Bad advice to an electronics contract manufacturer

There is such a service, contract manufacturing of electronics: you come with documentation - you get a product. The service includes the purchase of components, their acceptance, production and assembly of boards, testing, final assembly and delivery. Contractor manufacturing also has hull production and machining, though not everywhere.

Production can be taken both for the full cycle and for individual work, for example soldering, when the customer ships the boards and components for them as raw materials. In Russia, such services are provided by very different companies - with and without special acceptance, large, medium, small, garage picks, sometimes even without their own production facilities. The market is very competitive, production is underloaded, the service is more or less standard - it would seem that everything is available for the rapid development of customer-oriented service.

I’ll tell you about this service through the prism of our experience, in the form of harmful advice to a contractor. The image is collective, everyone has a little bit funny. If you recognize yourself, this is a good sign, because you have received invaluable feedback and you can become better. Some tips will fall well on other services, use it!

Reception of the order.

- Everyone wants to work with you. Yes, yes, because only you were lucky enough to become the owners of the Assembly Line. Do not rush to answer letters, the client will wait.

- Develop a unique form of receiving an order, and not some, but in Excel. Add to it more beautiful multi-colored design and drop-down lists with inappropriate options. It’s nothing that all this data is already in the product documentation, because it’s more convenient for you to work with the same requests. If the client resists and does not want to fill out - ignore him, he is to blame. He will be back, with a completed form and a guilty look.

Negotiation and pricing

- Never tell the client the price structure for their services, because then he might think something is wrong! Enough for one digit. Justify it with a story about an unprecedented quality, not like that of others. If you nevertheless came down to the separation of services and purchases by different cells in the commercial offer, never disclose any more details. Let the customer himself guess how to reduce the cost, this is not your concern.

- In his pathetic attempts to save money, the Customer again makes corrections to the documentation, changes the lot size back and forth, tightens the deal in every way? Just give him time to think, but for now write that you refuse to make calculations, but rather just ignore him. Let him think first, and then write to you.

- If for some reason you have not been given a contract, call the Customer and tell him everything that you think about him, preferably in a rude form. Then offended hang up the phone. The market is huge, no one will ever know that you did it.

- If the customer could not immediately name the target cost price - then he is a sucker, feel free to multiply the price by 2.

Dates

- If the customer wants to quickly - promise that it will be fast. Then you can always say that it was a joke.

- All deadlines have passed - never call yourself. Let the customer call, because he will show weakness and a dependent position, and you can busily explain to him how much more to wait. He will apologize and promise not to bother about trifles anymore.

Quality assurance

- Tell all customers how you are doing well. This is work on quality. Only unsure losers keep statistics on marriage.

- Optical control, x-rays and other expensive toys are designed to dust the brains of naive customers. True quality is guaranteed only by honest eyes and kind hands of Galina Nikitishna from your manual quality control department. Repeat this more often for everyone to believe.

- Never check what kind of files they sent to you there for production, do not offer corrections to increase technological effectiveness, run as is. Let the customer pay for his stupidity.

Themselves are good too - a little about the Customer.

- Work only with your production, it is good, because your own. It’s also nearby. If your production cannot be used in any technology, it means that it is from the evil one and it is not worth using it in development.

- Change the documentation often in the process. It doesn’t matter that everything is already up and running, you know that you can still have time to move that resistor!

- If, for some unknown reason, your serviceable-looking products massively burn out during testing, feel free to ship everything back to production, let them sort it out. As a problem, indicate something like “the HZCh-32 indicator does not light on the stand”. Do not show the schemes and methods - after all, this is your trade secret

PS: Actually, we are friends with the production, basically they are great guys, do not think.

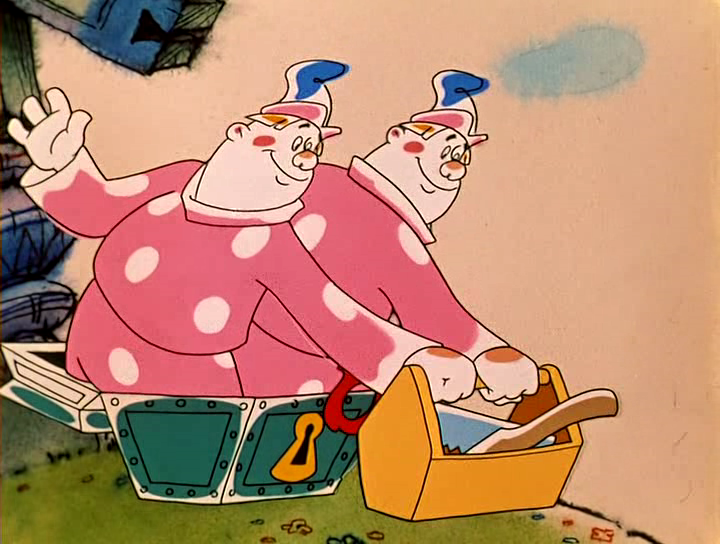

I just always want better. The client and the customer are mirror images of each other, like twins who live and grow up together.