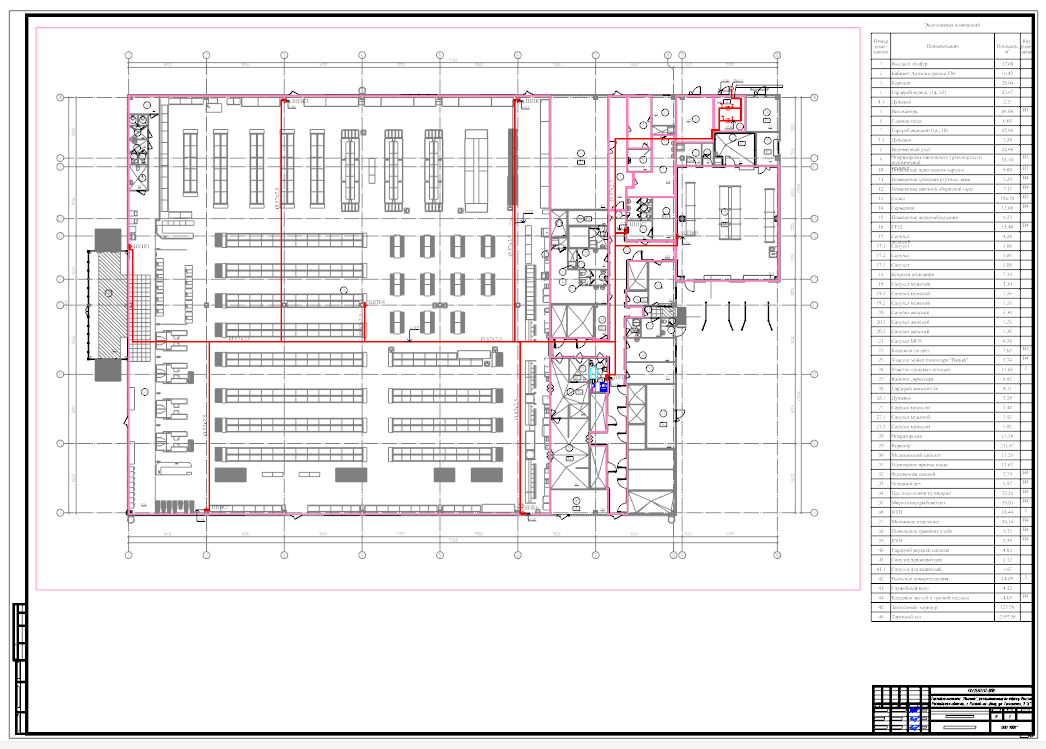

Now, regarding the design of the project. Modern CAD systems usually assume that the construction (drawing) of the object model takes place on the Model tab, and everything related to the design of the drawing (frames, stamps, sizes) is performed on the Sheet tabs. nanoCAD VK provides a convenient function that allows you to insert frames with stamps into the project according to GOST. The function significantly speeds up the creation and filling of drawing design elements. But there was a fly in the ointment here: this function works only on the Model tab. The solution was to create a frame in the model, and then copy it to a sheet, but I would like the functionality to work in sheets, without requiring any additional operations.

Plan of the internal fire water supply and fire fighting pumping station

The specification was generated automatically, but the program did not take into account additional equipment that is not connected to the network. I hope the developers fill this gap as well. In addition, setting up a template for a specification is, to put it mildly, a non-trivial task. The help for the program does not describe this setting, so it’s difficult for an engineer who is far from programming to understand without the help of specialists.

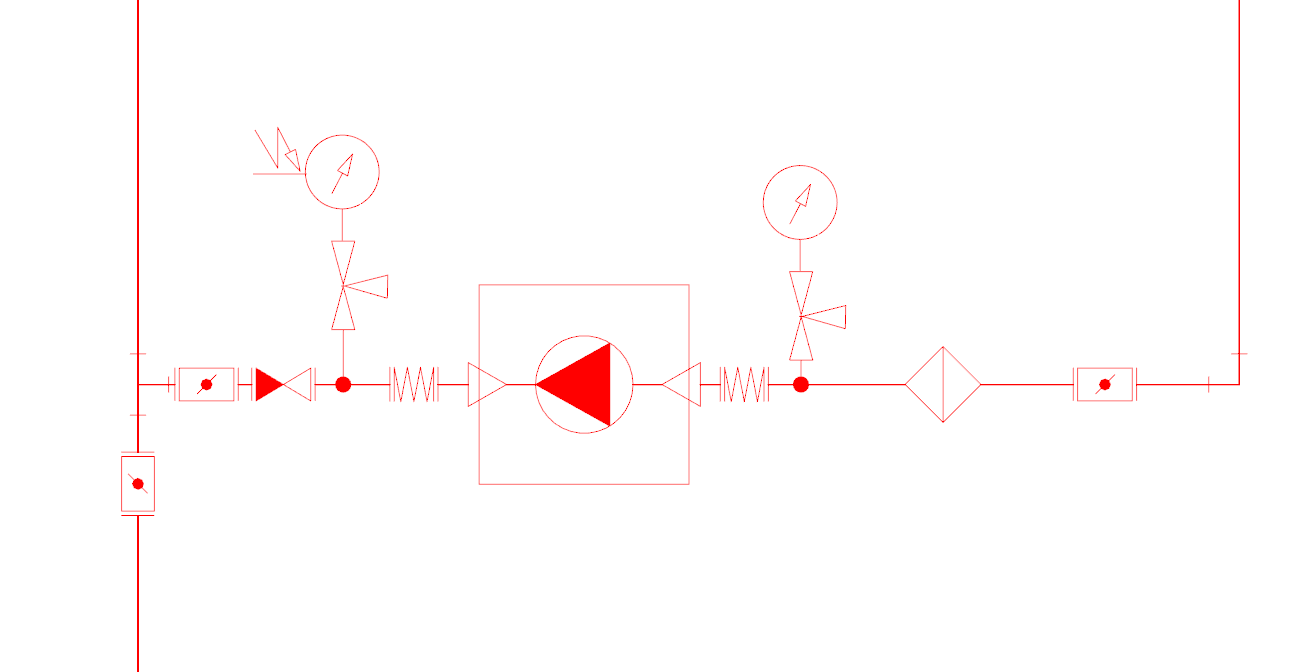

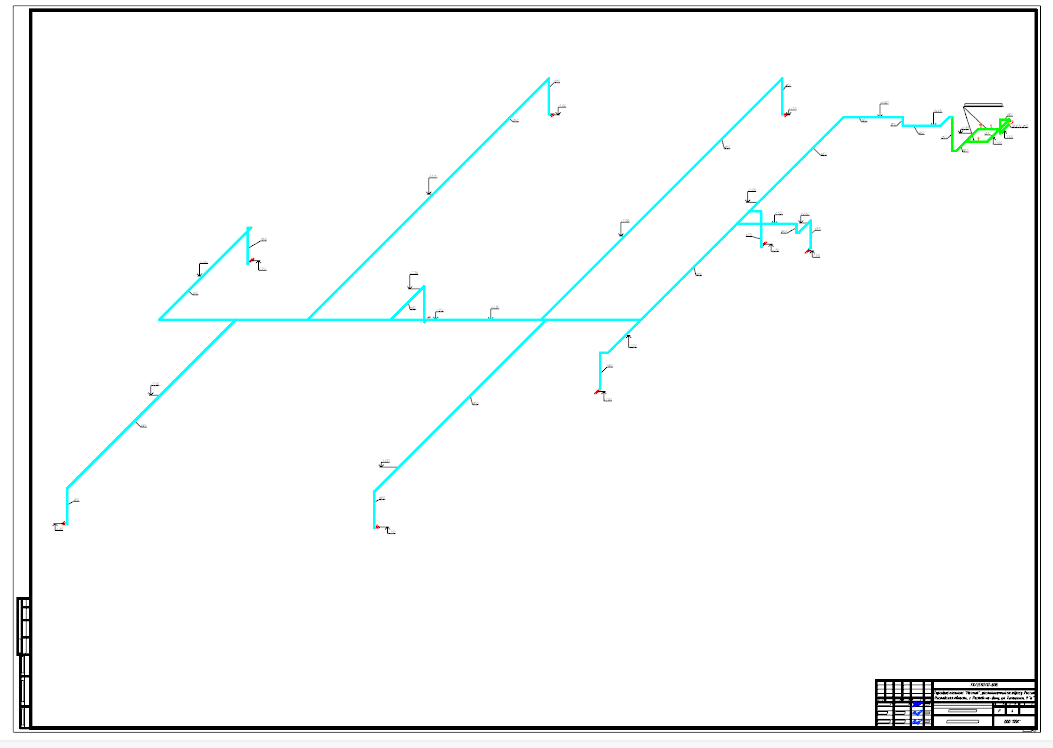

Axonometric diagram of the internal fire water supply and fire extinguishing pumping station

Well, finally, about the joint design. We uploaded the designed ERW model in IFC format for transmission to a customer who works in Revit. The result of our work was a set of drawings in DWG format, designed in accordance with GOST, and an IFC file. There were no problems exporting the model to IFC. Now we are waiting for an answer from the customer.

3D model of the internal fire water supply and fire extinguishing pump station

To summarize. You can design a fire extinguishing pumping station in nanoCAD VK. All necessary documentation is completed on time and in accordance with Russian standards. What pleased the management of the company.

While working on another project, we used a three-dimensional architectural sub-base, uploaded in IFC format. In nanoCAD VK, the architecture was loaded, but it was installed with an offset: it turned out that the architect took other axes as the base point, as a result of which there was a displacement of objects made in nanoCAD VK. The solution may be to customize the export at the customer or combine the base points of the projects.

We are actively continuing to master the methods of information design and in the future, I hope we can talk about new successes ... ”

Joint work with Vyacheslav on the project was very useful. Developers eliminate the causes of problems that arose during the creation of the project (pressure gauges, pumps, etc.), so that in the future such difficulties will not appear.

Meanwhile, the next version was released - nanoCAD VK 8.5. I will say a few words about her innovations.

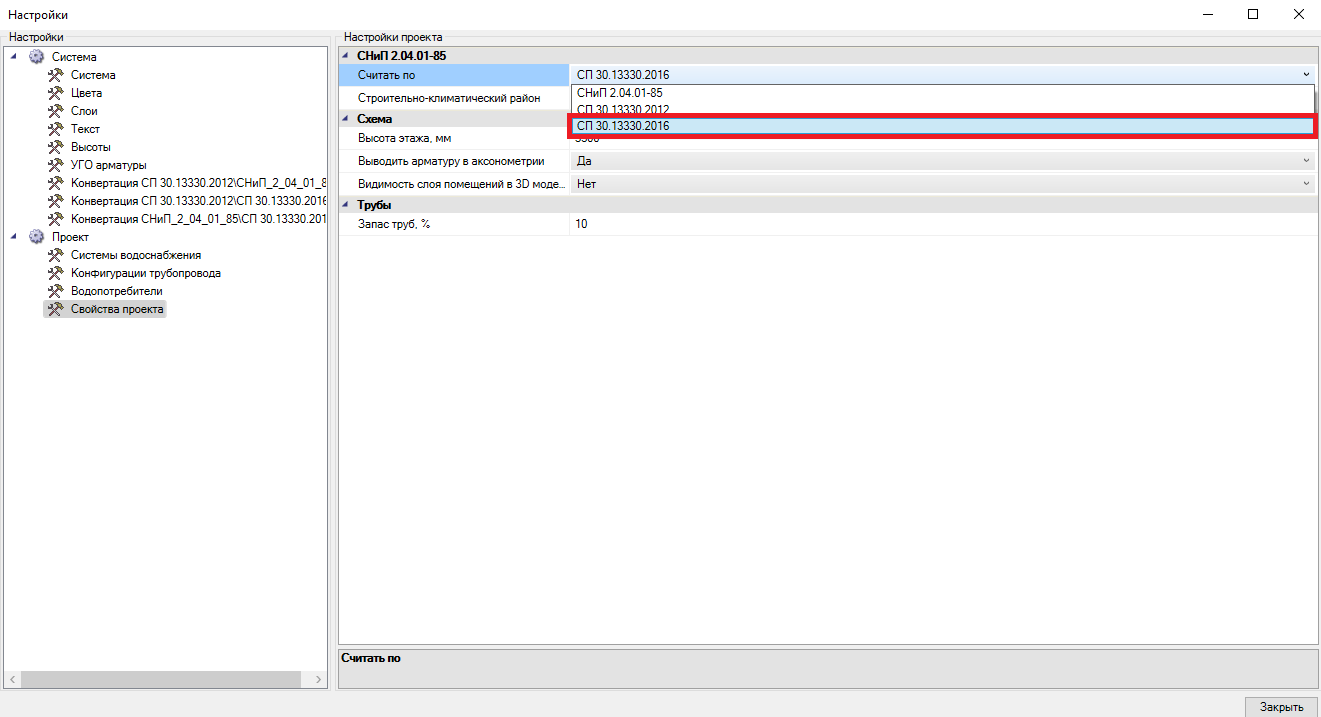

The calculation was implemented for SP 30.13330.2016, introduced in mid-June 2017. He was very much expected - there were a lot of comments to SP 30.13330.2012. As soon as the new joint venture entered into force on 30.13330.2016, they began to ask us when it would appear in the program. And we did not let our users down: nanoCAD VK 8.5 has this calculation.

Settlement Settings

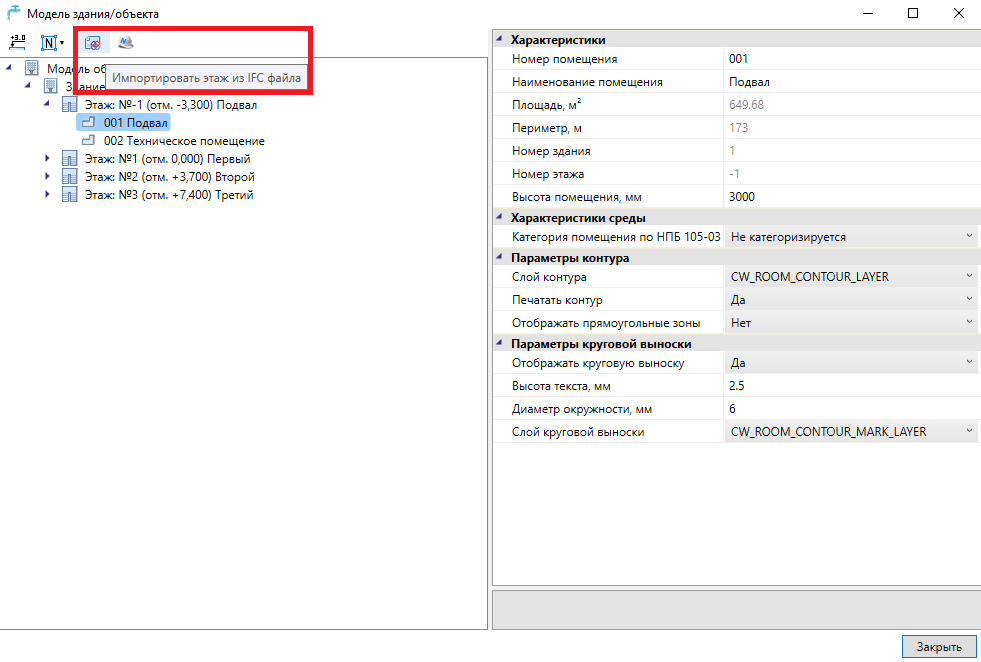

Many users asked to add the ability to import premises from the IFC format. We did it. Imported as the geometry of the premises, and the basic attribute information.

Import floors from an IFC file

Thus, the degree of integration of nanoCAD VK with other BIM systems has become even higher. This innovation will be appreciated by users whose allied architects (builders) work in ARCHICAD, Allplan, Revit, etc.

I hope the article is informative. The following material is not far off - and it will also be devoted to work on an interesting project.

Nikolay Suvorov, SuvorovN

Project Manager nanoCAD VK and Heating

Nanosoft CJSC

The author is sincerely grateful to the design engineer of Delta LLC, Vyacheslav Yurievich Zatserkovny, for the help and information provided in the preparation of this article.