Electricity in the data center

The work of any data center rests on the "three pillars" - power supply, cooling and security systems. And the key infrastructure among them, without a doubt, is the power supply system.

Uninterrupted base

The Selectel Data Center “Flower 2” is designed for a power consumption of 2500 kVA and corresponds to the Tier III level, according to which the power and cooling channels are duplicated according to the 2N redundancy scheme. This gives a significant advantage in terms of reliability of power supply to both customers hosting their equipment and the data center maintenance service - maintenance or replacement of failed components can be performed without shutting down the power of the data center (including customer equipment).

Electricity is supplied to the data center through two independent inputs from the city power grid and supplied to two transformer substations TP 10 (6) / 0.4. Substations are the property of Selectel and are located in a complex of buildings also owned by the company. This is another important point for customers in terms of infrastructure reliability - in Russia, a fairly large number of data centers are located on rented premises, and therefore depend on the market for rental and even on the mood of the owners.

In transformer substations, a high “urban” voltage of 6 kV is reduced to 380 V (400 V), and then fed to the main switchboards (main switchboards) with a protective automation system.

This power supply can have various kinds of interference (bursts and dips, high-frequency noise, etc.), and therefore is not suitable for noise-sensitive servers and communication equipment, as well as air conditioning and automation systems of the data center itself.

Therefore, through busbars, the 380 V (400 V) power supply is then supplied to 2 groups of industrial UPSs (uninterruptible power supplies), each of which is a 6x400 kVA module with double conversion function. Here, the alternating voltage is rectified into a direct current voltage, and then again converted into alternating 380 V (400 V), but with an ideal sinusoid shape.

In addition to the interference cleaning function, the UPSs perform another important task - they provide power to the data center from the battery (batteries) in the event of a complete disconnection of the external "city" power supply during the transition to the emergency power source - DGU (diesel generator sets). For these purposes, the UPSs are connected to mutually redundant arrays of 130 battery 12 V batteries. The charge of these batteries is enough for the period of the data center under full load up to 10 minutes. In the event of an external power failure, the automatic transfer switch (automatic transfer switch) automation starts in a separate room three diesel generators with a capacity of 1800 kVA each, which can provide power to the data center for an unlimited time.

DGUs have N + 1 redundancy, that is, two DGUs are enough for normal operation of the Tsvetochnaya 2 data center, plus one DGU in reserve. A fuel stock is stored on the territory of the data center for 48 hours of DGU operation, and there is also a service agreement with two suppliers for emergency fuel delivery in case of prolonged city blackout.

On average, it takes up to 3 minutes to start the DGU and their output to the workload mode - the UPS battery with a margin is enough for this operation. To ensure a reliable start of diesel engines even in winter time, the coolant is constantly heated in the diesel generator set, and this parameter is monitored both at regular rounds and remotely through the monitoring system.

The inputs of the external “urban” power supply and the diesel generator set are connected in parallel to each other through the ATS and their outputs feed the input-distribution devices (2x ASU). From the output of two ASUs, power is supplied to 2 groups of UPSs, respectively, then from each group of UPSs, through separate busbars, is supplied to the guaranteed power supply panels (SHGP), and then directly to the machine rooms to the rack power distribution cabinets (SHS). In these cabinets, the voltage of 380 V (400 V) is divided into 230 V buses to power computer and network equipment. UPSs provide a European standard 400/230 V.

Four separate busbars from two independent sources come to each engine room, and they are laid in different ways to avoid simultaneous mechanical damage. So there is a power backup according to the 2N scheme.

Accurate consumption metering

Each switchboard cabinet incorporates an intelligent device that records energy consumption in each rack with the recording of readings in a log file. Although for customers who place their servers or racks in the engine room, energy consumption does not affect the cost of rent, for data center personnel this information is extremely important. Unusually high, or vice versa, low consumption indicates a possible malfunction and requires the attention of personnel.

From distribution cabinets, power is also supplied to the racks via 2 separate cables (by customer order, including with an ABP device in the rack). Servers with 2 power supply units (PSUs) are connected to sockets from different inputs into the rack, and equipment with one PSU is connected to ABP sockets (optional).

Maintenance and monitoring is the key to reliable power supply

Regardless of the degree of reliability that was originally laid in the power supply system of the data center, the equipment requires constant monitoring and regular maintenance. All information about the status of power supply systems, including diesel generator sets, is collected on large screens in the Monitoring Center. In addition, in the event of deviations from the norm, messages come to the tablets of duty engineers.

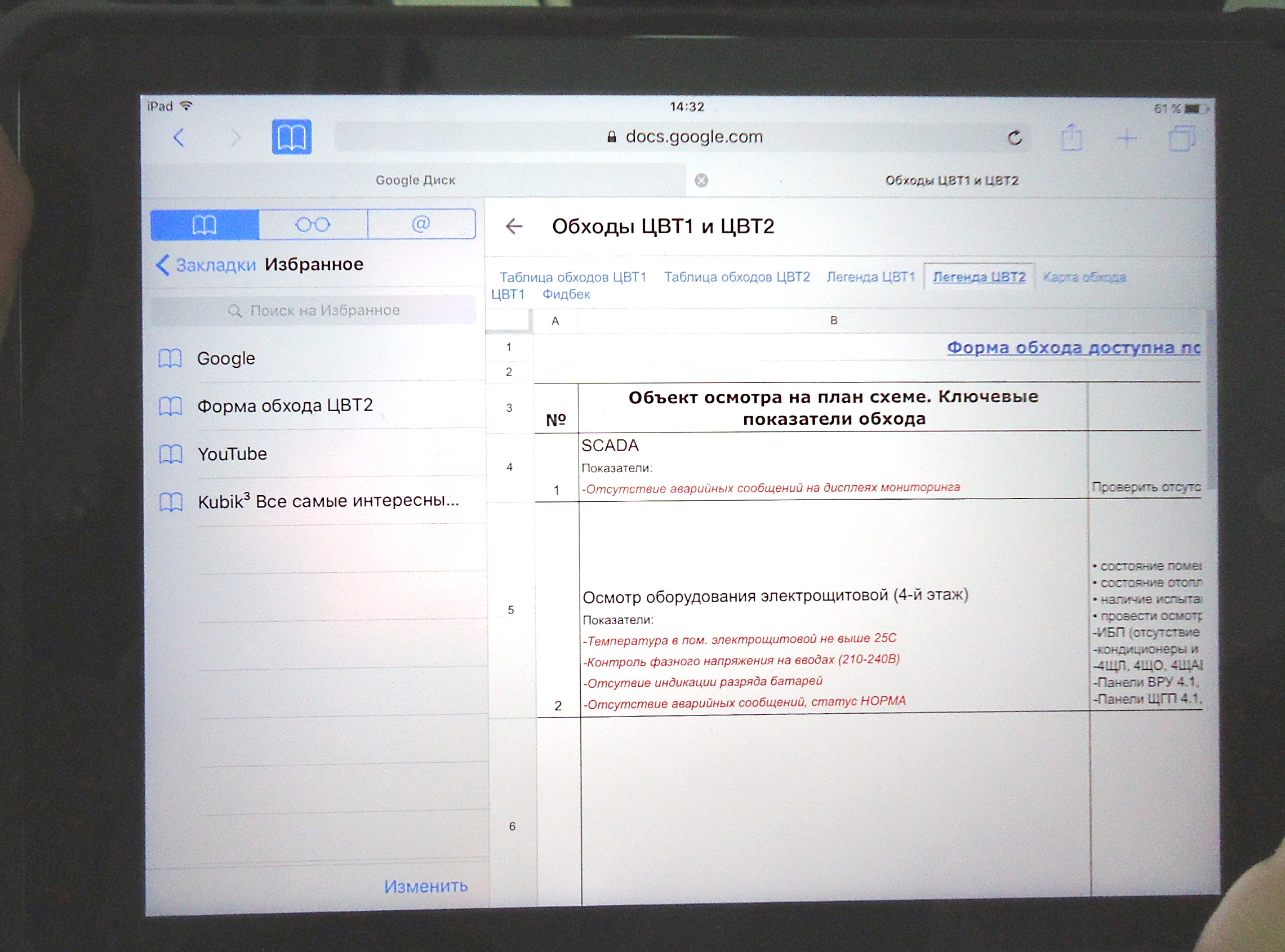

According to the regulations, duty engineers and electricians make constant rounds of the machine rooms and, accordingly, the premises where the power electrical equipment is located. Each employee has a tablet with an inspection plan. On the tablet, in addition to the bypass plan, there is also a description of the inspection task at each bypass point.

After inspecting a room or a site with equipment, the employee makes a mark on the tablet, and at the end of the tour, a tour protocol is automatically generated, which is stored in the data center archive. Outwardly, this is similar to how pilots always read out the instructions (check list) for checking the aircraft systems before takeoff, even if they know this instruction by heart.

In addition to monitoring, electrical equipment undergoes regular maintenance with a certain frequency. Initially, it is inspected in working condition with the help of a thermal imager for warming contacts, then it turns off and all contacts are pulled. At the same time, dust is removed from the cabinets and other units. By the way, access to premises with equipment is allowed only in shoe covers, and in some of them also in dustproof overalls. Here is such a sophisticated electrical household that powers Selectel customers' servers and network equipment.