The biggest telescopes. From a notebook and eyes to 340 megapixel cameras and data centers. Part 1

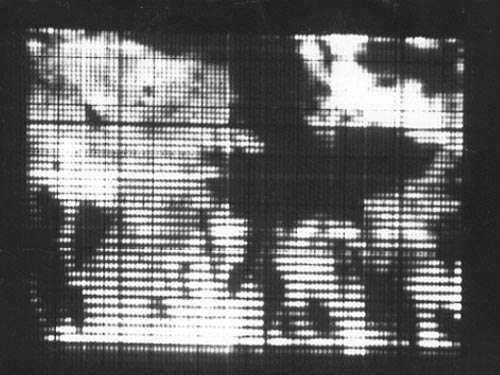

It has been almost 11 years since I graduated from KNU. Shevchenko specialty astronomer physicist. These were the most interesting years in the development of science and astronomy in particular, which I had missed because the mind was absorbed by the project that generated more traffic than all of Belarus . But now, having knowledge and experience in the field of data processing and storage, I wanted to return to the well-forgotten old and see what modern servers and data centers can be useful for science. Just think, just 50 years ago, photographic plates and journals were the carrier of astronomical data, the first CCD matrix was used in astronomy in 1973 and measured 100 × 100 pixels, with its help and with a telescope with a lens diameter of 20 cm, the first digital shot of the moon.

The first shot of the Moon from a charge-coupled device, due to the small number of pixels, the matrix structure of the radiation receiver is noticeable

And 40 years ago, in 1979, the CCDs found their use in professional astronomy, in the Kitt Peak Observatory, a telescope with a 1-meter objective diameter was installed a digital camera 320x512 pixels in size, which showed significant advantages in comparison with a photographic plate. It is also worth noting that the pixel size matters and here it was significantly larger than the pixels in the cameras of modern mobile phones, where many of the manufacturers, for the purpose of marketing, put millions of smaller pixels, reducing their size, since the area of the matrix with height they did not increase their numbers, which not only did not improve the quality of the resulting image, but on the contrary worsened it. That's because the snapshot from the matrix, even with 0.01 megapixel, looks very decent, since the first CCDs, with a small number of pixels,

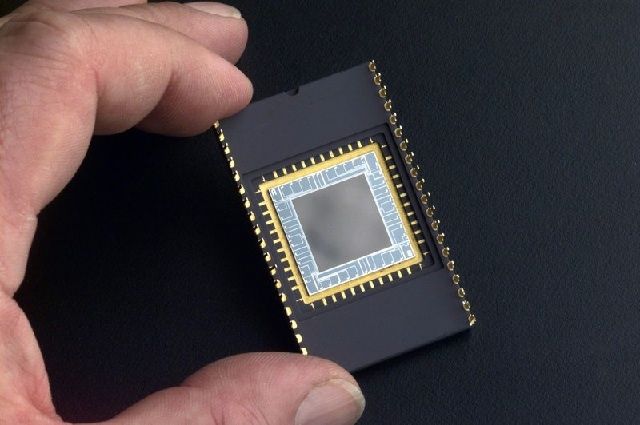

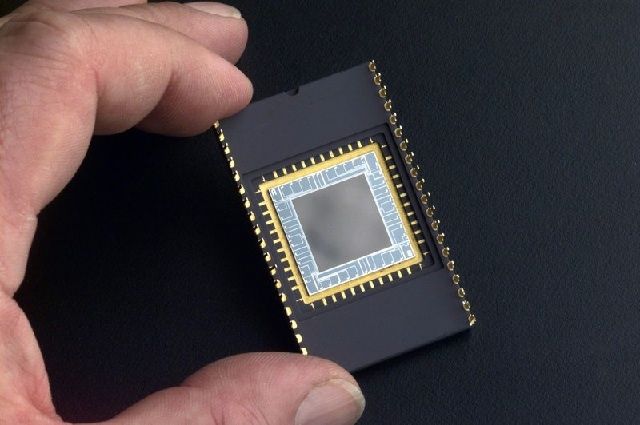

CCD array that is sensitive to the UV range

And if, at the very beginning, the simplest computing power was enough for storing data and processing it - back in 1988, 20 MB of disk space promised a long and carefree life, then over time the needs began to grow strongly. I still remember that in 2005, at the department, with the support of the Swiss Foundation, the first virtual X-ray and gamma observatory VIRGO was opened, with several powerful computers and a fiber-optic line at that time to the UNREN scientific network that provides transmission and reception of data at speeds up to 10 Mbit / s, in which the data of observations of space telescopes were processed in a wide range of the electromagnetic spectrum - from the radio to the gamma range. New data arrived daily, and terabytes had to be stored and processed. And then the volumes only grew.

But a bit of history, before moving on.

It is very difficult to answer the question of who first invented the telescope. More in the XIII century. Roger Bacon, found a combination of lenses in which distant objects seemed close, and the invention of the telescope was announced at the beginning of the 17th century. In the Netherlands, three optics were announced at once - Lippersgei, Metzius and Jansen. But the fact is indisputable that Galileo Galilei on January 7, 1610 conducted the first astronomical observations, not just looking at the sky with the armed eye, but describing the observed (phases of Venus, Jupiter’s satellites, sunspots, the structure of the Milky Way) in accordance with the heliocentric picture of the world, justifying and deepening it.

Telescope galilee

But even then it was noticed that the images of astronomical objects are distorted - they contain aberrations, for which they began to use long-focus lenses to deal with. So the world's largest “air” telescopes appeared, for example, the Hevelius telescope was 50 meters long.

Hevelius

A Air Telescope Huygens used a tool 68 meters long, but Ozu is still considered the record holder, using an air telescope 98 meters long, but the image from him was so poor in quality and control was so uncomfortable (several people needed to control the telescope) that he failed to make so significant discoveries, and the record of 1664 still remains unbroken.

Aberrations, even in aerial telescopes, were quite noticeable, and the use of lenses with a diameter of more than 20 cm made their design impossible. So, for example, if you use a lens with a diameter of 1 m, the length of the air telescope should be as much as 2 km. It becomes clear that the solution to the problem of aberrations is on a different path. And already in the middle of the XVIII century. Telescopes with multi-lens lenses and eyepieces appear, which almost completely compensate for chromatic aberration resulting from dispersion (the refractive index of light in a medium depends on the wavelength and therefore the rays of different wavelength are collected in different "foci"), compensating for this effect with a diffusing lens .

And one of the pioneers of multi-lens telescopes was John Dollond, who, thanks to the use of a variety of lenses, built a telescope of only 1.5 meters in length, giving a better image than the Huygens 68-meter telescope. Nevertheless, the process of making lenses was rather complicated - the glass was melted several times in the furnace and cooled for many months, so that it could give it the desired shape and uniform structure, and then there was another equally long stage of polishing. That is why apochromatic refractors (lens telescopes that correct spherical and chromatic aberration) are still quite expensive to manufacture to this day, and a telescope with a large objective diameter could not be made at that time, the glass cracked during processing and non-uniformities appeared,

The biggest telescope of John Dollond The

further development of telescope construction is connected with the ban on exports, as a result of which the “dollars” stopped coming from England to Europe. The way out was found by the German optician Joseph Fraunhofer, who in the early nineteenth century. He invented new and improved refractors, improved the technology of making lenses, he managed to build a refractor with a lens diameter of 7 inches, and in 1818 began manufacturing a 9 inch refractor for Dorpat in Tartu (Estonia), where the telescope was successfully installed in 1824.

Later, Merz and Meier, the heirs of the Fraunhofer knowledge, in 1839 produced a 15-inch refractor for the newly created Pulkovo Observatory. A telescope with a lens diameter of 38 cm and a length of 7 meters kept the world championship for 8 years, but still contained quite a lot of aberrations.

As for the maximum diameter of the lens, which it became possible to manufacture at that time, then it is appropriate to recall the Swiss optics Pierre Ginan, who at the end of the XVIII century. tried to make a lens with a maximum diameter at that time, having built a melting furnace for 80 kg of glass and by 1799, after 7 years of failure, having spent almost all personal funds, achieved the ability to produce lenses of 10-15 cm in diameter - success for that time was unheard of. Later, in 1824, by inventing the technology for the destruction of the streaky structure of glass blanks, sawing rejected pieces, destroying the marriage and fusing again, he managed to make a lens with a diameter of 45 cm, after which he died. But his work was not in vain, American Alwan Clark, an artist by specialty, inspired by his successes,

And after 11 years, the company Alwan Clark and Sons, installed a 26-inch refractor at the Naval Observatory near Washington, with which Asaf Hall discovered the satellites of Mars - Phobos and Deimos in 1877. In 1878, the Pulkovo Observatory ordered from Alvan Clark for 300,000 rubles a 30-inch refractor, which was manufactured and installed by 1885, and in 1888 on Mount Hamilton in California (Lick Observatory), with a donation of 700 magnate 000 dollars was installed Clark's largest telex pro with a 36-inch lens diameter.

James Lick telescope versus man

Inspired by the act of Lika, Charles Yerks decided to donate over a million dollars to build the largest refractor in the world with a 40-inch lens diameter. The work was also performed by Clark, but without its founder, since Clark died in 1887. This refractor remains the largest to this day, since the limit has been reached, at which the lens absorbs too much light and deforms under its own weight, which begins to spoil the image to a large extent.

Telescope Yerkes Observatory, lens diameter 102 cm, the world's largest refractor

There was no point in building refractors with a large lens diameter for another reason — a large secondary spectrum; these telescopes were extremely inconvenient for spectral and photometric observations — with much smaller telescopes one could get much better results. But these telescopes have greatly enriched stellar astronomy with many discoveries and they continue to function successfully to this day.

As for mirror telescopes - reflectors, where instead of a lens a concave mirror is used as a lens, the idea of creating them arose during the life of Gallieu, in 1616 N. Zucchi was proposed the scheme, and later in 1638 N. Mersen. However, the first mirror telescope was able to make Isaac Newton in 1688, this reflector was very small. Its main spherical bronze mirror had a diameter of only 2.5 cm, at a distance of 6.5 cm from the center of the main mirror, an even smaller one was located - a secondary mirror reflecting light rays into the eyepiece located on the side.

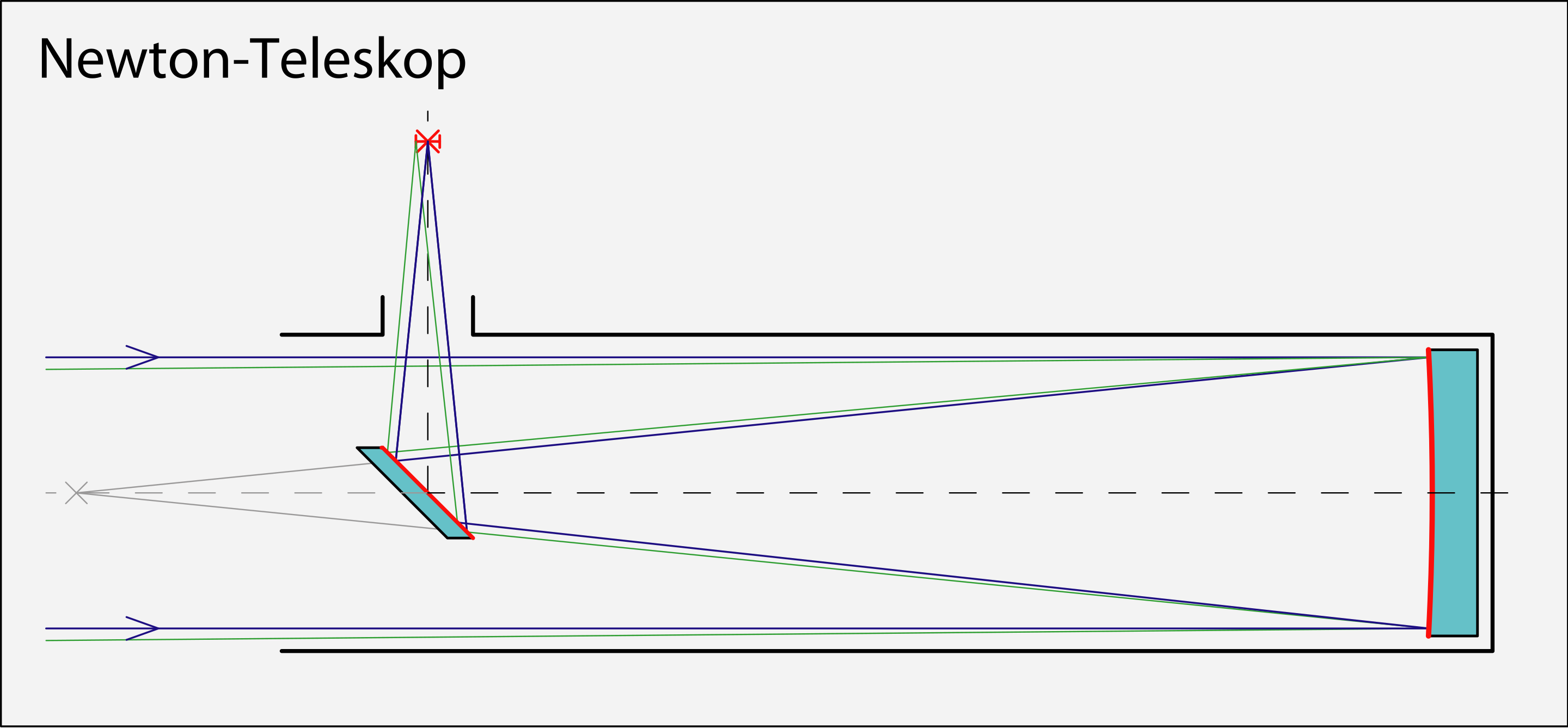

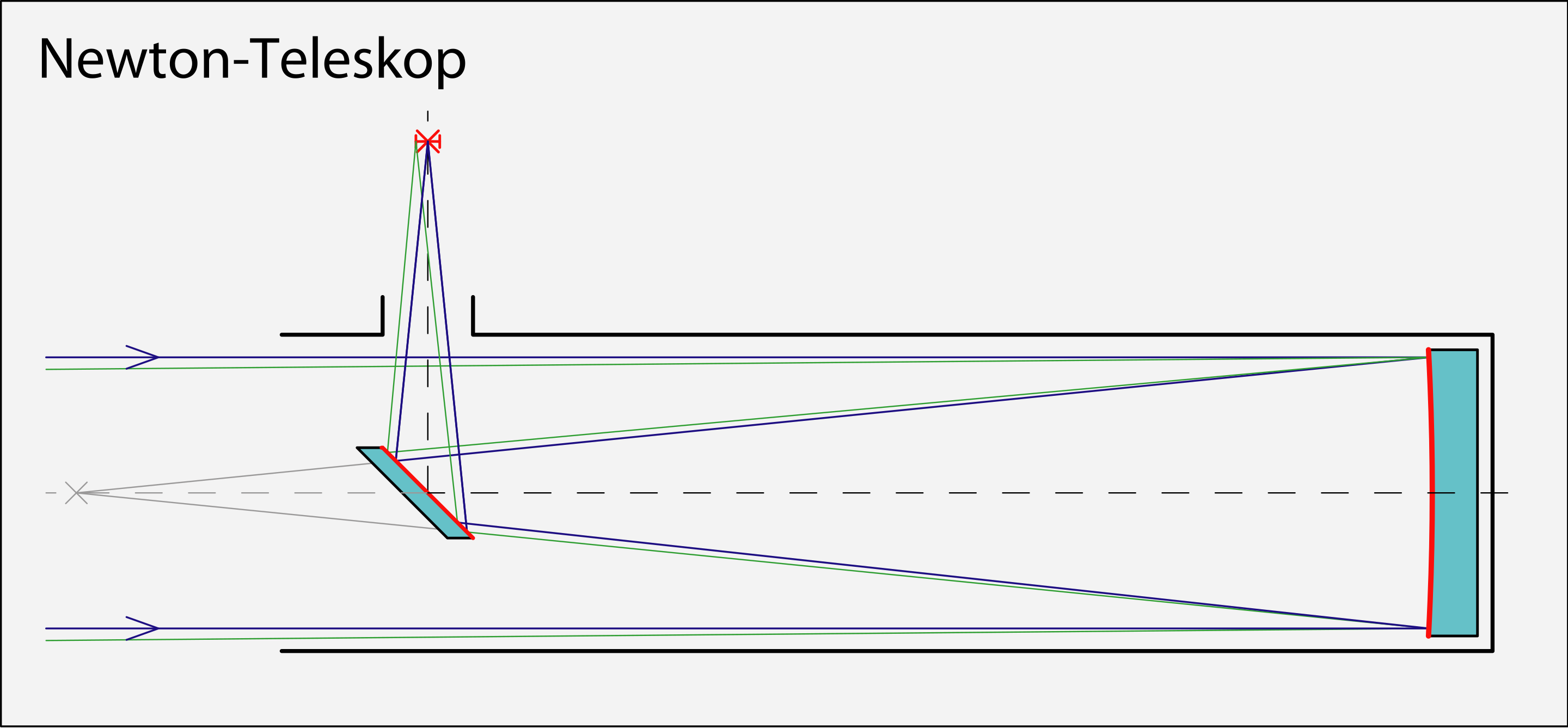

Optical scheme of the Newton telescope

In the beginning, Newton applied an eyepiece, in which the telescope gave an increase of 41 times, but changing the eyepiece to a longer one, thereby reducing the magnification to 25 times. Newton noticed that the objects look brighter and clearer. It was then that it became clear that the goal of the telescope is not only to “bring closer” the object, but also to collect as much light from it as possible in order to examine it in more detail with maximum quality, since the area of the telescope's lens repeatedly exceeds the area of the pupil of the eye. Today, it is generally accepted that the maximum useful telescope magnification, which allows you to unlock the full potential of an instrument, until the moment when aberrations begin to be noticeable due to exceeding the physical limit of the telescope's optics, are 2 times larger than the objective diameter in mm. That is, for the first Newton telescope it was 50 times,

View of Saturn with insufficient, optimal and excessive magnification

For example, the galaxy “Andromeda Nebula”, or M31 according to Monsieur's catalog, has angular dimensions 6 times larger than the disk of the full Moon, however, in order to examine it you will need a telescope, since its brightness is much less than the moon and you need to collect as much light as possible to see its details. Without a telescope, it looks like a dim speck in the night sky, much smaller than the moon, but this is nothing more than an optical illusion.

John Hadley Telescope (Newton's system)

Already in 1721, John Hadley built Newton's reflector with a lens diameter of 15 cm and a focal length of 158 cm, in which it was easy to observe Jupiter’s satellites and even discern the Cassini slit in Saturn’s rings, which was difficult to see in the 37-meter air telescope used Huygens.

Later, more sophisticated schemes were invented, using parabolic concave mirrors instead of a spherical and smaller secondary concave elliptical mirrors, from which the light reflected back — into a hole in the center of the main mirror, behind which the eyepiece stood, resulting in an image not turned upside down, as in Newton's system, and direct, and the length of the pipe at the same time decreased, and the spherical aberration was largely corrected.

The optical scheme of the Gregory telescope system

. In 1732-1768, James Short produced several telescopes using the Gregory system, the largest of which had a diameter of 55 cm. And William Herschel, from 1773, was able to make 430 mirrors for 20 years, as a result, he built the largest reflectors with focal lengths of 20 and 40 English feet (about 12 meters).

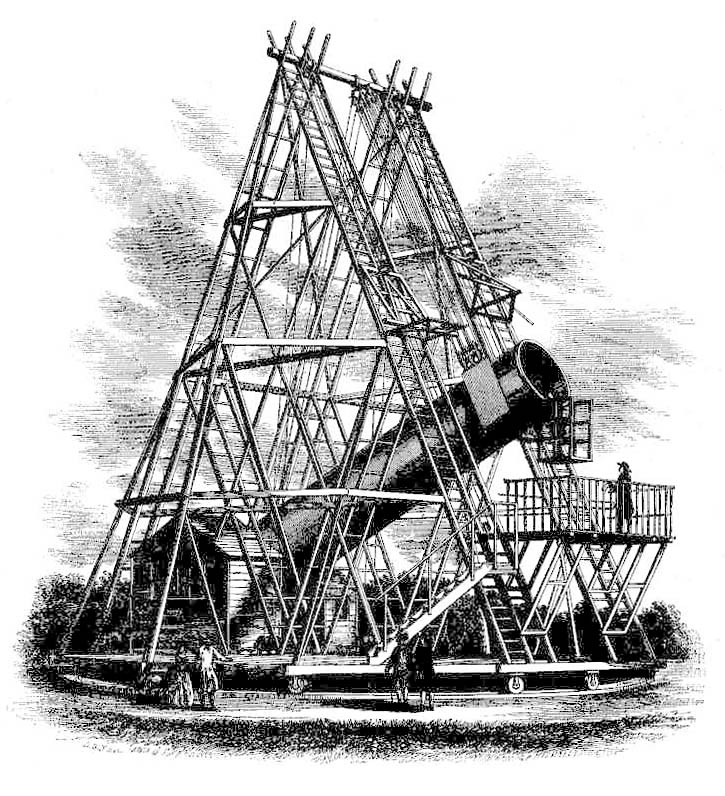

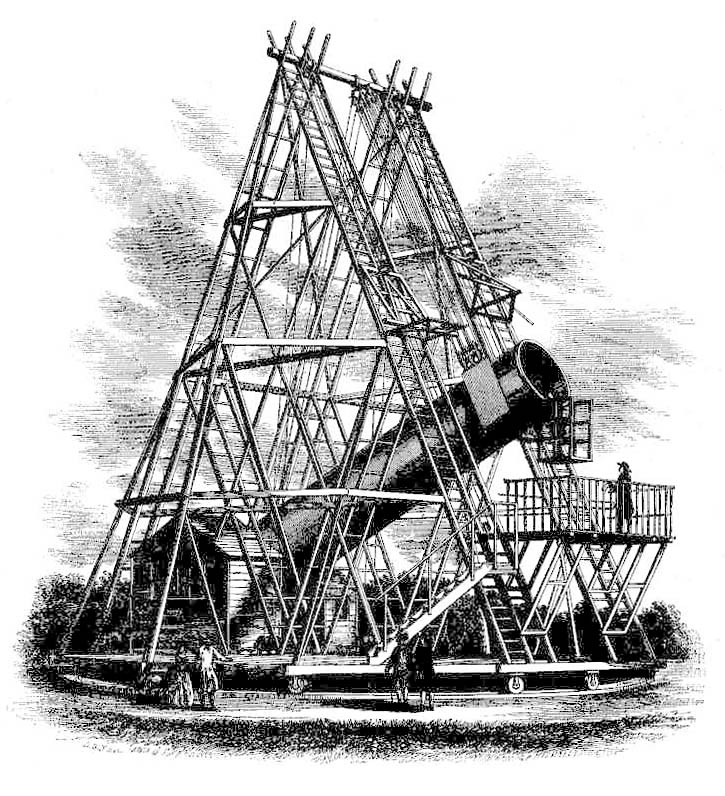

William Herschel's largest telescope with a focal length of 12 meters

The diameter of the bronze lens of a 40-foot reflector was 122 cm, and its thickness was about 9 cm, the mirror weighed at least a ton and sagged under its own weight. 75% of it consisted of copper and 25% of tin. The mirror very quickly darkened, cracked and demanded frequent repolishing, which Herschel performed manually for the first 15 years, as did the manufacture of new mirrors, where the polishing process took over 16 hours and did not allow to come off for a minute. It was extremely inconvenient to control the telescope and therefore Herschel, along with her sister Caroline, used telescopes of smaller diameter for most of their discoveries. Interestingly, during his life, Herschel discovered more than 2,500 nebulae, 806 double stars, performed 4 complete reviews of the night sky visible to him, and Caroline during her 98 years life, among other things, managed to discover 2 comets. His son John continued his work,

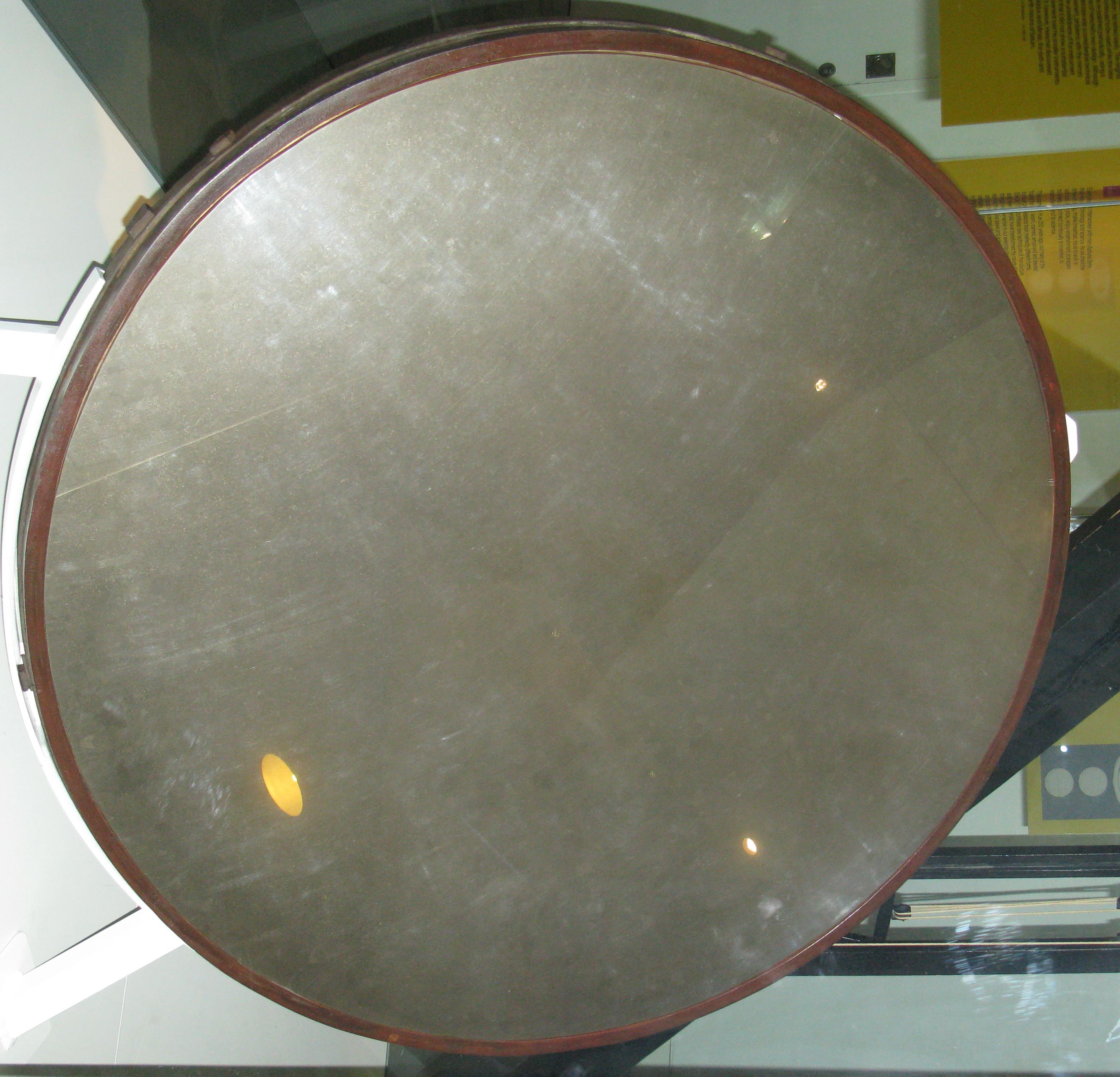

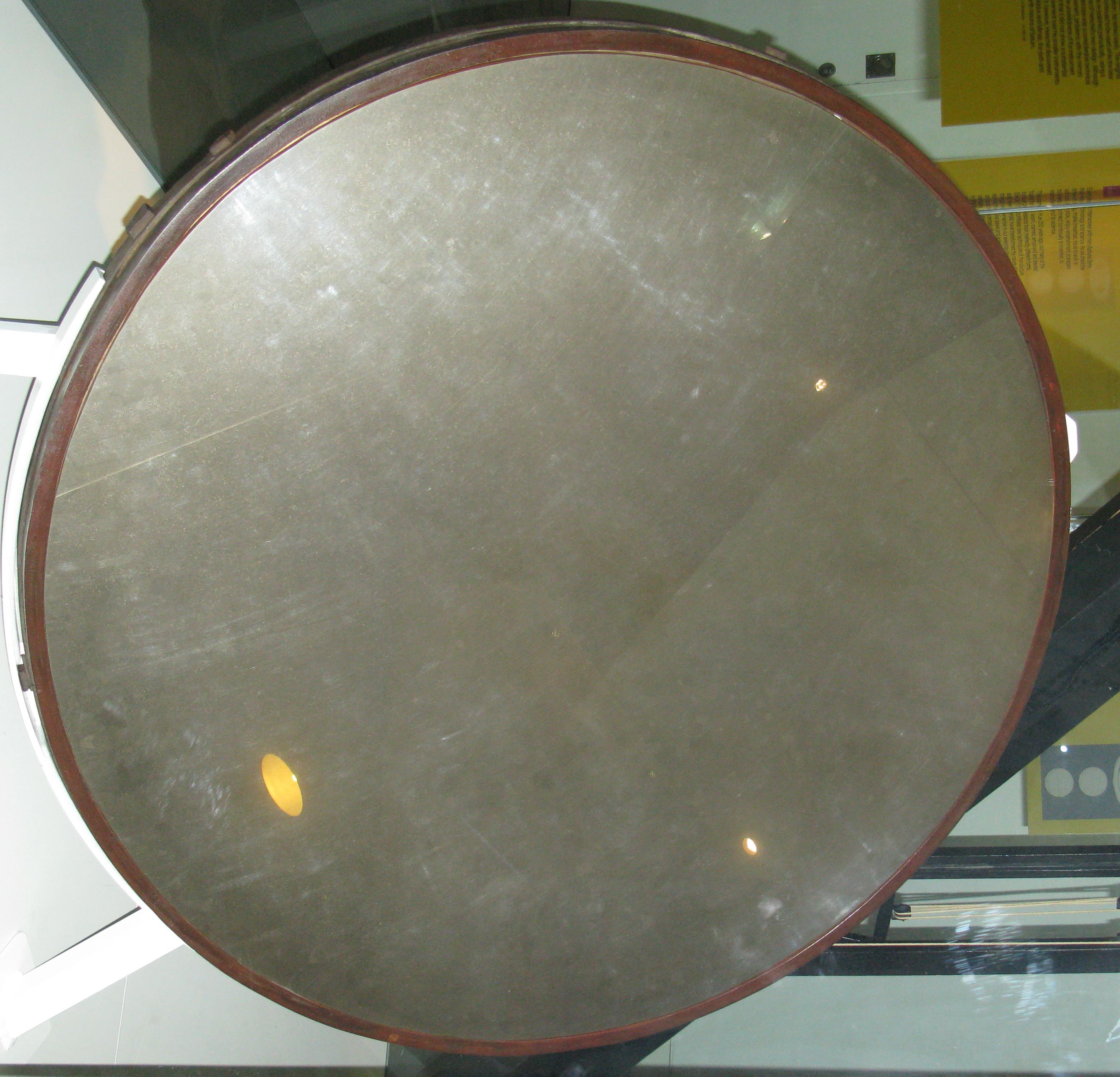

Today, the mirror of the largest telescope Herschel is stored in Slow.

In 1845, the English brewer William Lassel, fascinated by astronomy, builds a reflector with a diameter of 61 cm, installs it in his Starfield estate near Liverpool and a year later, on 10 October 1846, the satellite opened recently the planet Neptune - Triton, later with the help of the same tool he manages to detect the satellites of Uranus - Ariel and Umbriel. And in 1861 he managed to build a telescope with a lens diameter of 122 cm, like that of the Herschel telescope, which was later installed in Malta to conduct observations on the more southern part of the starry sky.

122 cm brand dedicated to William Lassel telescope

If we talk about the largest reflector of the XIX century, then he managed to build William Parson, who bears the title of Lord Ross. With a large capital, he decided to build the largest telescope in the world, but unfortunately all the paper with the secrets of manufacturing, James Short, destroyed and Ross had to invent a lot. Nevertheless, having spent a lot of energy and 20,000 pounds, huge money at that time, the telescope in 1845 was ready (it took 3 years to build). The diameter of the main mirror was 183 cm, weight 3 tons, pipe length 16 meters. The telescope was controlled by a complex system of blocks and cables, which were supposed to serve 2 people, had a limited field - could rise and fall, and turn side to side by only 15 degrees. The climate of Ireland can hardly be called the best - for the year 60-80 clear nights, mostly in winter,

Reconstructed Lord Ross’s telescope in Ireland is available for viewing at Birr Castle ( website ).

The telescope was restored in 2001 using drawings preserved by Ross’s wife and some modern technologies, the faded heavy mirror was replaced with a light aluminum one. To surpass Ross by building a telescope with a large mirror diameter, it was possible only at the beginning of the last century.

The fashion for glass mirrors appeared as early as the middle of the 19th century, since the glass was simpler in processing, and the silver coating reflected 2 times more light than bronze mirrors. In addition, the mirror was much lighter. In 1878, a reflector with a mirror diameter of 122 cm was installed, and already in 1888 - the largest 19th-century glass reflector. with a mirror diameter of 153 cm.

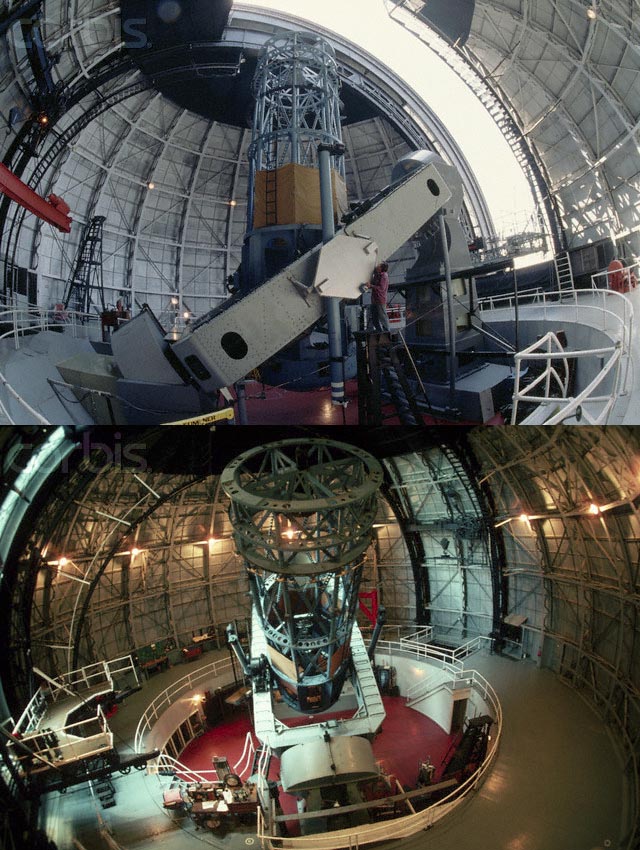

However, the final victory of glass reflectors over metal was in 1917, when the Mount Wilson Observatory, at the expense of millionaire John D. Hooker, built a reflector with a lens diameter of 2.58 meters.

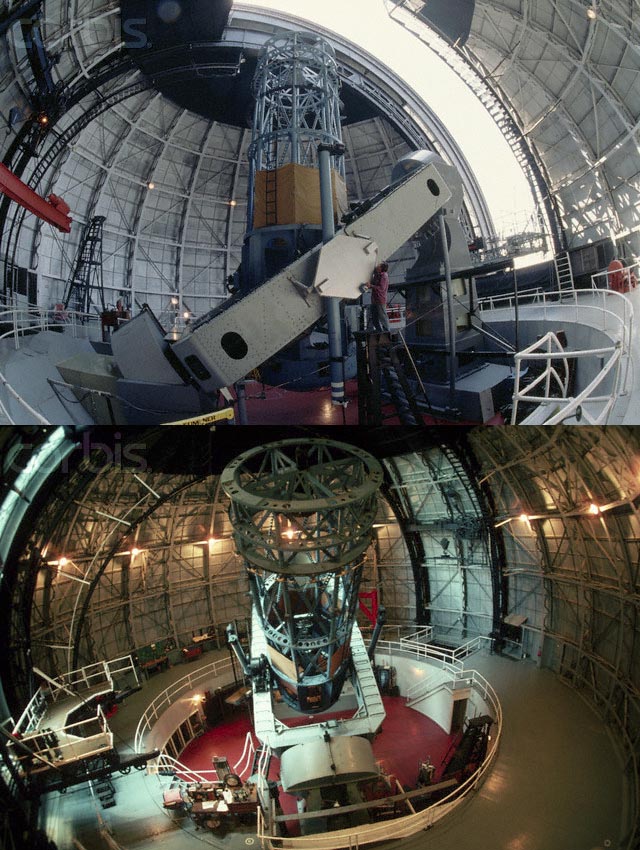

100-inch reflector of Mount Wilson

The decisive victory of glass mirrors over metal ones was due to the invention of the Foucault's “shadows” method, which increased the manufacturing quality of optics and, as a result, the reflectivity of the mirror up to 90-95%. In 1930, they invented a method of aluminizing mirrors, as a result of which silver was replaced with aluminum, more resistant to oxygen, which, due to the presence of an oxide film, did not fade so quickly, but also reflected rays of a wider spectral range, such as ultraviolet, to which silver coating is simply not capable.

The 5-meter Hale telescope installed at the Mount Palomar Observatory began to be built in 1936, but due to the war its commissioning lasted until 1948, and for 28 years it remained the largest in the world.

Hale's 508-cm telescope (Palomar Observatory, USA)

SLR-telescopes gradually gain in popularity, which largely compensate for most aberrations, and also help reduce the size of instruments.

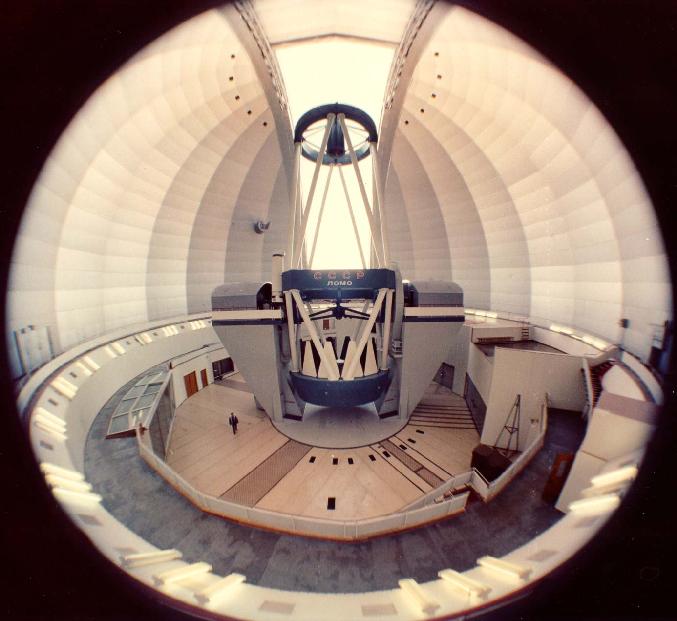

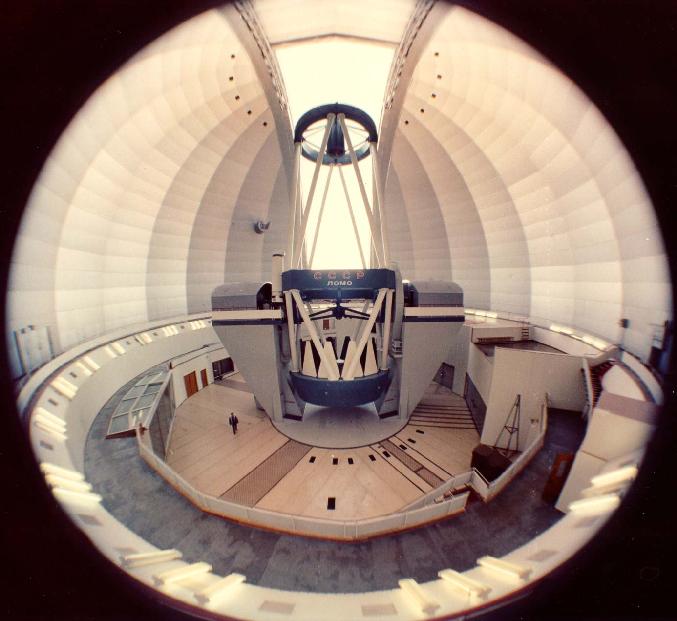

In 1975, a large alt-azimuth telescope with a main mirror diameter of 6.05 meters, located in the Caucasus, in Karachay-Cherkessia near the village of Nizhny Arkhyz on Mount Semiruchy (height 2070 m) at the Zelenchutsk Observatory, comes into operation.

Panoramic view of the BTA (Large Alt-Azimuth Telescope)

The history of the creation of this telescope is interesting. BTA was another example of the USSR gigantomania and, in essence, the goal of its creation was to surpass the Americans, they decided that a meter for these would be enough. After all, the Americans, designing the Hale telescope, considered it inexpedient to make it larger in diameter due to possible aberrations resulting from the deformation of the main mirror due to its large own weight.

Dome 6-meter BTA

It is funny that the optical industry was not ready for such a task and in Lytkarino a special plant was built for this purpose in the workshop available for the production of mirror reflectors. The task was set on March 25, 1960, the most difficult, was to build a 516 ton melting furnace for making a billet weighing 70 tons, burn it, process it with high precision, and make 60 holes for the unloading mechanism from the rear side. In 1963, the furnace was ready, another 3 years is spent on the construction of a workshop. As a result, three blanks were cast. The first billet cracked after the start of processing, since the burning and cooling process was attempted to be reduced, this happened 1.5 years after the start of cooling. The second blank was more successful, it was cast on November 20, 1964, then the process of burning and long-term cooling was started, which lasted until December 5, 1966 - 2 years and 19 days. The polishing process was no less simple, it was necessary to develop a scheme and build a special diamond cutter, as a result, over 7,000 carats of crushed diamonds and 1.5 years of time were spent on polishing. After processing, the weight of the billet dropped to 42 tons and further, on September 4, 1968, the billet was transferred for more accurate processing of its front side. At the Kolomna Heavy Machine-Tool Plant, the workpiece is installed in a technological frame, where LOMO specialists carry out its further high-precision processing - grinding, until January 1969, and then polishing, which was completed in July 1971, in a special thermostatted case on a unique grinding machine. In the next 2 months, the quality of the optics was checked using various methods. The polishing process was no less simple, it was necessary to develop a scheme and build a special diamond cutter, as a result, over 7,000 carats of crushed diamonds and 1.5 years of time were spent on polishing. After processing, the weight of the billet dropped to 42 tons and further, on September 4, 1968, the billet was transferred for more accurate processing of its front side. At the Kolomna Heavy Machine-Tool Plant, the workpiece is installed in a technological frame, where LOMO specialists carry out its further high-precision processing - grinding, until January 1969, and then polishing, which was completed in July 1971, in a special thermostatted case on a unique grinding machine. In the next 2 months, the quality of the optics was checked using various methods. The polishing process was no less simple, it was necessary to develop a scheme and build a special diamond cutter, as a result, over 7,000 carats of crushed diamonds and 1.5 years of time were spent on polishing. After processing, the weight of the billet dropped to 42 tons and further, on September 4, 1968, the billet was transferred for more accurate processing of its front side. At the Kolomna Heavy Machine-Tool Plant, the workpiece is installed in a technological frame, where LOMO specialists carry out its further high-precision processing - grinding, until January 1969, and then polishing, which was completed in July 1971, in a special thermostatted case on a unique grinding machine. In the next 2 months, the quality of the optics was checked using various methods. as a result, over 7,000 carats of crushed diamonds and 1.5 years of time were spent on polishing. After processing, the weight of the billet dropped to 42 tons and further, on September 4, 1968, the billet was transferred for more accurate processing of its front side. At the Kolomna Heavy Machine-Tool Plant, the workpiece is installed in a technological frame, where LOMO specialists carry out its further high-precision processing - grinding, until January 1969, and then polishing, which was completed in July 1971, in a special thermostatted case on a unique grinding machine. In the next 2 months, the quality of the optics was checked using various methods. as a result, over 7,000 carats of crushed diamonds and 1.5 years of time were spent on polishing. After processing, the weight of the billet dropped to 42 tons and further, on September 4, 1968, the billet was transferred for more accurate processing of its front side. At the Kolomna Heavy Machine-Tool Plant, the workpiece is installed in a technological frame, where LOMO specialists carry out its further high-precision processing - grinding, until January 1969, and then polishing, which was completed in July 1971, in a special thermostatted case on a unique grinding machine. In the next 2 months, the quality of the optics was checked using various methods. On September 4, 1968, the billet was transferred for more precise processing of its front side. At the Kolomna Heavy Machine-Tool Plant, the workpiece is installed in a technological frame, where LOMO specialists carry out its further high-precision processing - grinding, until January 1969, and then polishing, which was completed in July 1971, in a special thermostatted case on a unique grinding machine. In the next 2 months, the quality of the optics was checked using various methods. On September 4, 1968, the billet was transferred for more precise processing of its front side. At the Kolomna Heavy Machine-Tool Plant, the workpiece is installed in a technological frame, where LOMO specialists carry out its further high-precision processing - grinding, until January 1969, and then polishing, which was completed in July 1971, in a special thermostatted case on a unique grinding machine. In the next 2 months, the quality of the optics was checked using various methods. which was completed in July 1971. In the next 2 months, the quality of the optics was checked using various methods. which was completed in July 1971. In the next 2 months, the quality of the optics was checked using various methods.

Its transportation was no less difficult, we had to build 2 new river ports, several bridges, strengthen, expand and build hundreds of kilometers of roads so that the harvesting could be delivered to the destination. Nevertheless, they were afraid to risk the original, since the process of making a new mirror from a duplicate blank would require another 3-4 years. Therefore, it was decided to transport the simulator, which was done from May 12 to June 5, 1974. The main mirror of the telescope was delivered to the observatory on August 21, 1974. During transportation, temperature and vibration were carefully controlled, for safety, the mirror was placed in a special thermally insulated and anti-vibration container with multiple sensors.

Mirror transportation on the Moscow River

The observatory itself began to be built back in 1967, the telescope tower was planned to be 53 meters high and 45 meters in diameter, but in addition to the tower it was necessary to build a whole scientific town - houses of scientists, a power unit, water and power supply systems, a mountain road for delivering large loads 16 km. The total area of the scientific town was 50 hectares. In the kilometer distance from BTA there is a hotel for observers and staff housing and scientists, as well as other outbuildings.

Transportation of gears, drives and racks BTA (1968)

The main construction work was completed in 1971, after the installation of the telescope’s structure began. The total weight is 850 tons, the moving part is 650 tons, it was quite difficult to deliver and install the mount, for installation it was necessary to build a special crane. Also, since the mirror requires re-illumination every 5 years, the vacuum aluminizing installation VUAZ-6 was built (work on its manufacture lasted from 1963 to 1968, and in 1970 it was delivered to the observatory). Later aluminization technology was improved and it became possible to change the coating every 10 years.

In the middle of 1974, the debugging of all systems of the telescope was completed, on August 21, 1974, the main mirror and frame were delivered to the observatory, in September the mirror was reopened, cleaned and installed in the frame, and in October, work was carried out with a discharge mechanism.

The telescope mirror is a meniscus with a diameter of 6050 mm and a thickness of 650 mm, two main sources of its deformation are known - due to temperature gradients in the material, arising under the influence of the environment, and due to the very weight of the mirror. According to the Rayleigh optics quality criterion, deviations due to deformations of no more than 1 / 8λ (the wavelength of the observed radiation) are acceptable, which is no more than 0.035 μm. Based on these data, it was calculated that the BTA mirror is sufficient to unload at 60 end points, both in the end and in the radial directions, while the amplitude of deformations in the working area was 3 times less than the calculated one and was not more than 0.0096 microns.

No less important was the mount and its ability to move with great precision along both axes; to compensate for the Earth's rotation and image stability, greater accuracy of movement of the 650-ton design was required - in tenths of an angular second, which was ensured by hydrostatic bearings. The mount “floats” on hydrostatic oil cushions, where the oil is under a huge pressure of 70 atmospheres, acting evenly, which allows you to move such a heavy structure by applying a force of 15 kg to the 6 meter shoulder.

On November 3, 1974, the telescope was put into trial operation, and on December 30, 1975, an act of the State Interdepartmental Commission for the commissioning of the Large Azimuth Telescope was approved.

But not everything turned out well. After testing, the main mirror of the telescope revealed defects in the working surface. The Americans mocked the Soviets for a long time, since the telescope was inferior in quality to the Hale telescope, and it was also not built at the best point in terms of astroclimate. In 1979, the mirror was replaced with the existing duplicate and the quality was no worse than Hale, but the unfavorable climate remained. Nevertheless, the telescope remained the largest in the world until 1993.

It should be noted that in 2007, after almost 30 years of waiting, the defective mirror received a second life. It was allocated 200 million rubles for its correction, cut off a 8-mm-thick layer from the mirror and began to polish it. The polishing procedure could take 3 years, but stretched out for 10 years due to lack of funding.

Delivery of the mirror also took a lot of time:

Not without unforeseenness as a result of lack of planning. It turned out that the mirror could not enter the territory of the observatory of the Russian Academy of Sciences, since the gates simply were not designed for such dimensions - it was necessary to demolish part of the brickwork.

On February 14, 2018, the mirror successfully arrived at the observatory, the delivery cost 11 million rubles and took 7 days, because of the fragility of the cargo, it could not be transported at a speed of more than 40 km / h, because of the snowfall it was necessary to sprinkle roads and one of the stages to overcome 50 km took 2 days, and the last 16 kilometers of mountain serpentine transport speed did not exceed 10 km / h. But astronomers are no longer in a hurry - it’s still impossible to start installing a mirror before the onset of a warm spring, and the installation procedure will take 3-4 months.

Now the BTA telescope is among the ten largest and best telescopes in the world.

Continued (link will be available here) ...

Thank you for staying with us. Do you like our articles? Want to see more interesting materials? Support us by placing an order or recommending to friends, 30% discount for Habr users on a unique analogue of the entry-level servers that we invented for you: The whole truth about VPS (KVM) E5-2650 v4 (6 Cores) 10GB DDR4 240GB SSD 1Gbps from $ 20 or how to share the server? (Options are available with RAID1 and RAID10, up to 24 cores and up to 40GB DDR4).

VPS (KVM) E5-2650 v4 (6 Cores) 10GB DDR4 240GB SSD 1Gbps until spring for free if you pay for a period of six months, you can order here .

Dell R730xd 2 times cheaper? Only we have 2 x Intel Dodeca-Core Xeon E5-2650v4 128GB DDR4 6x480GB SSD 1Gbps 100 TV from $ 249 in the Netherlands and the USA! Read about How to build an infrastructure building. class c using servers Dell R730xd E5-2650 v4 worth 9000 euros for a penny?

The first shot of the Moon from a charge-coupled device, due to the small number of pixels, the matrix structure of the radiation receiver is noticeable

And 40 years ago, in 1979, the CCDs found their use in professional astronomy, in the Kitt Peak Observatory, a telescope with a 1-meter objective diameter was installed a digital camera 320x512 pixels in size, which showed significant advantages in comparison with a photographic plate. It is also worth noting that the pixel size matters and here it was significantly larger than the pixels in the cameras of modern mobile phones, where many of the manufacturers, for the purpose of marketing, put millions of smaller pixels, reducing their size, since the area of the matrix with height they did not increase their numbers, which not only did not improve the quality of the resulting image, but on the contrary worsened it. That's because the snapshot from the matrix, even with 0.01 megapixel, looks very decent, since the first CCDs, with a small number of pixels,

CCD array that is sensitive to the UV range

And if, at the very beginning, the simplest computing power was enough for storing data and processing it - back in 1988, 20 MB of disk space promised a long and carefree life, then over time the needs began to grow strongly. I still remember that in 2005, at the department, with the support of the Swiss Foundation, the first virtual X-ray and gamma observatory VIRGO was opened, with several powerful computers and a fiber-optic line at that time to the UNREN scientific network that provides transmission and reception of data at speeds up to 10 Mbit / s, in which the data of observations of space telescopes were processed in a wide range of the electromagnetic spectrum - from the radio to the gamma range. New data arrived daily, and terabytes had to be stored and processed. And then the volumes only grew.

But a bit of history, before moving on.

It is very difficult to answer the question of who first invented the telescope. More in the XIII century. Roger Bacon, found a combination of lenses in which distant objects seemed close, and the invention of the telescope was announced at the beginning of the 17th century. In the Netherlands, three optics were announced at once - Lippersgei, Metzius and Jansen. But the fact is indisputable that Galileo Galilei on January 7, 1610 conducted the first astronomical observations, not just looking at the sky with the armed eye, but describing the observed (phases of Venus, Jupiter’s satellites, sunspots, the structure of the Milky Way) in accordance with the heliocentric picture of the world, justifying and deepening it.

Telescope galilee

But even then it was noticed that the images of astronomical objects are distorted - they contain aberrations, for which they began to use long-focus lenses to deal with. So the world's largest “air” telescopes appeared, for example, the Hevelius telescope was 50 meters long.

Hevelius

A Air Telescope Huygens used a tool 68 meters long, but Ozu is still considered the record holder, using an air telescope 98 meters long, but the image from him was so poor in quality and control was so uncomfortable (several people needed to control the telescope) that he failed to make so significant discoveries, and the record of 1664 still remains unbroken.

Aberrations, even in aerial telescopes, were quite noticeable, and the use of lenses with a diameter of more than 20 cm made their design impossible. So, for example, if you use a lens with a diameter of 1 m, the length of the air telescope should be as much as 2 km. It becomes clear that the solution to the problem of aberrations is on a different path. And already in the middle of the XVIII century. Telescopes with multi-lens lenses and eyepieces appear, which almost completely compensate for chromatic aberration resulting from dispersion (the refractive index of light in a medium depends on the wavelength and therefore the rays of different wavelength are collected in different "foci"), compensating for this effect with a diffusing lens .

And one of the pioneers of multi-lens telescopes was John Dollond, who, thanks to the use of a variety of lenses, built a telescope of only 1.5 meters in length, giving a better image than the Huygens 68-meter telescope. Nevertheless, the process of making lenses was rather complicated - the glass was melted several times in the furnace and cooled for many months, so that it could give it the desired shape and uniform structure, and then there was another equally long stage of polishing. That is why apochromatic refractors (lens telescopes that correct spherical and chromatic aberration) are still quite expensive to manufacture to this day, and a telescope with a large objective diameter could not be made at that time, the glass cracked during processing and non-uniformities appeared,

The biggest telescope of John Dollond The

further development of telescope construction is connected with the ban on exports, as a result of which the “dollars” stopped coming from England to Europe. The way out was found by the German optician Joseph Fraunhofer, who in the early nineteenth century. He invented new and improved refractors, improved the technology of making lenses, he managed to build a refractor with a lens diameter of 7 inches, and in 1818 began manufacturing a 9 inch refractor for Dorpat in Tartu (Estonia), where the telescope was successfully installed in 1824.

Later, Merz and Meier, the heirs of the Fraunhofer knowledge, in 1839 produced a 15-inch refractor for the newly created Pulkovo Observatory. A telescope with a lens diameter of 38 cm and a length of 7 meters kept the world championship for 8 years, but still contained quite a lot of aberrations.

As for the maximum diameter of the lens, which it became possible to manufacture at that time, then it is appropriate to recall the Swiss optics Pierre Ginan, who at the end of the XVIII century. tried to make a lens with a maximum diameter at that time, having built a melting furnace for 80 kg of glass and by 1799, after 7 years of failure, having spent almost all personal funds, achieved the ability to produce lenses of 10-15 cm in diameter - success for that time was unheard of. Later, in 1824, by inventing the technology for the destruction of the streaky structure of glass blanks, sawing rejected pieces, destroying the marriage and fusing again, he managed to make a lens with a diameter of 45 cm, after which he died. But his work was not in vain, American Alwan Clark, an artist by specialty, inspired by his successes,

And after 11 years, the company Alwan Clark and Sons, installed a 26-inch refractor at the Naval Observatory near Washington, with which Asaf Hall discovered the satellites of Mars - Phobos and Deimos in 1877. In 1878, the Pulkovo Observatory ordered from Alvan Clark for 300,000 rubles a 30-inch refractor, which was manufactured and installed by 1885, and in 1888 on Mount Hamilton in California (Lick Observatory), with a donation of 700 magnate 000 dollars was installed Clark's largest telex pro with a 36-inch lens diameter.

James Lick telescope versus man

Inspired by the act of Lika, Charles Yerks decided to donate over a million dollars to build the largest refractor in the world with a 40-inch lens diameter. The work was also performed by Clark, but without its founder, since Clark died in 1887. This refractor remains the largest to this day, since the limit has been reached, at which the lens absorbs too much light and deforms under its own weight, which begins to spoil the image to a large extent.

Telescope Yerkes Observatory, lens diameter 102 cm, the world's largest refractor

There was no point in building refractors with a large lens diameter for another reason — a large secondary spectrum; these telescopes were extremely inconvenient for spectral and photometric observations — with much smaller telescopes one could get much better results. But these telescopes have greatly enriched stellar astronomy with many discoveries and they continue to function successfully to this day.

As for mirror telescopes - reflectors, where instead of a lens a concave mirror is used as a lens, the idea of creating them arose during the life of Gallieu, in 1616 N. Zucchi was proposed the scheme, and later in 1638 N. Mersen. However, the first mirror telescope was able to make Isaac Newton in 1688, this reflector was very small. Its main spherical bronze mirror had a diameter of only 2.5 cm, at a distance of 6.5 cm from the center of the main mirror, an even smaller one was located - a secondary mirror reflecting light rays into the eyepiece located on the side.

Optical scheme of the Newton telescope

In the beginning, Newton applied an eyepiece, in which the telescope gave an increase of 41 times, but changing the eyepiece to a longer one, thereby reducing the magnification to 25 times. Newton noticed that the objects look brighter and clearer. It was then that it became clear that the goal of the telescope is not only to “bring closer” the object, but also to collect as much light from it as possible in order to examine it in more detail with maximum quality, since the area of the telescope's lens repeatedly exceeds the area of the pupil of the eye. Today, it is generally accepted that the maximum useful telescope magnification, which allows you to unlock the full potential of an instrument, until the moment when aberrations begin to be noticeable due to exceeding the physical limit of the telescope's optics, are 2 times larger than the objective diameter in mm. That is, for the first Newton telescope it was 50 times,

View of Saturn with insufficient, optimal and excessive magnification

For example, the galaxy “Andromeda Nebula”, or M31 according to Monsieur's catalog, has angular dimensions 6 times larger than the disk of the full Moon, however, in order to examine it you will need a telescope, since its brightness is much less than the moon and you need to collect as much light as possible to see its details. Without a telescope, it looks like a dim speck in the night sky, much smaller than the moon, but this is nothing more than an optical illusion.

John Hadley Telescope (Newton's system)

Already in 1721, John Hadley built Newton's reflector with a lens diameter of 15 cm and a focal length of 158 cm, in which it was easy to observe Jupiter’s satellites and even discern the Cassini slit in Saturn’s rings, which was difficult to see in the 37-meter air telescope used Huygens.

Later, more sophisticated schemes were invented, using parabolic concave mirrors instead of a spherical and smaller secondary concave elliptical mirrors, from which the light reflected back — into a hole in the center of the main mirror, behind which the eyepiece stood, resulting in an image not turned upside down, as in Newton's system, and direct, and the length of the pipe at the same time decreased, and the spherical aberration was largely corrected.

The optical scheme of the Gregory telescope system

. In 1732-1768, James Short produced several telescopes using the Gregory system, the largest of which had a diameter of 55 cm. And William Herschel, from 1773, was able to make 430 mirrors for 20 years, as a result, he built the largest reflectors with focal lengths of 20 and 40 English feet (about 12 meters).

William Herschel's largest telescope with a focal length of 12 meters

The diameter of the bronze lens of a 40-foot reflector was 122 cm, and its thickness was about 9 cm, the mirror weighed at least a ton and sagged under its own weight. 75% of it consisted of copper and 25% of tin. The mirror very quickly darkened, cracked and demanded frequent repolishing, which Herschel performed manually for the first 15 years, as did the manufacture of new mirrors, where the polishing process took over 16 hours and did not allow to come off for a minute. It was extremely inconvenient to control the telescope and therefore Herschel, along with her sister Caroline, used telescopes of smaller diameter for most of their discoveries. Interestingly, during his life, Herschel discovered more than 2,500 nebulae, 806 double stars, performed 4 complete reviews of the night sky visible to him, and Caroline during her 98 years life, among other things, managed to discover 2 comets. His son John continued his work,

Today, the mirror of the largest telescope Herschel is stored in Slow.

In 1845, the English brewer William Lassel, fascinated by astronomy, builds a reflector with a diameter of 61 cm, installs it in his Starfield estate near Liverpool and a year later, on 10 October 1846, the satellite opened recently the planet Neptune - Triton, later with the help of the same tool he manages to detect the satellites of Uranus - Ariel and Umbriel. And in 1861 he managed to build a telescope with a lens diameter of 122 cm, like that of the Herschel telescope, which was later installed in Malta to conduct observations on the more southern part of the starry sky.

122 cm brand dedicated to William Lassel telescope

If we talk about the largest reflector of the XIX century, then he managed to build William Parson, who bears the title of Lord Ross. With a large capital, he decided to build the largest telescope in the world, but unfortunately all the paper with the secrets of manufacturing, James Short, destroyed and Ross had to invent a lot. Nevertheless, having spent a lot of energy and 20,000 pounds, huge money at that time, the telescope in 1845 was ready (it took 3 years to build). The diameter of the main mirror was 183 cm, weight 3 tons, pipe length 16 meters. The telescope was controlled by a complex system of blocks and cables, which were supposed to serve 2 people, had a limited field - could rise and fall, and turn side to side by only 15 degrees. The climate of Ireland can hardly be called the best - for the year 60-80 clear nights, mostly in winter,

Reconstructed Lord Ross’s telescope in Ireland is available for viewing at Birr Castle ( website ).

The telescope was restored in 2001 using drawings preserved by Ross’s wife and some modern technologies, the faded heavy mirror was replaced with a light aluminum one. To surpass Ross by building a telescope with a large mirror diameter, it was possible only at the beginning of the last century.

The fashion for glass mirrors appeared as early as the middle of the 19th century, since the glass was simpler in processing, and the silver coating reflected 2 times more light than bronze mirrors. In addition, the mirror was much lighter. In 1878, a reflector with a mirror diameter of 122 cm was installed, and already in 1888 - the largest 19th-century glass reflector. with a mirror diameter of 153 cm.

However, the final victory of glass reflectors over metal was in 1917, when the Mount Wilson Observatory, at the expense of millionaire John D. Hooker, built a reflector with a lens diameter of 2.58 meters.

100-inch reflector of Mount Wilson

The decisive victory of glass mirrors over metal ones was due to the invention of the Foucault's “shadows” method, which increased the manufacturing quality of optics and, as a result, the reflectivity of the mirror up to 90-95%. In 1930, they invented a method of aluminizing mirrors, as a result of which silver was replaced with aluminum, more resistant to oxygen, which, due to the presence of an oxide film, did not fade so quickly, but also reflected rays of a wider spectral range, such as ultraviolet, to which silver coating is simply not capable.

The 5-meter Hale telescope installed at the Mount Palomar Observatory began to be built in 1936, but due to the war its commissioning lasted until 1948, and for 28 years it remained the largest in the world.

Hale's 508-cm telescope (Palomar Observatory, USA)

SLR-telescopes gradually gain in popularity, which largely compensate for most aberrations, and also help reduce the size of instruments.

In 1975, a large alt-azimuth telescope with a main mirror diameter of 6.05 meters, located in the Caucasus, in Karachay-Cherkessia near the village of Nizhny Arkhyz on Mount Semiruchy (height 2070 m) at the Zelenchutsk Observatory, comes into operation.

Panoramic view of the BTA (Large Alt-Azimuth Telescope)

The history of the creation of this telescope is interesting. BTA was another example of the USSR gigantomania and, in essence, the goal of its creation was to surpass the Americans, they decided that a meter for these would be enough. After all, the Americans, designing the Hale telescope, considered it inexpedient to make it larger in diameter due to possible aberrations resulting from the deformation of the main mirror due to its large own weight.

Dome 6-meter BTA

It is funny that the optical industry was not ready for such a task and in Lytkarino a special plant was built for this purpose in the workshop available for the production of mirror reflectors. The task was set on March 25, 1960, the most difficult, was to build a 516 ton melting furnace for making a billet weighing 70 tons, burn it, process it with high precision, and make 60 holes for the unloading mechanism from the rear side. In 1963, the furnace was ready, another 3 years is spent on the construction of a workshop. As a result, three blanks were cast. The first billet cracked after the start of processing, since the burning and cooling process was attempted to be reduced, this happened 1.5 years after the start of cooling. The second blank was more successful, it was cast on November 20, 1964, then the process of burning and long-term cooling was started, which lasted until December 5, 1966 - 2 years and 19 days. The polishing process was no less simple, it was necessary to develop a scheme and build a special diamond cutter, as a result, over 7,000 carats of crushed diamonds and 1.5 years of time were spent on polishing. After processing, the weight of the billet dropped to 42 tons and further, on September 4, 1968, the billet was transferred for more accurate processing of its front side. At the Kolomna Heavy Machine-Tool Plant, the workpiece is installed in a technological frame, where LOMO specialists carry out its further high-precision processing - grinding, until January 1969, and then polishing, which was completed in July 1971, in a special thermostatted case on a unique grinding machine. In the next 2 months, the quality of the optics was checked using various methods. The polishing process was no less simple, it was necessary to develop a scheme and build a special diamond cutter, as a result, over 7,000 carats of crushed diamonds and 1.5 years of time were spent on polishing. After processing, the weight of the billet dropped to 42 tons and further, on September 4, 1968, the billet was transferred for more accurate processing of its front side. At the Kolomna Heavy Machine-Tool Plant, the workpiece is installed in a technological frame, where LOMO specialists carry out its further high-precision processing - grinding, until January 1969, and then polishing, which was completed in July 1971, in a special thermostatted case on a unique grinding machine. In the next 2 months, the quality of the optics was checked using various methods. The polishing process was no less simple, it was necessary to develop a scheme and build a special diamond cutter, as a result, over 7,000 carats of crushed diamonds and 1.5 years of time were spent on polishing. After processing, the weight of the billet dropped to 42 tons and further, on September 4, 1968, the billet was transferred for more accurate processing of its front side. At the Kolomna Heavy Machine-Tool Plant, the workpiece is installed in a technological frame, where LOMO specialists carry out its further high-precision processing - grinding, until January 1969, and then polishing, which was completed in July 1971, in a special thermostatted case on a unique grinding machine. In the next 2 months, the quality of the optics was checked using various methods. as a result, over 7,000 carats of crushed diamonds and 1.5 years of time were spent on polishing. After processing, the weight of the billet dropped to 42 tons and further, on September 4, 1968, the billet was transferred for more accurate processing of its front side. At the Kolomna Heavy Machine-Tool Plant, the workpiece is installed in a technological frame, where LOMO specialists carry out its further high-precision processing - grinding, until January 1969, and then polishing, which was completed in July 1971, in a special thermostatted case on a unique grinding machine. In the next 2 months, the quality of the optics was checked using various methods. as a result, over 7,000 carats of crushed diamonds and 1.5 years of time were spent on polishing. After processing, the weight of the billet dropped to 42 tons and further, on September 4, 1968, the billet was transferred for more accurate processing of its front side. At the Kolomna Heavy Machine-Tool Plant, the workpiece is installed in a technological frame, where LOMO specialists carry out its further high-precision processing - grinding, until January 1969, and then polishing, which was completed in July 1971, in a special thermostatted case on a unique grinding machine. In the next 2 months, the quality of the optics was checked using various methods. On September 4, 1968, the billet was transferred for more precise processing of its front side. At the Kolomna Heavy Machine-Tool Plant, the workpiece is installed in a technological frame, where LOMO specialists carry out its further high-precision processing - grinding, until January 1969, and then polishing, which was completed in July 1971, in a special thermostatted case on a unique grinding machine. In the next 2 months, the quality of the optics was checked using various methods. On September 4, 1968, the billet was transferred for more precise processing of its front side. At the Kolomna Heavy Machine-Tool Plant, the workpiece is installed in a technological frame, where LOMO specialists carry out its further high-precision processing - grinding, until January 1969, and then polishing, which was completed in July 1971, in a special thermostatted case on a unique grinding machine. In the next 2 months, the quality of the optics was checked using various methods. which was completed in July 1971. In the next 2 months, the quality of the optics was checked using various methods. which was completed in July 1971. In the next 2 months, the quality of the optics was checked using various methods.

Its transportation was no less difficult, we had to build 2 new river ports, several bridges, strengthen, expand and build hundreds of kilometers of roads so that the harvesting could be delivered to the destination. Nevertheless, they were afraid to risk the original, since the process of making a new mirror from a duplicate blank would require another 3-4 years. Therefore, it was decided to transport the simulator, which was done from May 12 to June 5, 1974. The main mirror of the telescope was delivered to the observatory on August 21, 1974. During transportation, temperature and vibration were carefully controlled, for safety, the mirror was placed in a special thermally insulated and anti-vibration container with multiple sensors.

Mirror transportation on the Moscow River

The observatory itself began to be built back in 1967, the telescope tower was planned to be 53 meters high and 45 meters in diameter, but in addition to the tower it was necessary to build a whole scientific town - houses of scientists, a power unit, water and power supply systems, a mountain road for delivering large loads 16 km. The total area of the scientific town was 50 hectares. In the kilometer distance from BTA there is a hotel for observers and staff housing and scientists, as well as other outbuildings.

Transportation of gears, drives and racks BTA (1968)

The main construction work was completed in 1971, after the installation of the telescope’s structure began. The total weight is 850 tons, the moving part is 650 tons, it was quite difficult to deliver and install the mount, for installation it was necessary to build a special crane. Also, since the mirror requires re-illumination every 5 years, the vacuum aluminizing installation VUAZ-6 was built (work on its manufacture lasted from 1963 to 1968, and in 1970 it was delivered to the observatory). Later aluminization technology was improved and it became possible to change the coating every 10 years.

In the middle of 1974, the debugging of all systems of the telescope was completed, on August 21, 1974, the main mirror and frame were delivered to the observatory, in September the mirror was reopened, cleaned and installed in the frame, and in October, work was carried out with a discharge mechanism.

The telescope mirror is a meniscus with a diameter of 6050 mm and a thickness of 650 mm, two main sources of its deformation are known - due to temperature gradients in the material, arising under the influence of the environment, and due to the very weight of the mirror. According to the Rayleigh optics quality criterion, deviations due to deformations of no more than 1 / 8λ (the wavelength of the observed radiation) are acceptable, which is no more than 0.035 μm. Based on these data, it was calculated that the BTA mirror is sufficient to unload at 60 end points, both in the end and in the radial directions, while the amplitude of deformations in the working area was 3 times less than the calculated one and was not more than 0.0096 microns.

No less important was the mount and its ability to move with great precision along both axes; to compensate for the Earth's rotation and image stability, greater accuracy of movement of the 650-ton design was required - in tenths of an angular second, which was ensured by hydrostatic bearings. The mount “floats” on hydrostatic oil cushions, where the oil is under a huge pressure of 70 atmospheres, acting evenly, which allows you to move such a heavy structure by applying a force of 15 kg to the 6 meter shoulder.

On November 3, 1974, the telescope was put into trial operation, and on December 30, 1975, an act of the State Interdepartmental Commission for the commissioning of the Large Azimuth Telescope was approved.

But not everything turned out well. After testing, the main mirror of the telescope revealed defects in the working surface. The Americans mocked the Soviets for a long time, since the telescope was inferior in quality to the Hale telescope, and it was also not built at the best point in terms of astroclimate. In 1979, the mirror was replaced with the existing duplicate and the quality was no worse than Hale, but the unfavorable climate remained. Nevertheless, the telescope remained the largest in the world until 1993.

It should be noted that in 2007, after almost 30 years of waiting, the defective mirror received a second life. It was allocated 200 million rubles for its correction, cut off a 8-mm-thick layer from the mirror and began to polish it. The polishing procedure could take 3 years, but stretched out for 10 years due to lack of funding.

If there was a task to make a new mirror, now it would be simply impossible - first we would have to build a glass furnace from scratch, despite the fact that at present its manufacturer practically does not exist, well, and then the years of cooling and so on . For the mirror polishing, modern technologies were used that were not available in the 1960s. The restored mirror has a jeweler's precision polishing the entire working surface of 28 square meters. m - deviation from the ideal shape of a paraboloid of rotation does not exceed 0.3 microns.

Delivery of the mirror also took a lot of time:

Now the people have become more cunning than in 2007, every year more and more bureaucrats, and more organizations than inspecting organizations than workers, - told a source in the Russian Academy of Sciences who was familiar with the situation. - As soon as some business appears, then ten inspectors with a spoon appear on one worker with a bipod, and everyone wants to get something. Therefore, transportation of a mirror is a huge amount of documents, which eats an incredible amount of time and money. ”

Not without unforeseenness as a result of lack of planning. It turned out that the mirror could not enter the territory of the observatory of the Russian Academy of Sciences, since the gates simply were not designed for such dimensions - it was necessary to demolish part of the brickwork.

On February 14, 2018, the mirror successfully arrived at the observatory, the delivery cost 11 million rubles and took 7 days, because of the fragility of the cargo, it could not be transported at a speed of more than 40 km / h, because of the snowfall it was necessary to sprinkle roads and one of the stages to overcome 50 km took 2 days, and the last 16 kilometers of mountain serpentine transport speed did not exceed 10 km / h. But astronomers are no longer in a hurry - it’s still impossible to start installing a mirror before the onset of a warm spring, and the installation procedure will take 3-4 months.

Now the BTA telescope is among the ten largest and best telescopes in the world.

Continued (link will be available here) ...

Thank you for staying with us. Do you like our articles? Want to see more interesting materials? Support us by placing an order or recommending to friends, 30% discount for Habr users on a unique analogue of the entry-level servers that we invented for you: The whole truth about VPS (KVM) E5-2650 v4 (6 Cores) 10GB DDR4 240GB SSD 1Gbps from $ 20 or how to share the server? (Options are available with RAID1 and RAID10, up to 24 cores and up to 40GB DDR4).

VPS (KVM) E5-2650 v4 (6 Cores) 10GB DDR4 240GB SSD 1Gbps until spring for free if you pay for a period of six months, you can order here .

Dell R730xd 2 times cheaper? Only we have 2 x Intel Dodeca-Core Xeon E5-2650v4 128GB DDR4 6x480GB SSD 1Gbps 100 TV from $ 249 in the Netherlands and the USA! Read about How to build an infrastructure building. class c using servers Dell R730xd E5-2650 v4 worth 9000 euros for a penny?