Review of Anet A6 and Anet A8 3D Printers

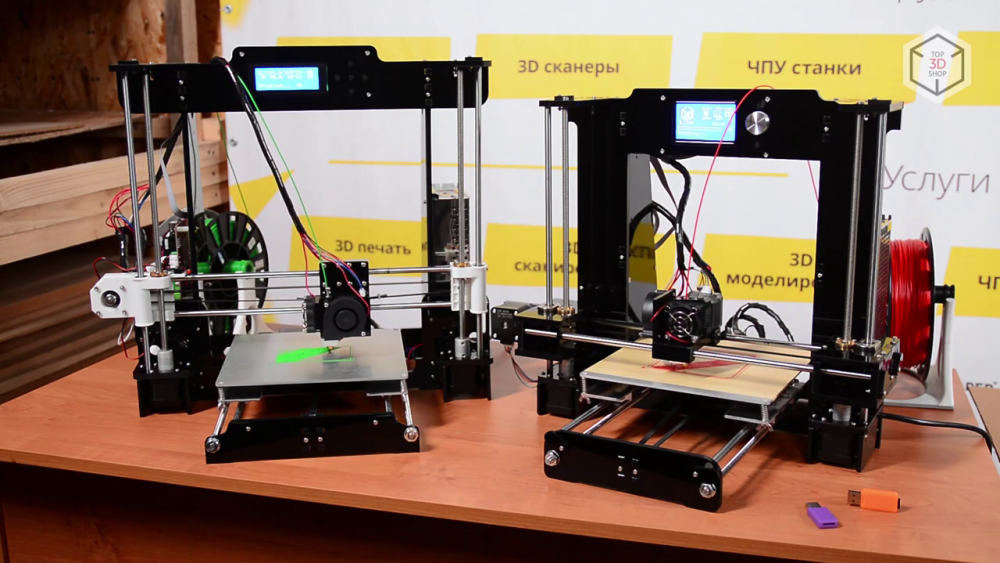

Hello! With you Top 3D Shop and in the next review of 3D equipment, we will tell you about the Anet A6 and A8 FDM printers .

Video

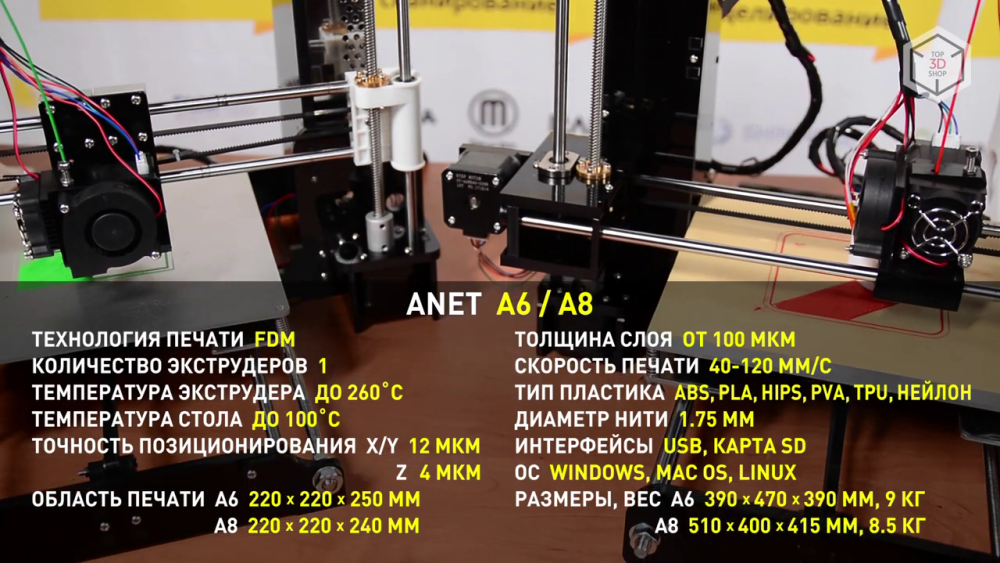

Anet A6 / A8

Specifications

- Printing technology: FDM

- Number of extruders: 1

- Extruder temperature: up to 260˚C

- Table temperature: up to 100˚C

- Layer thickness: from 100 microns

- Positioning accuracy: X / Y - 12 microns, Z - 4 microns

- Printing area: 220x220x250 mm (A8 - 220x220x240 mm)

- Print speed: 40-120 mm / s

- Plastic Type: ABS, PLA, HIPS, PVA, TPU, Nylon

- Thread Diameter: 1.75 mm

- Interfaces: USB, SD cards

- OS: Windows, Mac OS, Linux

- Dimensions, weight: 390x470x390 mm, 9 kg (A8 - 510x400x415 mm, 8.5 kg)

- Price A6 - 15200 rubles, A8 - 13600 rubles, A8M Double - on request .

Description

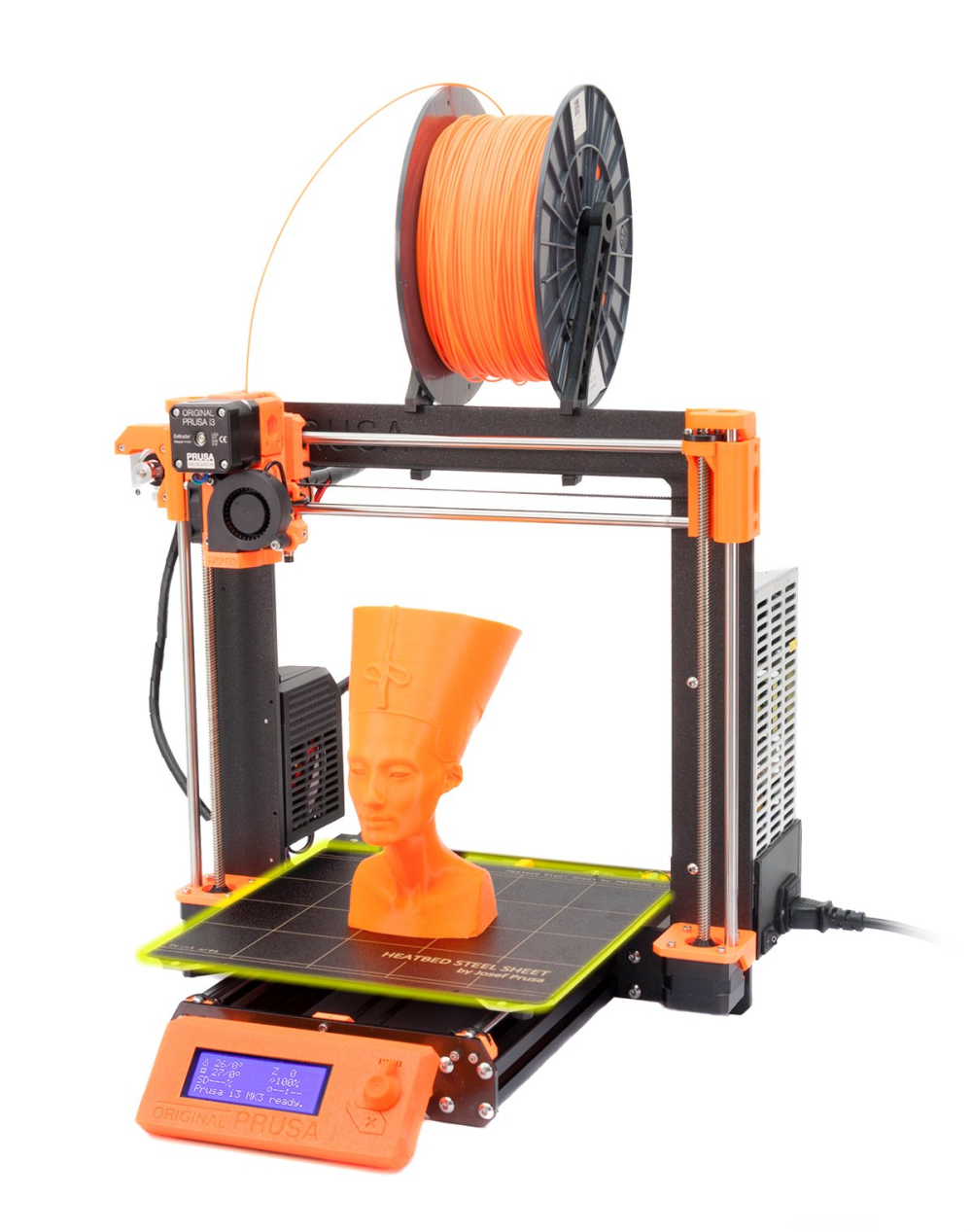

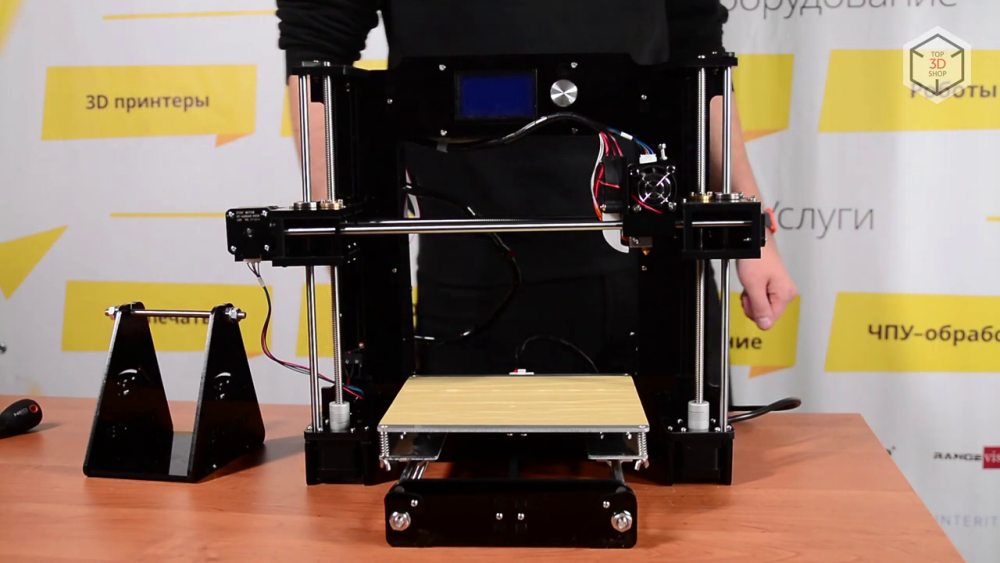

Anet A6 and Anet A8 are the most popular among self-assembled 3D printers. This is an affordable alternative to the legendary — and not cheap — Prusa i3 printer.

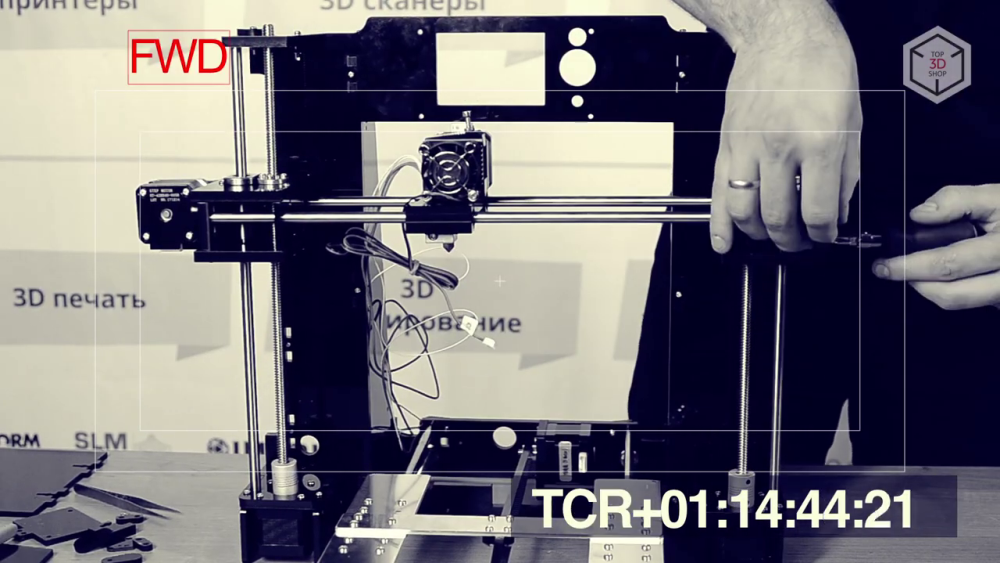

Devices "Anet" are supplied fully disassembled. There is an opinion that it is very very difficult to assemble these printers by yourself. To refute this misconception, we decided to shoot the entire assembly process of Anet A6.

Assembly

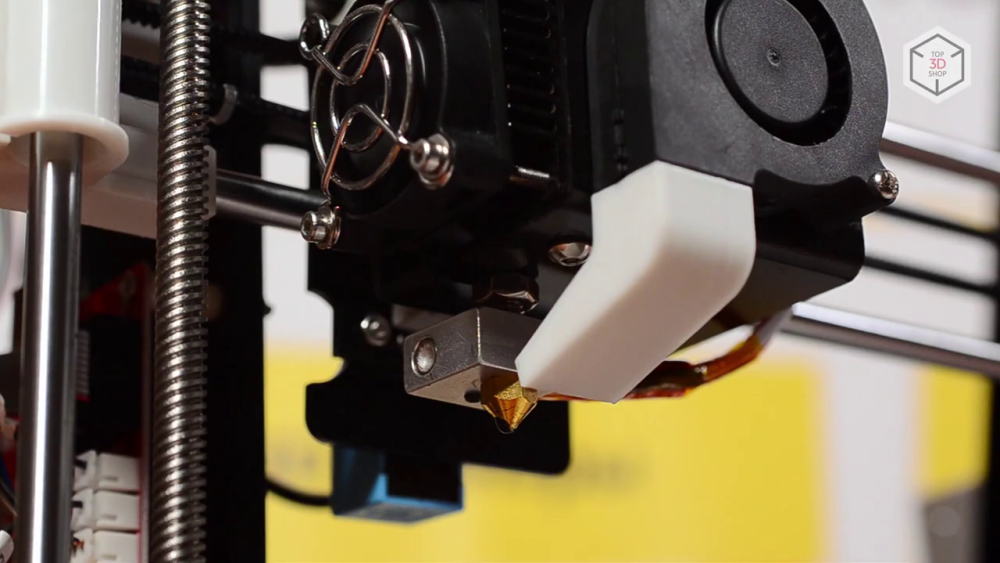

After assembling the frame and guides, the engineer proceeds to the installation of the stepper motors and the heated table. The next step is to install the extruder. And we will continue the story about these printers on the example of the model A8.

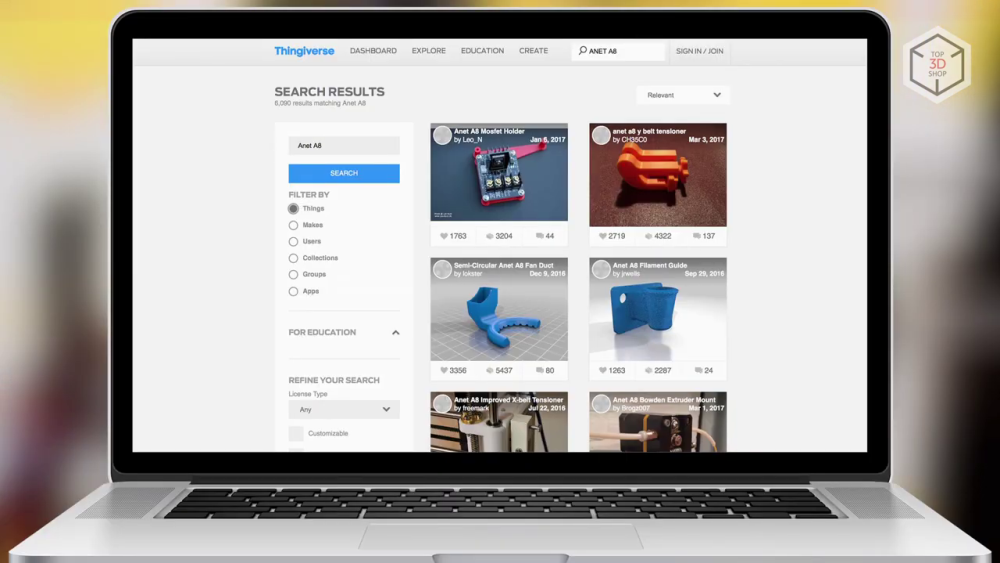

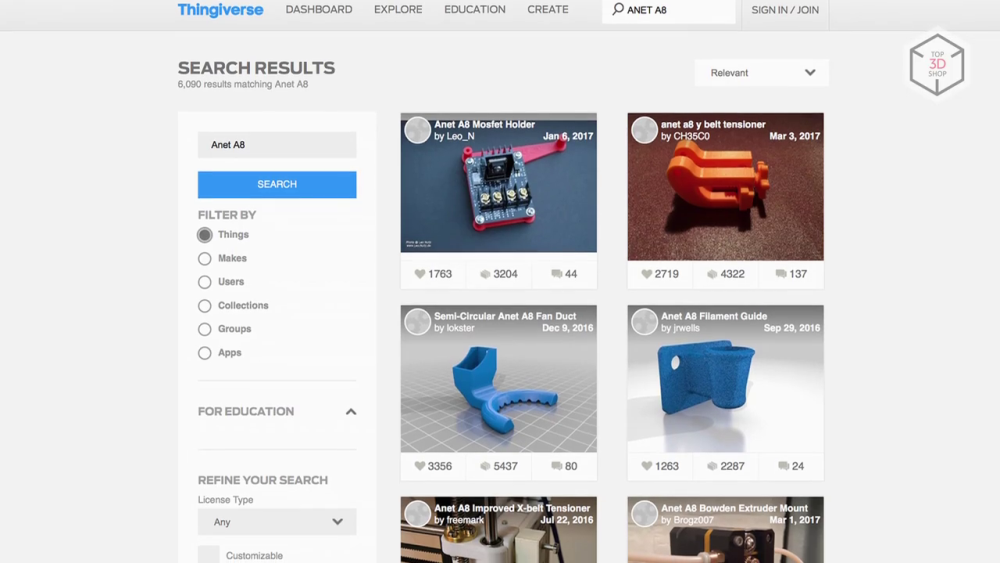

These devices attract novice 3D printers not only at low prices. With proper configuration, they are ready to work with a variety of plastics. In addition, there are options for self-refinement of their design - only on Thingiverse can you find dozens of 3D-models for the upgrade.

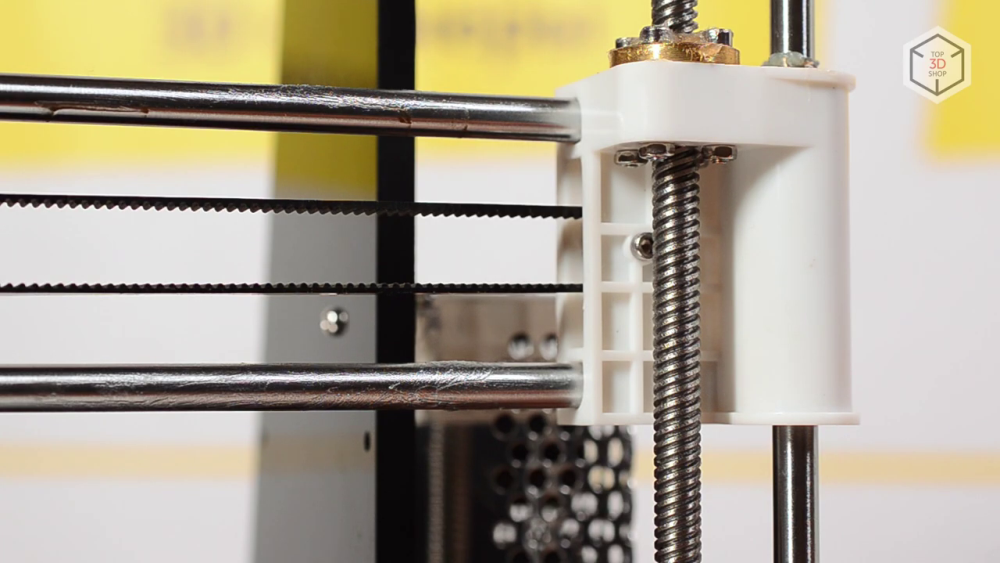

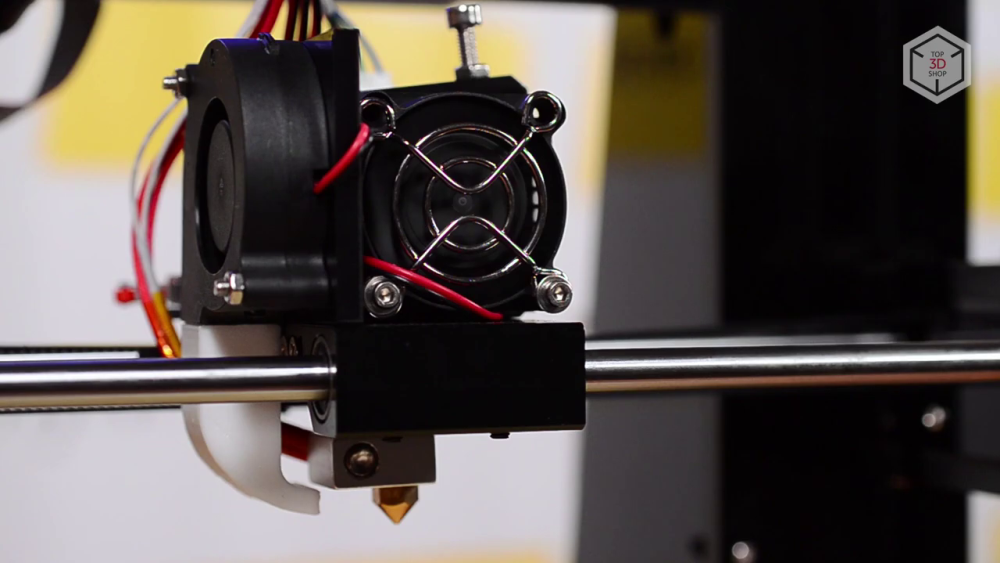

Anet A8 and A6 have an acrylic frame, equipped with single-extruder and heated table. The operating temperature range allows you to work with common types of plastics - ABS, PLA, HIPS, PVA.

To some, such a design may seem too simple, but we will attribute this to the advantages — access to the nodes, tuning and upgrading are simplified.

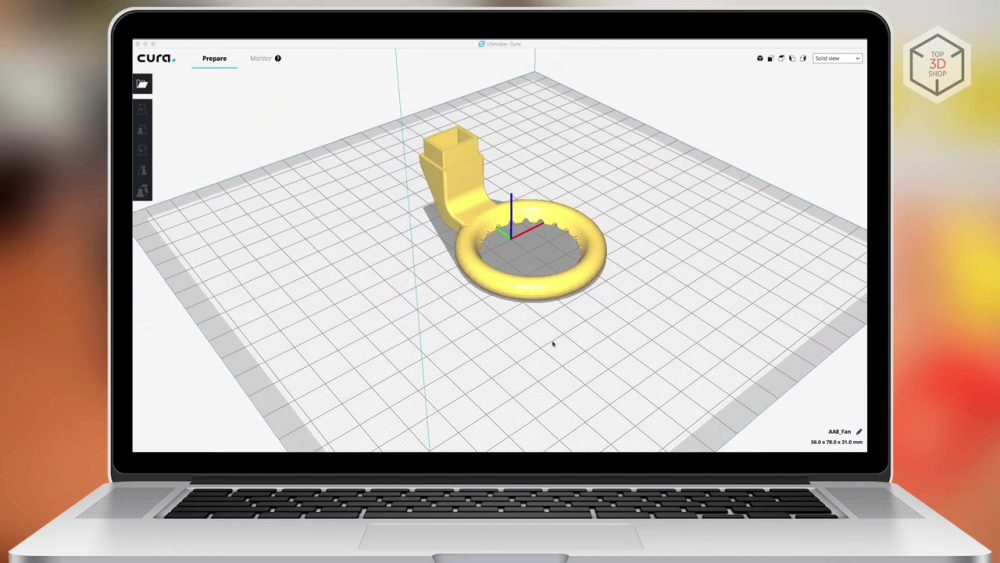

To prepare a 3D model for printing on Anet printers, you can use any available slicer - it comes with a flash drive with installation files Cura and RepetierHost.

Let's return to assembly "a-sixth". The engineer installs the power supply and display. It then places the motherboard and limit switches.

Paper instructions are not included - all documentation is supplied on the included USB flash drive. In the network you can find video on the assembly, but not all of them are relevant - the manufacturer periodically makes changes to the design.

The final stage is switching. The engineer connects all the components of the printer to the motherboard: extruder, motors, table, power supply, limit switches and display.

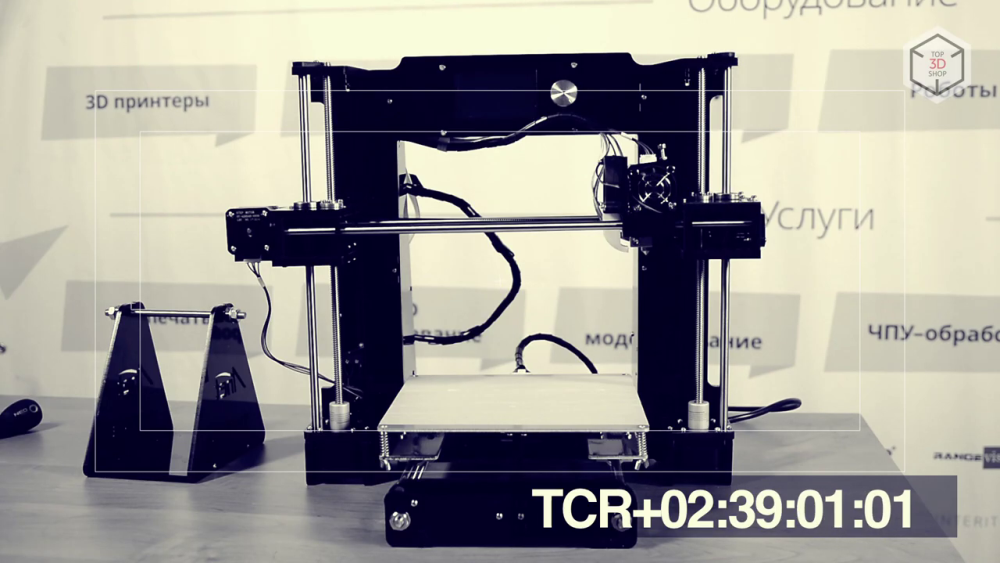

Printer A6 is ready to go. The entire assembly process took less than three hours.

Differences

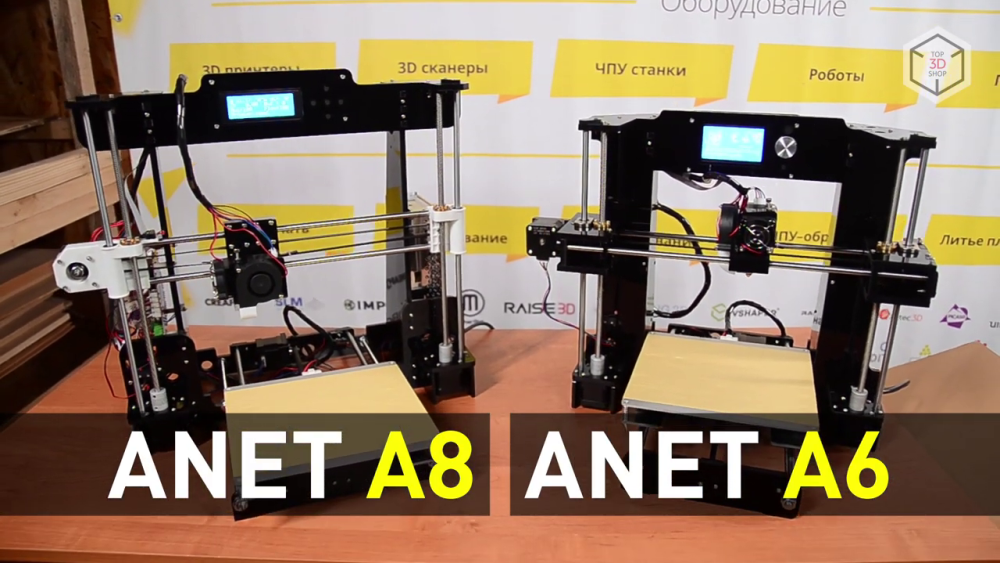

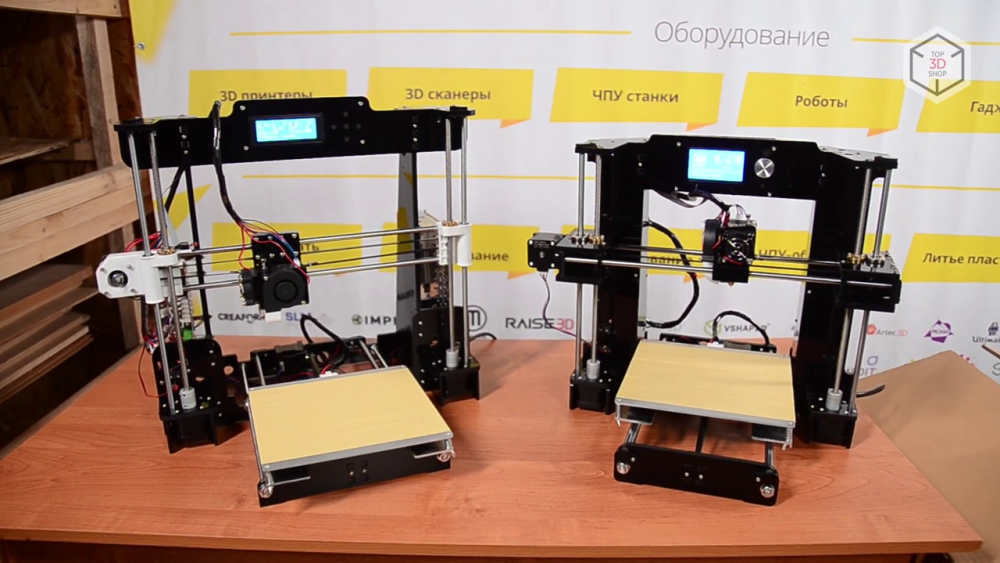

Compare now both models. Anet A6 and A8 have a similar design. But they also have significant differences.

Model A8 is larger than “a-sixth”, but their print areas are almost the same.

The second noticeable difference is the placement of the extruder. In "Aneta A6" it is horizontal. It is believed that this feature, coupled with a less vibration-prone frame, increases the stability of printing.

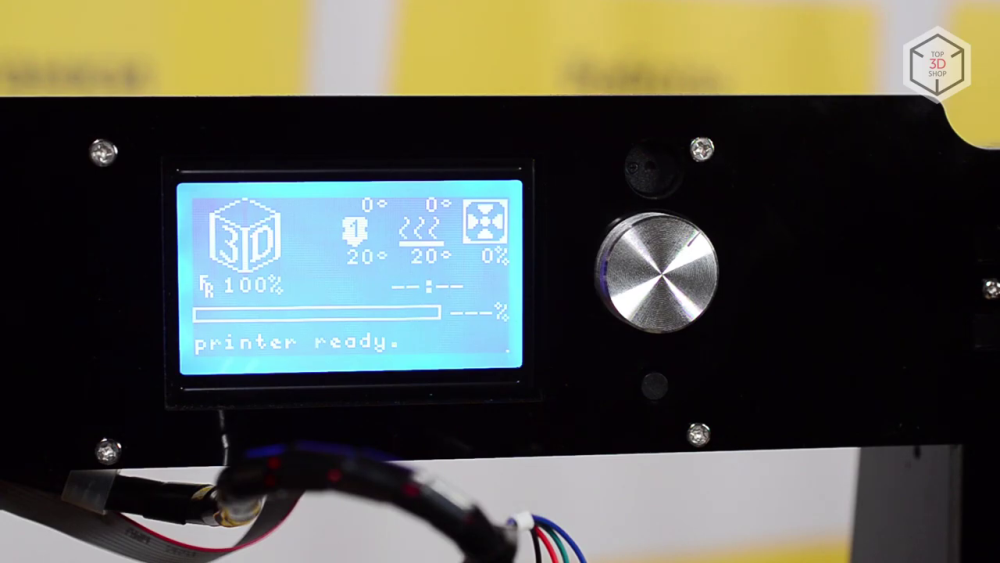

Finally, the “a-sixth” model is easier to manage - it is equipped with a more informative display, a multi-function control knob and can beep once printing is completed.

However, today the Anet A8 is considered more popular. It is somewhat cheaper, and this is an important factor of choice for the budget segment. Plus - it has more documentation. Both official and prepared by the owners. If you collect a 3D printer yourself, there is not much information. Another point - for the A8 there are a large number of modifications from the user community. They can be found on Thingiverse.

Anet A8 has a modification of the A8M Double, it differs from the basic printer by the presence of two heads and the possibility of printing with two materials.

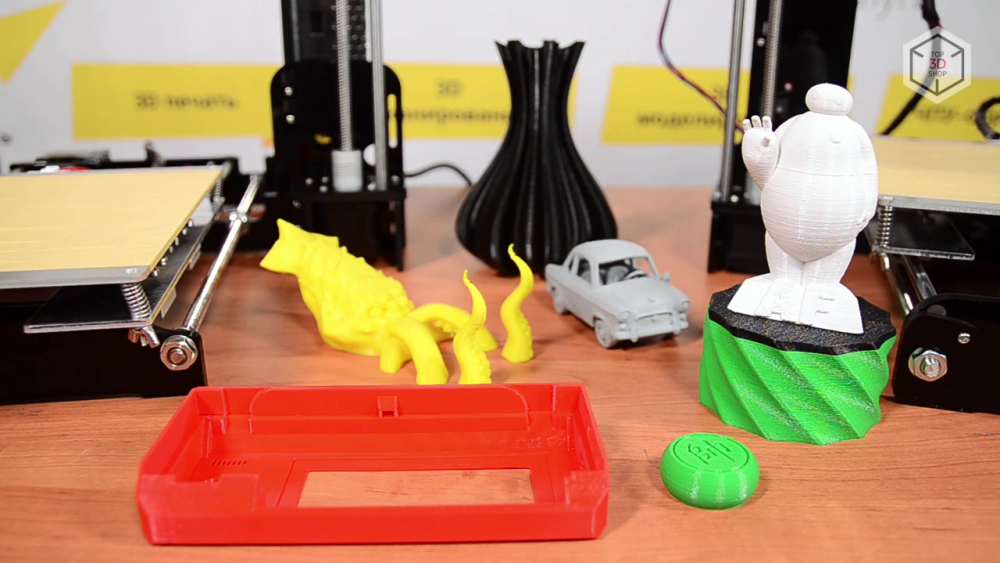

The print results of both models are very high quality, especially considering the low price of these 3D printers.

Yes, the assembly of "Anetov" will be more difficult than puzzles from "Ikea". Especially if you take the first steps in 3D printing. But "mission is feasible." The main thing - do not rush. If you want to get a ready-to-use, calibrated device, contact Top 3D Shop - a paid assembly is performed by experienced engineers.

Price, the possibility of modifications, high-quality prints - the reasons for recommending Anet A6 and A8 3D printers.

These devices are a great tool for homemade artists who are willing to spend time constantly improving print results. In addition, "Aneta" will be useful to makers who are experiencing the need for budgetary additive technologies.

Choose an inexpensive printer? Contact us at sales@top3dshop.ruand we will select the optimal device for your requirements and capabilities.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks: