All that you did not know about the new SOLIDWORKS 2019 and did not have time to ask

Everyone who follows the news of the CAD market knows that Dassault Systèmes held

an interactive event on SOLIDWORKS FORUM on October 2 and introduced the updated SOLIDWORKS 2019 design system .

The new version of SOLIDWORKS - a huge step forward. Changed product interface, significantly improved performance. We will tell about all this below.

SOLIDWORKS 2019 is a design system built on the basis of the Dassault Systèmes 3DEXPERIENCE platform . It covers the entire process of developing industrial products and, in particular, helps to solve complex problems arising in the design of parts.

The new version of SOLIDWORKS can highlight several important new products and improvements.

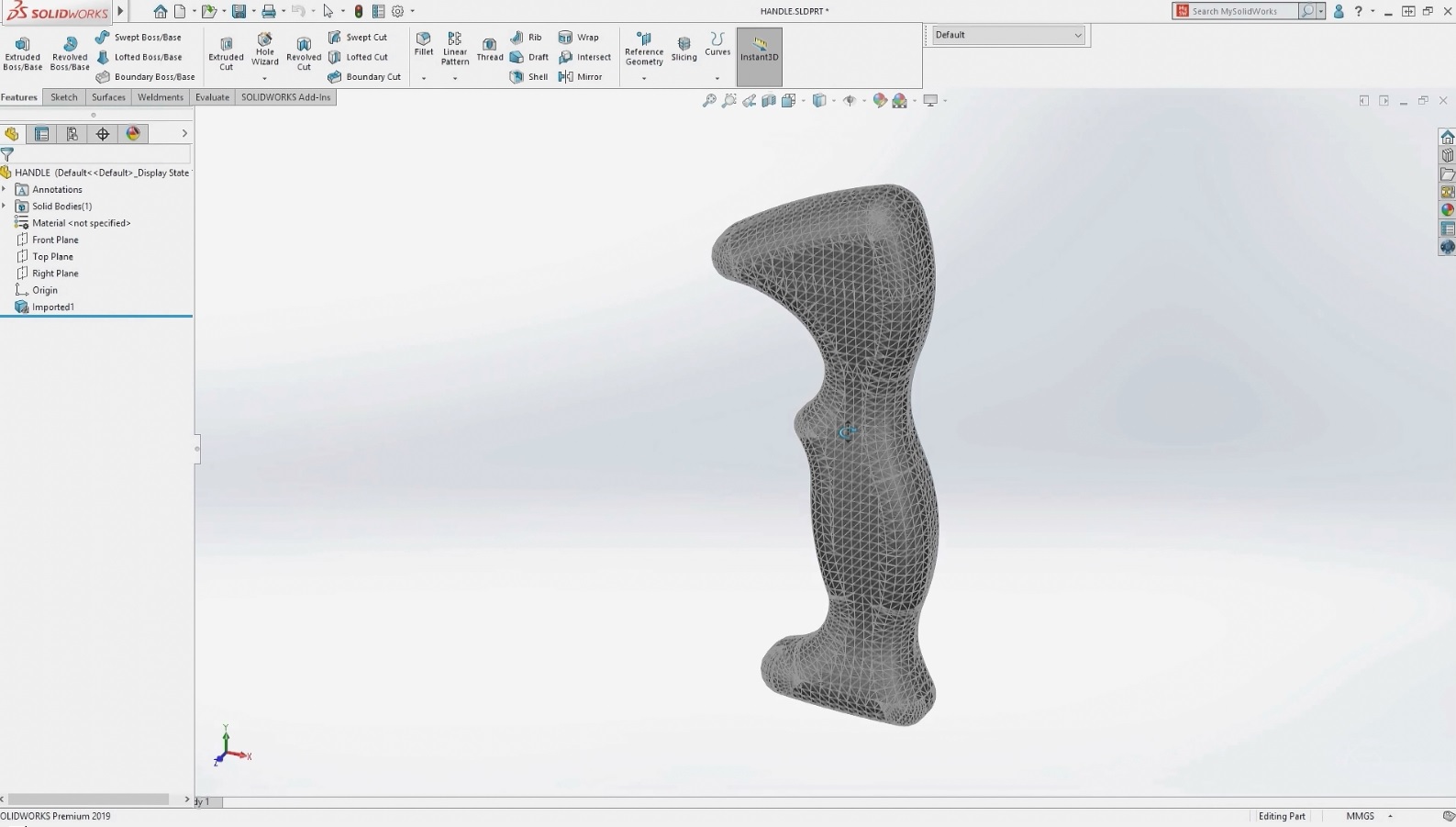

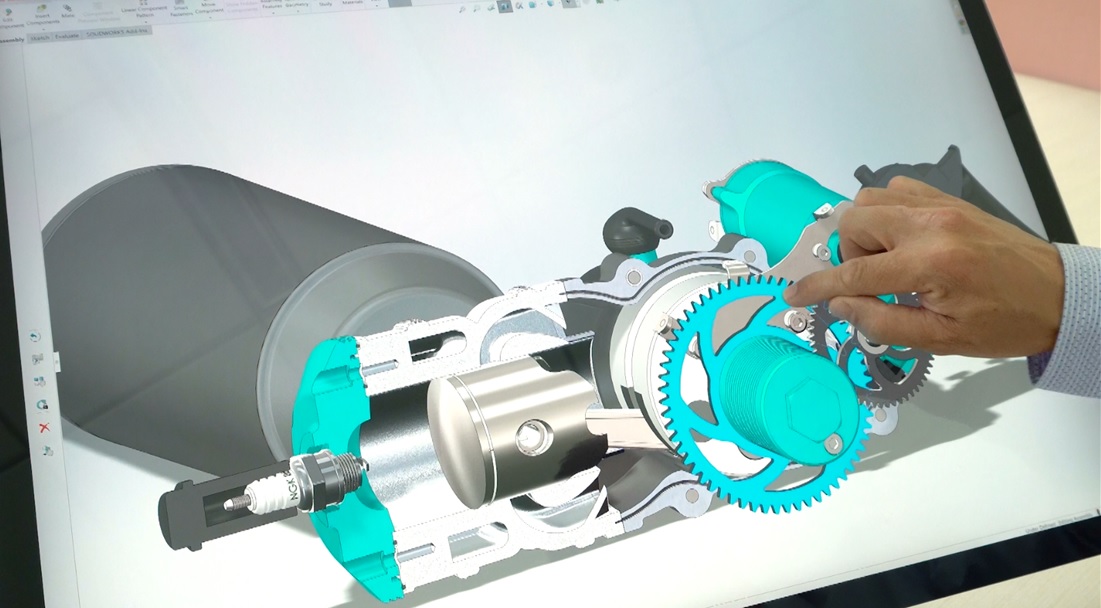

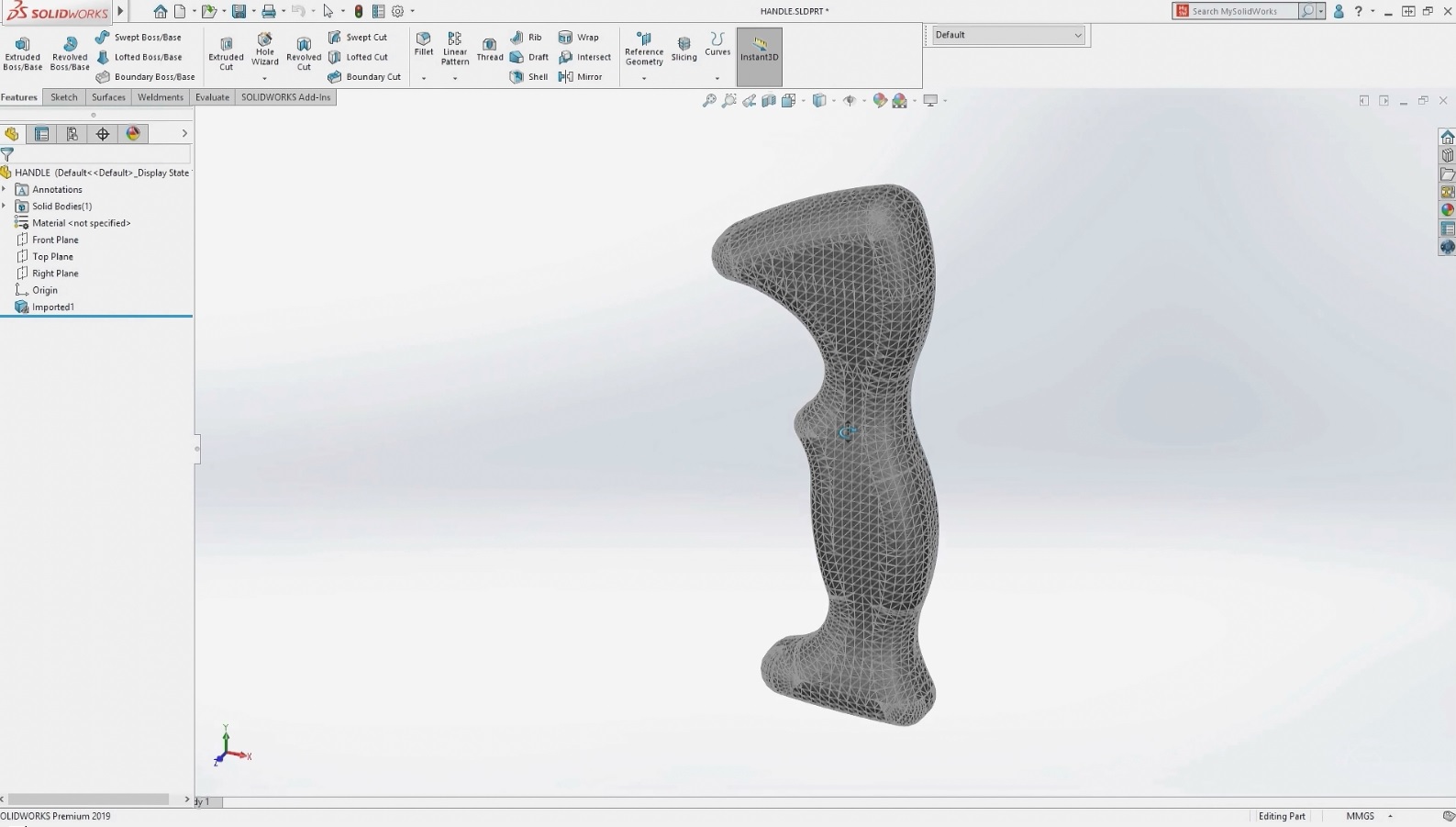

Improved performance with mesh geometry. Particular attention is paid to tools that accelerate the creation of assemblies. With the help of reverse engineering procedures, grids are imported and solid-state models are created for transfer to production.

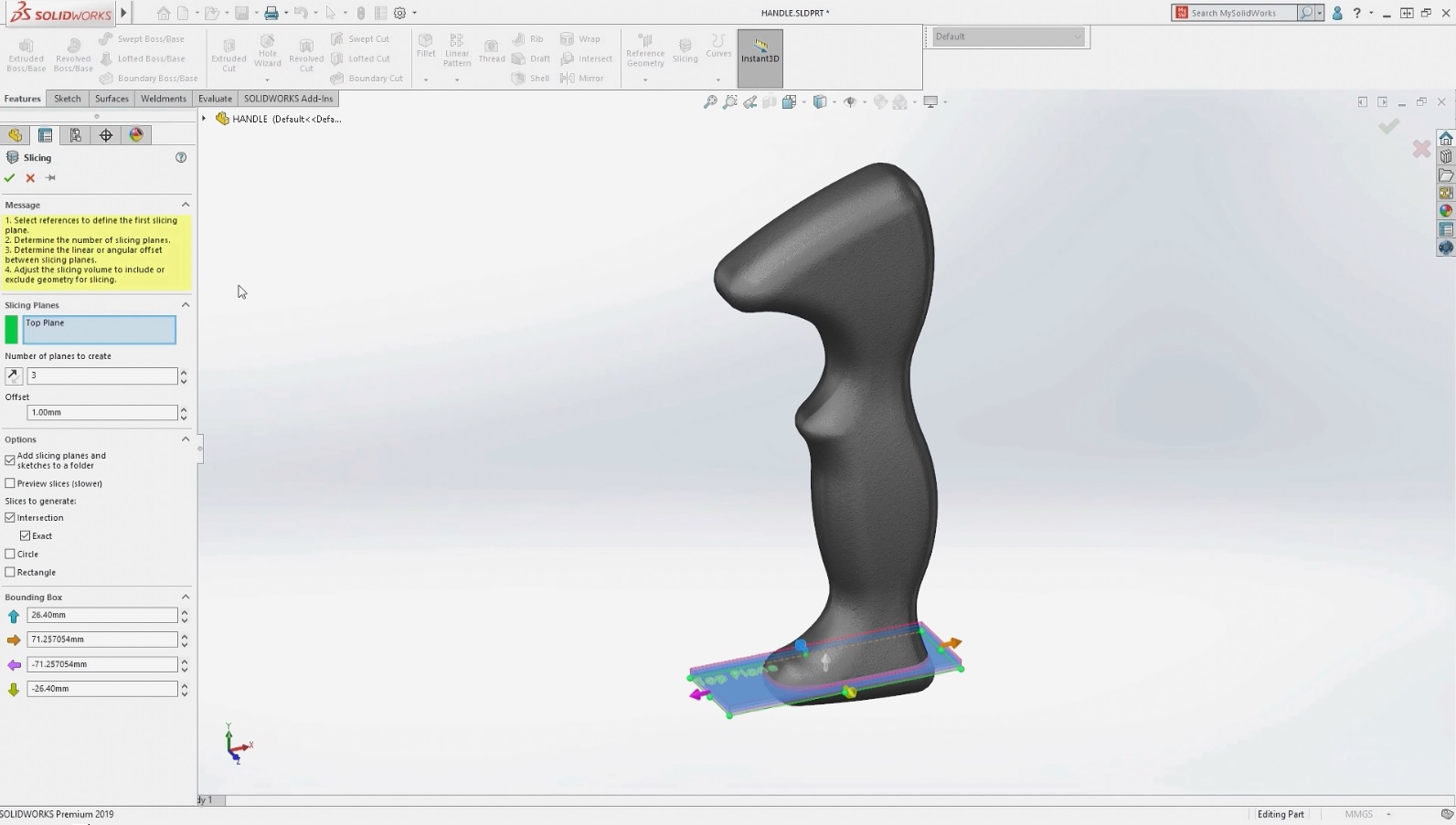

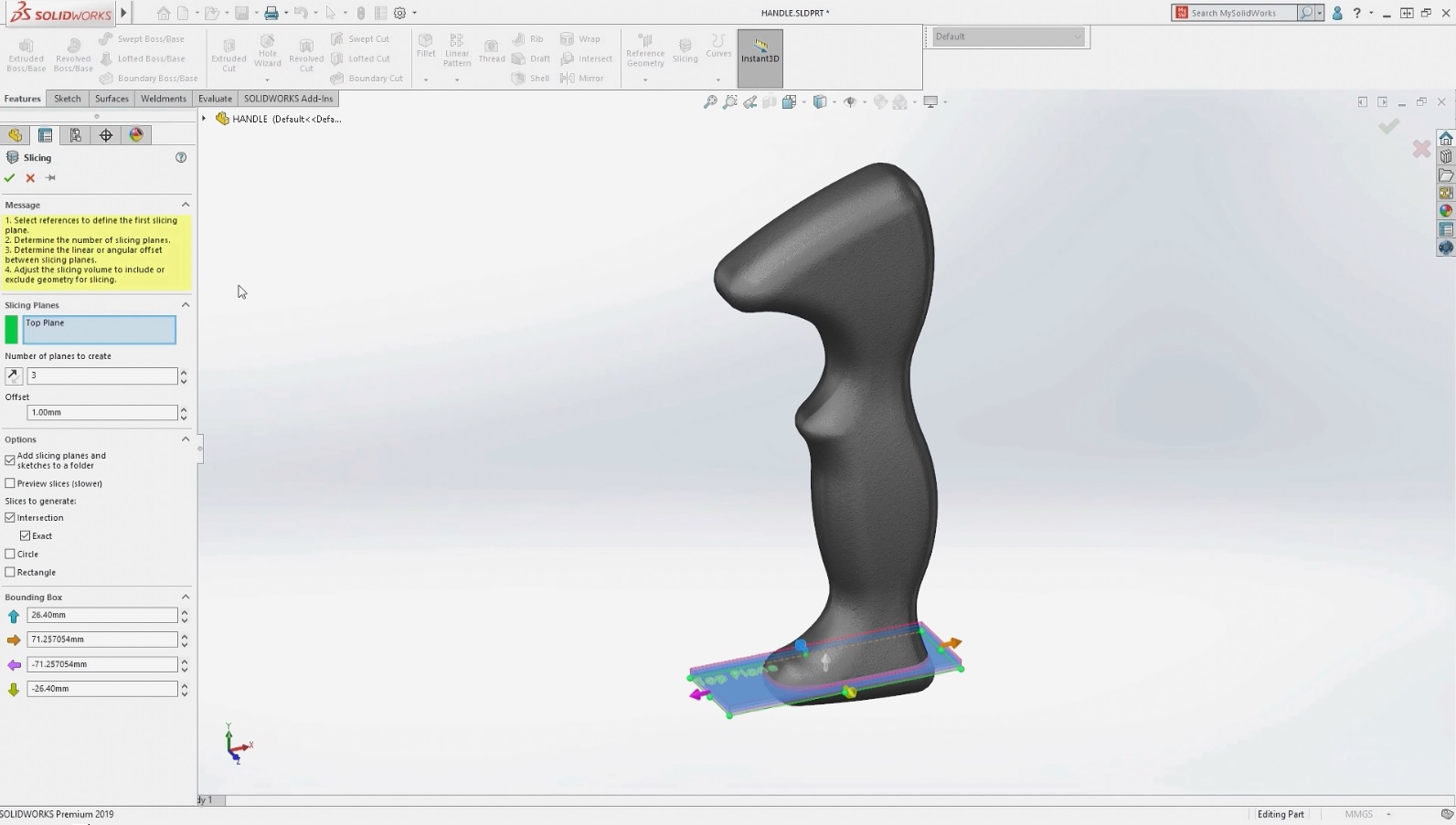

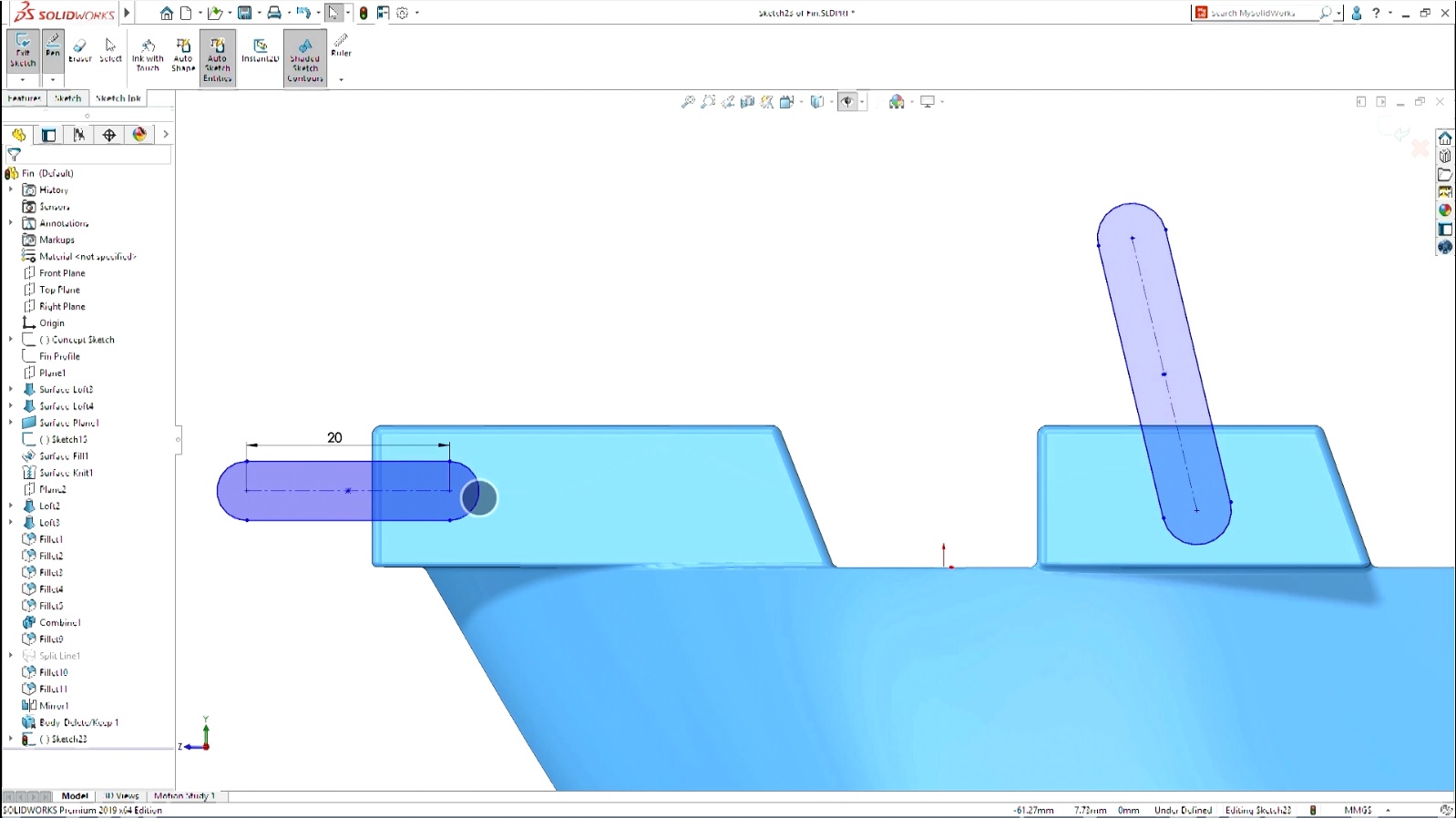

A tool for creating 2D sections at the intersection of the grid and a set of planes has been added to the product. To do this, it is enough to set the number of cutting planes and the distance between them. The resulting sketches-sections can be further edited.

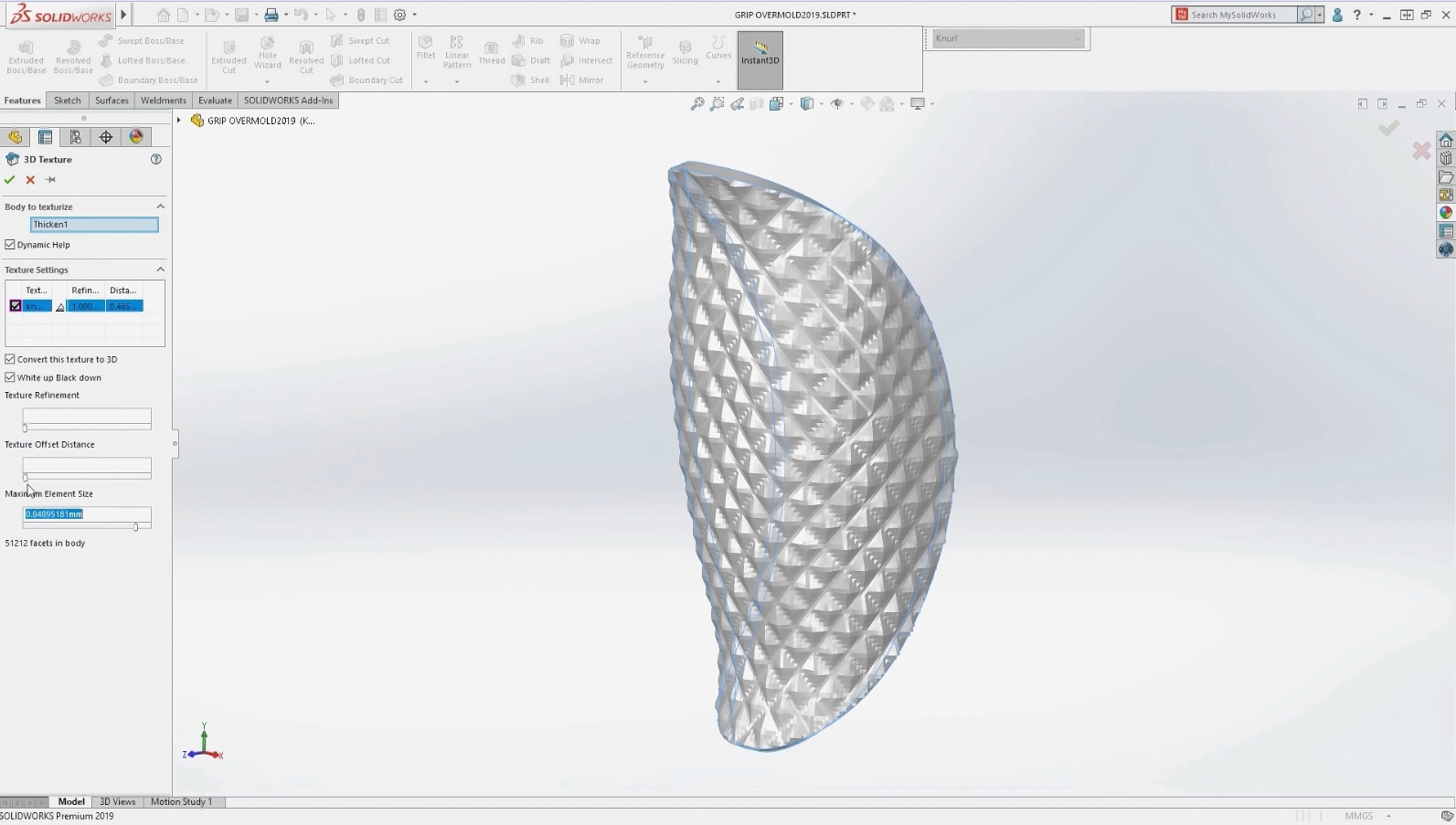

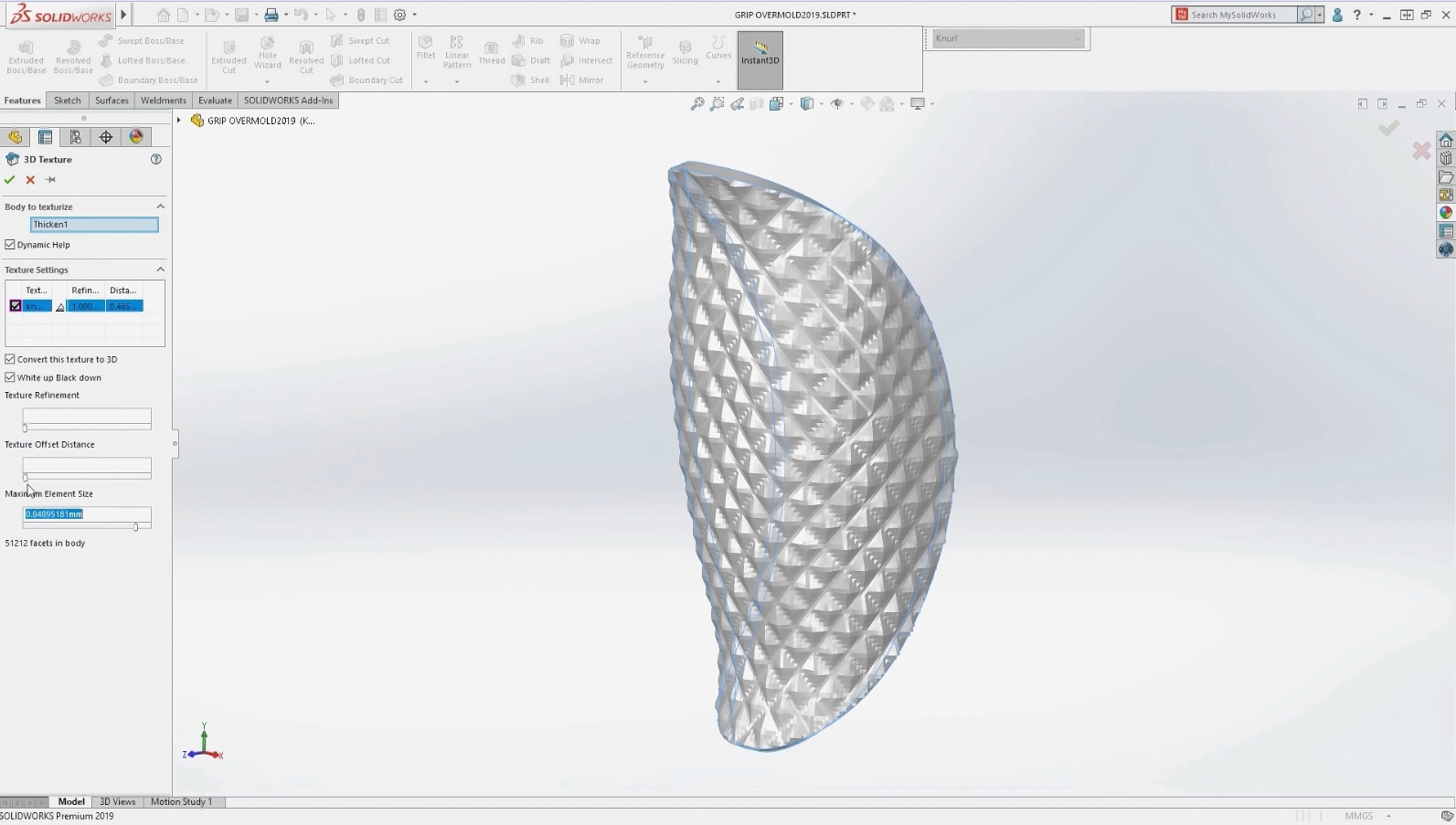

The new tool "3D-texture" uses 2D-images for the formation of spatial textures. An image placed on a surface is converted by this tool into 3D geometry.

In SOLIDWORKS 2019, a tool for checking for spatial intersections appeared. He analyzes the component parts and checks the correctness of welded structures. The function of grouping assembly dependencies by status is also available. She proposes to remove erroneous and inactive dependencies that were formed due to changes in the assembly.

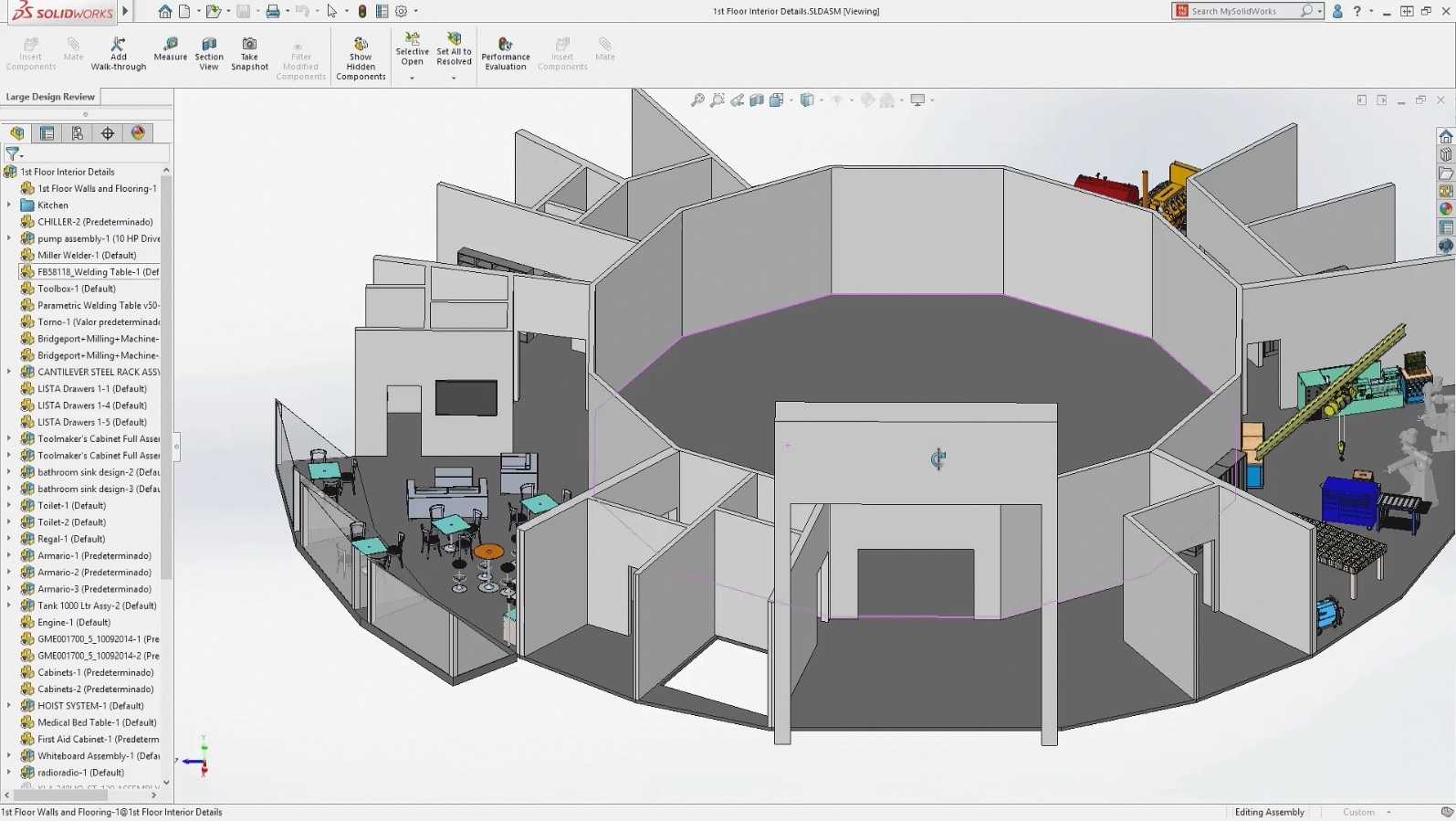

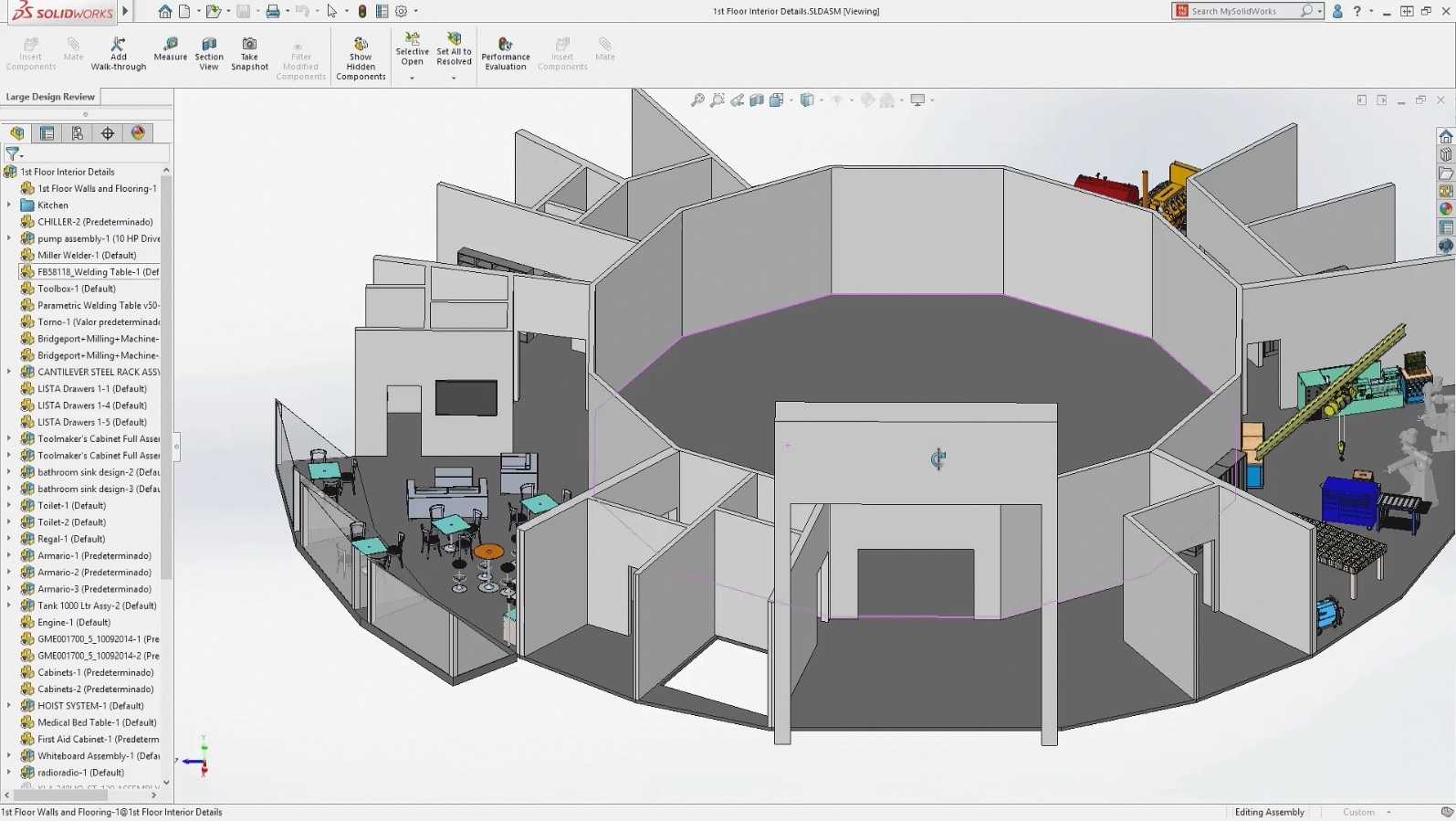

The updated version has improved viewing capabilities for large projects. Manipulations with large assemblies in real time are now much faster.

In large assemblies, you can now add dependencies between components automatically. To do this, simply select one of the components and adjust the parameters accordingly.

In the new version it is easy to open "heavy" assemblies (from 10 thousand parts and above), it is comfortable to work and edit with them.

The Defeature function is used to create simplified copies of assemblies — for example, when you transfer them to your colleagues or to demonstrate on web resources. You indicate which components should be presented in their original form, and which - in the form of simplified geometric elements (cylinders, extruded polygons, etc.) without unnecessary details. Such simplified copies give a good idea of the shape of the assembly and at the same time help protect your intellectual property.

User interface enhancements are designed to further increase productivity. The SOLIDWORKS 2019 startup page displays the icons of the 100 most recent documents, and they can be filtered by type: parts, assemblies, or drawings. In seconds, you can find the desired model by entering a fragment of its name in the search field.

The left side of the screen displays the structure of an open model, where it is easy to trace the relationships between its components. To manage external links is a new interactive dialog box.

Collaboration features are essential for a clear and fast interaction between specialists. In SOLIDWORKS 2019, 3D markers can be applied to parts and assemblies, including with a pen and touches. You do not need to take screen shots manually: notes are stored with the model and can be exported in PDF format at the right time. In this way, for example, the project manager may ask the designer to clarify the sizes of parts used in the assembly.

This is a completely new feature aimed at working with VR devices. It makes it even more convenient to work with large assemblies.

With the help of virtual reality glasses and a joystick, you can easily navigate inside your assembly, view the details in it and get the metadata of any part in real time. To do this, just point the joystick on the part and press the button.

Details marked in augmented reality mode are remembered in the project and can be worked out after exiting this mode.

The SOLIDWORKS CAM system solves most of the problems of programming modern CNC machines. Milling 3-4-5-coordinate machines (in 3 + 1, 3 + 2 modes), lathes, laser cutting machines, plasma cutting machines and water-jet cutting machines are supported.

Among the key capabilities of metalworking (CAM Milling) - automatic analysis of parts for the recognition of technological elements in its composition. It is also possible to generate a part processing plan based on the rules of the technological database (in SQL format). This is quite a convenient function, with the help of which you can use an already existing database for one or another detail or machine, or add your own. In this way, the system learns your personal preferences.

And another useful feature is the CAM NC Editor. She checks the control program code before it is transmitted to the machine. The editor supports milling and turning machines. By running it, you can see all the trajectories and adjust them if an error is detected.

Metalworking functions reduce the time required to manufacture parts.

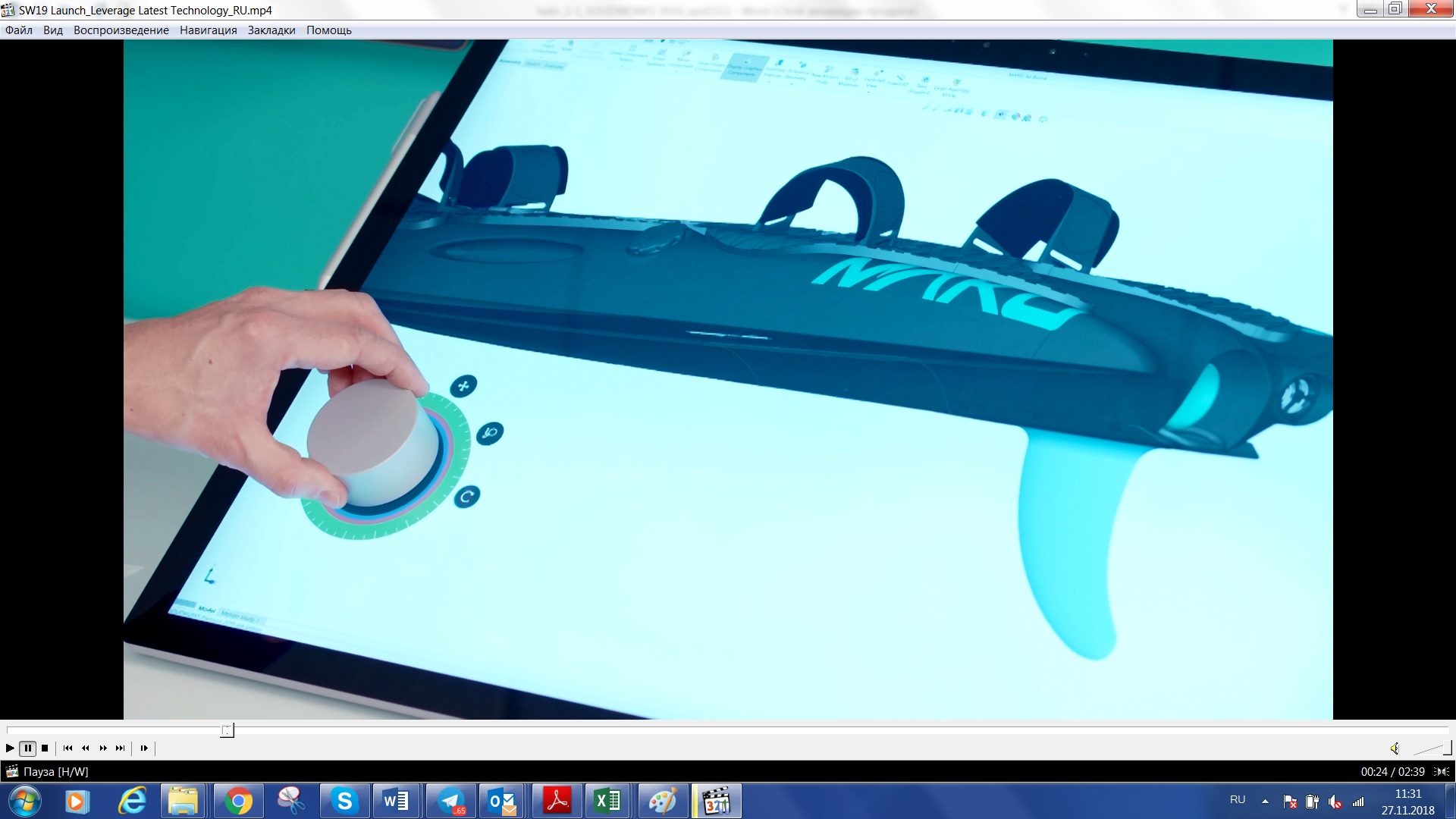

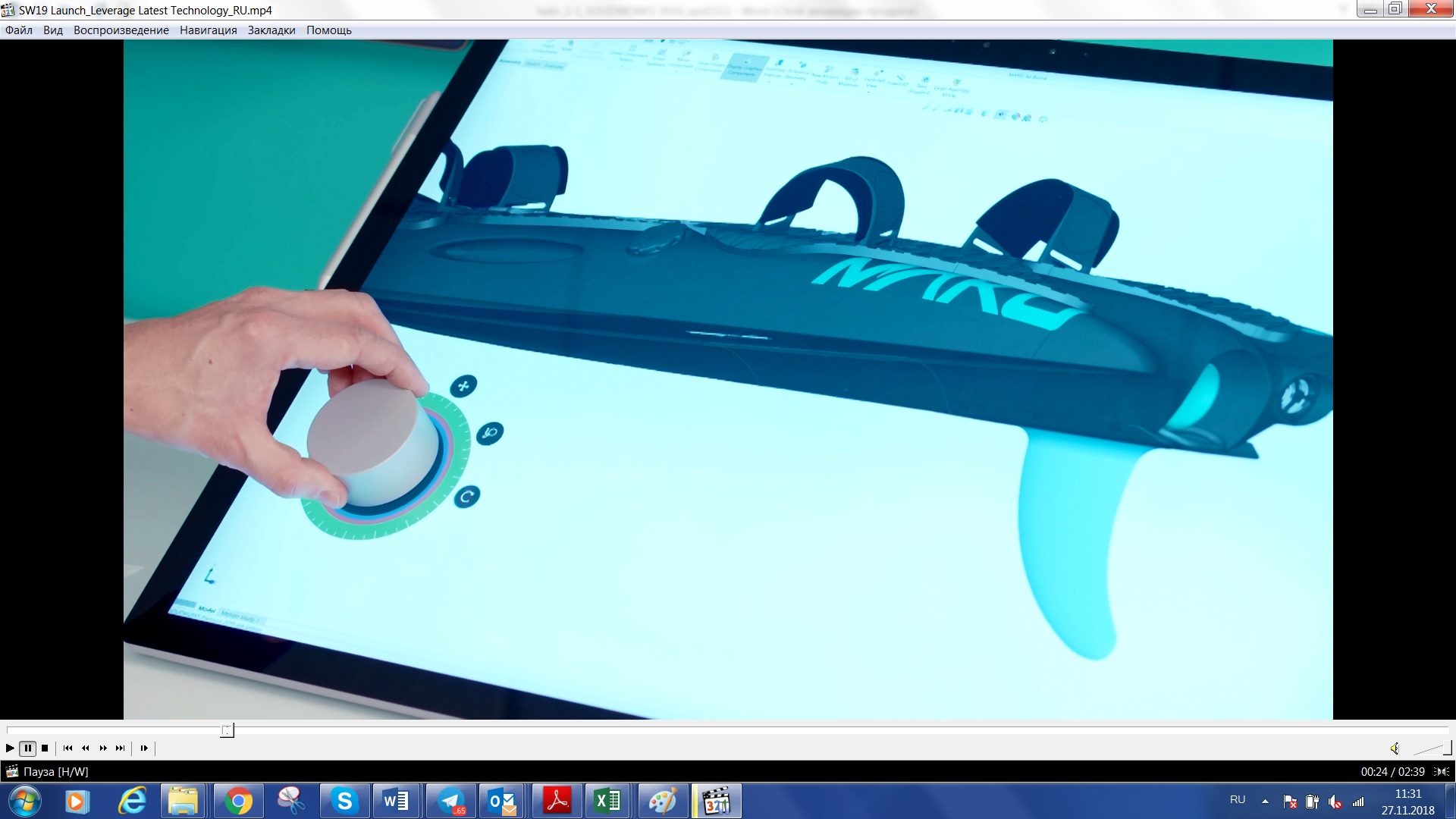

Now in SOLIDWORKS supported work with the controller Surface Dial. When the controller is superimposed on the touch screen, graphical tools appear around it to pan, zoom and rotate the element on the screen.

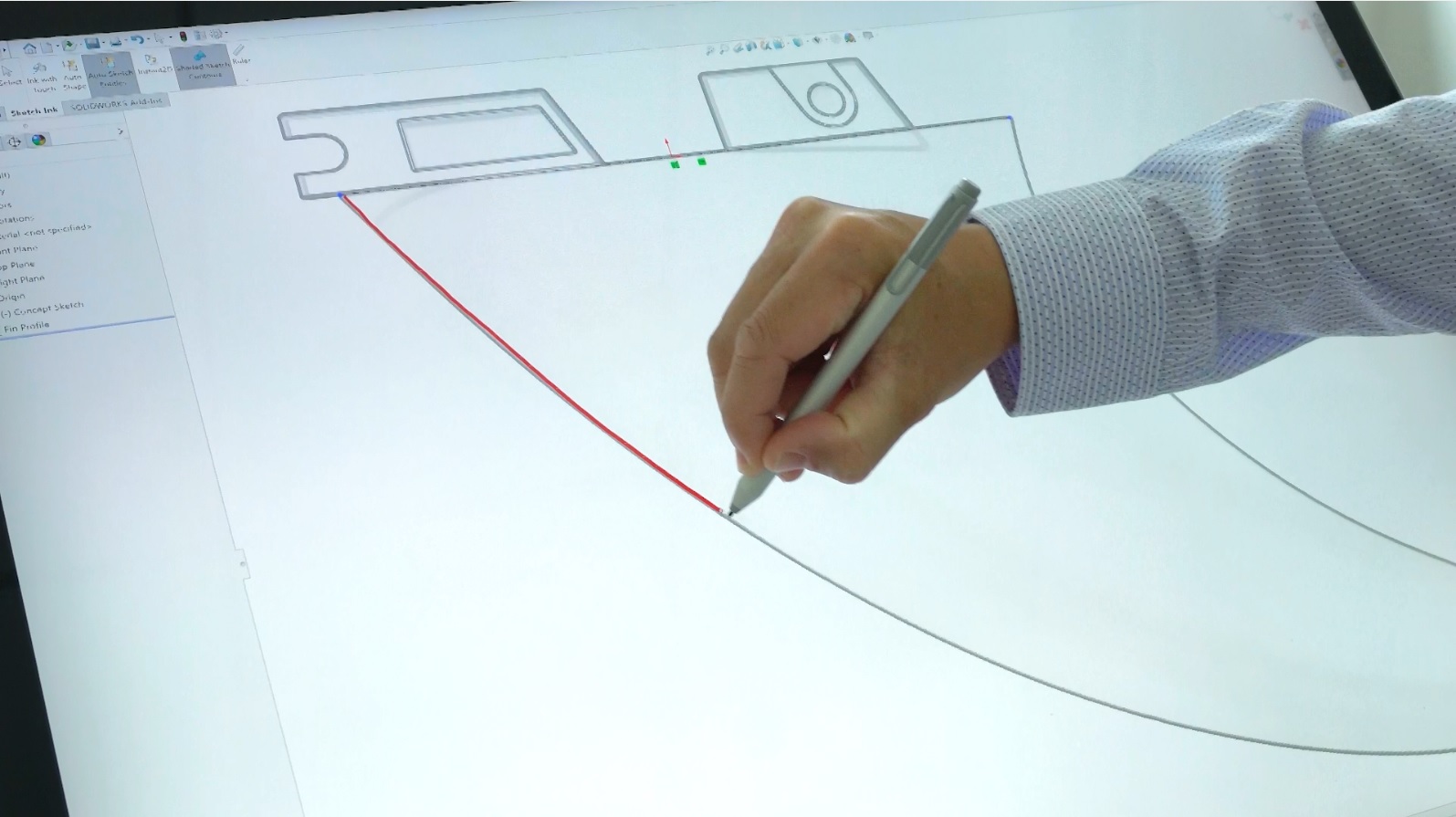

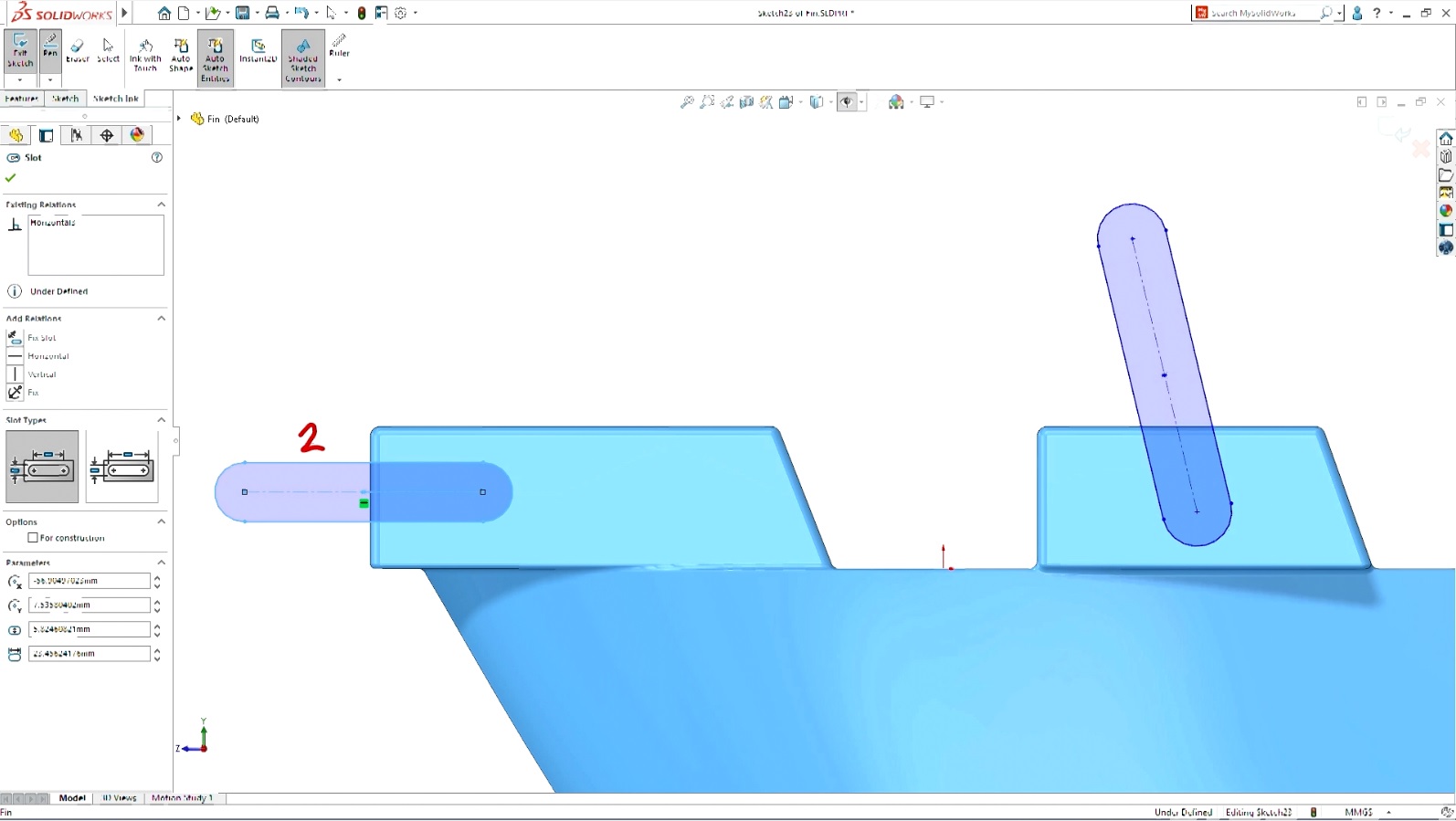

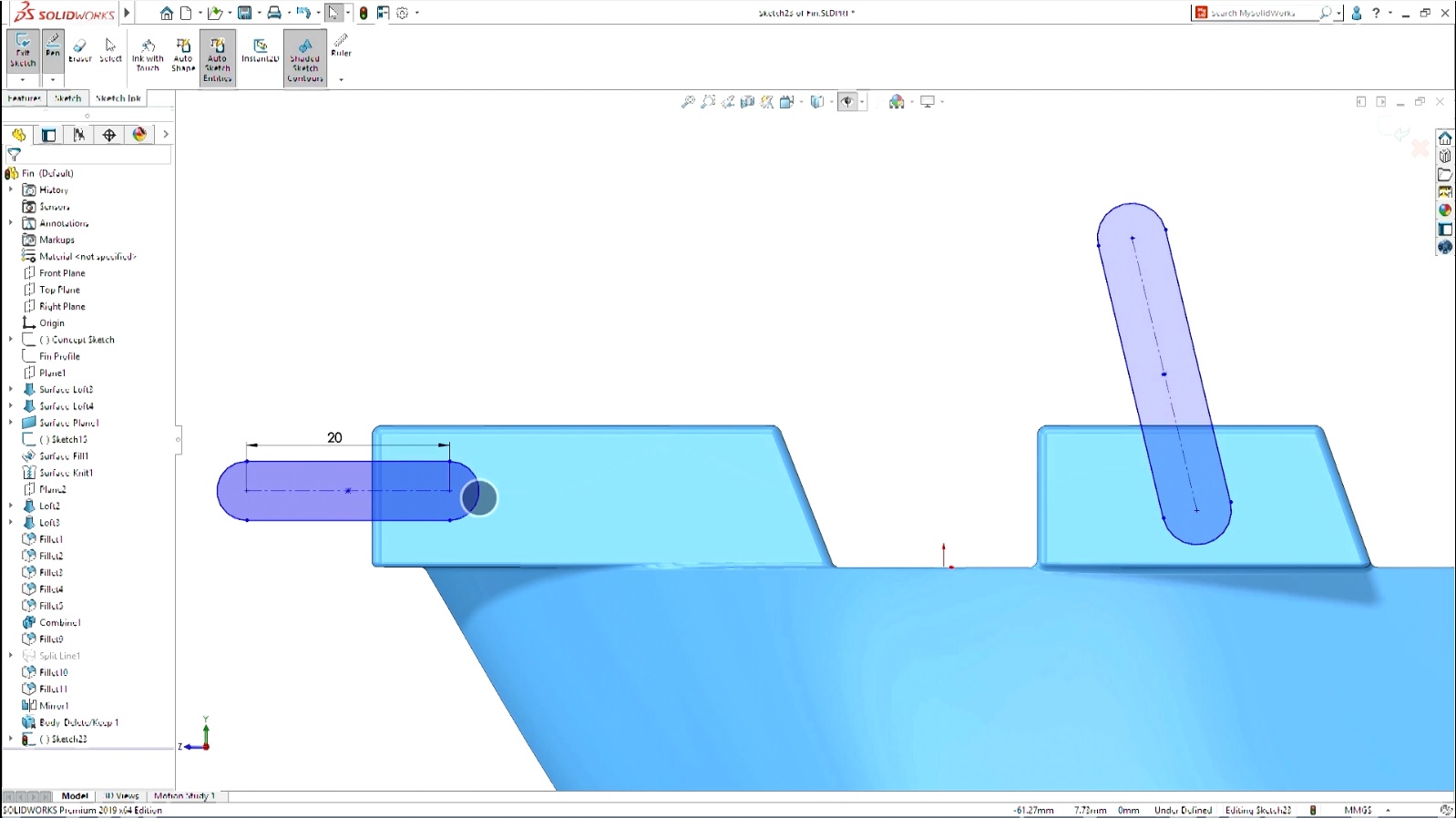

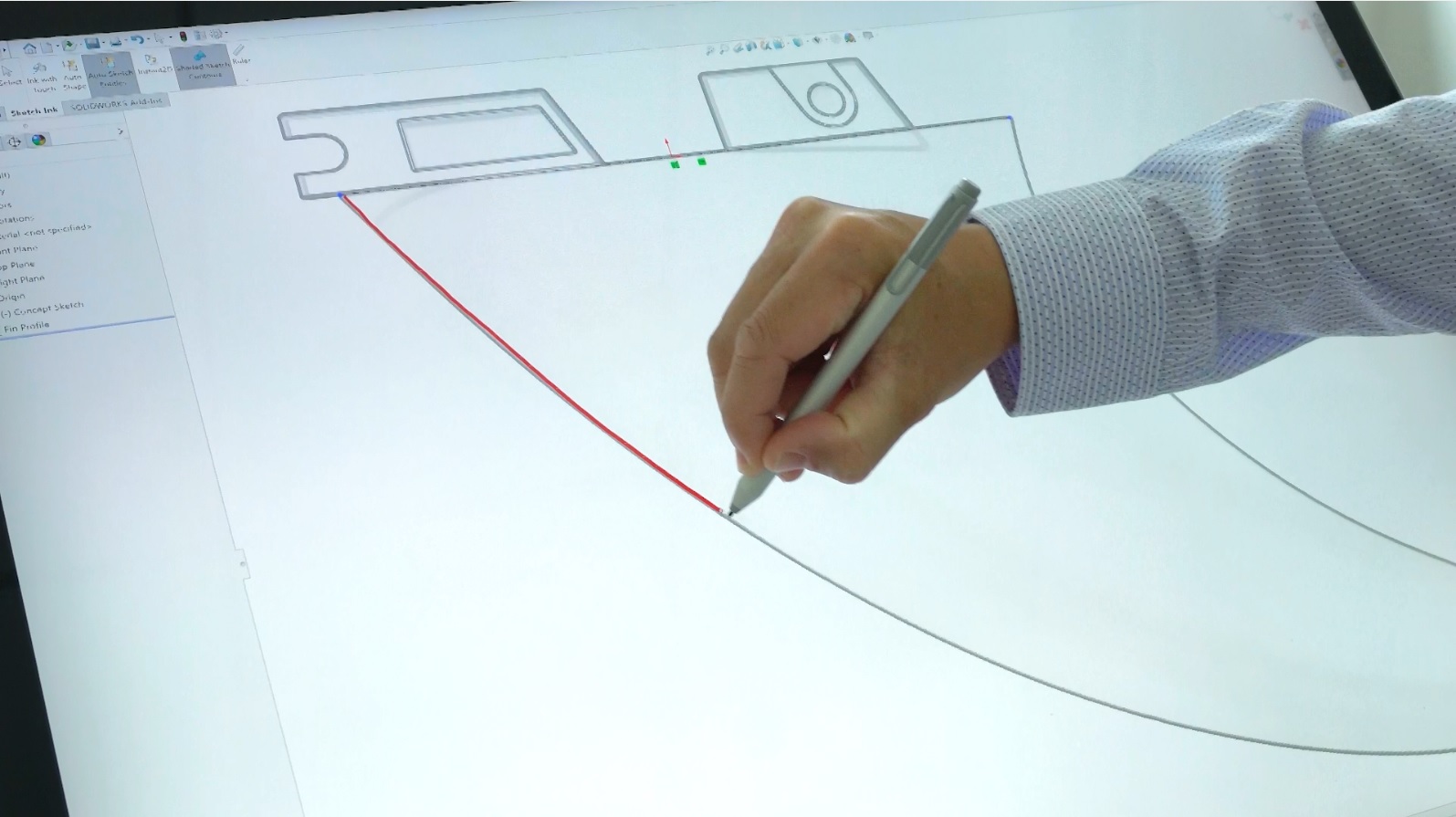

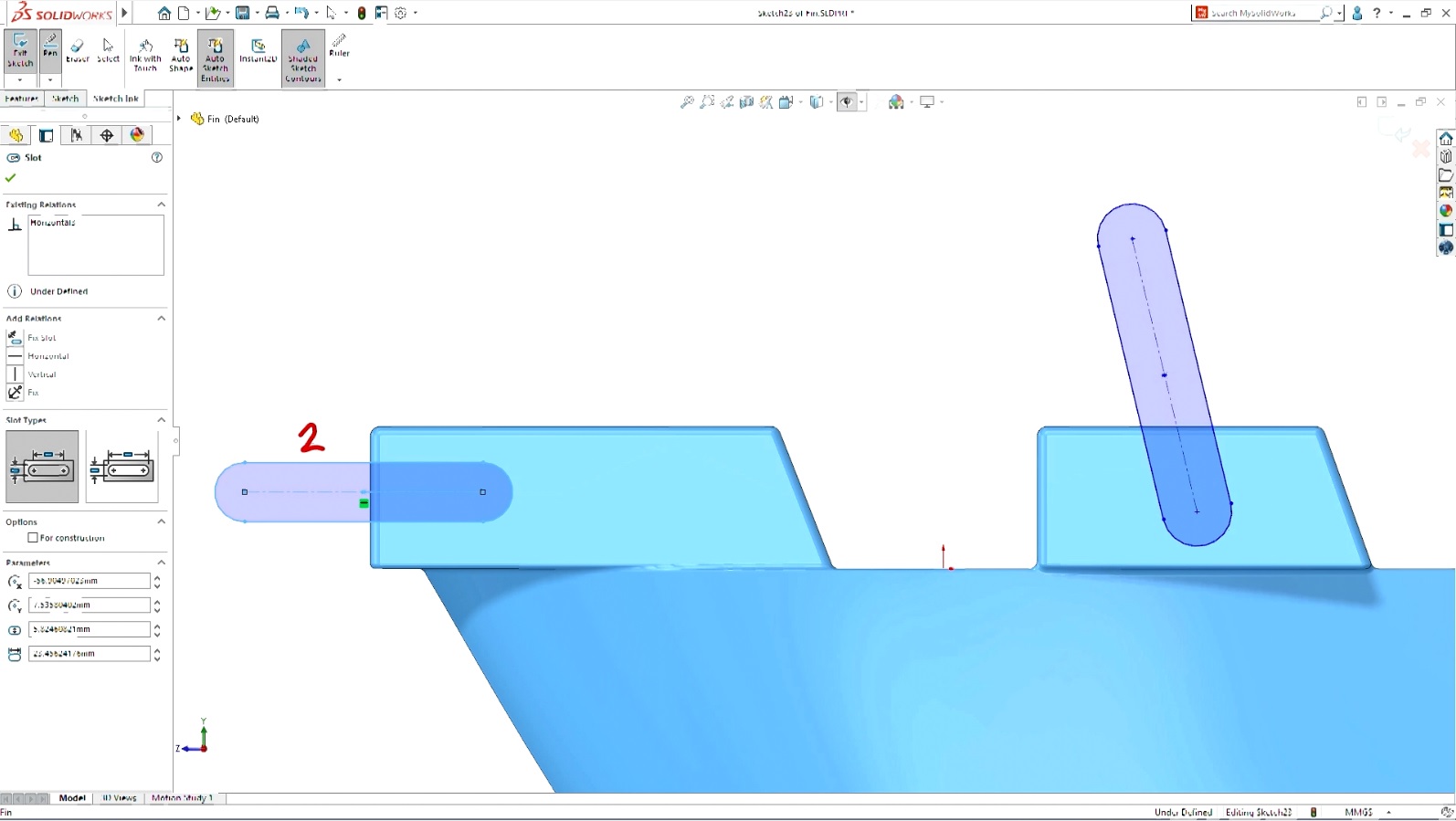

In SOLIDWORKS 2019, the ability to create thumbnails with gestures and using a graphic pen is available. Drawn contours can be converted to splines and edited.

In addition, the drawn sketches can be automatically converted to pre-defined forms. Dimensions can be specified in real time by recording them directly on the touch screen. SOLIDWORKS decrypts the information entered manually by the user.

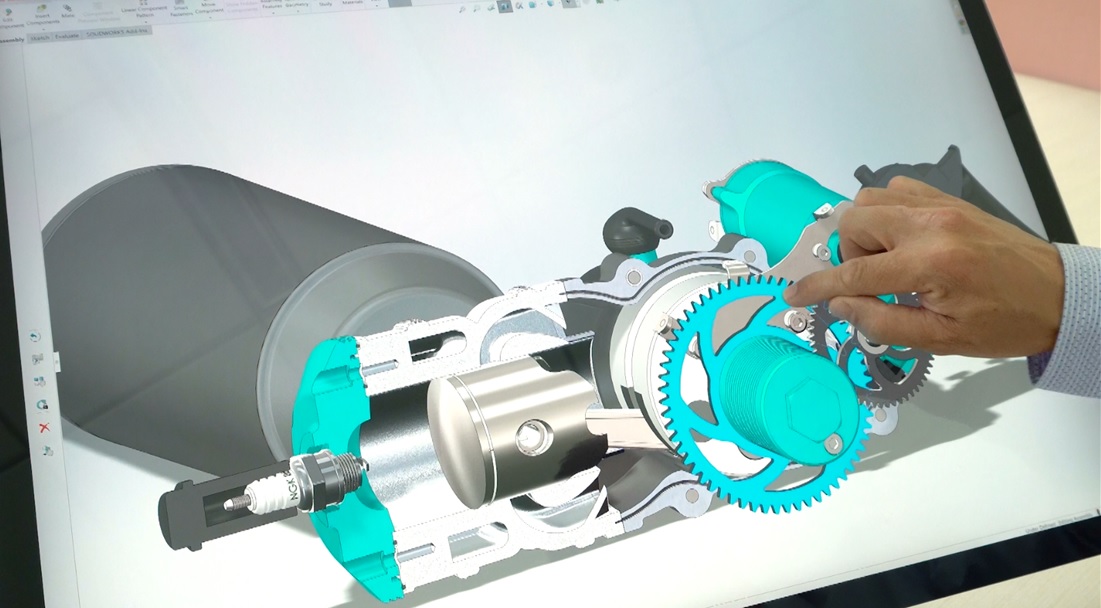

An intuitive working environment also deserves attention. On the touch screen, you can quickly collect all the necessary details and intuitively manipulate the assembly model.

The main areas on which the developers of SOLIDWORKS 2019 have focused are manufacturability, modeling, performance, and new technologies. Nevertheless, improvements in the new version of the product to one degree or another touched almost all areas.

Concluding the article, we want to briefly highlight the most significant innovations:

As you probably noticed, updates in the new version of SOLIDWORKS are focused on increasing the productivity of engineers. They provide significant time savings, help reduce financial costs and improve the quality of working documentation. In addition, promising technologies of virtual reality have been introduced into the product; they are just beginning to develop, and we are trying to give our users the opportunity to start using them as early as possible in their projects.

We hope that this review gave you an idea of the new features of SOLIDWORKS 2019. For more information on improvements and new features of the product, please visit the

SOLIDWORKS 2019 demo and see the schedule of events for resellers here

an interactive event on SOLIDWORKS FORUM on October 2 and introduced the updated SOLIDWORKS 2019 design system .

The new version of SOLIDWORKS - a huge step forward. Changed product interface, significantly improved performance. We will tell about all this below.

What is SOLIDWORKS 2019?

SOLIDWORKS 2019 is a design system built on the basis of the Dassault Systèmes 3DEXPERIENCE platform . It covers the entire process of developing industrial products and, in particular, helps to solve complex problems arising in the design of parts.

The new version of SOLIDWORKS can highlight several important new products and improvements.

Accelerating the design process

Improved performance with mesh geometry. Particular attention is paid to tools that accelerate the creation of assemblies. With the help of reverse engineering procedures, grids are imported and solid-state models are created for transfer to production.

A tool for creating 2D sections at the intersection of the grid and a set of planes has been added to the product. To do this, it is enough to set the number of cutting planes and the distance between them. The resulting sketches-sections can be further edited.

The new tool "3D-texture" uses 2D-images for the formation of spatial textures. An image placed on a surface is converted by this tool into 3D geometry.

In SOLIDWORKS 2019, a tool for checking for spatial intersections appeared. He analyzes the component parts and checks the correctness of welded structures. The function of grouping assembly dependencies by status is also available. She proposes to remove erroneous and inactive dependencies that were formed due to changes in the assembly.

Simplify large builds

The updated version has improved viewing capabilities for large projects. Manipulations with large assemblies in real time are now much faster.

In large assemblies, you can now add dependencies between components automatically. To do this, simply select one of the components and adjust the parameters accordingly.

In the new version it is easy to open "heavy" assemblies (from 10 thousand parts and above), it is comfortable to work and edit with them.

Elimination of unnecessary details

The Defeature function is used to create simplified copies of assemblies — for example, when you transfer them to your colleagues or to demonstrate on web resources. You indicate which components should be presented in their original form, and which - in the form of simplified geometric elements (cylinders, extruded polygons, etc.) without unnecessary details. Such simplified copies give a good idea of the shape of the assembly and at the same time help protect your intellectual property.

Improved user interface

User interface enhancements are designed to further increase productivity. The SOLIDWORKS 2019 startup page displays the icons of the 100 most recent documents, and they can be filtered by type: parts, assemblies, or drawings. In seconds, you can find the desired model by entering a fragment of its name in the search field.

The left side of the screen displays the structure of an open model, where it is easy to trace the relationships between its components. To manage external links is a new interactive dialog box.

Teamwork

Collaboration features are essential for a clear and fast interaction between specialists. In SOLIDWORKS 2019, 3D markers can be applied to parts and assemblies, including with a pen and touches. You do not need to take screen shots manually: notes are stored with the model and can be exported in PDF format at the right time. In this way, for example, the project manager may ask the designer to clarify the sizes of parts used in the assembly.

Augmented Reality (XR)

This is a completely new feature aimed at working with VR devices. It makes it even more convenient to work with large assemblies.

With the help of virtual reality glasses and a joystick, you can easily navigate inside your assembly, view the details in it and get the metadata of any part in real time. To do this, just point the joystick on the part and press the button.

Details marked in augmented reality mode are remembered in the project and can be worked out after exiting this mode.

SOLIDWORKS CAM

The SOLIDWORKS CAM system solves most of the problems of programming modern CNC machines. Milling 3-4-5-coordinate machines (in 3 + 1, 3 + 2 modes), lathes, laser cutting machines, plasma cutting machines and water-jet cutting machines are supported.

Among the key capabilities of metalworking (CAM Milling) - automatic analysis of parts for the recognition of technological elements in its composition. It is also possible to generate a part processing plan based on the rules of the technological database (in SQL format). This is quite a convenient function, with the help of which you can use an already existing database for one or another detail or machine, or add your own. In this way, the system learns your personal preferences.

And another useful feature is the CAM NC Editor. She checks the control program code before it is transmitted to the machine. The editor supports milling and turning machines. By running it, you can see all the trajectories and adjust them if an error is detected.

Metalworking functions reduce the time required to manufacture parts.

New ways to interact with the user

Now in SOLIDWORKS supported work with the controller Surface Dial. When the controller is superimposed on the touch screen, graphical tools appear around it to pan, zoom and rotate the element on the screen.

In SOLIDWORKS 2019, the ability to create thumbnails with gestures and using a graphic pen is available. Drawn contours can be converted to splines and edited.

In addition, the drawn sketches can be automatically converted to pre-defined forms. Dimensions can be specified in real time by recording them directly on the touch screen. SOLIDWORKS decrypts the information entered manually by the user.

An intuitive working environment also deserves attention. On the touch screen, you can quickly collect all the necessary details and intuitively manipulate the assembly model.

The main areas on which the developers of SOLIDWORKS 2019 have focused are manufacturability, modeling, performance, and new technologies. Nevertheless, improvements in the new version of the product to one degree or another touched almost all areas.

Concluding the article, we want to briefly highlight the most significant innovations:

- Check for spatial intersections in multibody parts and support for welded joints

- Isolating components using the external links control window

- Noise Reduction in SOLIDWORKS Visualize Scenes with Machine Learning Algorithms

- Increase rendering performance by an order of magnitude

- 3D textures on parts surfaces

- Converting sketches to splines on touch screens

- 2D sketches along the contours of sections of the grid planes

- Build dependency grouping by status

Conclusion

As you probably noticed, updates in the new version of SOLIDWORKS are focused on increasing the productivity of engineers. They provide significant time savings, help reduce financial costs and improve the quality of working documentation. In addition, promising technologies of virtual reality have been introduced into the product; they are just beginning to develop, and we are trying to give our users the opportunity to start using them as early as possible in their projects.

We hope that this review gave you an idea of the new features of SOLIDWORKS 2019. For more information on improvements and new features of the product, please visit the

SOLIDWORKS 2019 demo and see the schedule of events for resellers here

If you have any questions about SOLIDWORKS, you can write to Andrey Vinogradov, Technical Manager, SOLIDWORKS, Dassault Systèmes in Russia and the CIS: andrey.vinogradov@3ds.com

If you have any questions about SOLIDWORKS, you can write to Andrey Vinogradov, Technical Manager, SOLIDWORKS, Dassault Systèmes in Russia and the CIS: andrey.vinogradov@3ds.com