We study nitrogen lasers - part 2. Longitudinal discharge lasers

In the last part, we looked at examples of self-made and factory designs of nitrogen lasers with a transverse discharge, and it was this topology that became the most popular for repetition by home-builders. And here are its advantages:

But this topology is not without some drawbacks. What exactly and what led to their elimination? Read on.

In the last part, I gave examples of commercially available nitrogen lasers in the West. But in the former USSR the “design school” was radically different.

If the nitrogen laser gradually reduces the pressure and increases the distance between the electrodes, then gradually you can come to the ... laser longitudinal discharge. When both the electrical discharge in the gas and the radiation are completely coaxial. In this case, the discharge burns in a thin glass tube, approximately as in a helium-neon laser. With a lower nitrogen pressure, the environment gain is lower, the pulse duration approaches the maximum possible (the normal value is 10-20 nanoseconds), and the power requirements are further reduced.

Longitudinal discharge lasers have advantages that cover the disadvantages of transverse discharge lasers:

The method of exciting a short-duration discharge is also radically different — it is usually excited by means of a high-voltage pulse transformer. The transformer is wound on a stack of ferrite rings high-voltage coaxial cable. The outer braid of the cable is cut into pieces so that, passing through a hole in the ring, these pieces of braid form one or 2-3 turns and the ends of these pieces of braid are connected in parallel. And the central core of the cable, over which evenly distributed pieces of braid, is wound on a stack of rings continuously, forming 10-15 turns. Thus, by changing the way the sheath is cut, it is possible to flexibly select the output voltage, while there are no fundamental limitations in the achievable output voltage. Such a transformer can have any transformation ratio,

Nevertheless, longitudinal discharge lasers are also not without drawbacks, besides the need for an optical resonator and a vacuum. They are the reason for their very low prevalence, except for the countries of the former USSR, where they occupied their niche of application, and in which they had to put up with these shortcomings. The main field of application of these lasers was the technological equipment of the microelectronic industry, which required high beam quality and the possibility of its very fine focusing with a relatively large (for some models) average power.

The laser longitudinal discharge is also characteristic:

Now we will look at the most famous and popular laser made in the USSR - LGI-21, also known as LGI-503. And this is my very first laser with which I started my passion for lasers. I got it back in my student days, while writing off devices from one of the laboratories. Like any laser, it consists of a radiator and a power supply. The declared laser power is 3 mW with a pulse repetition frequency up to 100 Hz, which is, in general, quite a bit.

Inside the emitter is a glass tube of coaxial design. In the center there is a thin tube in which the discharge burns, and on the outside there is a ballast volume containing some amount of nitrogen.

The power supply is designed inside quite simple. In the upper right corner there is a high-voltage pulse transformer, just to the left - storage capacitors, which are discharged by the thyratron to its primary winding, in the center - the TGI2-130 \ 10 pulse thyratron, to the left - the power high-voltage transformer with a voltage doubler. In the lower right corner there is a generator with two lamps for controlling the thyratron.

This is exactly the laser that I first learned to repair, adjust, carefully studied its device.

Now I will tell you how I managed for the first time to restore the operability of a sealed laser tube that stood in the LGI-503 laser, which happened quite a long time, at the very beginning of my hobby with laser technology.

After careful adjustment of the mirrors when turned on, the laser produced a very, very “sluggish” beam.

No tricks with the power source and the setting of the mirrors did not help any more - everything testified that the gas from it “ran out of steam”. Thinking that there would be no worse, I broke off the nipple on the laser tube and stuck a piece of glass tube to it. Inside, I inserted a piece of hose from the dropper and connected it to a vacuum pump. A needle was inserted into the gum with another hose from the dropper, on which there was a clip - an improvised gas leak.

Then I turned on the pump and waited for him to siphon the tube to the utmost vacuum, then slightly opened the leak and turned on the power supply. There was a bright and steady discharge in the tube, and a very bright (as to what it was) beam appeared at the output!

At the same time, in the "fresh air" the laser was able to produce lasing without the participation of the output mirror of the resonator, only its power was of course lower.

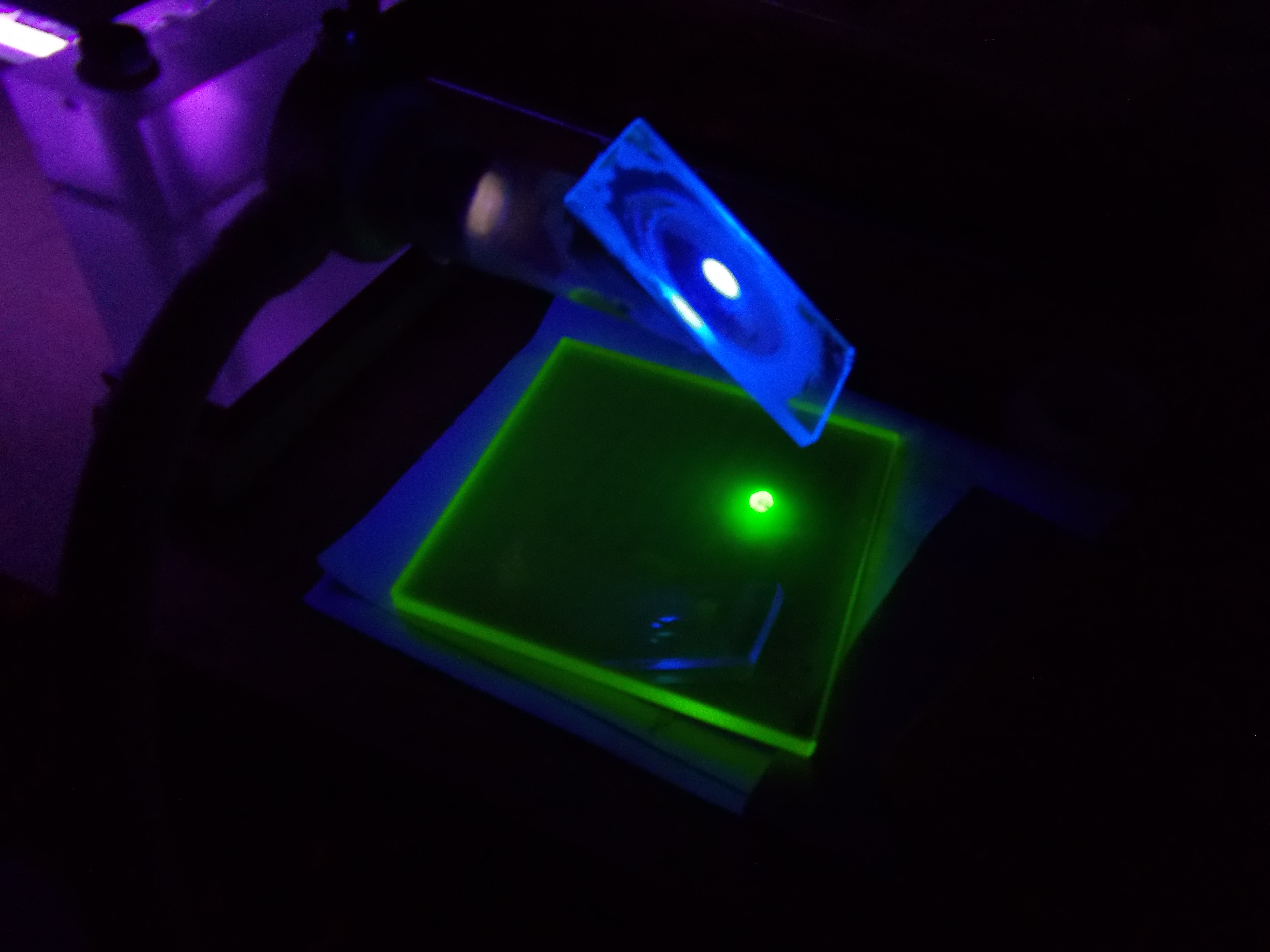

Especially beautiful under the beam is the luminescent plate of uranium glass.

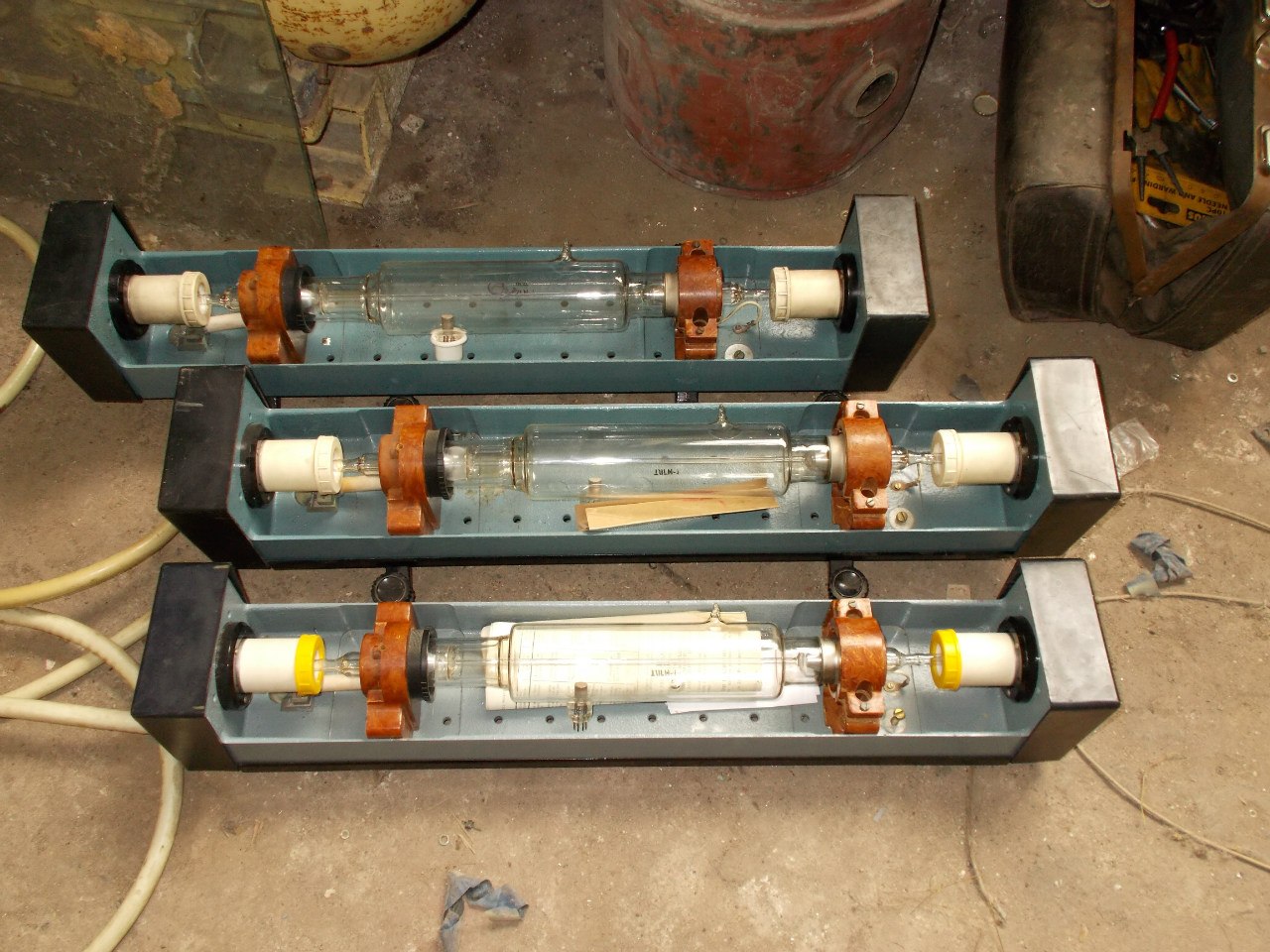

As it turned out, room air is quite efficient in low-pressure lasers with a longitudinal discharge. The selection of pressure could find the maximum radiation power. It was because I now had the opportunity to experiment a lot with a serial laser, so I did not bother with building a self-made cross-discharge. Moreover, I like the thin beam of a neat round section much more. Thus, the rehabilitation of the nitrogen laser tube is a very simple operation, it is enough to open it, pump it out again and find the optimal pressure. The pressure interval at which there is generation is relatively wide - from tenths to tens of millimeters of mercury. Now, when I managed to restore the laser tube for the first time, I decidedOn this, it is good to make money to consolidate your experience and make the following tubes sealed again. I gathered at the university laboratories 3 more non-working lasers and drove to a familiar glassblower who soldered new fittings for pumping and filling to the place of the exposed dowels.

There, in the glass-blowing workshop, these pipes were able to be pumped out and filled with pure nitrogen, but what is characteristic is that there was no noticeable difference in power output compared to air. The brightness of the luminescence spot looks the same as in the case of air and pumping at home.

Then the tubes were sealed, and the lasers were assembled and returned to customers. After that, it became much easier to get the used off components, and then the new lasers - I managed to get two tubes from the LGI-505 more powerful and much rarer nitrogen laser, whose power from different sources is from 40 to 120 mW. It also has a longitudinal discharge tube, but the construction is more “oak” - the discharge burns in a ceramic capillary, which is cooled outside by water, the cathode is made in the form of an aluminum cylinder of large diameter, the process is welded to the side, in which there are glowing pills of a substance for regeneration nitrogen, if the gas pressure in the tube for some reason decreases. Even more striking is Brewster’s massive quartz-made weekend windows. Photo tube below.

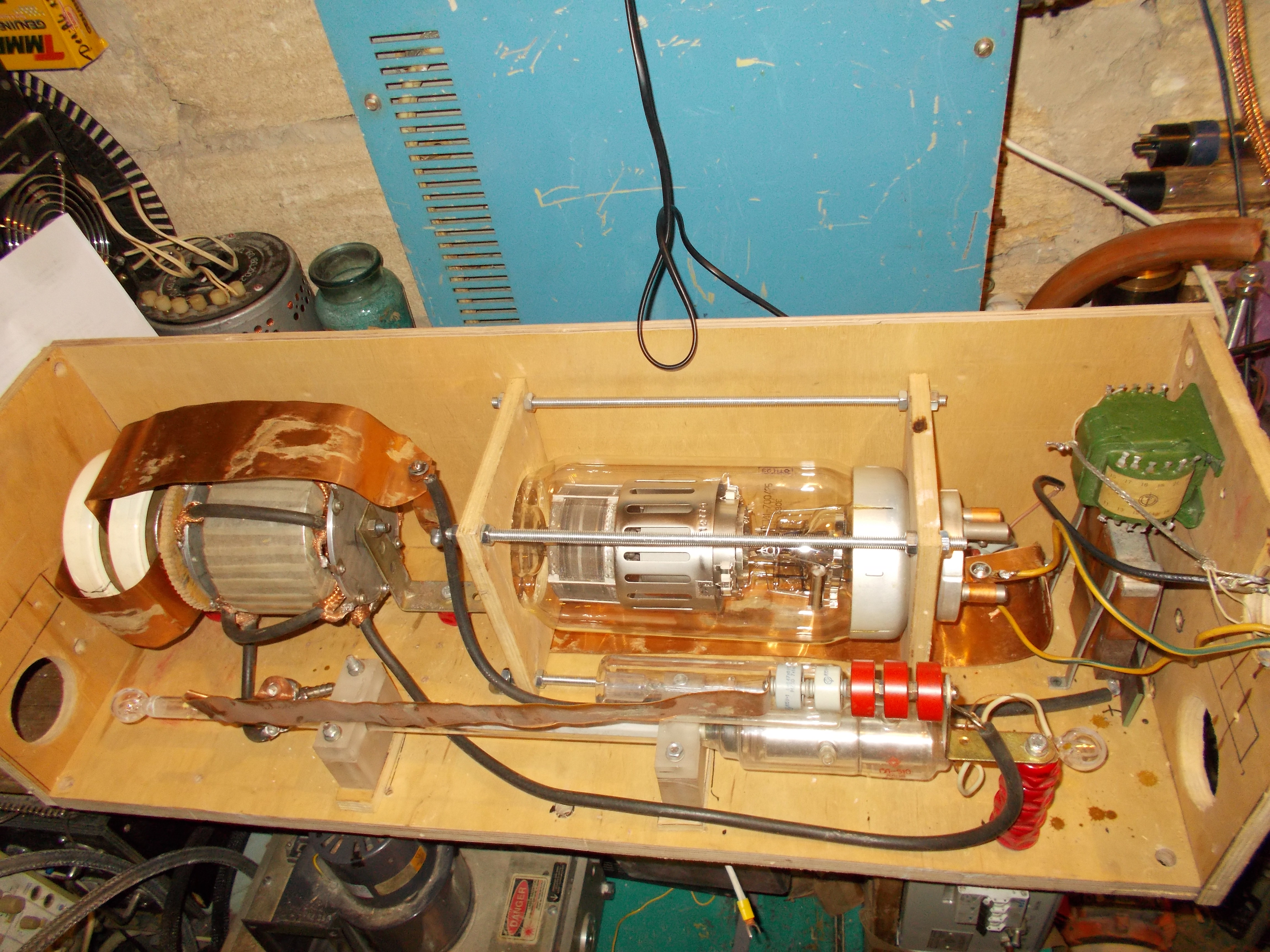

Inside the emitter, the tube is assembled together with nanosecond pulse formation chains consisting of a thyratron, a pulse transformer (a small tank with oil and insulators), and some other details. Since I only have the tubes themselves, the photo of the emitter is taken from Google.

But I still got the external power supply with the tubes. But he is only engaged in the development of high voltage for charging the storage capacitors inside the emitter and the thyratron control pulses.

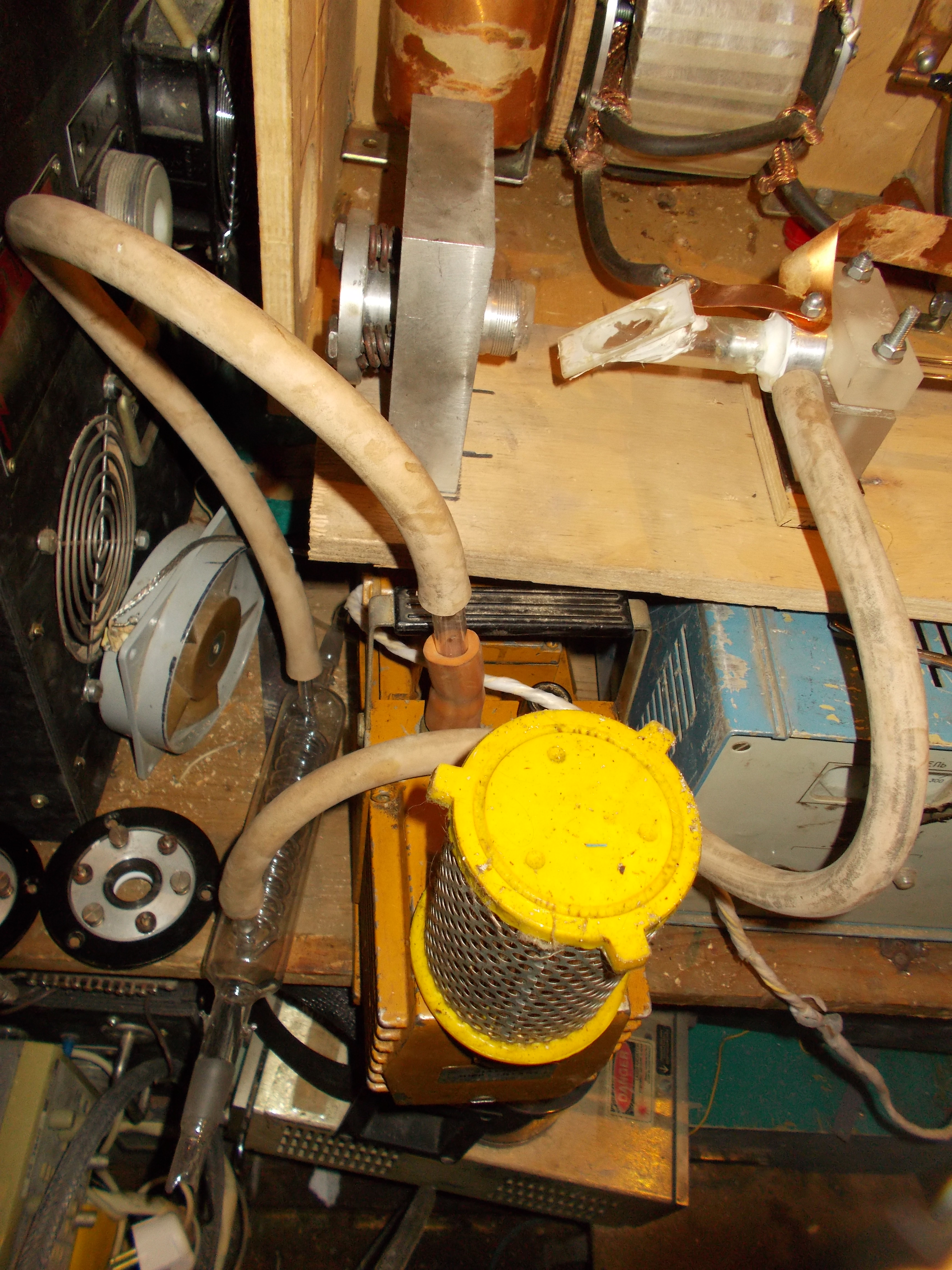

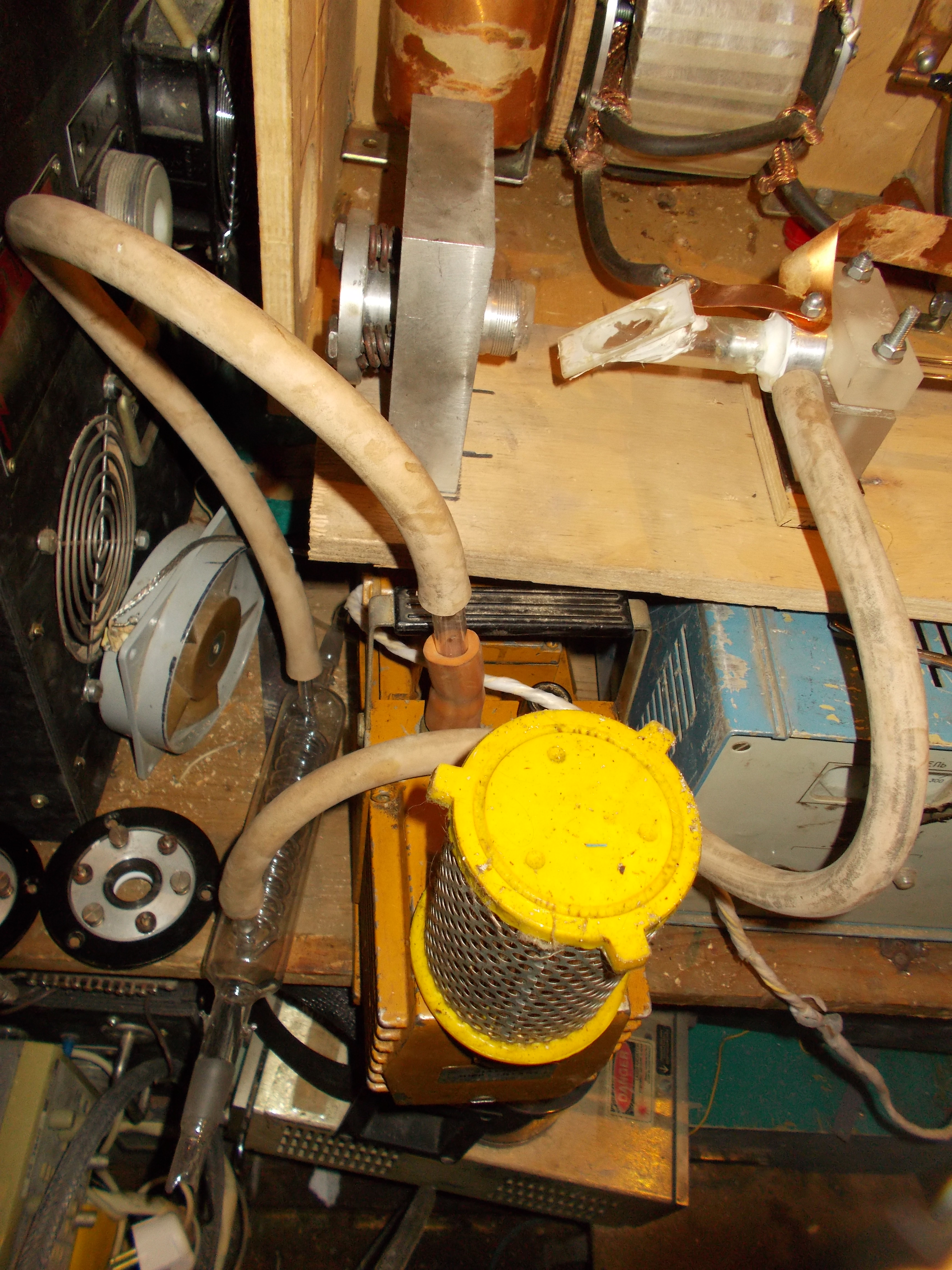

Inside it has a rather curious design - a high voltage generator is an old Soviet switching power supply on thyristors with a miniature oil transformer at the output, which has a water-cooling jacket.

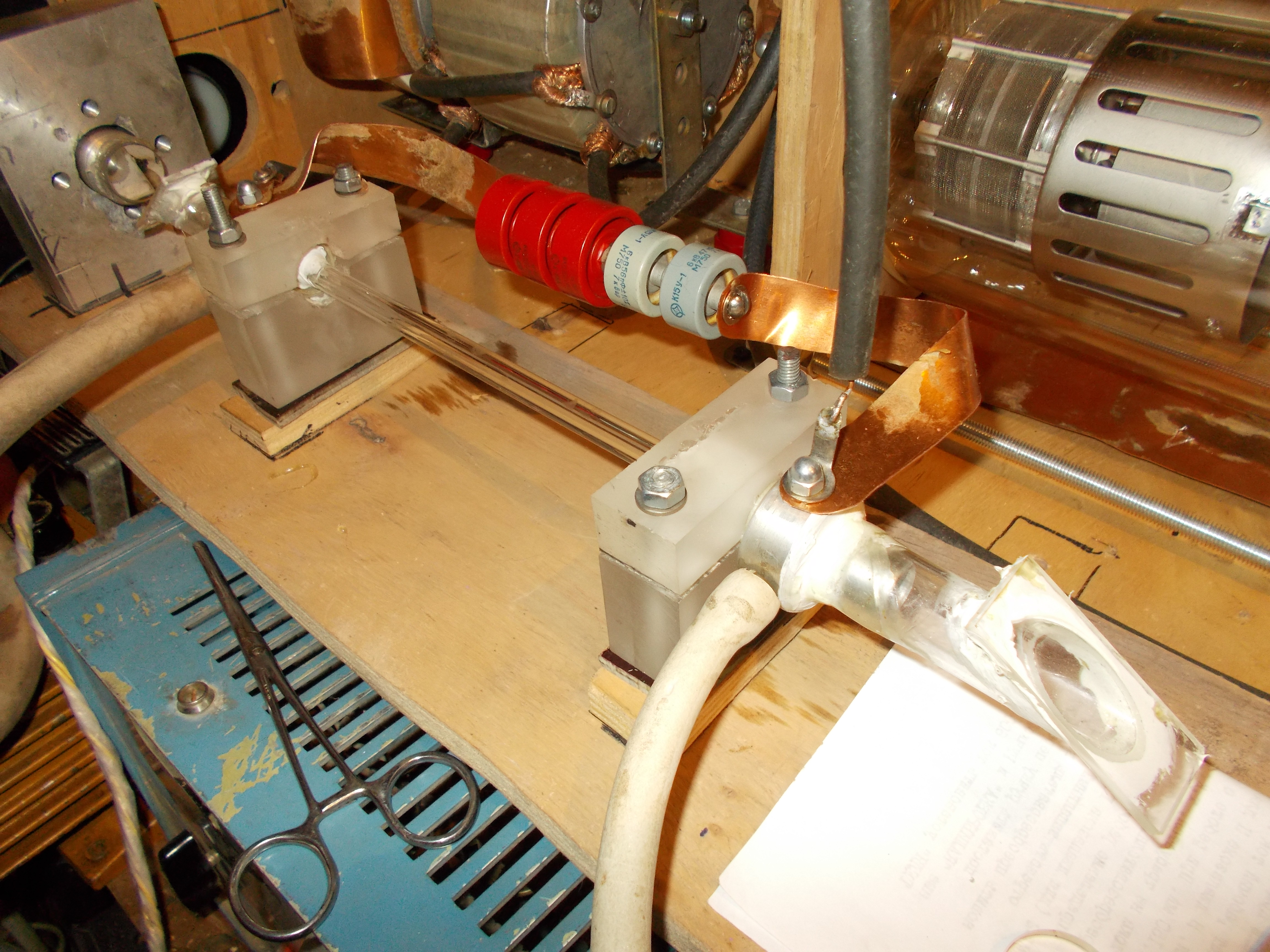

Using the diagrams from the enclosed instructions, I was able to restore the necessary “power part” of the radiator and launch the LGI-505. The circuit is essentially identical to that for LGI-21, only a pulse transformer, a tiratron more powerful, a storage capacitor of a larger capacity. The transformer is self-made, wound with a coaxial cable on 6 ferrite rings with a size of 120 * 80 * 12. The braid on the cable is cut into 8 parts, all parts are connected in parallel and form one coil of the primary winding. The central cable core forms 8 turns of the secondary winding. The amplitude of the voltage pulse from the transformer is estimated at about 70-80 kV. The thyratron was installed TGI1-1000 \ 25, which in principle is redundant, but there was no other at that time. A single capacitor k15-10 with a nominal 4700 pF 50 kV was used as a storage capacitor.

High voltage and control pulses are fed from the native power supply shown above.

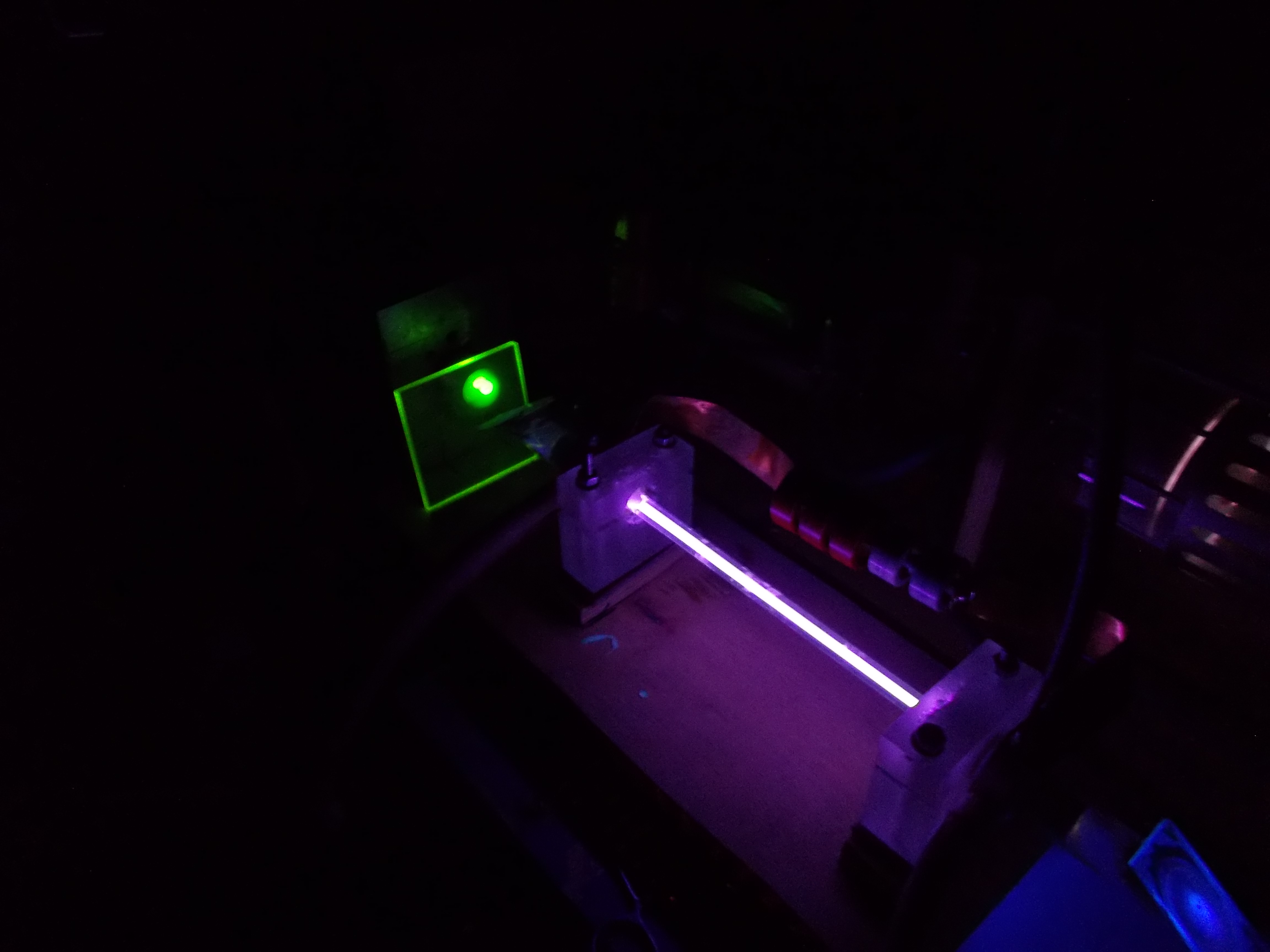

At the very first start, superluminescent radiation appeared at both ends of the tube, exceeding the LGI-21 laser with an optical resonator in power.

Adding a resonator to this laser tube has significantly increased the output power.

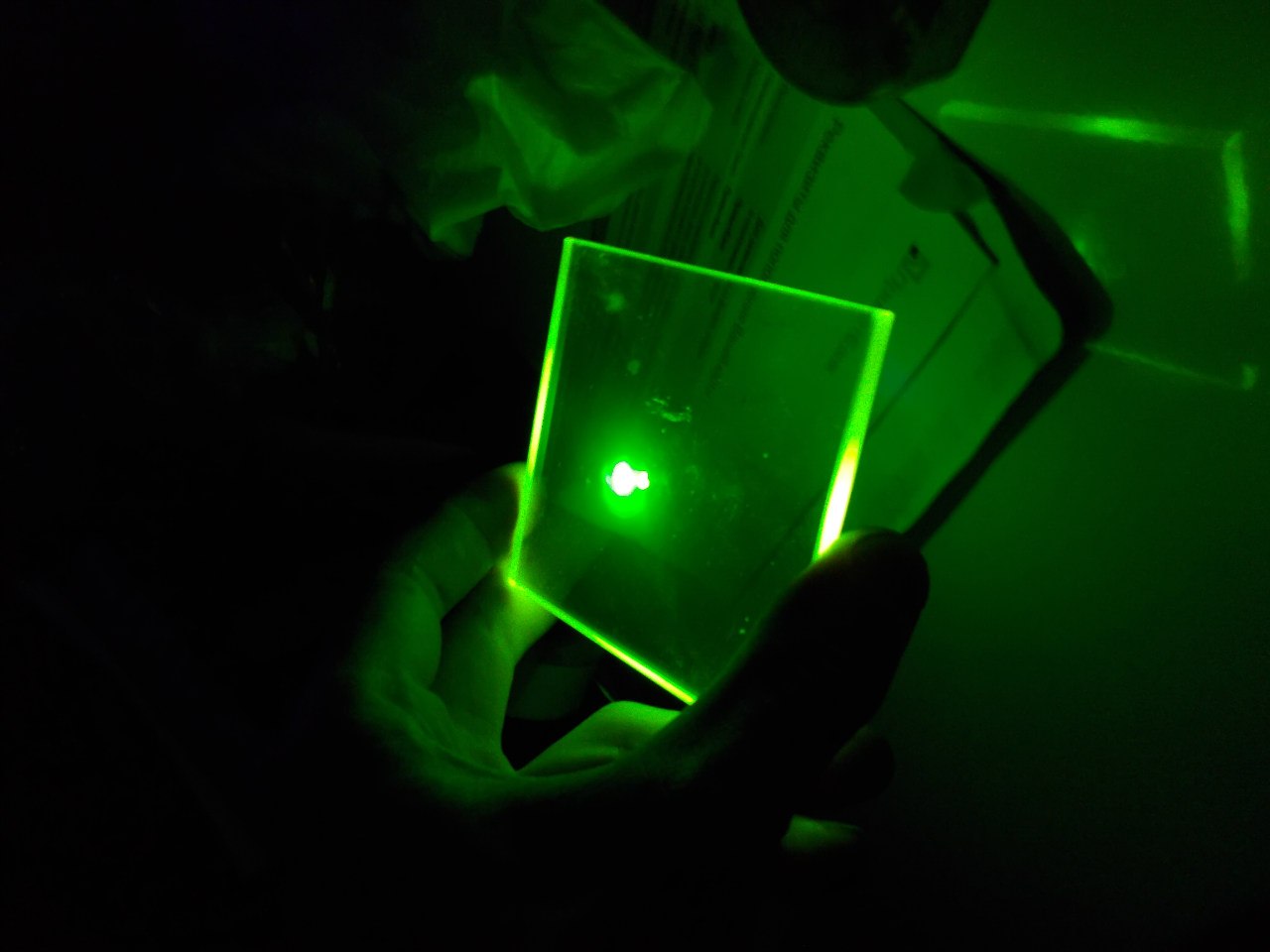

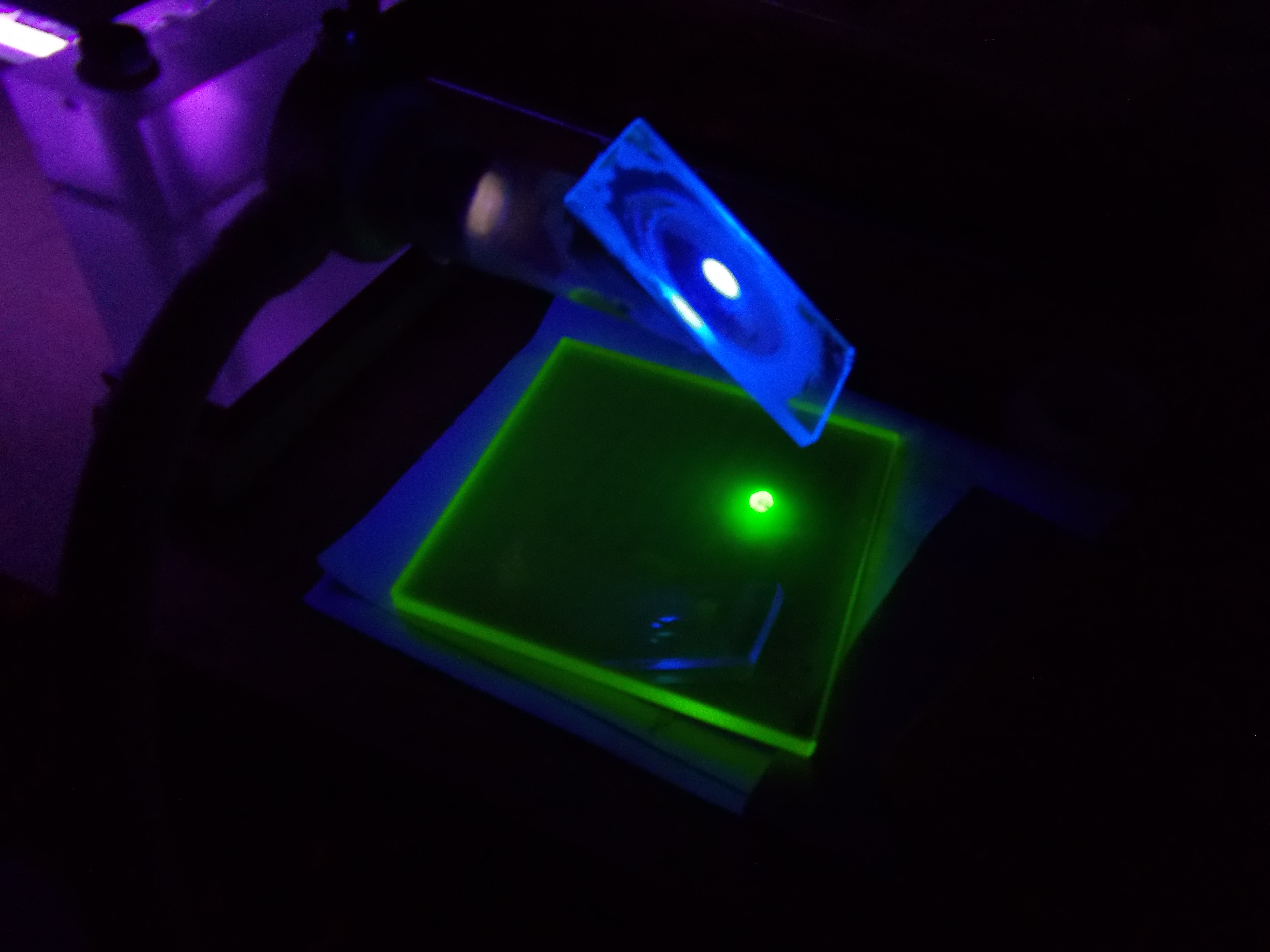

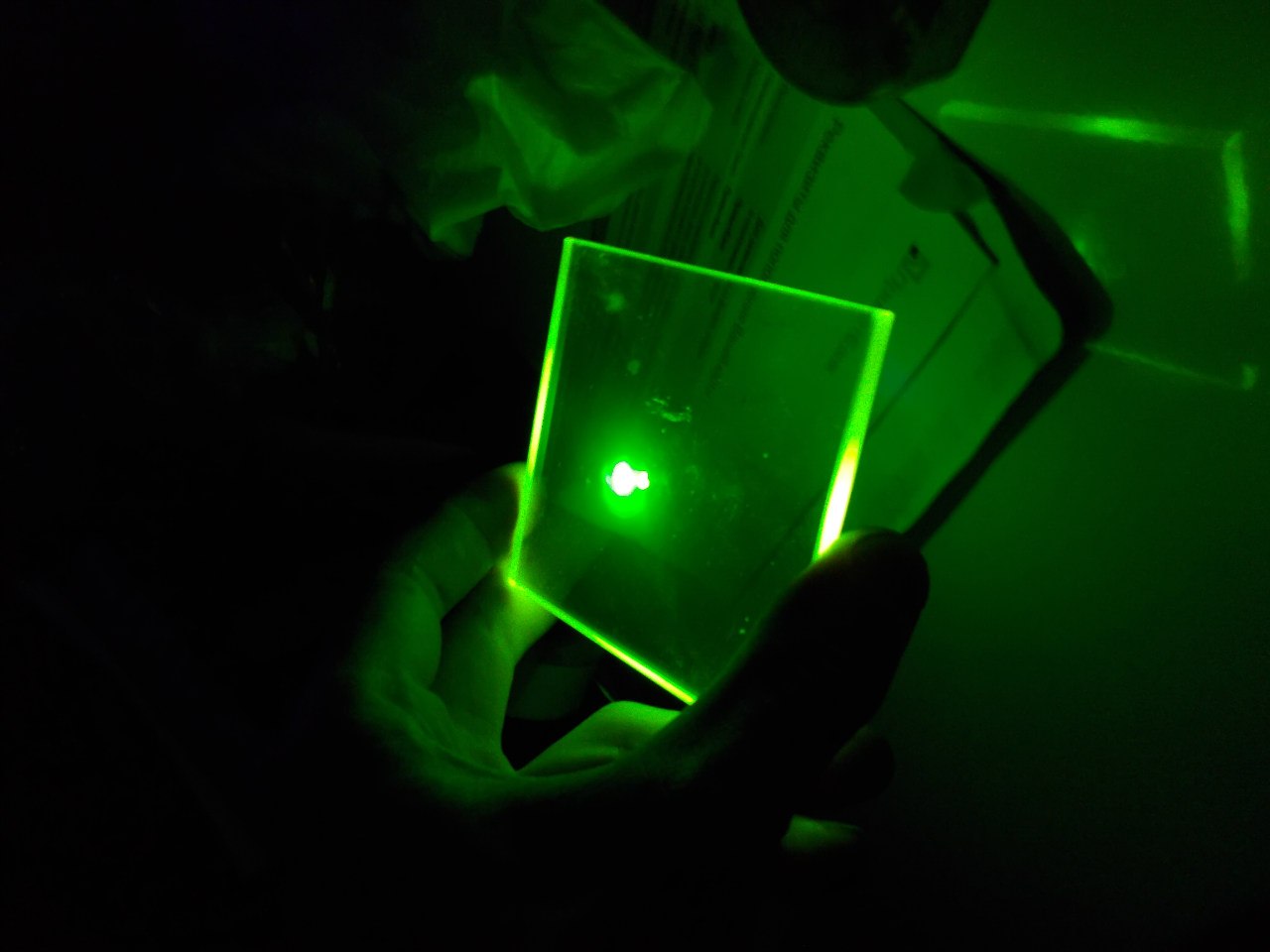

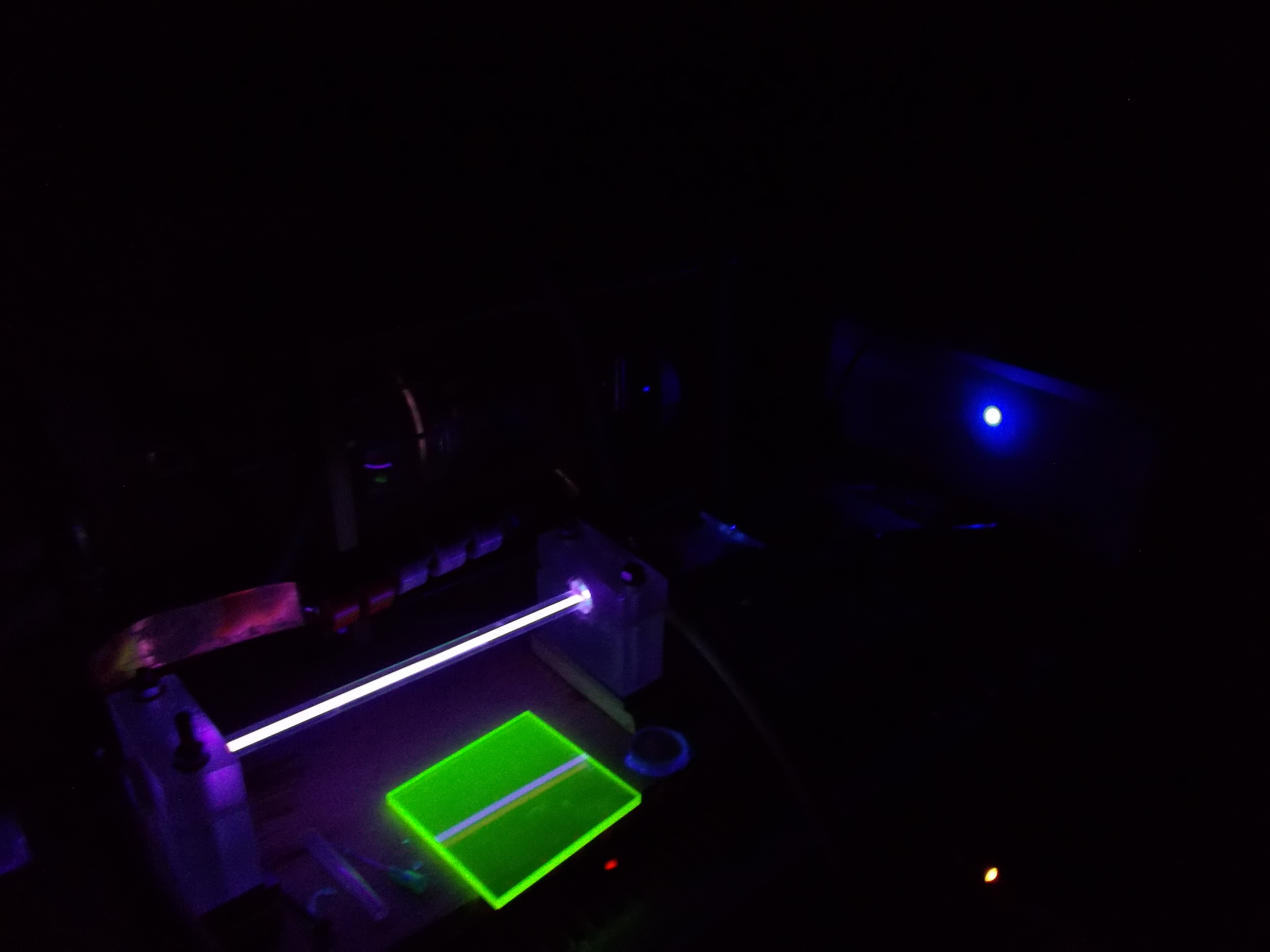

Particularly spectacular looks with the participation of uranium glass as a target.

This laser had every chance of becoming my finished product, even the outer case was finished.

But then began the construction of my copper vapor laser, and I needed from there first a TGI1-1000 \ 25 thyratron, and then a pulse transformer for experiments. And this construction was partially dismantled and put aside into the far corner, its further fate remained unknown until very recently. Until I wanted to make my own tube for a nitrogen laser.

Independently making a longitudinal discharge nitrogen laser is much more troublesome than a transverse discharge laser, since it requires working with glass tubes and fussing with vacuum, we also need a simple optical resonator made of an aluminized dummy mirror and a plane-parallel transparent window - the output mirror. But even in this case, it is possible to obtain generation using the traditional Blumlein generator assembled on several ceramic capacitors. Nitrogen lasers of the longitudinal discharge are very rarely found in home-builders, but they exist. For some reason, mostly from the Germans. The following are examples of designs.

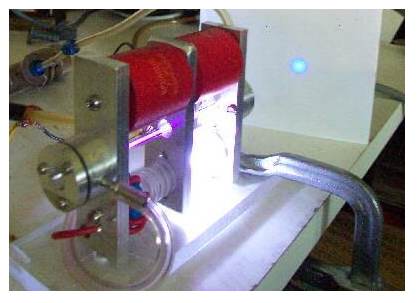

Laser from adrian-homelab.de

A miniature longitudinal nitrogen laser from deralchemist.wordpress.com

And another, apparently, which served as the primary source for the previous one, the Thomas Rapp laser from pulslaser.de.

It is a thin and round laser beam that is the main argument in favor of a longitudinal discharge laser.

Also on the Internet there are examples of conversions of damaged helium-neon lasers into nitrogen - in essence, the task is to build a power source and a vacuum system. Well, you need to carefully with this open the tube and stick to it fitting for pumping. The result is the same as in the case of a completely homemade tube.

And finally, my own design!

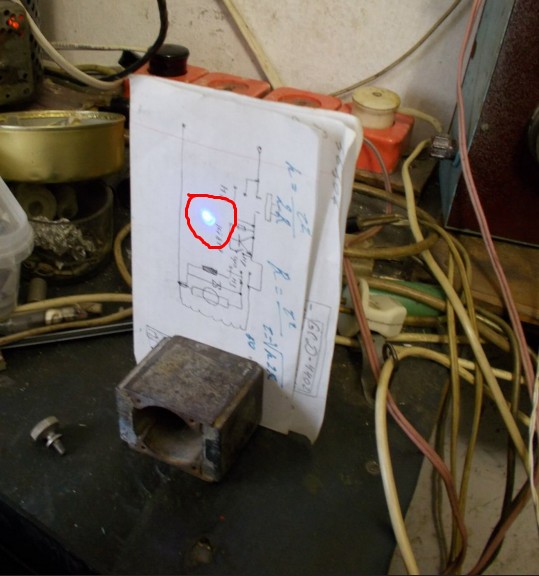

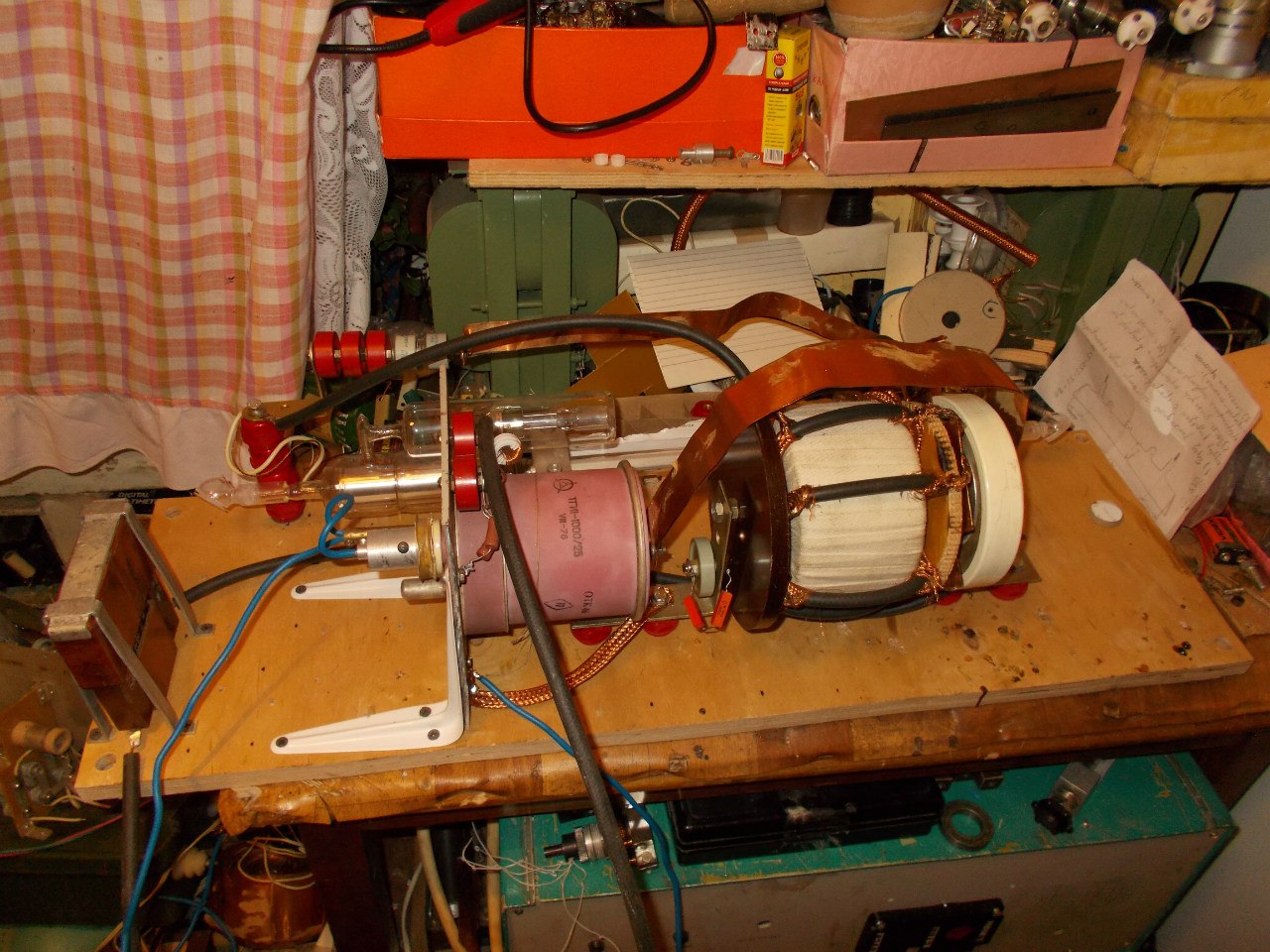

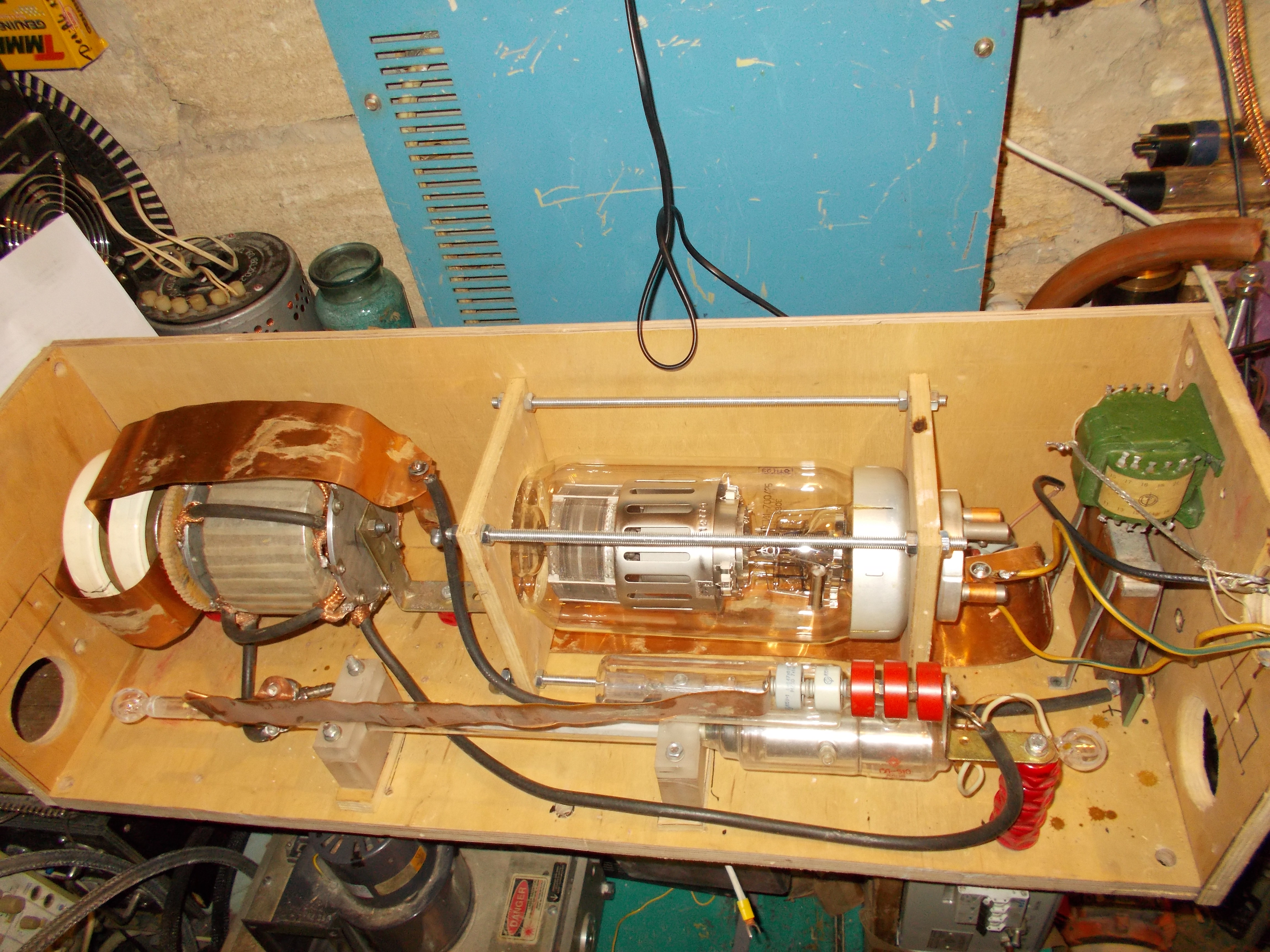

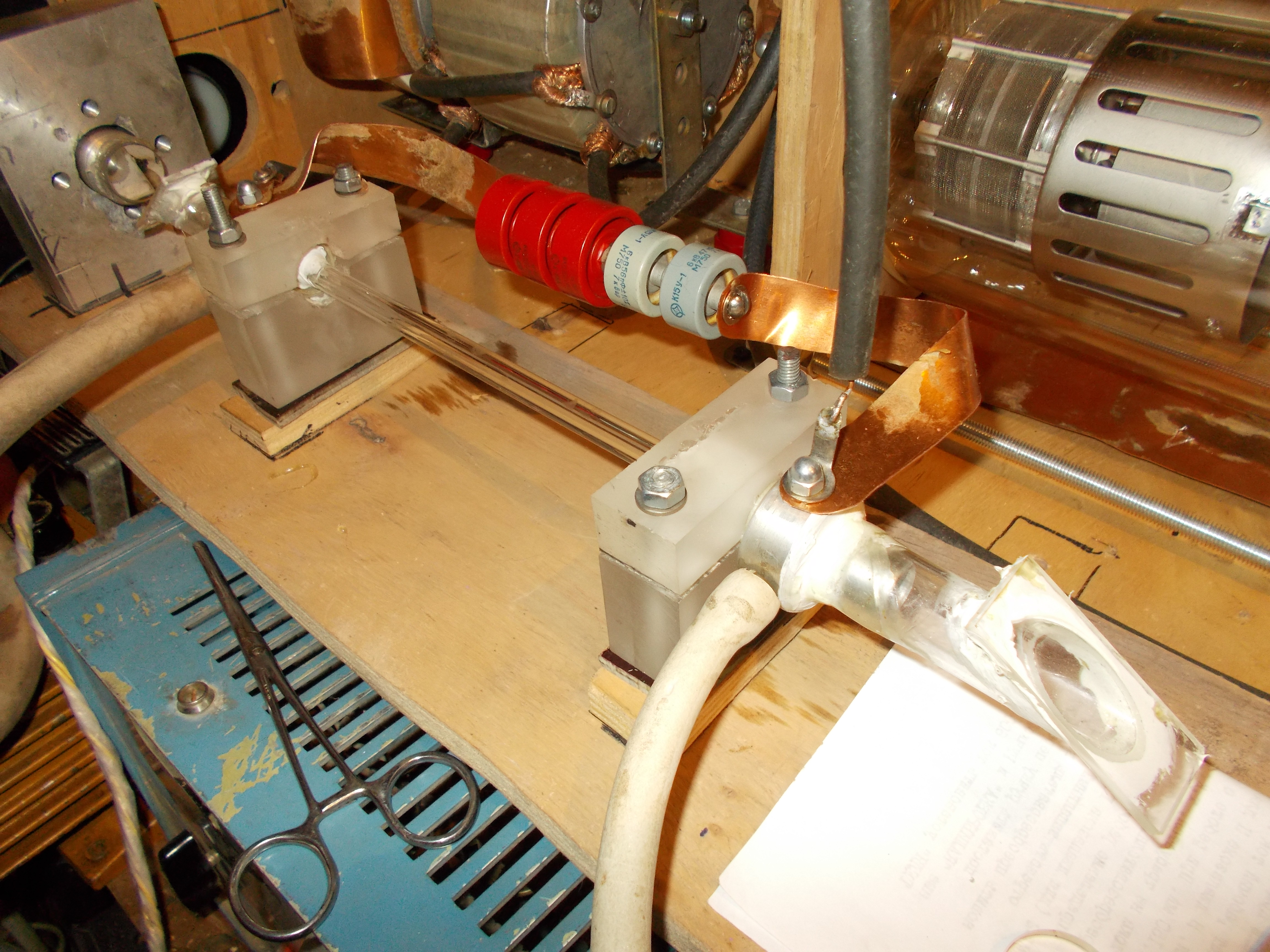

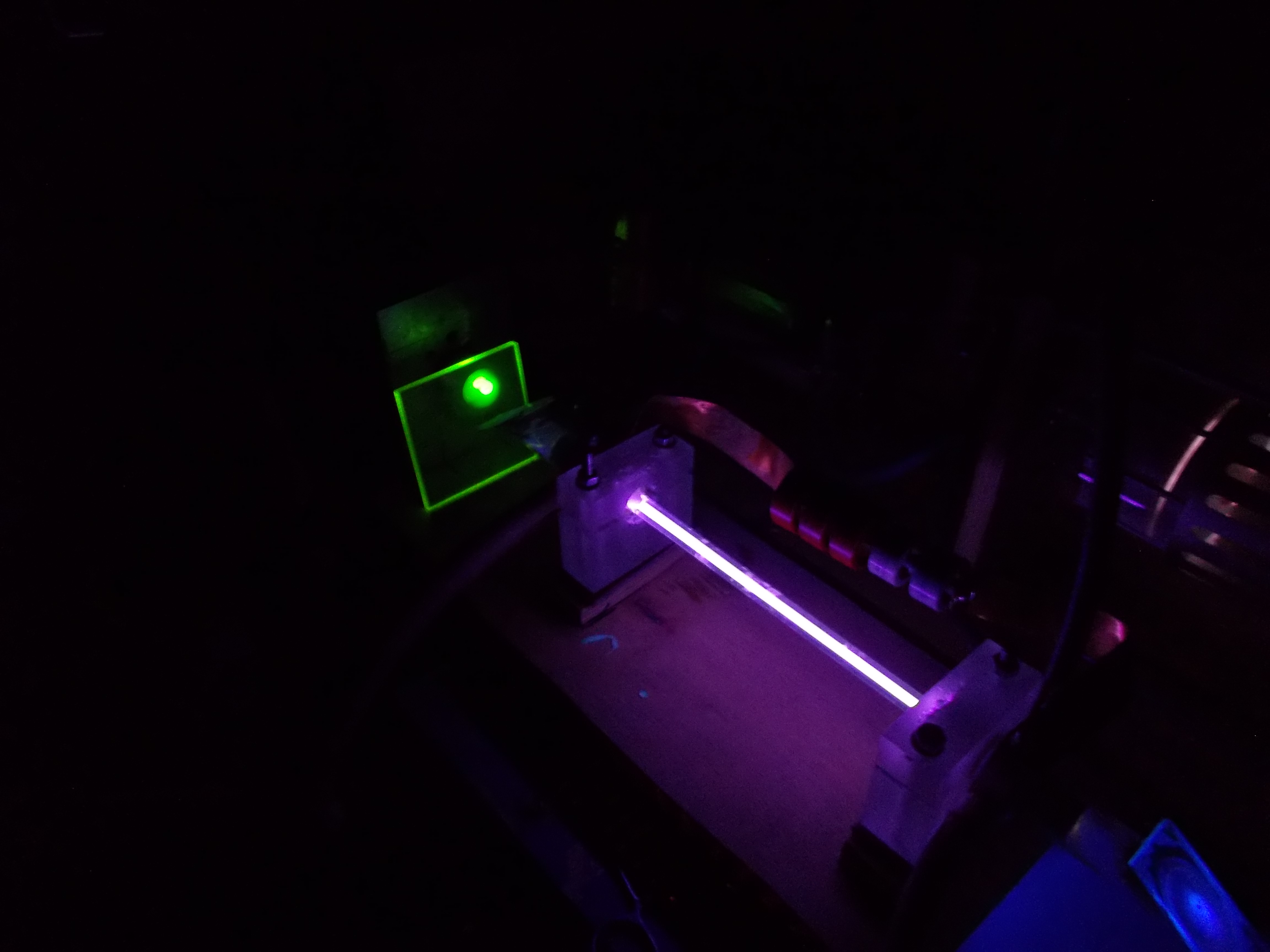

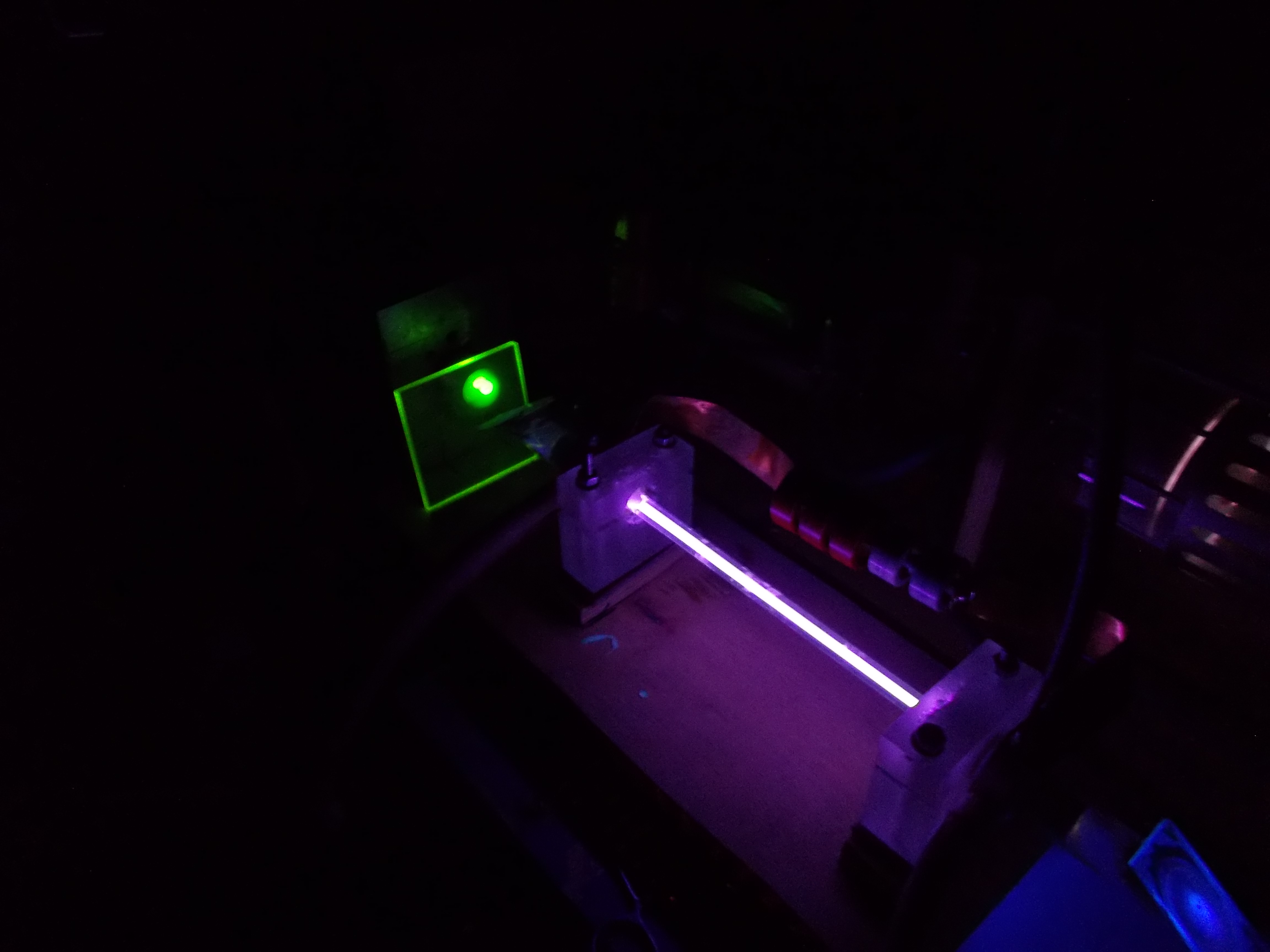

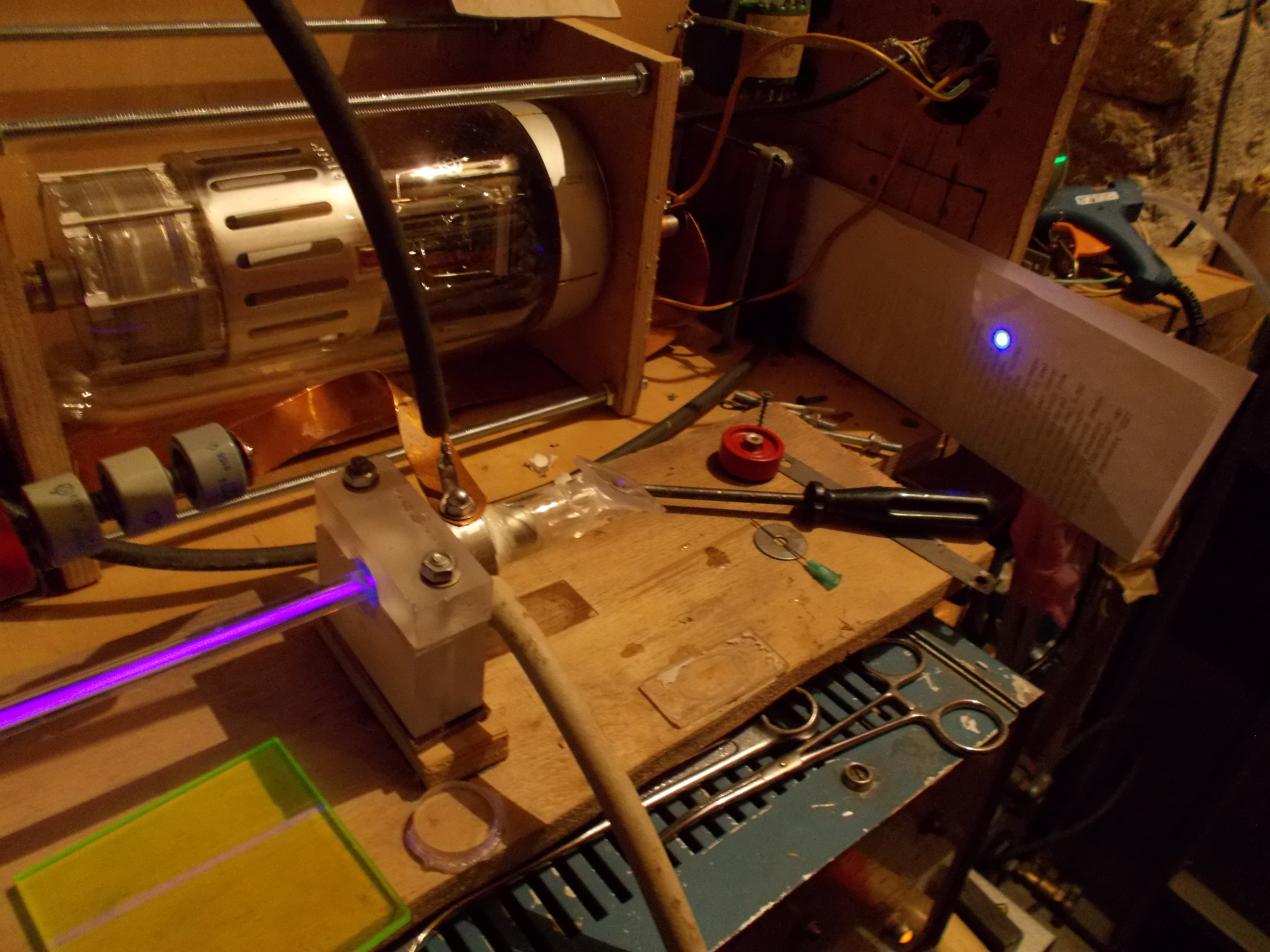

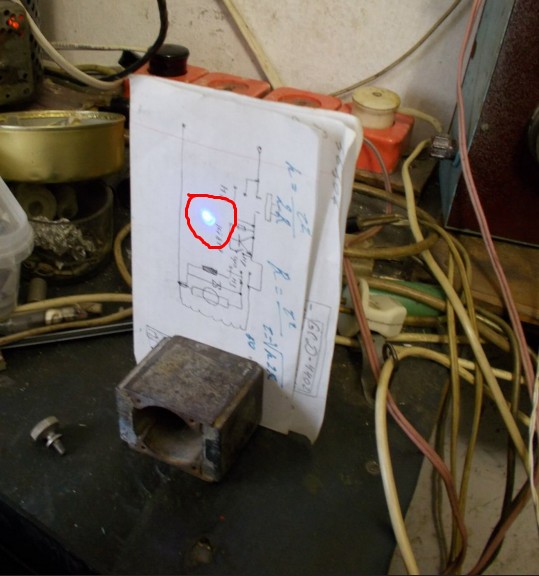

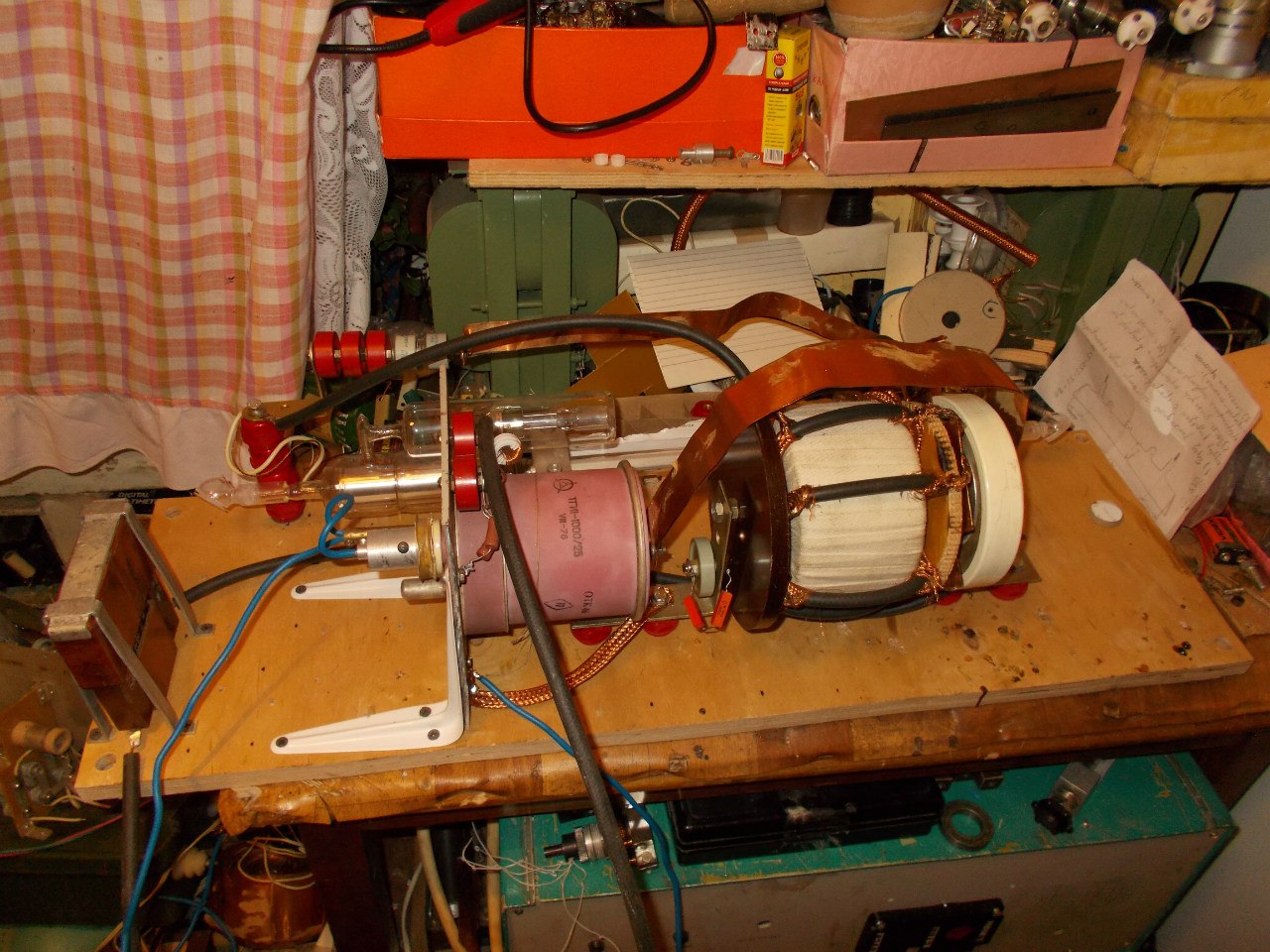

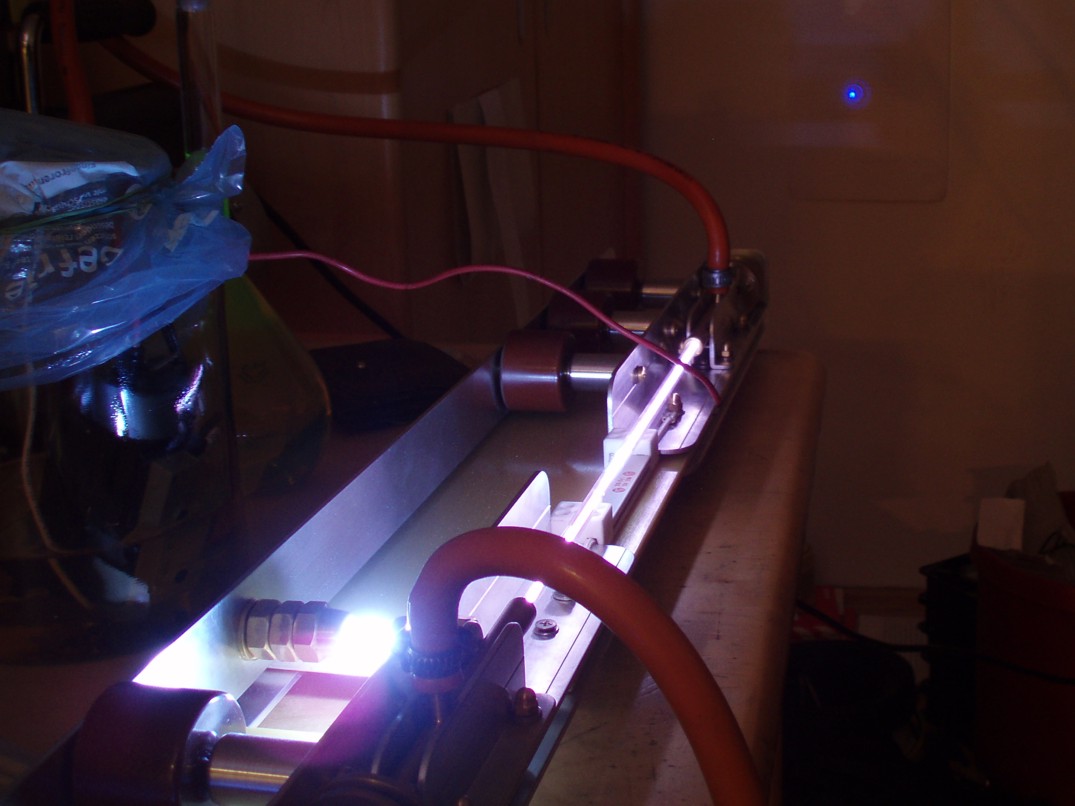

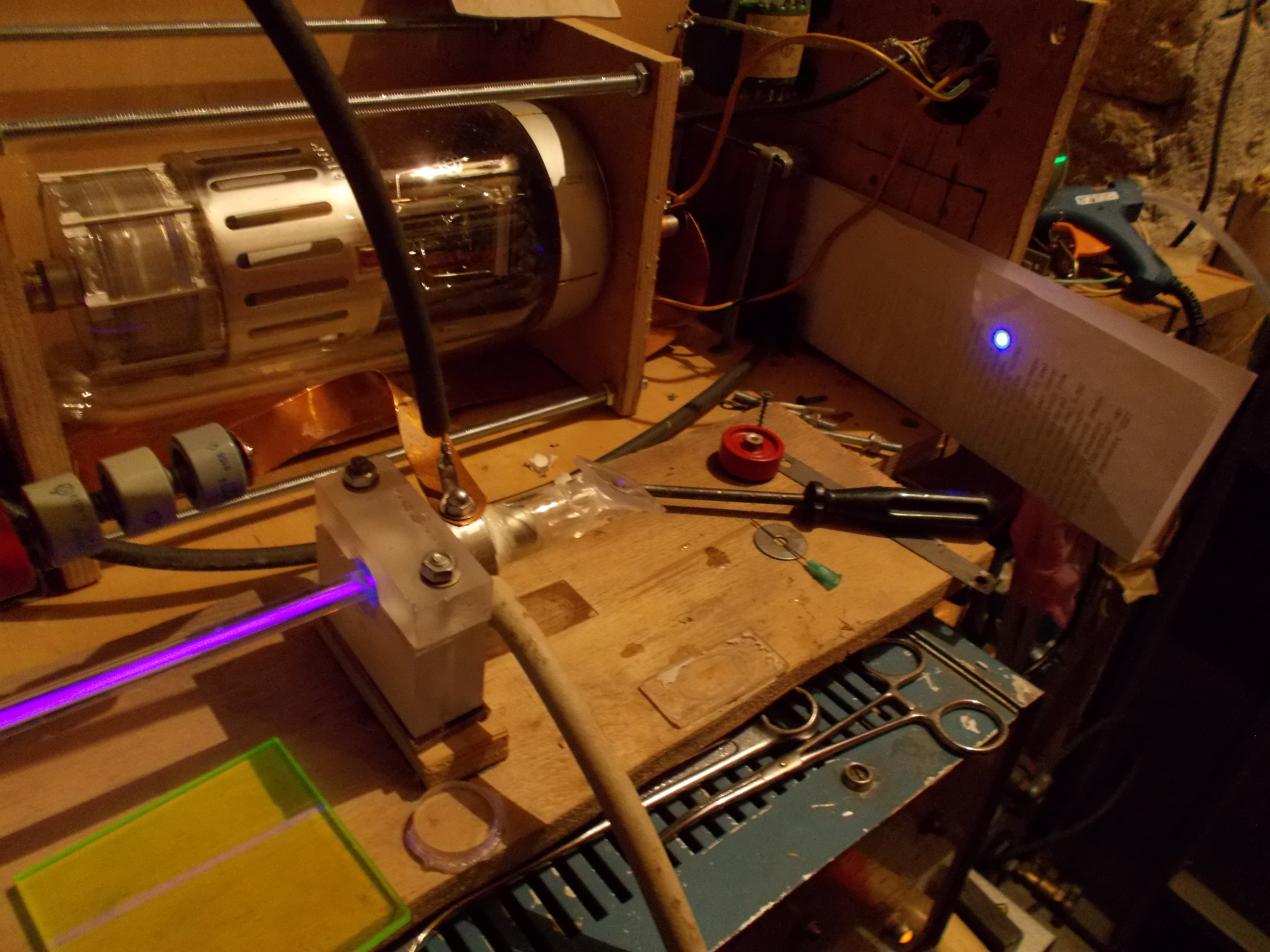

This laser was assembled on an existing electric platform, on which the LGI-505 laser was assembled with some cosmetic changes. A new, more cultivated pulse transformer was made, with the same parameters as they were.

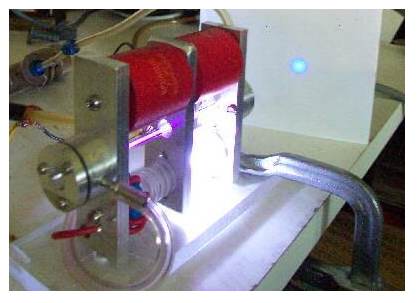

A new thyratron was installed, which showed its inconsistency in the power source of a copper vapor laser, but it works perfectly here - TGI1-700 \ 25, large and glass. A second capacitor, K15-10, was added to increase the overall power to the system. By changing the capacitor connection, you can select the appropriate "pump energy". As a result, the experimental platform began to look like this, together with the same LGI505 tube, on which it was tested.

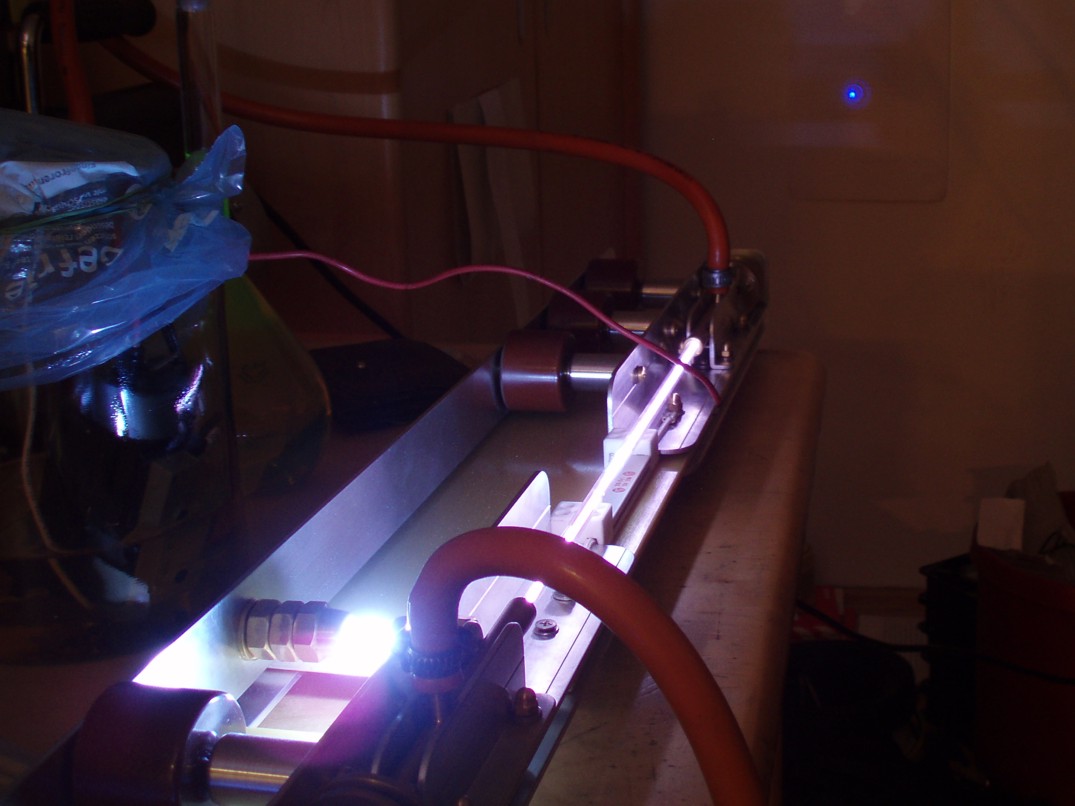

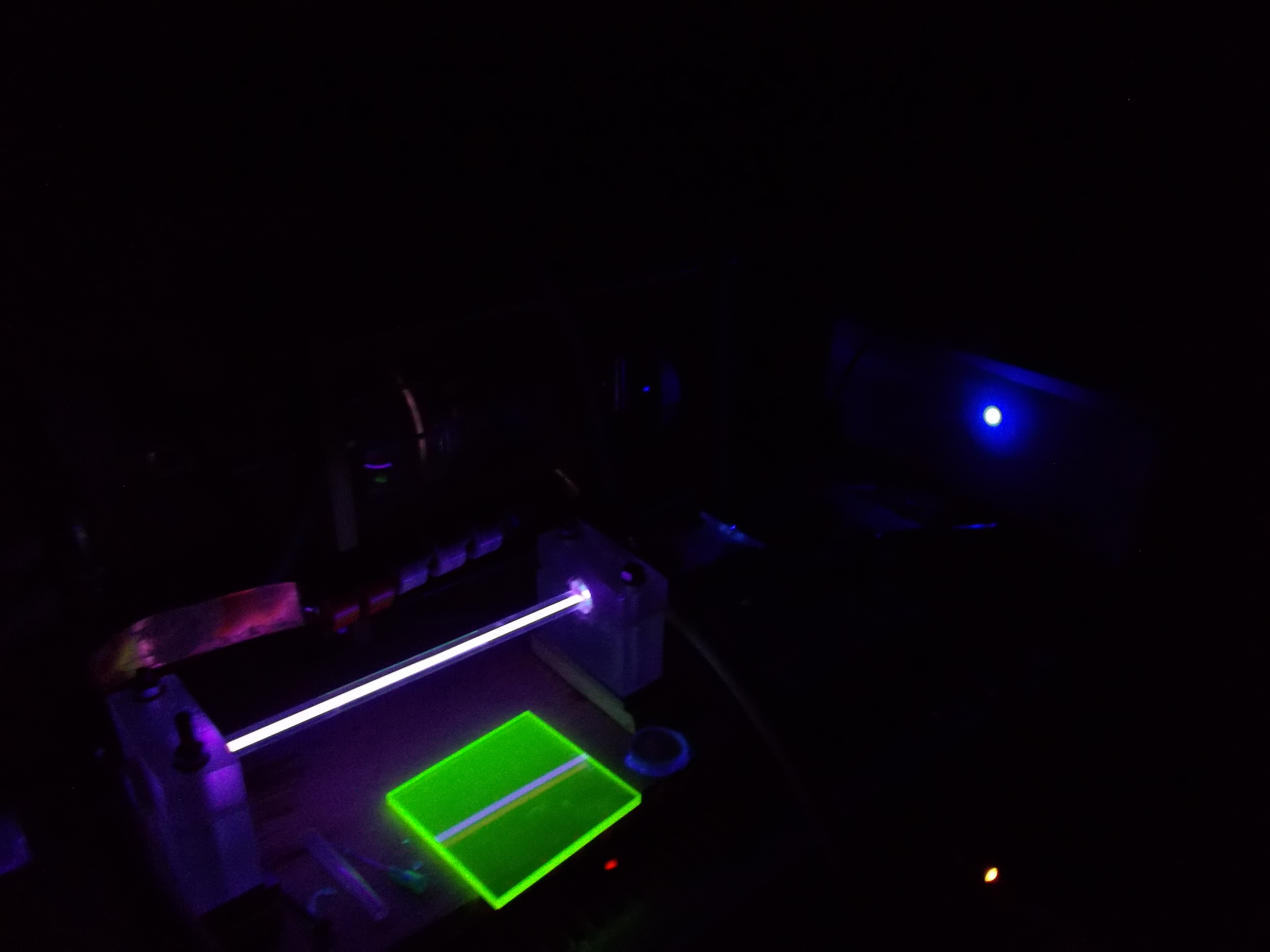

Then, instead of the LGI-505 tube, I installed my own tube.

The laser tube consists of a segment of a glass capillary with an internal diameter of 3.5 mm and a length of about 25 cm, on the ends of which aluminum electrodes are attached and glued. In each electrode there is a nozzle, through one the air is pumped out by the pump, and through the second - the air slowly flows into the tube. As a leak, the needle from an insulin syringe, which is inserted into the vacuum hose with an edge, showed itself perfectly. On the opposite side of each electrode there are nozzles on which pieces of a glass tube of larger diameter are put on and glued, the ends of which are cut at the Brewster angle. Quartz windows (as I thought) are glued to them to output the radiation. An aluminum mirror is installed on one side of the tube to increase the radiation power.

The tube is pumped out using a 3НВР1Д pump. When air leaks through the insulin needle, the equilibrium pressure is set to about 10 mm Hg. Art.

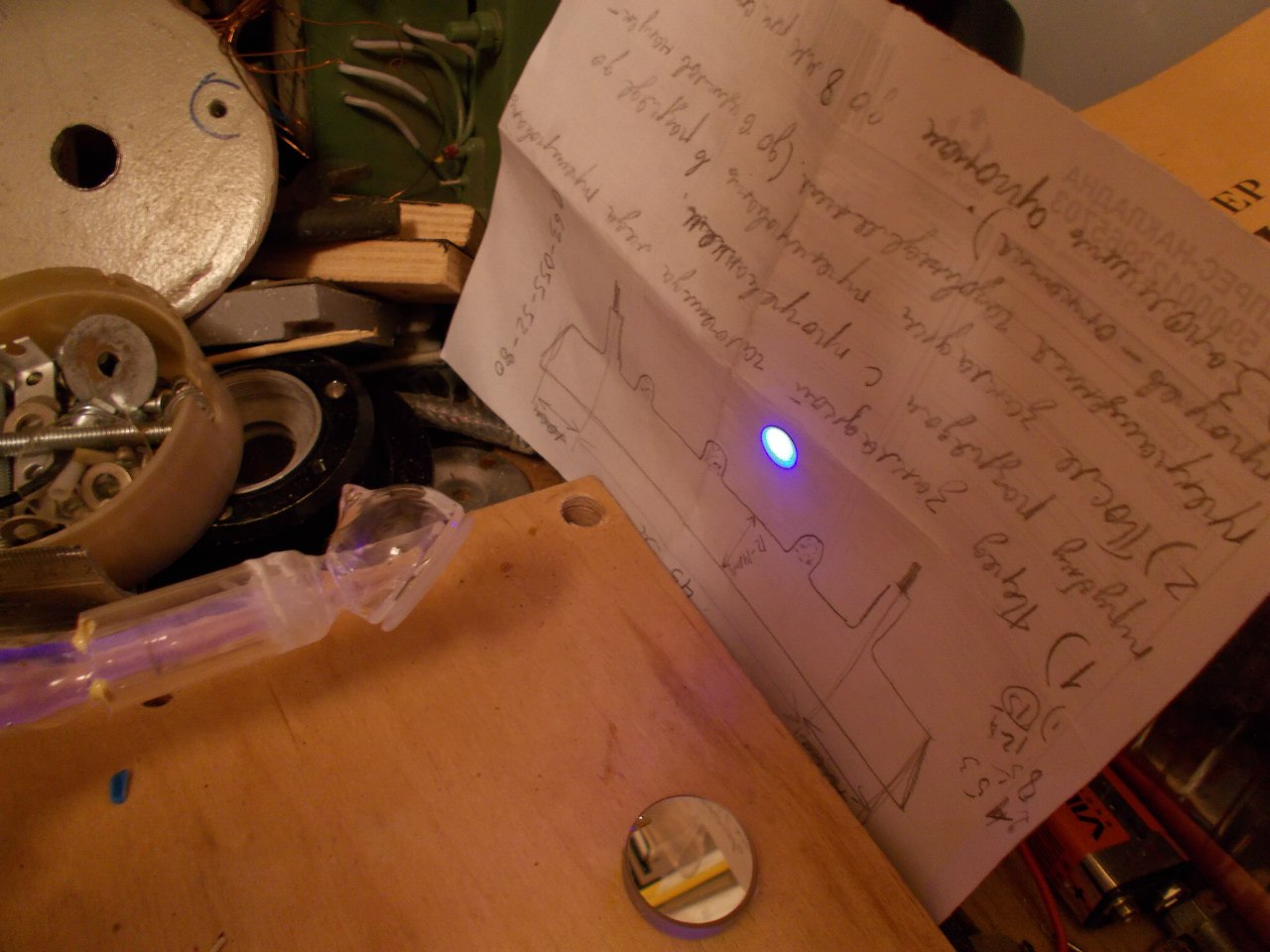

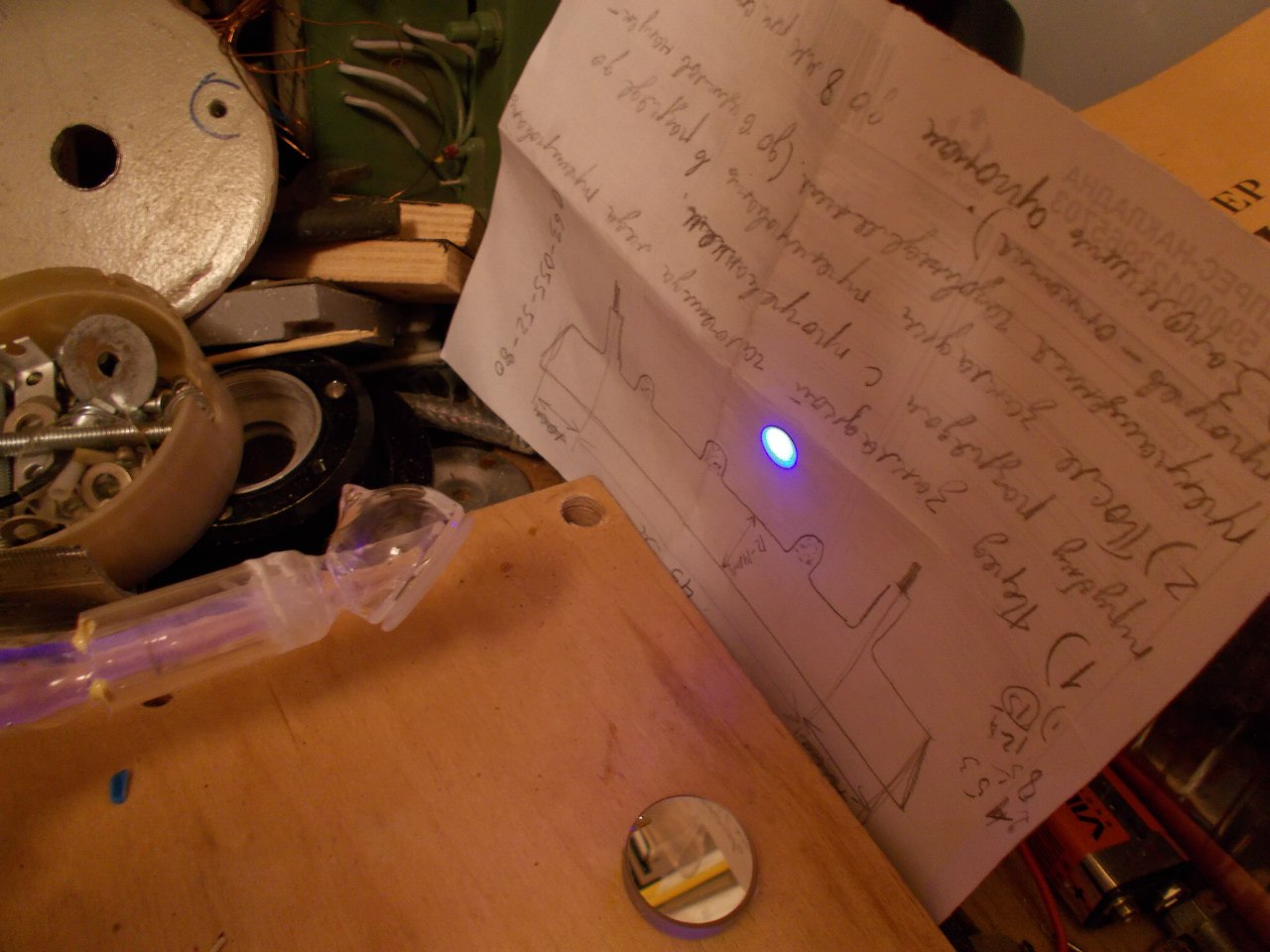

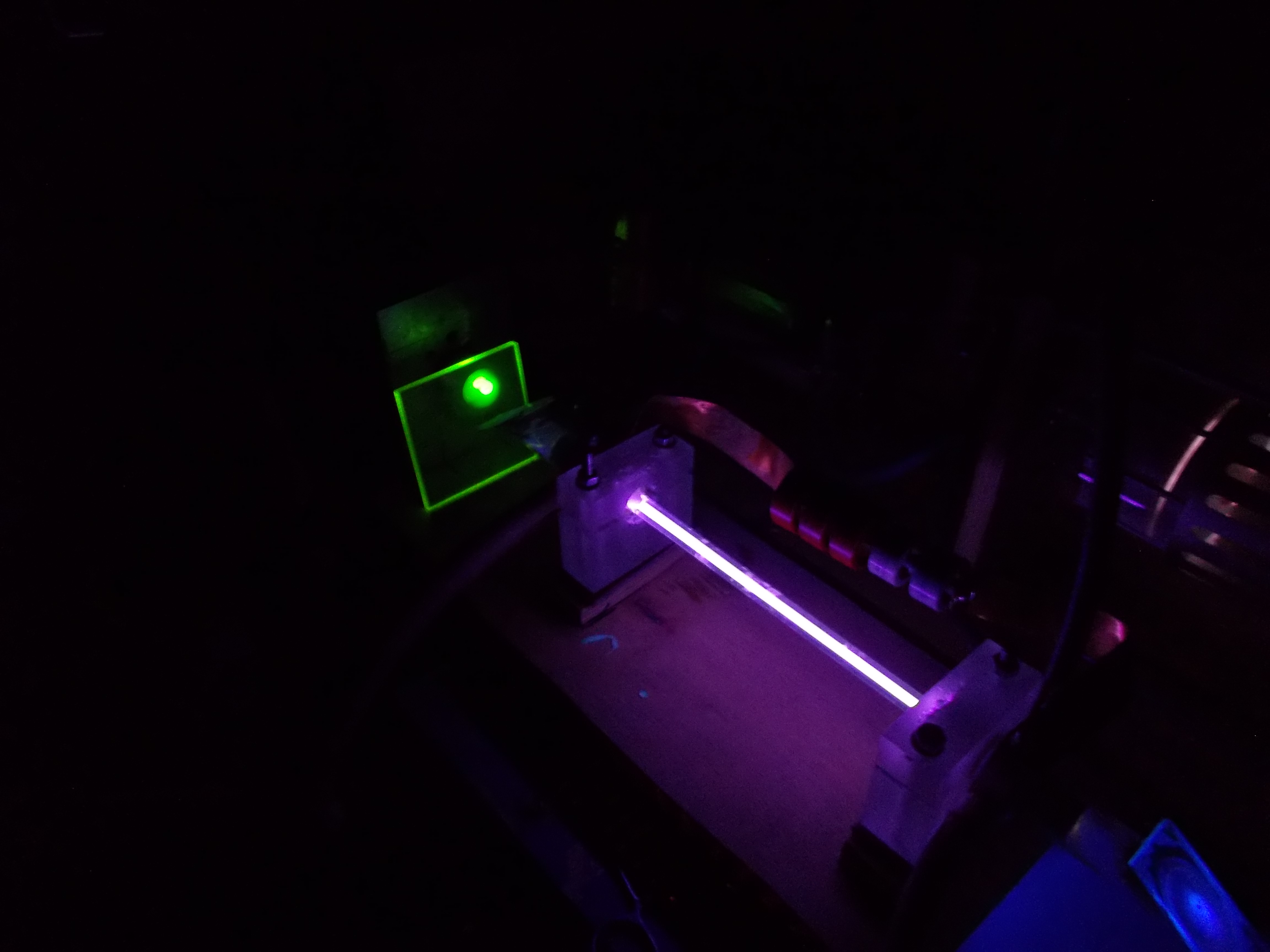

When you turn on the laser immediately earned. However, there was a complete surprise that the exit window did not let the radiation through at all, but only reflected it down, where it partially went down in the Pyrex tube and went down. The left window turned out to be really quartz and emitted radiation normally, superluminescence could be easily observed.

This is what happened on the side of the window that is not transparent to radiation.

If to block a deaf mirror, then the lower right glow decreased.

I had to replace the right window, this time with the correct one. After that, the output power exceeded that of LGI-21 and approached the power of LGI505, which worked in mirrorless mode.

Thus, the self-made longitudinal discharge nitrogen laser operating on air was completely successful! And since the tube works in flow-through mode, this means that it can work on other gases besides nitrogen and air. But this is a completely different story and a field for experiments. This is my first completely self-made laser, where both the active element (gas discharge tube) and the pumping system are self-made.

So, if someone wants to enter the world of lasers and related disciplines, then we can safely begin with the construction of a nitrogen laser. You can choose a transverse discharge laser as the simplest one, or a longitudinal discharge laser if you have a vacuum pump and spare parts for assembling a transformer pumping system. But, anyway, it is much more interesting than “connecting a laser diode to a ready-made driver and making a laser pointer”, since the involvement in the process of understanding the principles of laser operation as such is much deeper, and this gives invaluable experience and knowledge.

- Simplicity. As mentioned above, in many cases even the design of an improvised simplest nitrogen laser operating in atmospheric air is quite applicable, even with quite serious scientific work in the laboratory.

- A rather serious output pulse energy is tens of millijoules at large installations.

- A very short pulse duration, in some cases a component of hundreds of picoseconds.

- The combination of the previous two factors allows you to achieve huge pulsed power - tens to hundreds of megawatts.

But this topology is not without some drawbacks. What exactly and what led to their elimination? Read on.

In the last part, I gave examples of commercially available nitrogen lasers in the West. But in the former USSR the “design school” was radically different.

If the nitrogen laser gradually reduces the pressure and increases the distance between the electrodes, then gradually you can come to the ... laser longitudinal discharge. When both the electrical discharge in the gas and the radiation are completely coaxial. In this case, the discharge burns in a thin glass tube, approximately as in a helium-neon laser. With a lower nitrogen pressure, the environment gain is lower, the pulse duration approaches the maximum possible (the normal value is 10-20 nanoseconds), and the power requirements are further reduced.

Longitudinal discharge lasers have advantages that cover the disadvantages of transverse discharge lasers:

- High beam quality, since the discharge burns in a circular tube, and the laser usually works with a simple resonator made of an aluminized dummy mirror and output in the form of a plane-parallel glass plate. The beam, respectively, is also round of a more uniform intensity over the cross section.

- Ability to work at high pulse repetition rates (up to several thousand Hz).

- Relatively high average radiation power, in some cases reaching hundreds of mW.

- High stability of radiation power.

The method of exciting a short-duration discharge is also radically different — it is usually excited by means of a high-voltage pulse transformer. The transformer is wound on a stack of ferrite rings high-voltage coaxial cable. The outer braid of the cable is cut into pieces so that, passing through a hole in the ring, these pieces of braid form one or 2-3 turns and the ends of these pieces of braid are connected in parallel. And the central core of the cable, over which evenly distributed pieces of braid, is wound on a stack of rings continuously, forming 10-15 turns. Thus, by changing the way the sheath is cut, it is possible to flexibly select the output voltage, while there are no fundamental limitations in the achievable output voltage. Such a transformer can have any transformation ratio,

Nevertheless, longitudinal discharge lasers are also not without drawbacks, besides the need for an optical resonator and a vacuum. They are the reason for their very low prevalence, except for the countries of the former USSR, where they occupied their niche of application, and in which they had to put up with these shortcomings. The main field of application of these lasers was the technological equipment of the microelectronic industry, which required high beam quality and the possibility of its very fine focusing with a relatively large (for some models) average power.

The laser longitudinal discharge is also characteristic:

- Low energy single pulse.

- Low gas pressure in the tube requires the manufacture of sealed glass tubes, which is a rather labor-intensive glass blowing operation.

- Limited lifetime of sealed tubes due to gradual contamination of nitrogen with electrode spraying products.

Now we will look at the most famous and popular laser made in the USSR - LGI-21, also known as LGI-503. And this is my very first laser with which I started my passion for lasers. I got it back in my student days, while writing off devices from one of the laboratories. Like any laser, it consists of a radiator and a power supply. The declared laser power is 3 mW with a pulse repetition frequency up to 100 Hz, which is, in general, quite a bit.

Inside the emitter is a glass tube of coaxial design. In the center there is a thin tube in which the discharge burns, and on the outside there is a ballast volume containing some amount of nitrogen.

The power supply is designed inside quite simple. In the upper right corner there is a high-voltage pulse transformer, just to the left - storage capacitors, which are discharged by the thyratron to its primary winding, in the center - the TGI2-130 \ 10 pulse thyratron, to the left - the power high-voltage transformer with a voltage doubler. In the lower right corner there is a generator with two lamps for controlling the thyratron.

This is exactly the laser that I first learned to repair, adjust, carefully studied its device.

Now I will tell you how I managed for the first time to restore the operability of a sealed laser tube that stood in the LGI-503 laser, which happened quite a long time, at the very beginning of my hobby with laser technology.

After careful adjustment of the mirrors when turned on, the laser produced a very, very “sluggish” beam.

No tricks with the power source and the setting of the mirrors did not help any more - everything testified that the gas from it “ran out of steam”. Thinking that there would be no worse, I broke off the nipple on the laser tube and stuck a piece of glass tube to it. Inside, I inserted a piece of hose from the dropper and connected it to a vacuum pump. A needle was inserted into the gum with another hose from the dropper, on which there was a clip - an improvised gas leak.

Then I turned on the pump and waited for him to siphon the tube to the utmost vacuum, then slightly opened the leak and turned on the power supply. There was a bright and steady discharge in the tube, and a very bright (as to what it was) beam appeared at the output!

At the same time, in the "fresh air" the laser was able to produce lasing without the participation of the output mirror of the resonator, only its power was of course lower.

Especially beautiful under the beam is the luminescent plate of uranium glass.

As it turned out, room air is quite efficient in low-pressure lasers with a longitudinal discharge. The selection of pressure could find the maximum radiation power. It was because I now had the opportunity to experiment a lot with a serial laser, so I did not bother with building a self-made cross-discharge. Moreover, I like the thin beam of a neat round section much more. Thus, the rehabilitation of the nitrogen laser tube is a very simple operation, it is enough to open it, pump it out again and find the optimal pressure. The pressure interval at which there is generation is relatively wide - from tenths to tens of millimeters of mercury. Now, when I managed to restore the laser tube for the first time, I decided

There, in the glass-blowing workshop, these pipes were able to be pumped out and filled with pure nitrogen, but what is characteristic is that there was no noticeable difference in power output compared to air. The brightness of the luminescence spot looks the same as in the case of air and pumping at home.

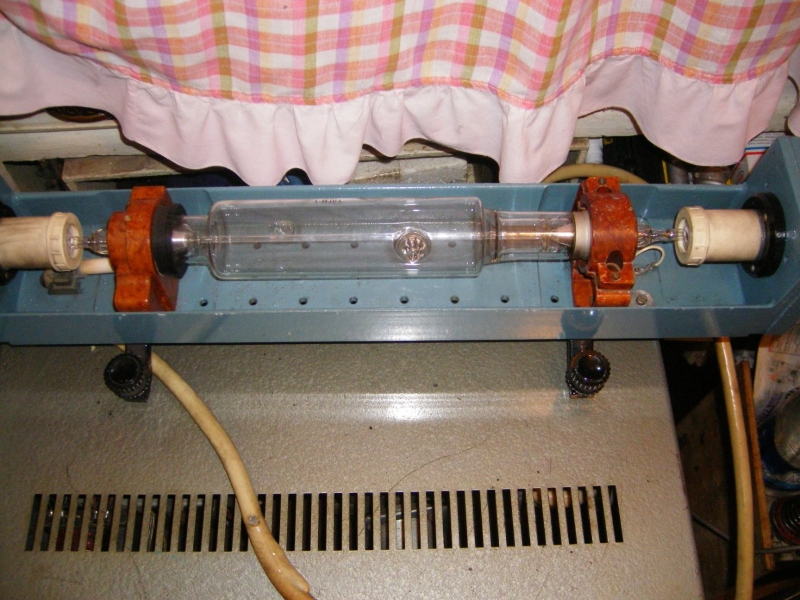

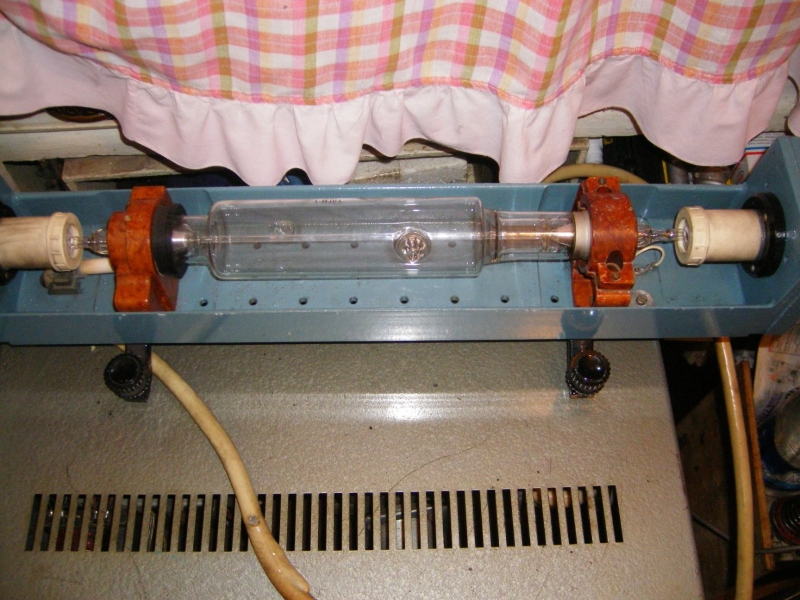

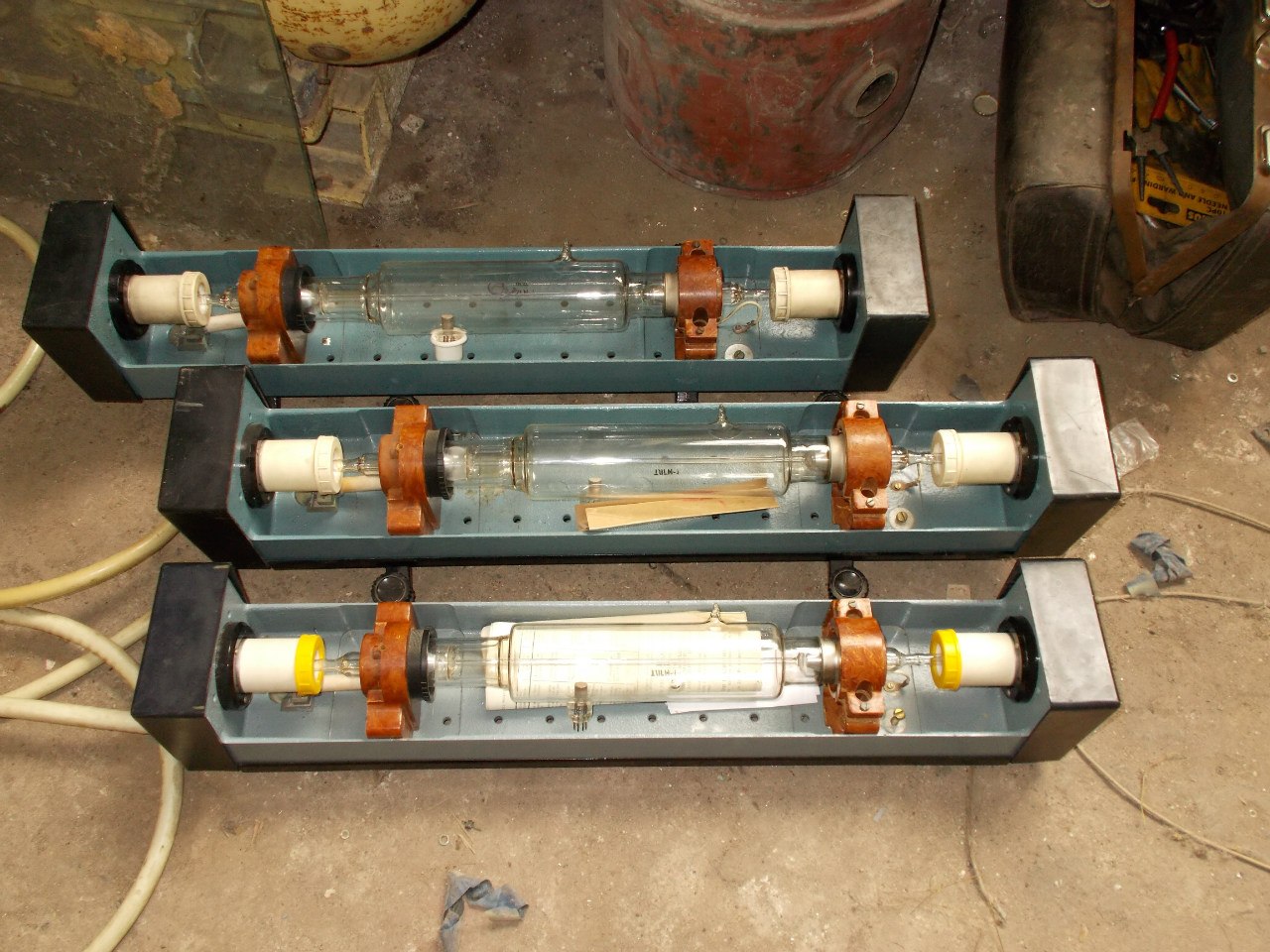

Then the tubes were sealed, and the lasers were assembled and returned to customers. After that, it became much easier to get the used off components, and then the new lasers - I managed to get two tubes from the LGI-505 more powerful and much rarer nitrogen laser, whose power from different sources is from 40 to 120 mW. It also has a longitudinal discharge tube, but the construction is more “oak” - the discharge burns in a ceramic capillary, which is cooled outside by water, the cathode is made in the form of an aluminum cylinder of large diameter, the process is welded to the side, in which there are glowing pills of a substance for regeneration nitrogen, if the gas pressure in the tube for some reason decreases. Even more striking is Brewster’s massive quartz-made weekend windows. Photo tube below.

Inside the emitter, the tube is assembled together with nanosecond pulse formation chains consisting of a thyratron, a pulse transformer (a small tank with oil and insulators), and some other details. Since I only have the tubes themselves, the photo of the emitter is taken from Google.

But I still got the external power supply with the tubes. But he is only engaged in the development of high voltage for charging the storage capacitors inside the emitter and the thyratron control pulses.

Inside it has a rather curious design - a high voltage generator is an old Soviet switching power supply on thyristors with a miniature oil transformer at the output, which has a water-cooling jacket.

Using the diagrams from the enclosed instructions, I was able to restore the necessary “power part” of the radiator and launch the LGI-505. The circuit is essentially identical to that for LGI-21, only a pulse transformer, a tiratron more powerful, a storage capacitor of a larger capacity. The transformer is self-made, wound with a coaxial cable on 6 ferrite rings with a size of 120 * 80 * 12. The braid on the cable is cut into 8 parts, all parts are connected in parallel and form one coil of the primary winding. The central cable core forms 8 turns of the secondary winding. The amplitude of the voltage pulse from the transformer is estimated at about 70-80 kV. The thyratron was installed TGI1-1000 \ 25, which in principle is redundant, but there was no other at that time. A single capacitor k15-10 with a nominal 4700 pF 50 kV was used as a storage capacitor.

High voltage and control pulses are fed from the native power supply shown above.

At the very first start, superluminescent radiation appeared at both ends of the tube, exceeding the LGI-21 laser with an optical resonator in power.

Adding a resonator to this laser tube has significantly increased the output power.

Particularly spectacular looks with the participation of uranium glass as a target.

This laser had every chance of becoming my finished product, even the outer case was finished.

But then began the construction of my copper vapor laser, and I needed from there first a TGI1-1000 \ 25 thyratron, and then a pulse transformer for experiments. And this construction was partially dismantled and put aside into the far corner, its further fate remained unknown until very recently. Until I wanted to make my own tube for a nitrogen laser.

Independently making a longitudinal discharge nitrogen laser is much more troublesome than a transverse discharge laser, since it requires working with glass tubes and fussing with vacuum, we also need a simple optical resonator made of an aluminized dummy mirror and a plane-parallel transparent window - the output mirror. But even in this case, it is possible to obtain generation using the traditional Blumlein generator assembled on several ceramic capacitors. Nitrogen lasers of the longitudinal discharge are very rarely found in home-builders, but they exist. For some reason, mostly from the Germans. The following are examples of designs.

Laser from adrian-homelab.de

A miniature longitudinal nitrogen laser from deralchemist.wordpress.com

And another, apparently, which served as the primary source for the previous one, the Thomas Rapp laser from pulslaser.de.

It is a thin and round laser beam that is the main argument in favor of a longitudinal discharge laser.

Also on the Internet there are examples of conversions of damaged helium-neon lasers into nitrogen - in essence, the task is to build a power source and a vacuum system. Well, you need to carefully with this open the tube and stick to it fitting for pumping. The result is the same as in the case of a completely homemade tube.

And finally, my own design!

This laser was assembled on an existing electric platform, on which the LGI-505 laser was assembled with some cosmetic changes. A new, more cultivated pulse transformer was made, with the same parameters as they were.

A new thyratron was installed, which showed its inconsistency in the power source of a copper vapor laser, but it works perfectly here - TGI1-700 \ 25, large and glass. A second capacitor, K15-10, was added to increase the overall power to the system. By changing the capacitor connection, you can select the appropriate "pump energy". As a result, the experimental platform began to look like this, together with the same LGI505 tube, on which it was tested.

Then, instead of the LGI-505 tube, I installed my own tube.

The laser tube consists of a segment of a glass capillary with an internal diameter of 3.5 mm and a length of about 25 cm, on the ends of which aluminum electrodes are attached and glued. In each electrode there is a nozzle, through one the air is pumped out by the pump, and through the second - the air slowly flows into the tube. As a leak, the needle from an insulin syringe, which is inserted into the vacuum hose with an edge, showed itself perfectly. On the opposite side of each electrode there are nozzles on which pieces of a glass tube of larger diameter are put on and glued, the ends of which are cut at the Brewster angle. Quartz windows (as I thought) are glued to them to output the radiation. An aluminum mirror is installed on one side of the tube to increase the radiation power.

The tube is pumped out using a 3НВР1Д pump. When air leaks through the insulin needle, the equilibrium pressure is set to about 10 mm Hg. Art.

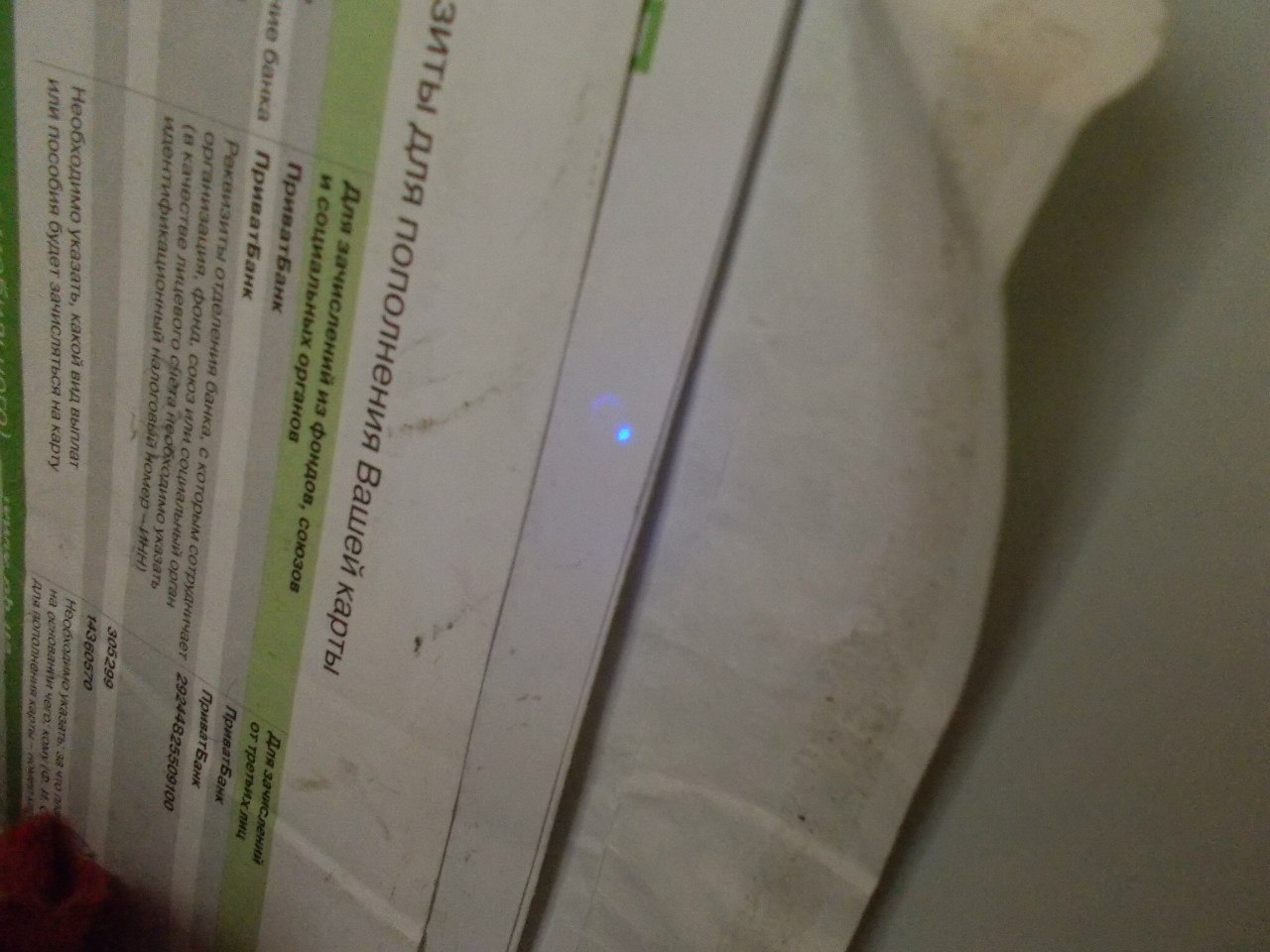

When you turn on the laser immediately earned. However, there was a complete surprise that the exit window did not let the radiation through at all, but only reflected it down, where it partially went down in the Pyrex tube and went down. The left window turned out to be really quartz and emitted radiation normally, superluminescence could be easily observed.

This is what happened on the side of the window that is not transparent to radiation.

If to block a deaf mirror, then the lower right glow decreased.

I had to replace the right window, this time with the correct one. After that, the output power exceeded that of LGI-21 and approached the power of LGI505, which worked in mirrorless mode.

Thus, the self-made longitudinal discharge nitrogen laser operating on air was completely successful! And since the tube works in flow-through mode, this means that it can work on other gases besides nitrogen and air. But this is a completely different story and a field for experiments. This is my first completely self-made laser, where both the active element (gas discharge tube) and the pumping system are self-made.

So, if someone wants to enter the world of lasers and related disciplines, then we can safely begin with the construction of a nitrogen laser. You can choose a transverse discharge laser as the simplest one, or a longitudinal discharge laser if you have a vacuum pump and spare parts for assembling a transformer pumping system. But, anyway, it is much more interesting than “connecting a laser diode to a ready-made driver and making a laser pointer”, since the involvement in the process of understanding the principles of laser operation as such is much deeper, and this gives invaluable experience and knowledge.