VXinspect: part quality control in 10 minutes

Today, we will analyze the possibilities of VXinspect - a software product designed to control geometry based on 3D scanning. It is an additional paid module built into the VXelements software and provides full interoperability with all Creaform technologies. Thus, you can start the research process immediately after completing the scan in the same software. However, VXinspect can be applied to control digital models obtained using any 3D scanners, since the program supports all common formats, such as .stl and .obj.

What can VXinspect do?

VXinspect software allows you to:

- Compare the result of a 3D scan with a reference CAD model;

- control linear, angular, diametrical dimensions in the plane and in space;

- quickly obtain information on deviations of the shape and relative position of the surfaces;

- create and edit a complete report on the measurements made.

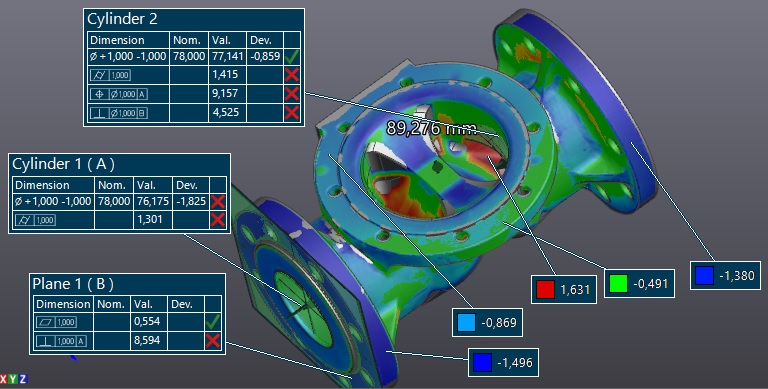

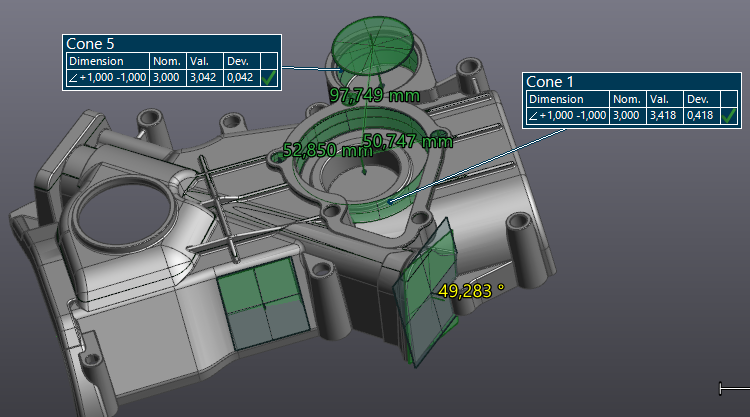

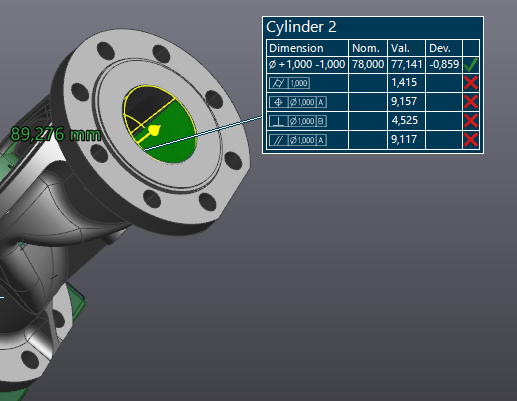

An example of controlling deviations from cylindricity, cylinder alignment, perpendicularity of the bore axis and plane

Convenient interface, a large number of supported formats, as well as the ability to replace objects of study, keeping all the measurements made, reduce the time to quality control of the product to a minimum. The automated calculation process completely eliminates the subjective error and does not require highly skilled operator.

VXinspect has no restrictions on file weight or overall dimensions of scanned products. The program is suitable for use in various industries, including mechanical engineering , aerospace , automotive .

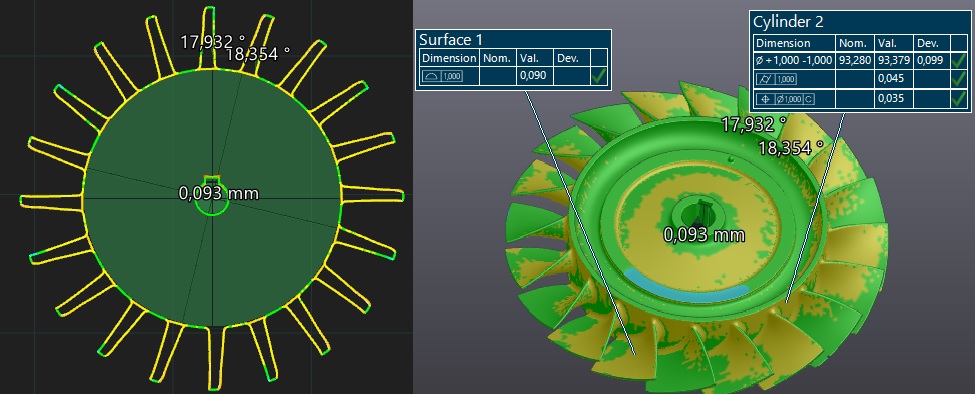

An example of the control of the blades on the corner, the control profile of the surface of the blade, the alignment of the central hole and the outer cylinder

What does the research process include?

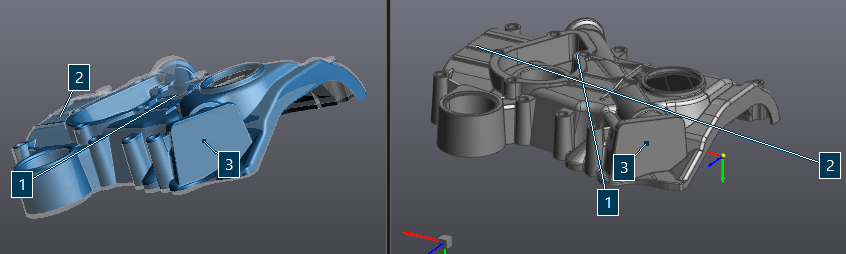

- The combination of the scan and the reference model

The combination is performed automatically, by analyzing the smallest deviations of the scan and model surfaces. To do this, you need to select three common points on models as close as possible to each other. It is also possible to make a combination, analyzing only selected surfaces that are basic.

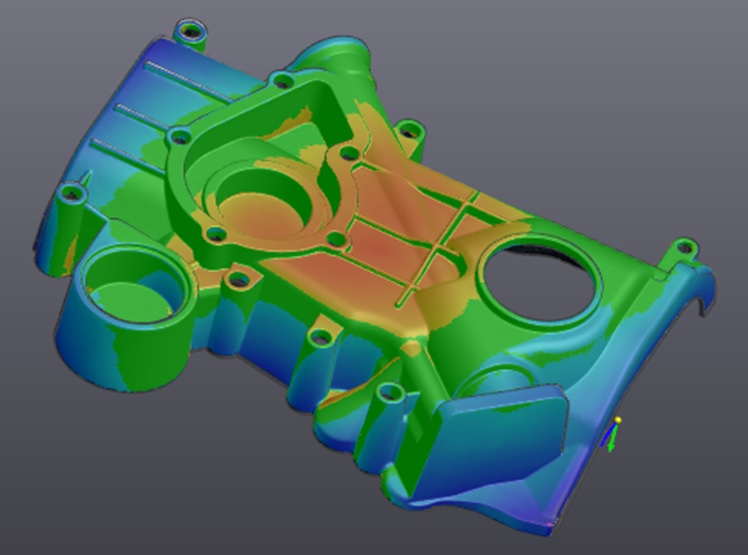

- Analysis of critical deviations in space

Using a special function, you can estimate the deviations of all points of surfaces, highlighting them in a separate color. This tool allows you to make changes to the settings: specify the necessary tolerances, maximum deviations, select a color map.

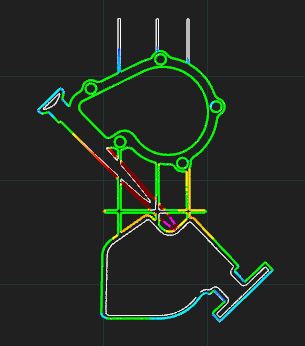

- Analysis of deviations in a given section (according to the drawing) The

capabilities of the VXinspect software allow you to create a section of the model in any plane and display a color map that characterizes the deviations of these surfaces. In the section we will see the lines of the reference model and the colored lines of the scan.

- Extraction of measurement objects, analysis of their accuracy within specified tolerances.

Thanks to a large set of tools, you can calculate and compare with the reference all the necessary dimensions, including linear, angular, diametric, accuracy of shape and relative position of surfaces. Measurements are carried out both in the plane and in space.

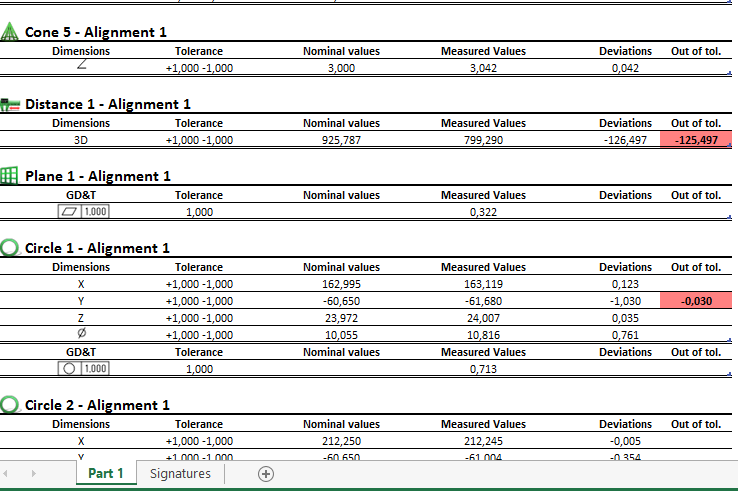

- Export of the report

Upon completion of the study, the developers of Creaform provided the ability to save the report, which includes information on all the measurements made with complete data for each (reference size, actual size, tolerance, deviation) and screenshots.

- Download a new 3D scan

- Automatic performance of points 2-5

If you perform quality control in a large-scale (mass) production, you can save time on conducting the study: VXinspect allows you to replace the 3D scan data without performing all the operations performed in the previous work. Just align the scan relative to the reference model — all other operations will be repeated automatically.

The whole process of working with VXinspect, from scanning a part to creating a report, is shown in the following video:

3 competitive advantages of VXinspect

In addition to all of the above, VXinspect has several advantages over its competitors. These include features:

- control not a specific size, but a surface, extracting the full amount of information about it (size, shape accuracy, location accuracy) in one operation (in the photo below);

- carry out measurements without a reference model (only in the case of using Creaform scanners);

- edit the report after exporting it. The report is saved in an Excel file format, so you can add necessary notes, screenshots and other changes to it.

VXinspect in action: a practical example of geometry control

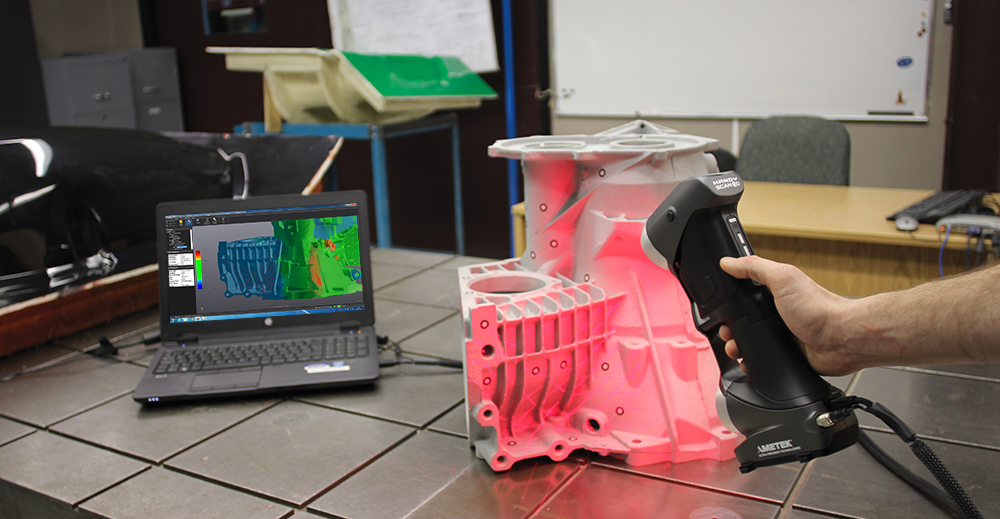

The task was to measure the depth of the defect on the surface of the part. The size of the scratch does not exceed 1 mm, which does not allow the use of traditional contact measurement methods. The scanning process using a laser 3D-scanner HandyScan 700 took 15 minutes, and the processing of the scan and get the result - no more than 10 minutes.

Let's sum up. VXinspect software is a versatile tool for controlling geometry, which has a wide functionality that allows you to perform most tasks in the quality control of products. This advanced product of Creaform is not inferior to existing competitive solutions, but at the same time has a relatively low price.