Review: WAZER, the first desktop waterjet cutting machine

WAZER waterjet cutting machine : water cuts metal - the first tabletop waterjet CNC machine.

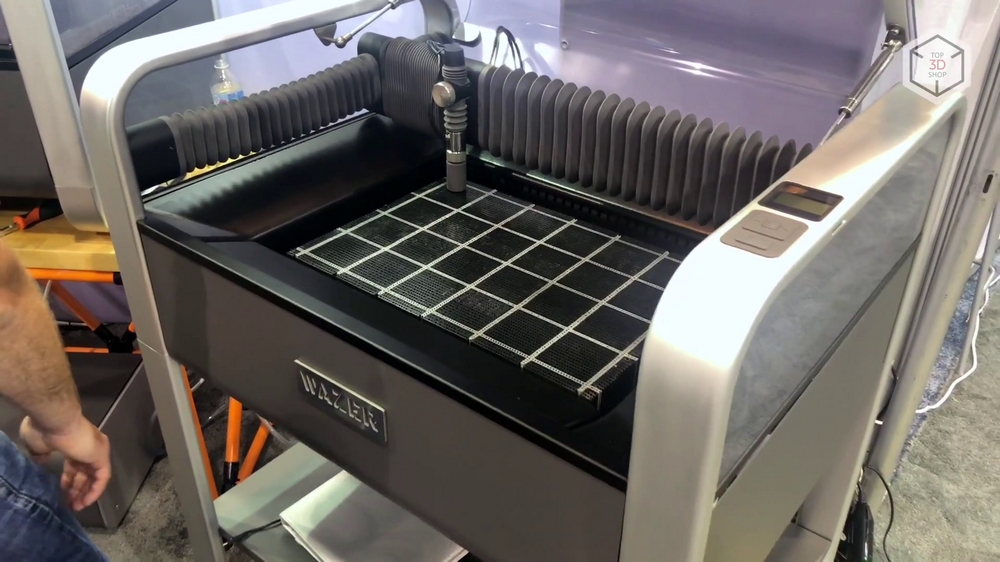

At the international industrial technology exhibition IMTS 2018, in Chicago, WAZER showed in action the first CNC table saw for waterjet cutting.

We show and tell: WAZER water cutter.

Video

Wazer

Specifications

- Operating Systems: Windows, Mac

- Injection pressure: 414-621 thousand kilopascals per square inch

- File Download: SD

- Supported file formats: DFX, SVG

- Power usage -

- Machine: 110-120 V, 250 W

- Pump: 110-120 V, 1500 W

- Expendable material: water, garnet sand

- Supported materials for cutting: metal, glass, plastic, ceramics and others

- Machine size: 864 x 635 x 534 (1194 with stand) mm

- Machine weight: 50 (filled - 136) kg

- Size of the working field: 305 x 460 mm

- The maximum thickness of the material being cut and the cutting speed: depends on the material, detailed table

- Positioning accuracy: 0.08 mm

- Cutting width: 1.5 mm

- Price: on request, pre-order

Story

"Weiser" began as a project at "Kickstarter", the launch of which was attended by several graduates of the University of Pennsylvania.

Very little time was taken by the recognition: the device is considered one of the most promising and awarded, for example, the prize “Editor’s Choice of Make Magazine 2019”.

Benefits

“Weiser” is a relatively compact equipment capable of working with a huge amount of materials cleanly and safely.

Device and principle of operation

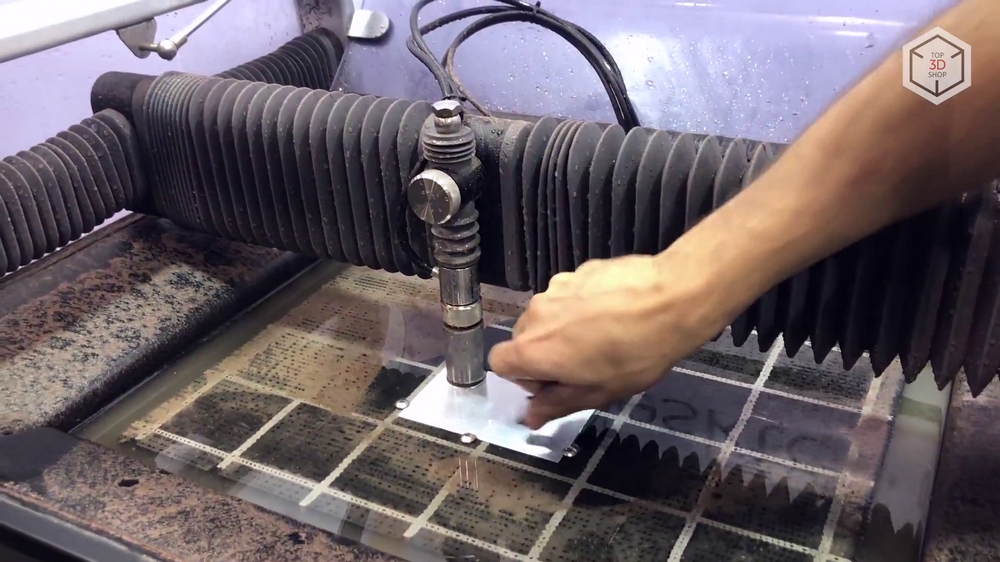

The machine mixes the abrasive particles into a stream of water — emitted under high pressure; this mixture can cut almost any material.

WAZER can cut extremely durable materials with high detail and precision, which can not be achieved with manual processing.

Materials

In the description of the machine on our website you can find a table of materials with thickness and cutting speed.

For example, a titanium plate 3 millimeters thick is cut at a speed of just under two centimeters per minute.

The list of processed materials includes aluminum, copper, tool and stainless steel, titanium, plastics, ceramics, glass.

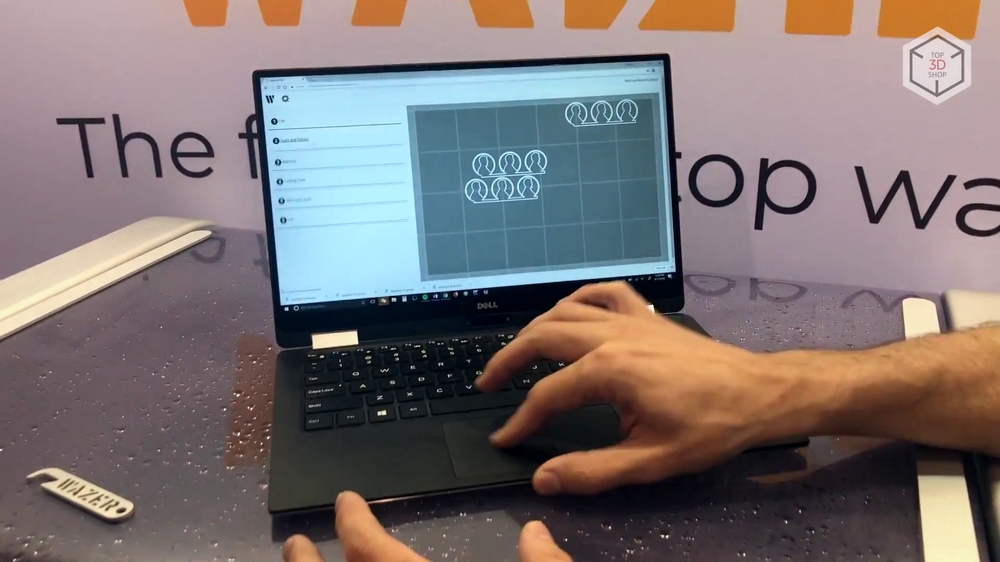

Included with the "Weiser" comes its own software. He works with digital models prepared in computer-aided design systems. WAZER software supports SVG and DXF formats.

The main consumable material of the machine is garnet sand of the 80 mesh fraction (i.e., the particle size is not more than 0.32 mm), the average consumption of which is about 150 grams per minute.

The service life of the head is about 3000 hours, the desktop is about 20,000.

The cost of industrial equipment for water-jet cutting starts from 100 thousand dollars. The cost of the installation WAZER in the United States is seven and a half thousand dollars - the standard kit includes a machine and a pump.

Application

We can recommend WAZER for any applications that require cutting sheet material, especially hard, such as metal and stone, but not only PVC, for example, cannot be cut with a laser — a poisonous and corrosive gas is formed that is dangerous for the operator and harmful to equipment here hydroabrasive cutting - the best option.

"Weiser" can be cut, in particular, moving functional metal parts, such as gears and other parts of mechanisms.

Preparations of blades and custom accessories for knives.

Figured ceramic tiles and furniture materials.

Author's artwork from the most different, sometimes unexpected raw materials.

Plastic decorative elements and much, much more.

Even culinary products. In this case, the abrasive is not needed, the meat WAZER cuts clean water.

This is the optimal voice for a private workshop or small business, or for production, where abrasive cutting is not the main activity, but performs auxiliary functions - manufacturing parts for repair, parts of prototypes, etc.

Where can one buy

You can pre-order the WAZER compact waterjet cutter in the Top 3D Shop, as well as select other equipment for your business - milling machines , laser engravers and cutters , 3D printers and robotics .

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks: