Homemade Laser Lightsaber - As It Was, Part 1

I welcome everyone, this article will discuss one of my most complex projects - a home-made installation with a copper vapor laser. I will make a reservation right away that the project was completed successfully, brought to a fully finished product and justifies the name that I gave it. I consider it necessary to tell in all details how it was implemented and what I had to face on the way to its implementation. The history of the installation is quite long, so it will have to be divided into several parts.

And one more small disclaimer: this project was implemented because of my great love for the art of obtaining laser radiation, largely for the sake of its implementation, therefore I ask you not to ask the question “why is this necessary” in the comments. The information presented is shown for informational purposes, the author is not responsible for the consequences of attempts to repeat the described.

A picture to attract attention.

And the continuation is under the cut.

First, you have to make some digression. The thing is that I’m probably one of those many people who once dreamed about their light sword or laser gun, at least in the form in which this is possible with current technologies. And as it turned out, everything is possible if you work on it. From the beginning of my student days, I became interested in electrical engineering, namely, in obtaining high voltages and high frequencies. So I discovered for myself such an interesting device as the Tesla transformer in its many manifestations using a variety of topologies and a variety of components. At the same time, I realized that I was especially attracted to the aesthetics of the diesel engine, namely, I wanted all my products to look like they came straight to me from the laboratories of Frankenstein or Tesla himself. That is why I launched the element base, consisting of old oil transformers, powerful radio tubes, high-frequency motor generators (umformers), measuring panel meters in a carbolite case, etc. Nevertheless, it turned out that it was already difficult to surprise anyone even with a rather long discharge from the Tesla transformer. Therefore, I decided to change the direction of activity, taking the niche into which very few people ventured to get into. Namely, to devote his hobby to laser technology. My dream was always to figure out what lasers are, to reveal the secrets of their device and work, finally, to build your own coherent radiation generator. Time passed, I studied a lot of literature, talked with different people, gradually accumulated experience in studying,

Among the entire variety of lasers, one of them deserves much more attention than the others - a copper vapor laser. When I managed to see and feel such a laser while working in one of the laboratories, it created my most powerful impressions. But the whole thing is this. This is the most effective laser operating in the visible range of the spectrum, capable of having a radiation power of tens of watts at wavelengths of 510 nm (bright green) and 578 nm (saturated yellow). A beam containing both emission lines has a unique greenish-lemon color and is able to burn through various combustible materials no worse than an infrared CO2 laser beam. The goal was to acquire such a laser.

While working with a similar laser in the laboratory, I realized that I can’t count on the purchase of a finished installation, despite the attempts made. Too big, heavy and expensive. Like any laser, it consists of two main parts - the emitter and the power source. Here is what one of the earliest models of such a laser looks like - LGI-101. The emitter is almost 2 meters long, and the power source has the size of a "full-fledged" home refrigerator. And it weighs like 4 refrigerators. The declared laser radiation power in total for both emission lines is 5 watts with a consumption of 2.5 kW. The appearance of the emitter and the power source can be seen in the photographs:

The emitter, in turn, consists of its own set of parts: the most important - the active element, then the resonator mirrors, the cooling system and the housing in which it is all assembled together. The power source consists of a number of functional blocks, which are described below. Therefore, I had to confine myself to searching only for the irreplaceable part - the active element (gas-discharge laser tube), and then mobilizing all my experience and swag to build all that is missing. After some time, with invaluable help from my friends, I finally received a treasured wooden box in the mail, with a completely new active element such as UL-102 “Quantum”, a more recent development compared to LGI-101. Compared with LGI-101, UL-102 is almost half the size, it produces exactly the same radiation power, and the power consumption is 1.5 times less, i.e. It is much more economical. The “naked” active element (AE) of the UL-102 looks like this.

This is a massive device made of metal, ceramic and glass. It is inside of it that the conversion of electrical energy into a high-current gas discharge takes place, from the heat of which metallic copper evaporates, and in which the copper atoms pass into an excited state. Upon transition from the excited state to the ground, the atoms emit photons, which, colliding with other excited atoms, will cause the emission of new photons, so until the light amplifies to the maximum possible value, which is determined by the degree of excitation of the active medium. In order for the light to freely pass through the laser tube and amplify in it, massive optical windows are located at the ends, and in order to expend less power to heat copper to its evaporation temperature, good thermal insulation of the internal ceramic discharge tube is required, which is enclosed in an pink ceramic outer casing. Electric energy is supplied to the two metal electrodes from the outside, and inside the tube there is neon under reduced atmospheric pressure. It is the discharge in neon that serves as the primary source of heat for the evaporation of copper, located in the form of small pieces inside the discharge channel, there are no vapors in the cold tube, and it would be impossible to ignite the discharge if there were a complete vacuum. Together with the laser tube, I also got a set of resonator mirrors. there are no vapors in the cold tube, and it would be impossible to ignite the discharge if there had been a complete vacuum. Together with the laser tube, I also got a set of resonator mirrors. there are no vapors in the cold tube, and it would be impossible to ignite the discharge if there had been a complete vacuum. Together with the laser tube, I also got a set of resonator mirrors.

Thus, the most important details have already appeared in me.

I already had an idea about the principle of operation of this laser and what is needed in order to get powerful coherent radiation from a set of spare parts. It was necessary to come up with the optimal system of thermal stabilization of the active element, put everything together in the form of a laser emitter, and most importantly - build a power source.

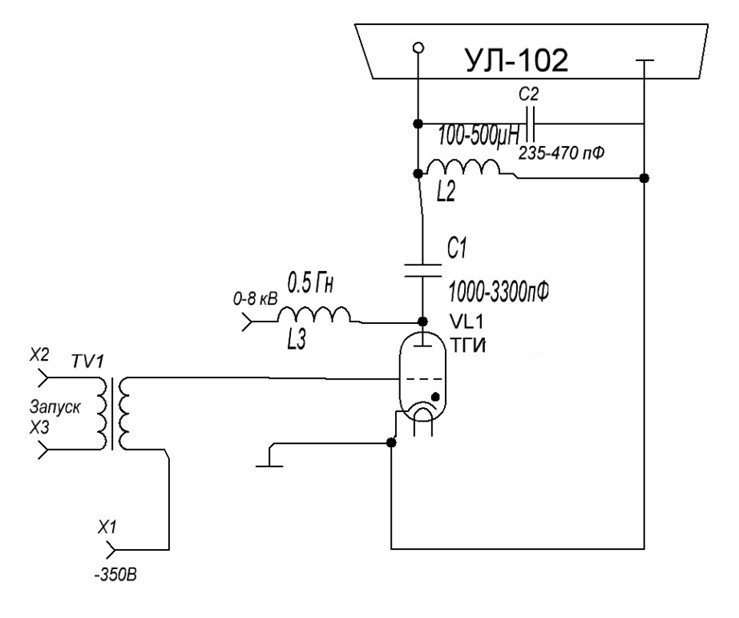

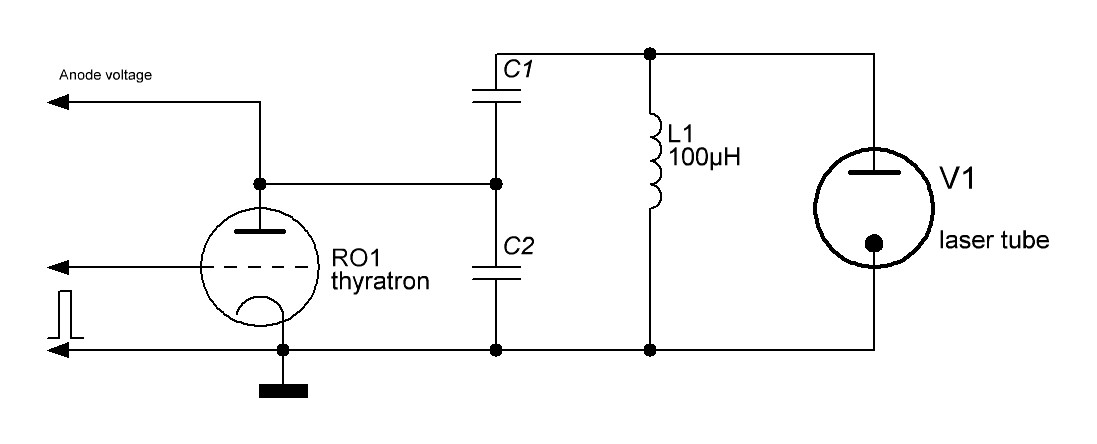

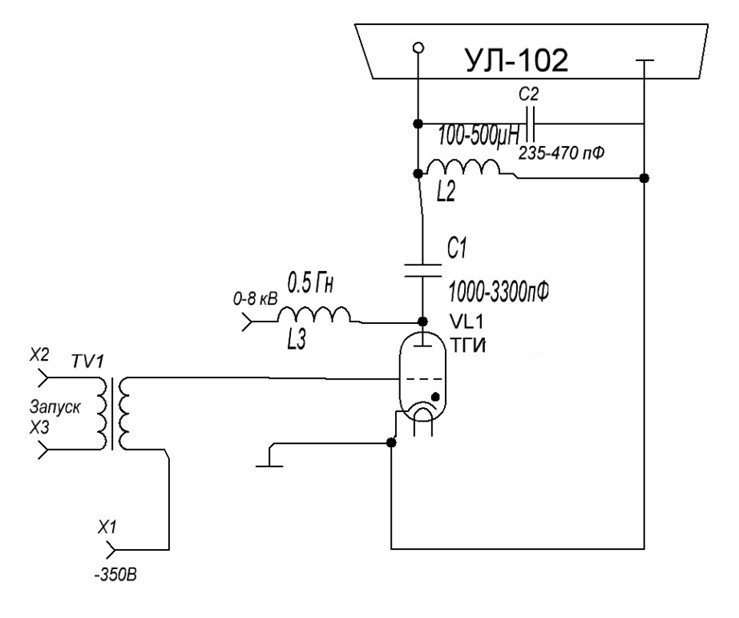

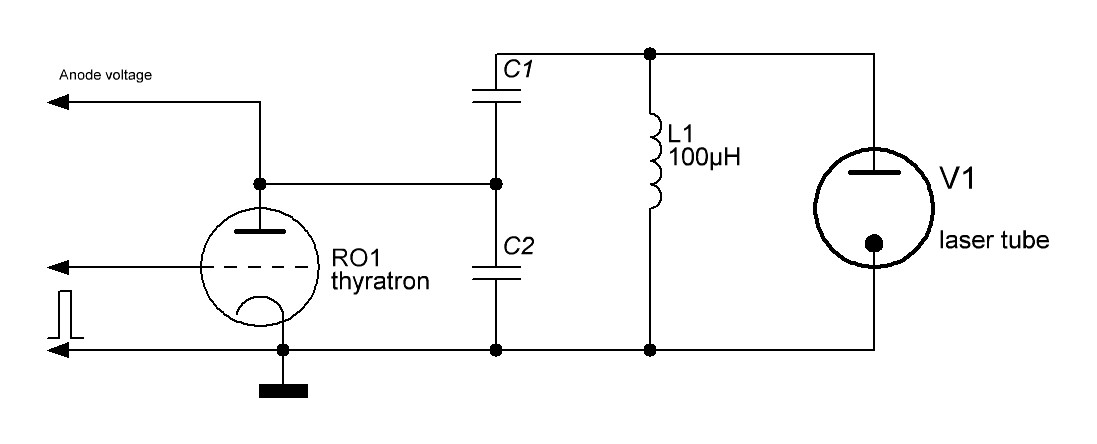

It is known from the literature that a copper vapor laser can operate only in a pulsed mode. The pulse repetition rate for the UL-102 tube can vary from 6 to 16 kHz. Each individual power pulse must have a steep front of current rise through the discharge. Ideally, the steepness of the current front through the discharge will be at the level of 50 nanoseconds, which is comparable with the lifetime of the excited state of copper atoms, and the current in the pulse will be several hundred amperes with a pulse duration of 300 to 1000 ns. Generally speaking, laser generation will turn out at a lower slope of the front, at the level of 100 ns, and even 300 ns, but its efficiency will be much worse. It should also be noted that the voltage at the electrodes of the tube at the pre-breakdown time should be at least 10 kV, and preferably more. The average power invested in the discharge by individual pulses, should be sufficient for heating and maintaining the optimum temperature of copper vapor, and for UL-102 the minimum value of this power is 1600 watts. There was good news: copper vapors have the highest gain. This means that the requirements for resonator alignment accuracy are very liberal (special high-precision devices for mounting and adjusting the position of mirrors are not needed). In addition, the gain is higher, the higher the concentration of copper atoms in the discharge, i.e. if heated sufficiently strongly, lasing can be obtained not with two, but with one mirror, or even without them at all (single-pass amplification of spontaneous emission or “superluminescence”). This greatly facilitated the task of constructing the primary layout, i.e. the task was simplified to the construction of only a power source, and the construction of the emitter can be postponed at that moment when the subtleties with power will be worked out. Now about nutrition. If you look at the power circuit of the tube, then at first glance everything is extremely simple. Just a few details when using the simplest topology, which in the literature is called the “direct excitation scheme”.

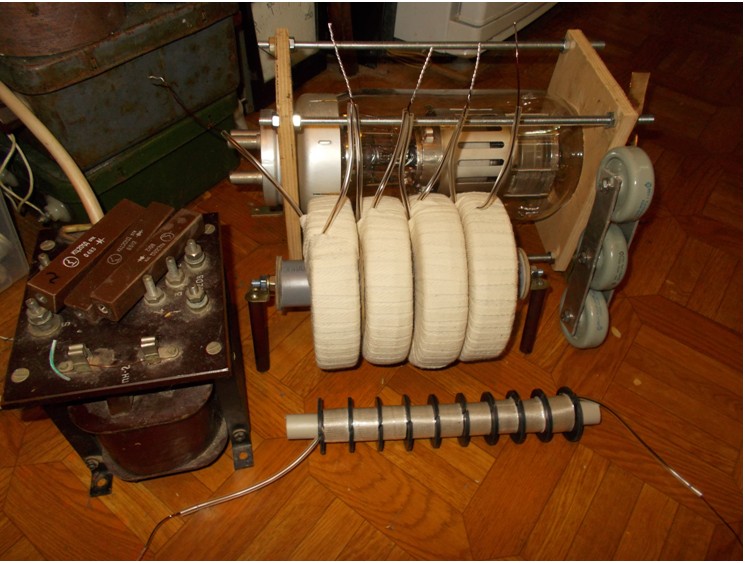

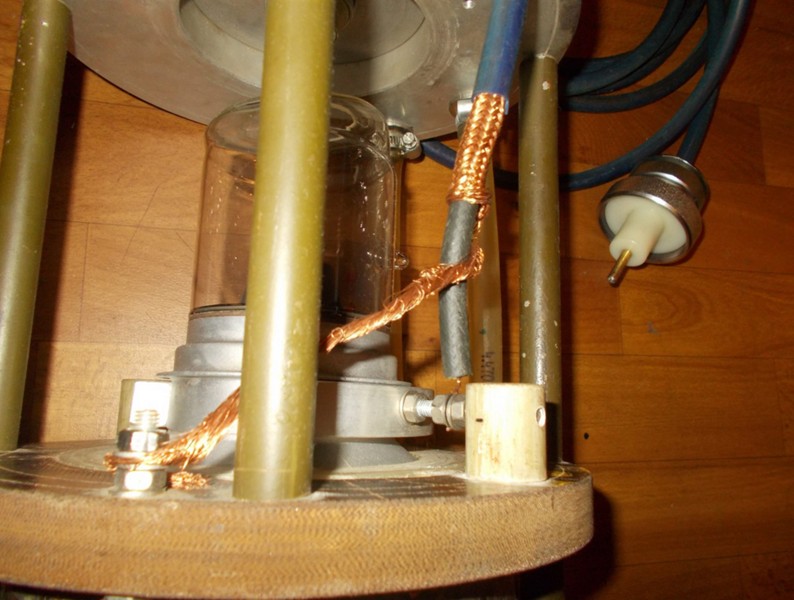

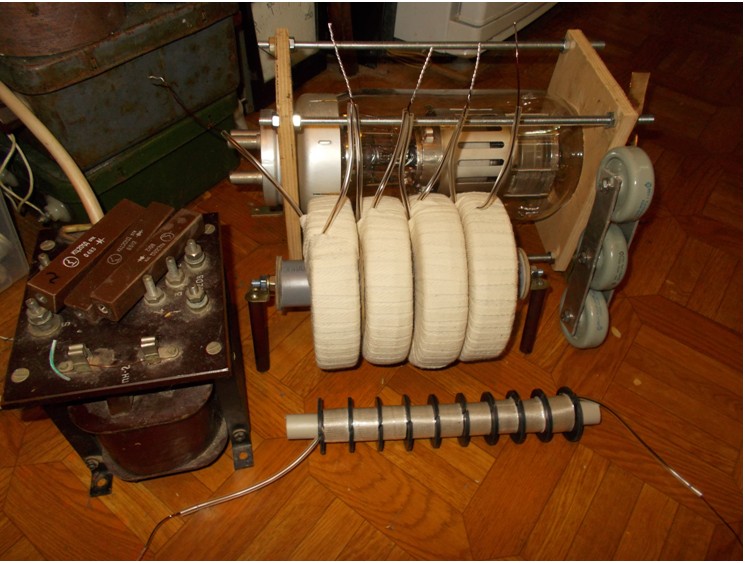

Everything is simple - 2 inductors, 2 capacitors, a switching thyratron, a thyratron control transformer. Everything is simple until you look at the values of the parts and the requirements for them. Since the task is to obtain a good slope of the front of the current pulse through the active element, the thyratron needs a high-speed, with hydrogen filling, high reverse voltage and high switching current. The desired minimum pulse current for a thyratron is 500 amperes. Better - 1000 or more. The reverse voltage needs at least 20, preferably 25 kV. Such thyratrons were usually used in radars and getting them is not easy. But I got lucky. A couple lay in the rubble of the swag. Glance fell on the beautiful glass TGI-700 \ 25, the size of a two-liter bottle of soda. According to the nominal parameters, confused only the relatively low (700 Hz) claimed speed, but decided to try to use it for now. Capacitors From 1000 to 3300 pF the main storage and 235-470 pF additional between the electrodes of the tube. Ugh, just that. But! Operating voltage is needed from 15 kV. And low loss at high frequency is highly desirable; spurious inductance should be minimized. After all, I need to get a short front of the current through the tube, otherwise I will not see coherent photons as my own ears. So, only ceramic capacitors with a high permissible reactive power are suitable, which are used in tube radio transmitters and the same radars. Fffuh, you can breathe out, I also have such ones, because they have accumulated since the time when I was engaged in Tesla. Inductance. But it’s more difficult with them ... Until now, I didn’t need chokes in my crafts, at least of such a magnitude, of 0.5 H, and even without a core, with high electric strength. Such a throttle is needed for the so-called. "Resonant charge" of storage capacitors. In this mode, the charging process occurs with maximum efficiency, and the voltage on the capacitor can be doubled relative to the supply. I had to wind up such a throttle from several sections, since there is experience. By connecting the desired number of sections, it was possible to regulate the inductance in steps, and by changing the distance between them, the inductance can be adjusted smoothly within certain limits. With the second blocking inductor, which is needed to prevent direct current from flowing through the active element, it is much simpler - there the necessary inductance is 100-300 μH, but electric strength is also needed high. Therefore, I also wound on a frame divided into sections. This is how the first “soup set” looked like for the most important, as I called it, power part of the power source.

But this is not enough. In order for the thyratron to work normally - you need a voltage source for the cathode to glow - the first weighty transformer appears. In order to ignite a discharge in a laser tube and commute it, a source of high constant voltage is needed, and it is very desirable to be able to regulate it from 0 to 7-8 kV. Finally, you need a generator of a powerful enough control signal to unlock the thyratron. Another difficult block appears to generate it. It was also easier with the latter, since there were blocks from the unsuccessful design of the Tesla lamp coil with a pulsed mode of operation, it was enough to reconfigure them to work at the desired frequency.

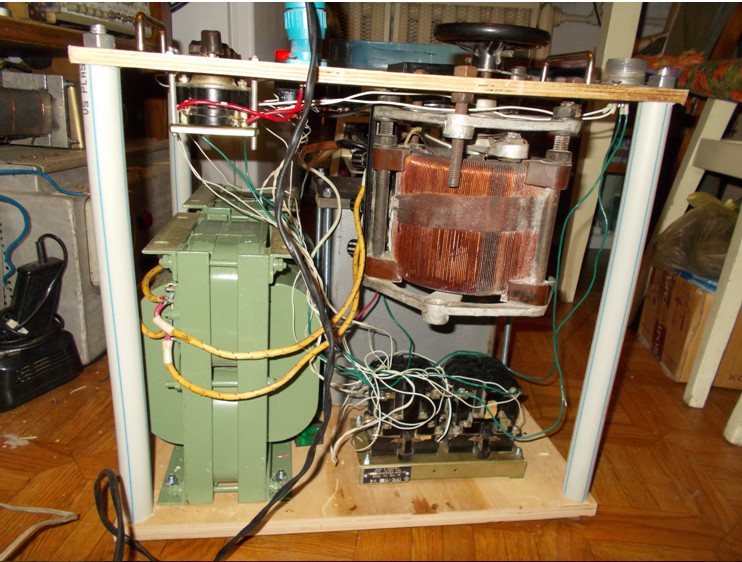

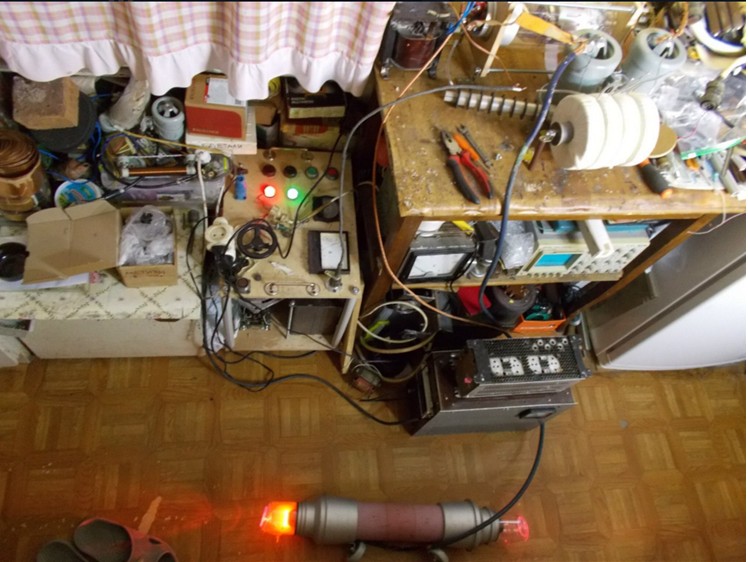

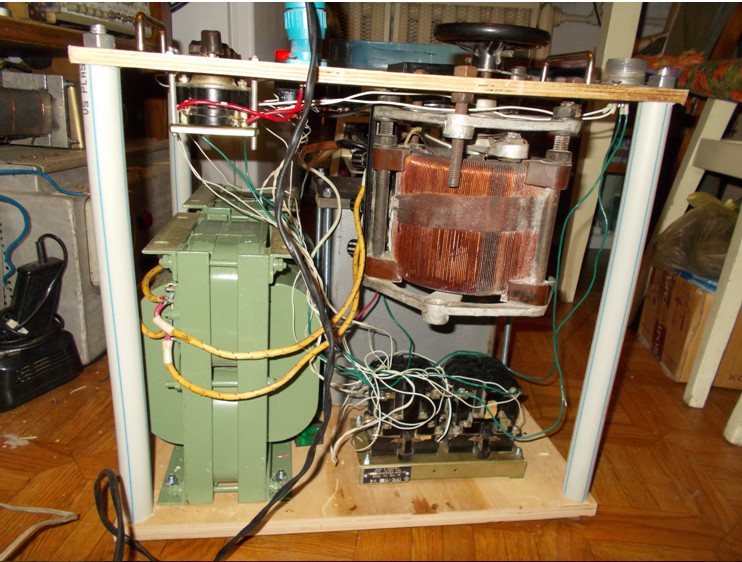

Here was assembled such a model subsystem of the anode voltage of the power unit, called "IVN" - a high voltage source. It consisted of two power transformers, giving up to 8 kV alternating voltage in series, a rectifier in the form of a diode bridge on KTs201D poles, a filtering capacitor k41-1a at 2 uF 10 kV, LATR at 9A in the primary circuit of power transformers, on and off buttons individually control generator and IVN, devices for monitoring voltage and current.

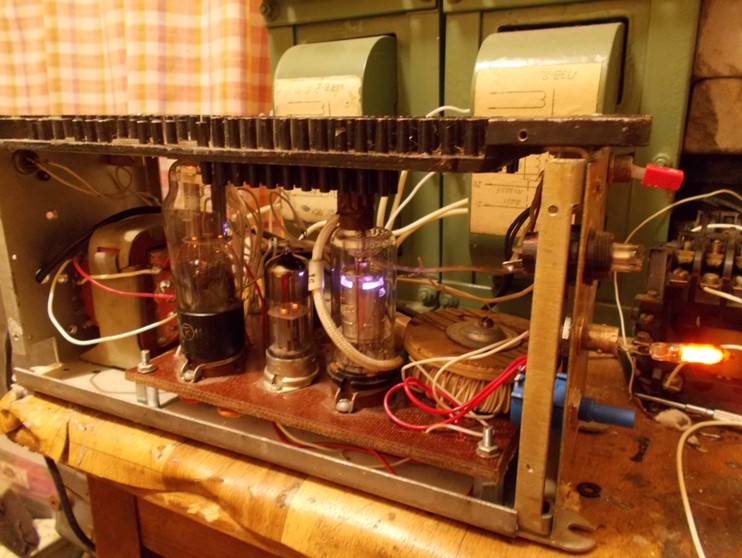

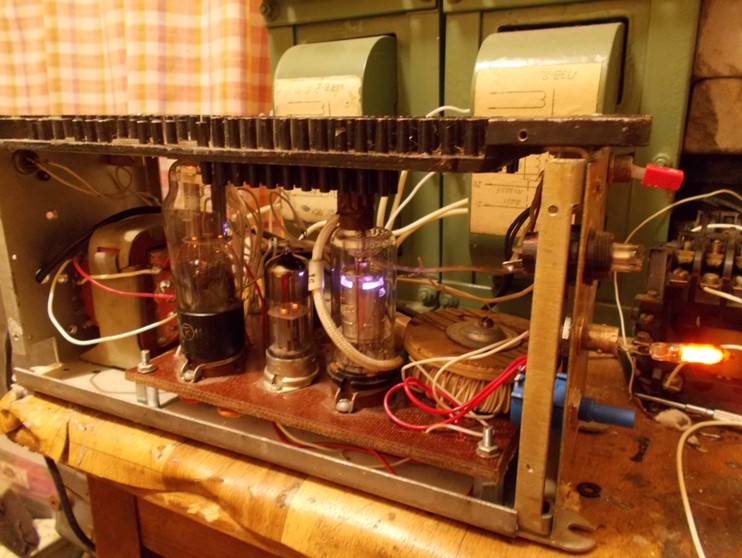

The control generator (submodulator) consists of two main blocks - a master oscillator and a power amplifier. Both blocks are made on lamps - in the master, a blocking generator on a 6n6p lamp with a pre-amplifier on the TGI1-10 \ 1 thyratron is used. The power supply of the anode circuits is rectified by the kenotron.

The second block is a power amplifier, at this stage it was assembled on a GMI-5 lamp, consists of an amplifier itself and a body kit in the form of bias sources for the first and second grid, also on kenotron rectifiers. An anode voltage of 2 kV is obtained using a voltage doubler, also on 6d22s kenotrons. That’s why there are so many lamps in this block.

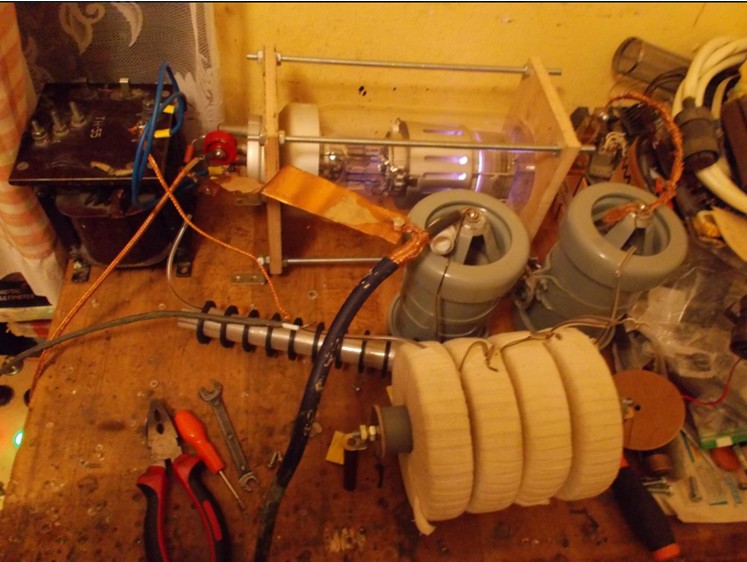

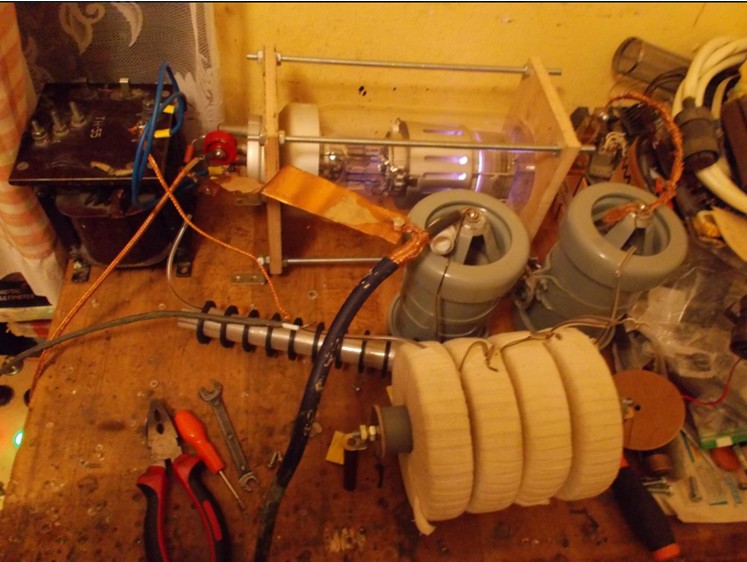

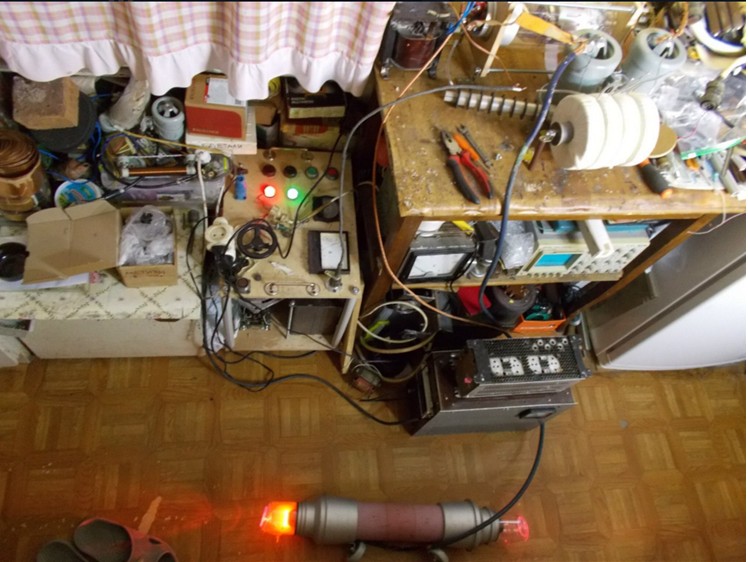

The moment has come when you need to connect all the elements into a single circuit. It looked like this.

The circuit of the power unit was located nearby on the table, and was assembled "on the snot", as it may have to redo something, adjust the values of the parts.

The launch was immediate.

At first glance, all components interact correctly. The transformers are buzzing, a discharge is lit in the laser tube, a characteristic squeak is heard with a frequency of 10 kHz, the switching thyratron is lit, but the supply voltage has yet to be increased to the “design” 6 kV. Strictly speaking, the voltage does not play a decisive role, it is important to achieve a certain average power invested in the laser discharge, which for this tube should be at least 1600 watts. This is where the matter stalled. At the turn of 500 watts, the thyratron lost control, simply hovering in the open position, leading to a short circuit in the IVN. Having played with the pulse repetition rate (hereinafter referred to as ChSI), the capacitance of the main and additional capacitors, and the inductance of the charging choke (from large sections), we managed to overcome this boundary and reach the boundary first at 1000, and then 1500 W.

However, after a short time, about 10 minutes, the thyratron lost control again, closing the IVN. And it became apparent that something was wrong with the thyratron! Its anode was red-hot!

During the time the device worked stably, the discharge channel in the laser tube also managed to heat up red-hot, for it, unlike the thyratron, it is more than regular work. But this temperature for the discharge channel is still completely insufficient.

After several attempts to restart, it became clear that in the thyratron of this type the power losses are too large, another thyratron, more suitable, is needed. I had to extract the TGI1-1000 \ 25 thyratron from another pulsed laser, at the same time I changed the topology of the power unit to a more “advanced” circuit, the so-called "Blumlyayn generator."

And the layout has completely changed - the long connecting cable between the laser tube and the power unit has disappeared.

In such a topology, things immediately went better. The circuit worked quite stably and it was possible to achieve an energy input into the discharge at the level of 2000 watts. The steady heating of the discharge channel has begun.

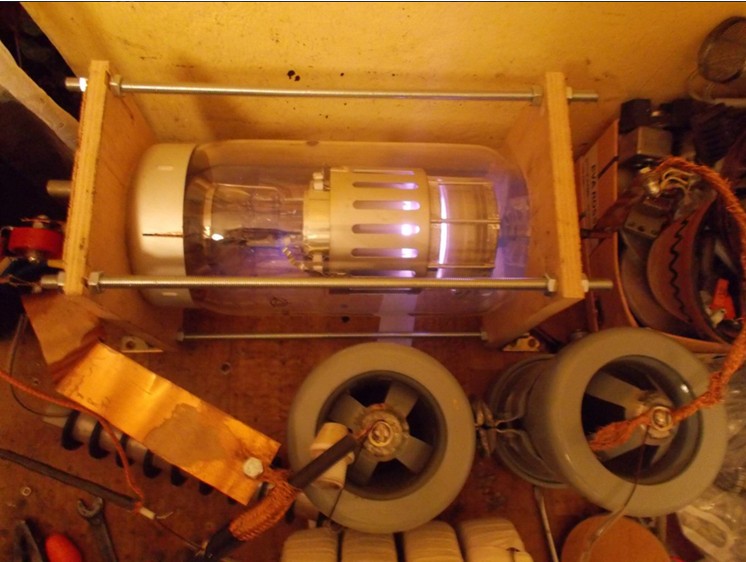

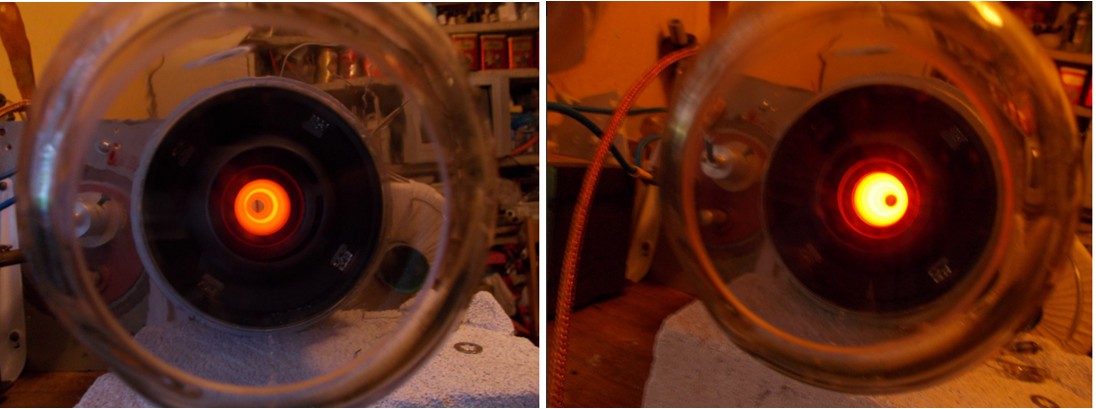

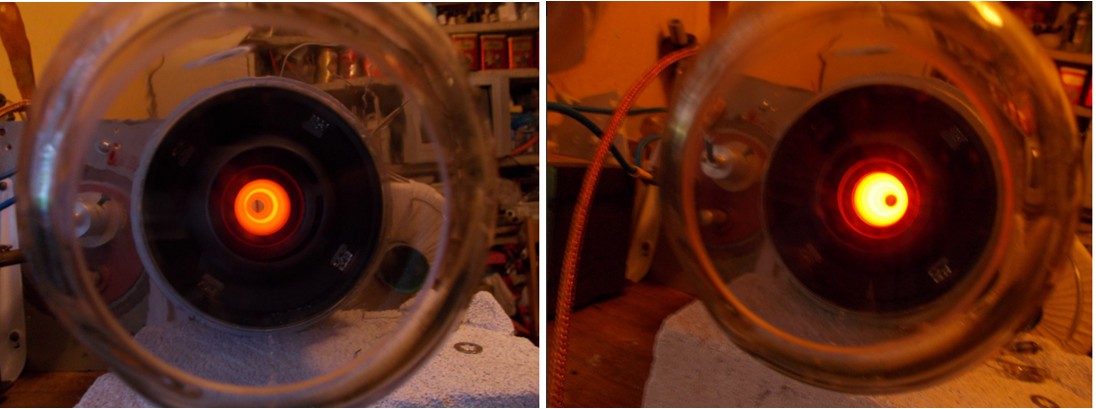

After about half an hour of work, the color of the discharge became noticeable. From orange neon, it first turned pink, then brightened until it became almost white, after which it acquired a dirty greenish-yellow hue. Spontaneous emission of copper appeared, which began to evaporate. Finally, against the background of light from the discharge, a comparatively bright green spot iridescent with “speckles” began to appear. Laser generation in the form of superluminescence, i.e. without resonator mirrors. The brightness of the laser light spot rapidly increased, in a few minutes it became dazzlingly bright.

If you install a blank resonator mirror on one side of the tube and catch its correct position, then the brightness increases by about 5 times, and the beam divergence greatly decreases.

The laser beam is clearly visible!

And if you put a lens in the path of the beam, then it is already able to burn on plywood. Which suggests that the light power is at least 0.5-1 watts. And this is with just one resonator mirror. So there is still a large reserve of output power to increase by installing a second mirror. For a home-made laser system, this is already a big success! Especially when such power schemes are mastered for the first time.

If you reflect the beam with a fragment of a CD-ROM into the wall, you can see that there are 2 components in the beam - green and yellow, the yellow component is still less pronounced than green.

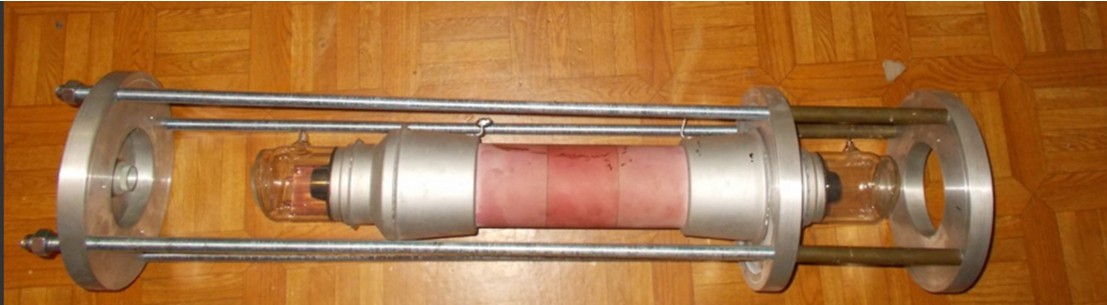

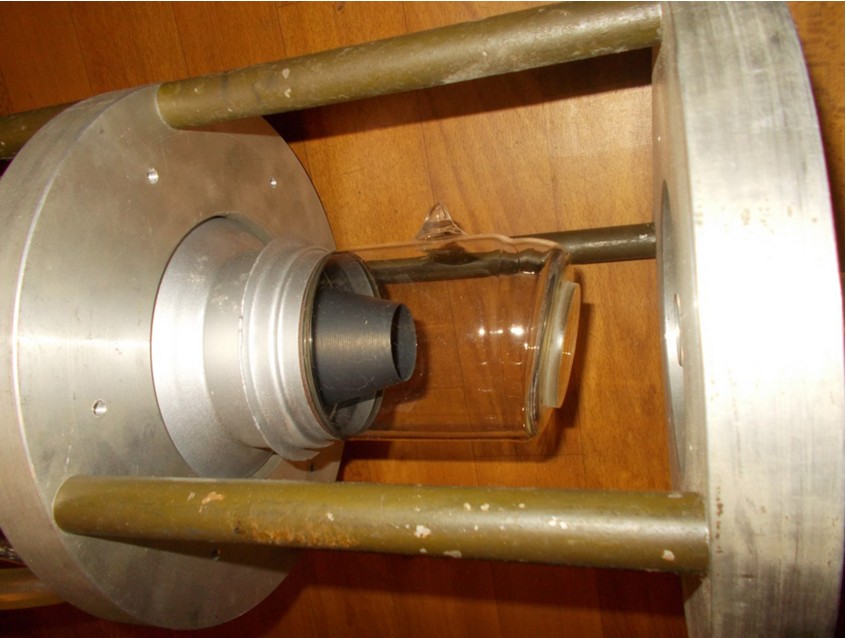

Nevertheless, despite the results obtained, there was one problem that did not allow us to proceed to the final assembly. Namely, the instability of the thyratron in the mode when the laser is already warmed up to operating temperature. A new thorough adjustment of the operating mode managed to slightly improve stability, and the added high-speed short-circuit protection made it easy to restart the IVN over and over again. But LATR was already in disrepair, the insulation of its winding was seriously damaged. The experiments had to be stopped for a while. It was decided to focus on the construction of the emitter. First of all, a casing with a water jacket was made, inside of which a laser tube was placed. It is needed in order to thermally stabilize the entire emitter so that the laser case does not heat up from the very hot side surface of the AE. It also performs the function of a reverse current conductor located coaxially with the AE. This allows you to slightly reduce the parasitic inductance of the AE. A piece of pipe from a lamppost bought in the acceptance of scrap metal and fragments of the casing of an old refrigerator were useful for its manufacture. The pipe was turned to the required size, and rings and the outer part were cut from the casing. The rings were put on the pipe, one layer of sheet sheathing was wrapped over it, and all this was brazed. The result was a metal pipe with double walls. A fixing flange was welded from below, which connects this part to the aluminum disk. In addition, 2 more aluminum disks were made on which resonator mirrors are mounted, and one textolite, on which the AE sector mount is placed. All these discs are pulled together by threaded rods to obtain a solid and rigid structure. To prevent breakdown, the “hot” AE electrode is separated from the casing by a self-made textolite insulator. The textolite was also home-made - a sleeve was wound from a fiberglass tape, each layer was coated with epoxy. Then the sleeve dried. After the epoxy was completely dried, the sleeve was turned on a lathe to the desired size.

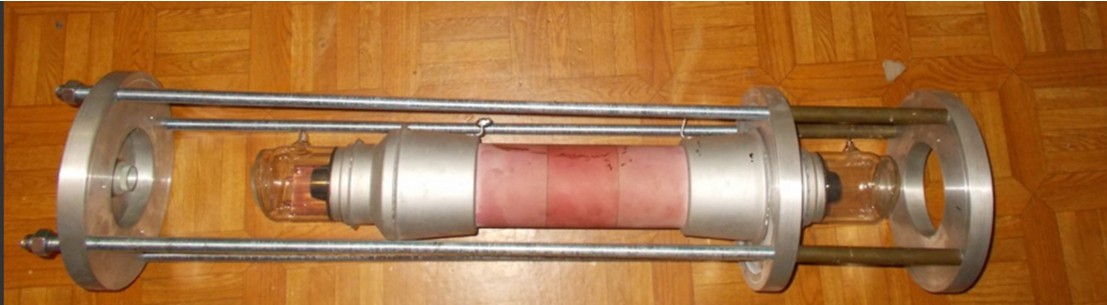

Emitter frame with a water jacket.

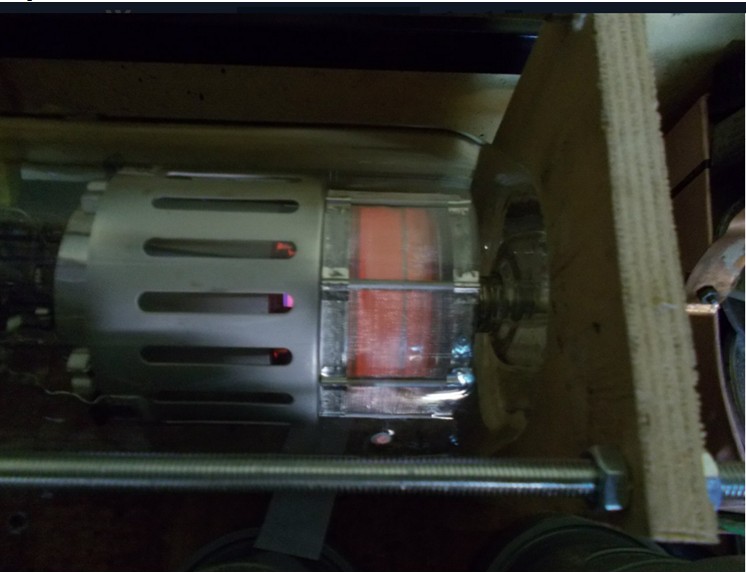

With the active element installed.

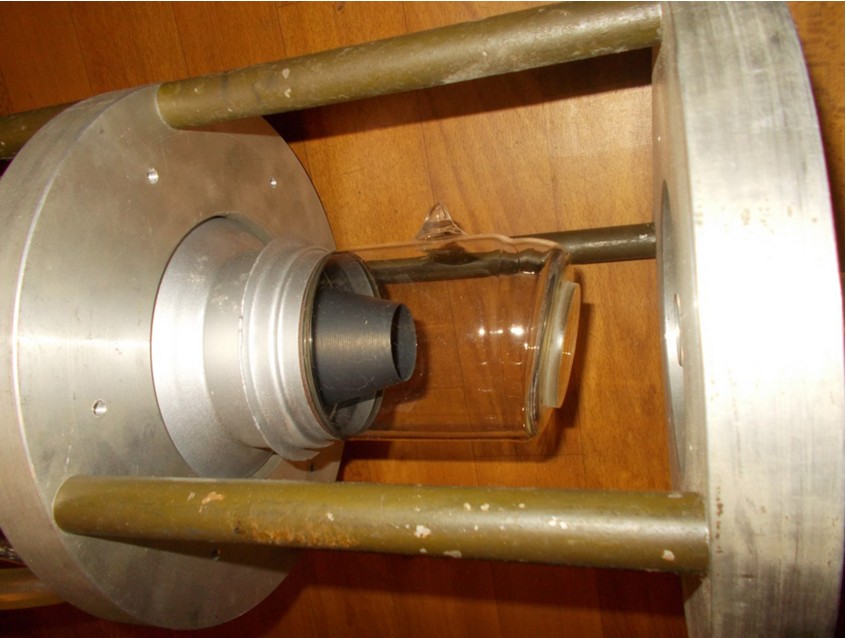

This is what the insulator of the active element looks like.

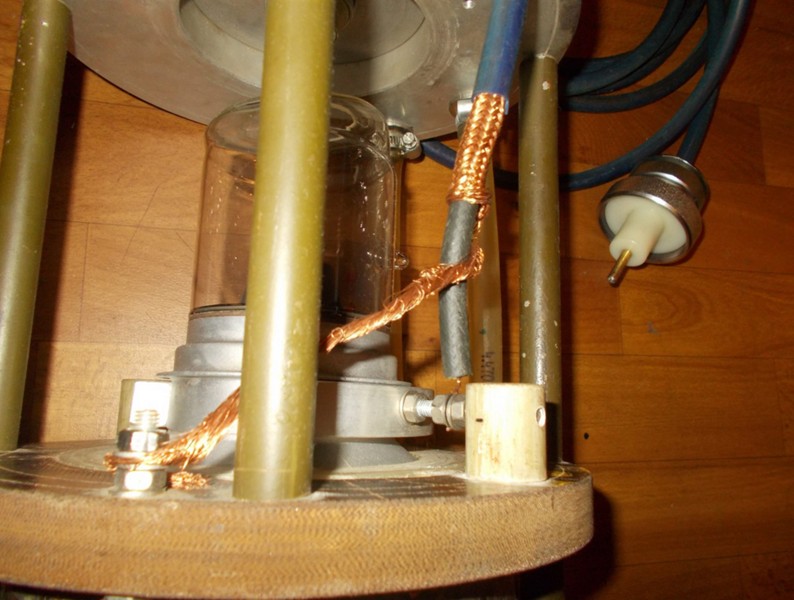

A connection cable with a large coaxial connector designed for a voltage of 50 kV was made. The connector housing is borrowed from the LGI-21 serial laser, and the connector core is home-made. Cable - antenna RK-50 from the radar, with monolithic insulation of the central core. The role of the additional 470 pF capacitor is now played by the distributed capacitance of this connecting cable together with the stray mounting capacitance.

As a result, such a design of the assembled emitter was obtained. It only remained to make the outer decorative casing, for which a sewer pipe with a diameter of 250 mm was already stocked. But so far I have put off this part of the work. It was necessary to make sure that the emitter was working properly.

It was impossible to continue working with the practically burned LATR, so it was decided to rewind the LATR, turning it into an autotransformer with fixed taps. Winding status “before”:

And “after”

A special multi-position switch had to be made for this winding and the frame of the former LATR. The components of the mobile part of the LATR were used.

Assembled with a winding, it turned out like this.

The converted autotransformer is installed in its place.

It was also added to the quick protection against short-circuit “slow” in the form of an automatic machine in a white case. You can start a new series of experiments. The launch attempt did not succeed - for some unknown reason, a GMI-5 lamp was found to be damaged in the power amplifier of the control signal. She blew air over the junction of legs with glass. Perhaps from insufficient cooling. In an immediate order, the lamp is replaced by a TGI-270 \ 12 ceramic thyratron. This required some alterations in the amplifier circuit, in particular, now the power supply circuits of the grids became unnecessary.

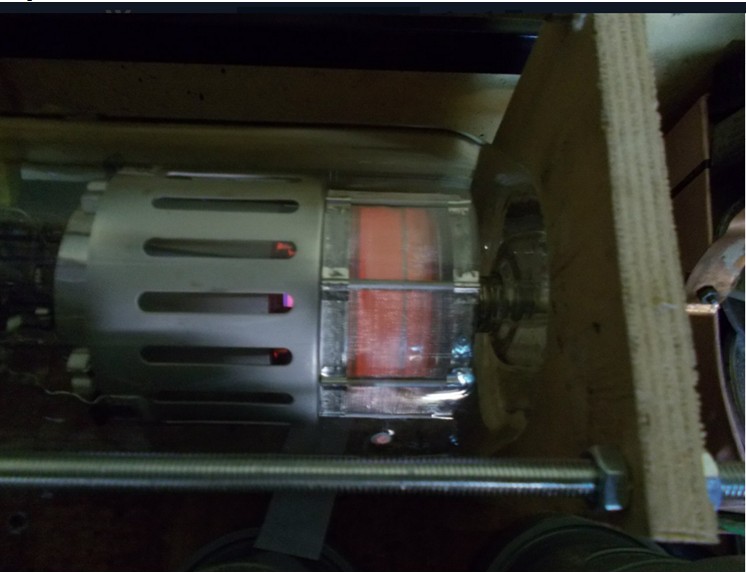

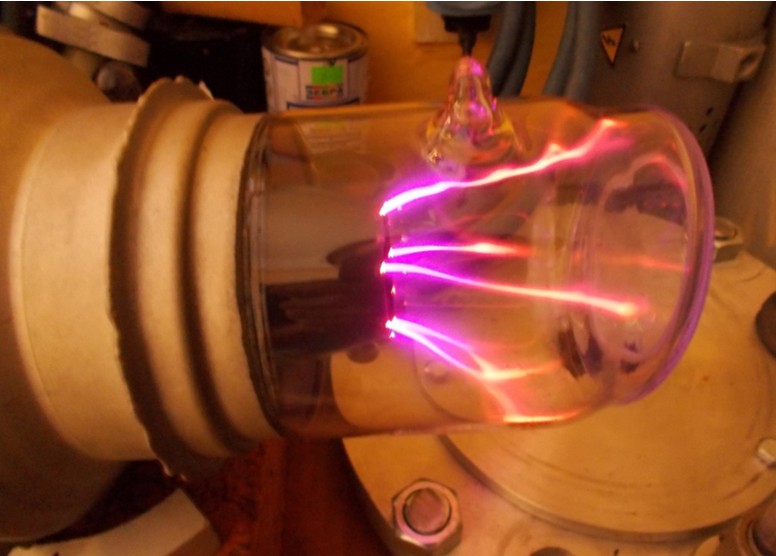

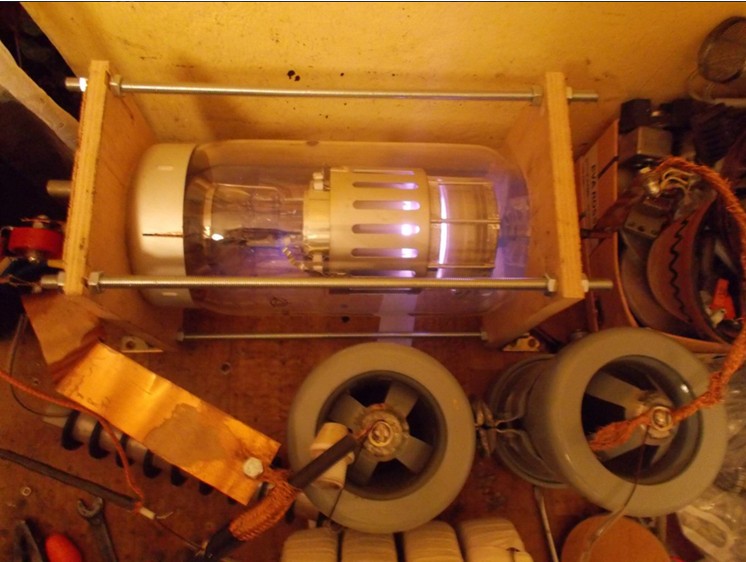

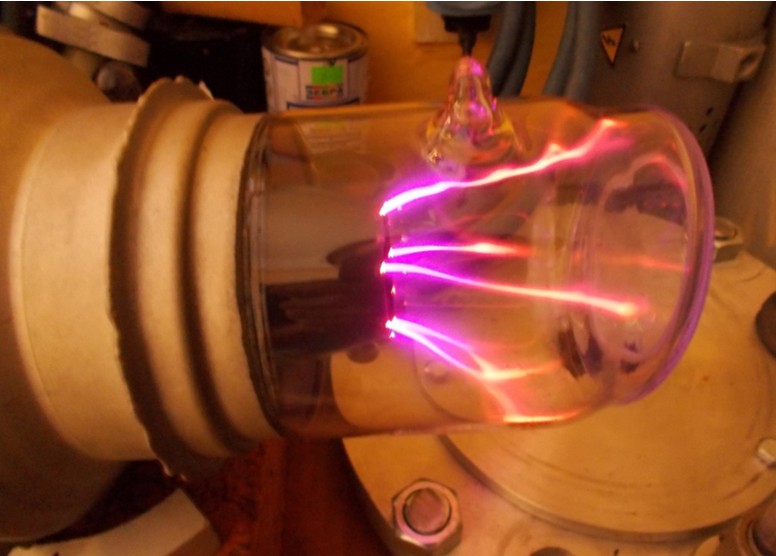

I must note that for all the alterations required, it took about 2 months of time - to manufacture the emitter frame, the alteration of the autotransformer and the power amplifier. All this time, the active element lay in the box. After all the alterations had been completed, it was removed from there, the emitter was fully assembled and an attempt was made to start it. Unsuccessful again. Active element detected by leaking air. This is how the discharge in it looks, for photography the AE was removed from the emitter.

At that moment, the project had to be stopped indefinitely. Continued, see in the next part.

And one more small disclaimer: this project was implemented because of my great love for the art of obtaining laser radiation, largely for the sake of its implementation, therefore I ask you not to ask the question “why is this necessary” in the comments. The information presented is shown for informational purposes, the author is not responsible for the consequences of attempts to repeat the described.

A picture to attract attention.

And the continuation is under the cut.

First, you have to make some digression. The thing is that I’m probably one of those many people who once dreamed about their light sword or laser gun, at least in the form in which this is possible with current technologies. And as it turned out, everything is possible if you work on it. From the beginning of my student days, I became interested in electrical engineering, namely, in obtaining high voltages and high frequencies. So I discovered for myself such an interesting device as the Tesla transformer in its many manifestations using a variety of topologies and a variety of components. At the same time, I realized that I was especially attracted to the aesthetics of the diesel engine, namely, I wanted all my products to look like they came straight to me from the laboratories of Frankenstein or Tesla himself. That is why I launched the element base, consisting of old oil transformers, powerful radio tubes, high-frequency motor generators (umformers), measuring panel meters in a carbolite case, etc. Nevertheless, it turned out that it was already difficult to surprise anyone even with a rather long discharge from the Tesla transformer. Therefore, I decided to change the direction of activity, taking the niche into which very few people ventured to get into. Namely, to devote his hobby to laser technology. My dream was always to figure out what lasers are, to reveal the secrets of their device and work, finally, to build your own coherent radiation generator. Time passed, I studied a lot of literature, talked with different people, gradually accumulated experience in studying,

Among the entire variety of lasers, one of them deserves much more attention than the others - a copper vapor laser. When I managed to see and feel such a laser while working in one of the laboratories, it created my most powerful impressions. But the whole thing is this. This is the most effective laser operating in the visible range of the spectrum, capable of having a radiation power of tens of watts at wavelengths of 510 nm (bright green) and 578 nm (saturated yellow). A beam containing both emission lines has a unique greenish-lemon color and is able to burn through various combustible materials no worse than an infrared CO2 laser beam. The goal was to acquire such a laser.

While working with a similar laser in the laboratory, I realized that I can’t count on the purchase of a finished installation, despite the attempts made. Too big, heavy and expensive. Like any laser, it consists of two main parts - the emitter and the power source. Here is what one of the earliest models of such a laser looks like - LGI-101. The emitter is almost 2 meters long, and the power source has the size of a "full-fledged" home refrigerator. And it weighs like 4 refrigerators. The declared laser radiation power in total for both emission lines is 5 watts with a consumption of 2.5 kW. The appearance of the emitter and the power source can be seen in the photographs:

The emitter, in turn, consists of its own set of parts: the most important - the active element, then the resonator mirrors, the cooling system and the housing in which it is all assembled together. The power source consists of a number of functional blocks, which are described below. Therefore, I had to confine myself to searching only for the irreplaceable part - the active element (gas-discharge laser tube), and then mobilizing all my experience and swag to build all that is missing. After some time, with invaluable help from my friends, I finally received a treasured wooden box in the mail, with a completely new active element such as UL-102 “Quantum”, a more recent development compared to LGI-101. Compared with LGI-101, UL-102 is almost half the size, it produces exactly the same radiation power, and the power consumption is 1.5 times less, i.e. It is much more economical. The “naked” active element (AE) of the UL-102 looks like this.

This is a massive device made of metal, ceramic and glass. It is inside of it that the conversion of electrical energy into a high-current gas discharge takes place, from the heat of which metallic copper evaporates, and in which the copper atoms pass into an excited state. Upon transition from the excited state to the ground, the atoms emit photons, which, colliding with other excited atoms, will cause the emission of new photons, so until the light amplifies to the maximum possible value, which is determined by the degree of excitation of the active medium. In order for the light to freely pass through the laser tube and amplify in it, massive optical windows are located at the ends, and in order to expend less power to heat copper to its evaporation temperature, good thermal insulation of the internal ceramic discharge tube is required, which is enclosed in an pink ceramic outer casing. Electric energy is supplied to the two metal electrodes from the outside, and inside the tube there is neon under reduced atmospheric pressure. It is the discharge in neon that serves as the primary source of heat for the evaporation of copper, located in the form of small pieces inside the discharge channel, there are no vapors in the cold tube, and it would be impossible to ignite the discharge if there were a complete vacuum. Together with the laser tube, I also got a set of resonator mirrors. there are no vapors in the cold tube, and it would be impossible to ignite the discharge if there had been a complete vacuum. Together with the laser tube, I also got a set of resonator mirrors. there are no vapors in the cold tube, and it would be impossible to ignite the discharge if there had been a complete vacuum. Together with the laser tube, I also got a set of resonator mirrors.

Thus, the most important details have already appeared in me.

I already had an idea about the principle of operation of this laser and what is needed in order to get powerful coherent radiation from a set of spare parts. It was necessary to come up with the optimal system of thermal stabilization of the active element, put everything together in the form of a laser emitter, and most importantly - build a power source.

It is known from the literature that a copper vapor laser can operate only in a pulsed mode. The pulse repetition rate for the UL-102 tube can vary from 6 to 16 kHz. Each individual power pulse must have a steep front of current rise through the discharge. Ideally, the steepness of the current front through the discharge will be at the level of 50 nanoseconds, which is comparable with the lifetime of the excited state of copper atoms, and the current in the pulse will be several hundred amperes with a pulse duration of 300 to 1000 ns. Generally speaking, laser generation will turn out at a lower slope of the front, at the level of 100 ns, and even 300 ns, but its efficiency will be much worse. It should also be noted that the voltage at the electrodes of the tube at the pre-breakdown time should be at least 10 kV, and preferably more. The average power invested in the discharge by individual pulses, should be sufficient for heating and maintaining the optimum temperature of copper vapor, and for UL-102 the minimum value of this power is 1600 watts. There was good news: copper vapors have the highest gain. This means that the requirements for resonator alignment accuracy are very liberal (special high-precision devices for mounting and adjusting the position of mirrors are not needed). In addition, the gain is higher, the higher the concentration of copper atoms in the discharge, i.e. if heated sufficiently strongly, lasing can be obtained not with two, but with one mirror, or even without them at all (single-pass amplification of spontaneous emission or “superluminescence”). This greatly facilitated the task of constructing the primary layout, i.e. the task was simplified to the construction of only a power source, and the construction of the emitter can be postponed at that moment when the subtleties with power will be worked out. Now about nutrition. If you look at the power circuit of the tube, then at first glance everything is extremely simple. Just a few details when using the simplest topology, which in the literature is called the “direct excitation scheme”.

Everything is simple - 2 inductors, 2 capacitors, a switching thyratron, a thyratron control transformer. Everything is simple until you look at the values of the parts and the requirements for them. Since the task is to obtain a good slope of the front of the current pulse through the active element, the thyratron needs a high-speed, with hydrogen filling, high reverse voltage and high switching current. The desired minimum pulse current for a thyratron is 500 amperes. Better - 1000 or more. The reverse voltage needs at least 20, preferably 25 kV. Such thyratrons were usually used in radars and getting them is not easy. But I got lucky. A couple lay in the rubble of the swag. Glance fell on the beautiful glass TGI-700 \ 25, the size of a two-liter bottle of soda. According to the nominal parameters, confused only the relatively low (700 Hz) claimed speed, but decided to try to use it for now. Capacitors From 1000 to 3300 pF the main storage and 235-470 pF additional between the electrodes of the tube. Ugh, just that. But! Operating voltage is needed from 15 kV. And low loss at high frequency is highly desirable; spurious inductance should be minimized. After all, I need to get a short front of the current through the tube, otherwise I will not see coherent photons as my own ears. So, only ceramic capacitors with a high permissible reactive power are suitable, which are used in tube radio transmitters and the same radars. Fffuh, you can breathe out, I also have such ones, because they have accumulated since the time when I was engaged in Tesla. Inductance. But it’s more difficult with them ... Until now, I didn’t need chokes in my crafts, at least of such a magnitude, of 0.5 H, and even without a core, with high electric strength. Such a throttle is needed for the so-called. "Resonant charge" of storage capacitors. In this mode, the charging process occurs with maximum efficiency, and the voltage on the capacitor can be doubled relative to the supply. I had to wind up such a throttle from several sections, since there is experience. By connecting the desired number of sections, it was possible to regulate the inductance in steps, and by changing the distance between them, the inductance can be adjusted smoothly within certain limits. With the second blocking inductor, which is needed to prevent direct current from flowing through the active element, it is much simpler - there the necessary inductance is 100-300 μH, but electric strength is also needed high. Therefore, I also wound on a frame divided into sections. This is how the first “soup set” looked like for the most important, as I called it, power part of the power source.

But this is not enough. In order for the thyratron to work normally - you need a voltage source for the cathode to glow - the first weighty transformer appears. In order to ignite a discharge in a laser tube and commute it, a source of high constant voltage is needed, and it is very desirable to be able to regulate it from 0 to 7-8 kV. Finally, you need a generator of a powerful enough control signal to unlock the thyratron. Another difficult block appears to generate it. It was also easier with the latter, since there were blocks from the unsuccessful design of the Tesla lamp coil with a pulsed mode of operation, it was enough to reconfigure them to work at the desired frequency.

Here was assembled such a model subsystem of the anode voltage of the power unit, called "IVN" - a high voltage source. It consisted of two power transformers, giving up to 8 kV alternating voltage in series, a rectifier in the form of a diode bridge on KTs201D poles, a filtering capacitor k41-1a at 2 uF 10 kV, LATR at 9A in the primary circuit of power transformers, on and off buttons individually control generator and IVN, devices for monitoring voltage and current.

The control generator (submodulator) consists of two main blocks - a master oscillator and a power amplifier. Both blocks are made on lamps - in the master, a blocking generator on a 6n6p lamp with a pre-amplifier on the TGI1-10 \ 1 thyratron is used. The power supply of the anode circuits is rectified by the kenotron.

The second block is a power amplifier, at this stage it was assembled on a GMI-5 lamp, consists of an amplifier itself and a body kit in the form of bias sources for the first and second grid, also on kenotron rectifiers. An anode voltage of 2 kV is obtained using a voltage doubler, also on 6d22s kenotrons. That’s why there are so many lamps in this block.

The moment has come when you need to connect all the elements into a single circuit. It looked like this.

The circuit of the power unit was located nearby on the table, and was assembled "on the snot", as it may have to redo something, adjust the values of the parts.

The launch was immediate.

At first glance, all components interact correctly. The transformers are buzzing, a discharge is lit in the laser tube, a characteristic squeak is heard with a frequency of 10 kHz, the switching thyratron is lit, but the supply voltage has yet to be increased to the “design” 6 kV. Strictly speaking, the voltage does not play a decisive role, it is important to achieve a certain average power invested in the laser discharge, which for this tube should be at least 1600 watts. This is where the matter stalled. At the turn of 500 watts, the thyratron lost control, simply hovering in the open position, leading to a short circuit in the IVN. Having played with the pulse repetition rate (hereinafter referred to as ChSI), the capacitance of the main and additional capacitors, and the inductance of the charging choke (from large sections), we managed to overcome this boundary and reach the boundary first at 1000, and then 1500 W.

However, after a short time, about 10 minutes, the thyratron lost control again, closing the IVN. And it became apparent that something was wrong with the thyratron! Its anode was red-hot!

During the time the device worked stably, the discharge channel in the laser tube also managed to heat up red-hot, for it, unlike the thyratron, it is more than regular work. But this temperature for the discharge channel is still completely insufficient.

After several attempts to restart, it became clear that in the thyratron of this type the power losses are too large, another thyratron, more suitable, is needed. I had to extract the TGI1-1000 \ 25 thyratron from another pulsed laser, at the same time I changed the topology of the power unit to a more “advanced” circuit, the so-called "Blumlyayn generator."

And the layout has completely changed - the long connecting cable between the laser tube and the power unit has disappeared.

In such a topology, things immediately went better. The circuit worked quite stably and it was possible to achieve an energy input into the discharge at the level of 2000 watts. The steady heating of the discharge channel has begun.

After about half an hour of work, the color of the discharge became noticeable. From orange neon, it first turned pink, then brightened until it became almost white, after which it acquired a dirty greenish-yellow hue. Spontaneous emission of copper appeared, which began to evaporate. Finally, against the background of light from the discharge, a comparatively bright green spot iridescent with “speckles” began to appear. Laser generation in the form of superluminescence, i.e. without resonator mirrors. The brightness of the laser light spot rapidly increased, in a few minutes it became dazzlingly bright.

If you install a blank resonator mirror on one side of the tube and catch its correct position, then the brightness increases by about 5 times, and the beam divergence greatly decreases.

The laser beam is clearly visible!

And if you put a lens in the path of the beam, then it is already able to burn on plywood. Which suggests that the light power is at least 0.5-1 watts. And this is with just one resonator mirror. So there is still a large reserve of output power to increase by installing a second mirror. For a home-made laser system, this is already a big success! Especially when such power schemes are mastered for the first time.

If you reflect the beam with a fragment of a CD-ROM into the wall, you can see that there are 2 components in the beam - green and yellow, the yellow component is still less pronounced than green.

Nevertheless, despite the results obtained, there was one problem that did not allow us to proceed to the final assembly. Namely, the instability of the thyratron in the mode when the laser is already warmed up to operating temperature. A new thorough adjustment of the operating mode managed to slightly improve stability, and the added high-speed short-circuit protection made it easy to restart the IVN over and over again. But LATR was already in disrepair, the insulation of its winding was seriously damaged. The experiments had to be stopped for a while. It was decided to focus on the construction of the emitter. First of all, a casing with a water jacket was made, inside of which a laser tube was placed. It is needed in order to thermally stabilize the entire emitter so that the laser case does not heat up from the very hot side surface of the AE. It also performs the function of a reverse current conductor located coaxially with the AE. This allows you to slightly reduce the parasitic inductance of the AE. A piece of pipe from a lamppost bought in the acceptance of scrap metal and fragments of the casing of an old refrigerator were useful for its manufacture. The pipe was turned to the required size, and rings and the outer part were cut from the casing. The rings were put on the pipe, one layer of sheet sheathing was wrapped over it, and all this was brazed. The result was a metal pipe with double walls. A fixing flange was welded from below, which connects this part to the aluminum disk. In addition, 2 more aluminum disks were made on which resonator mirrors are mounted, and one textolite, on which the AE sector mount is placed. All these discs are pulled together by threaded rods to obtain a solid and rigid structure. To prevent breakdown, the “hot” AE electrode is separated from the casing by a self-made textolite insulator. The textolite was also home-made - a sleeve was wound from a fiberglass tape, each layer was coated with epoxy. Then the sleeve dried. After the epoxy was completely dried, the sleeve was turned on a lathe to the desired size.

Emitter frame with a water jacket.

With the active element installed.

This is what the insulator of the active element looks like.

A connection cable with a large coaxial connector designed for a voltage of 50 kV was made. The connector housing is borrowed from the LGI-21 serial laser, and the connector core is home-made. Cable - antenna RK-50 from the radar, with monolithic insulation of the central core. The role of the additional 470 pF capacitor is now played by the distributed capacitance of this connecting cable together with the stray mounting capacitance.

As a result, such a design of the assembled emitter was obtained. It only remained to make the outer decorative casing, for which a sewer pipe with a diameter of 250 mm was already stocked. But so far I have put off this part of the work. It was necessary to make sure that the emitter was working properly.

It was impossible to continue working with the practically burned LATR, so it was decided to rewind the LATR, turning it into an autotransformer with fixed taps. Winding status “before”:

And “after”

A special multi-position switch had to be made for this winding and the frame of the former LATR. The components of the mobile part of the LATR were used.

Assembled with a winding, it turned out like this.

The converted autotransformer is installed in its place.

It was also added to the quick protection against short-circuit “slow” in the form of an automatic machine in a white case. You can start a new series of experiments. The launch attempt did not succeed - for some unknown reason, a GMI-5 lamp was found to be damaged in the power amplifier of the control signal. She blew air over the junction of legs with glass. Perhaps from insufficient cooling. In an immediate order, the lamp is replaced by a TGI-270 \ 12 ceramic thyratron. This required some alterations in the amplifier circuit, in particular, now the power supply circuits of the grids became unnecessary.

I must note that for all the alterations required, it took about 2 months of time - to manufacture the emitter frame, the alteration of the autotransformer and the power amplifier. All this time, the active element lay in the box. After all the alterations had been completed, it was removed from there, the emitter was fully assembled and an attempt was made to start it. Unsuccessful again. Active element detected by leaking air. This is how the discharge in it looks, for photography the AE was removed from the emitter.

At that moment, the project had to be stopped indefinitely. Continued, see in the next part.