How VR, AR and 3D printing work together: the VR Concept experience

We talk about the benefits of using VR and AR technologies in production and vocational training, including their interaction with 3D printing .

The presented material is a lecture by Ilya Vigora, the head of the VR Concept company , with whom he spoke at one of the Top 3D Expo conferences.

Video

Performance

Hello! My name is Ilya Vigor. I represent VR Concept, a developer of virtual and augmented reality software.

About company

We have been on the market since the beginning of zero, and we started developing software for VR in 2013. It is mainly used for teamwork with VR-models, for engineering and architectural-building education, for real work in industry and for VR-simulators.

New technologies in Russia

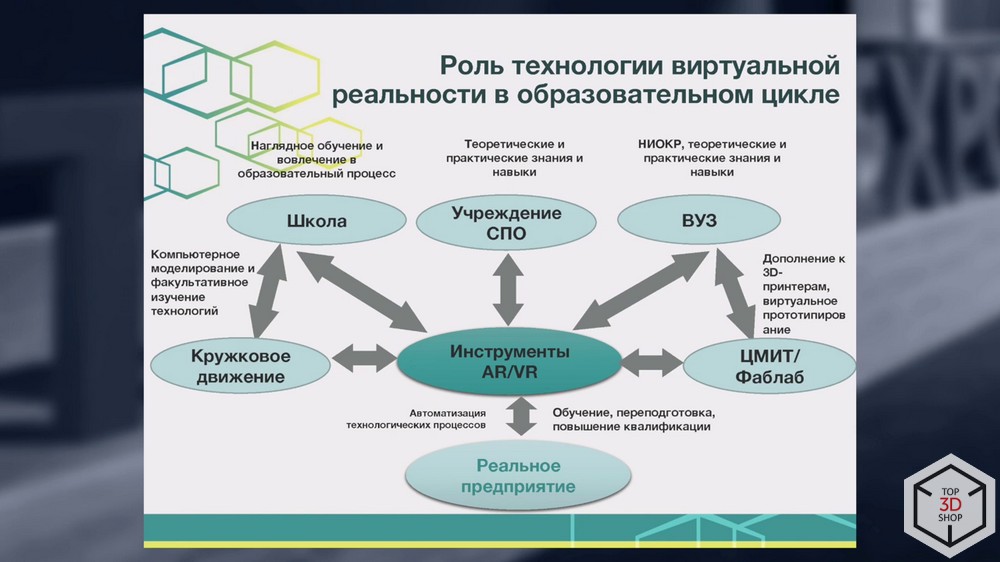

Now I would like to talk about why schools, universities, and so on are interested in education and tools such as 3D printing, drones, blockchains, and other fashionable pieces, where virtual reality, augmented reality, and so on are featured.

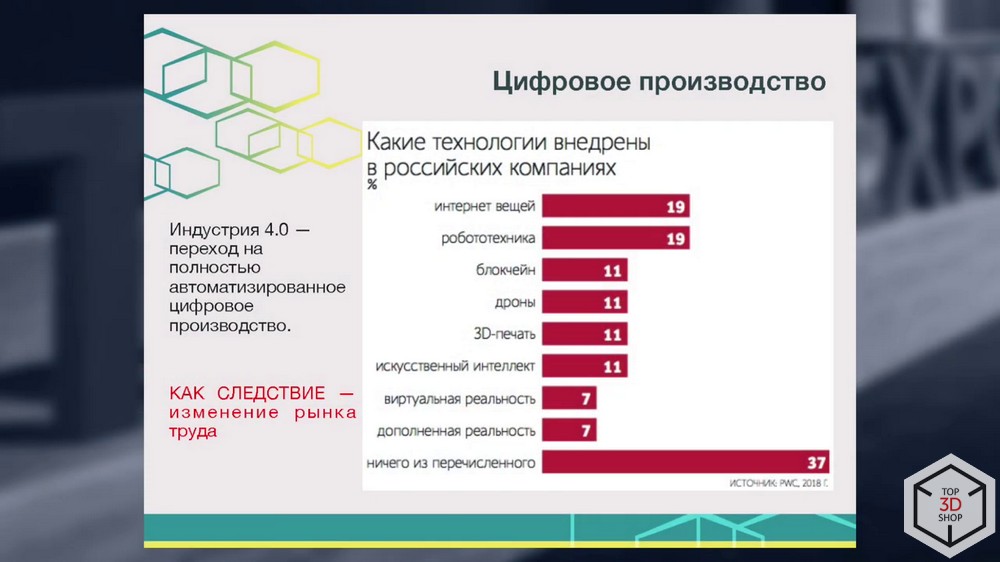

Here is a chart of PwC (PriceWaterhouseCoopers), this is the result of a survey - which Russian companies are introducing something from all these fashionable chips. There, what is called, industry 4.0, digital industry, factories of the future and so on. In the results of this survey, the Russian reality does not look the best. Only eleven percent of companies look towards 3D printing, much less towards virtual and augmented reality. But, anyway, the process goes. The engine is industrial companies, educational institutions - universities, quantoriums, schools, and so on. They are also starting to look towards teaching students how to work with these tools.

In education and industry

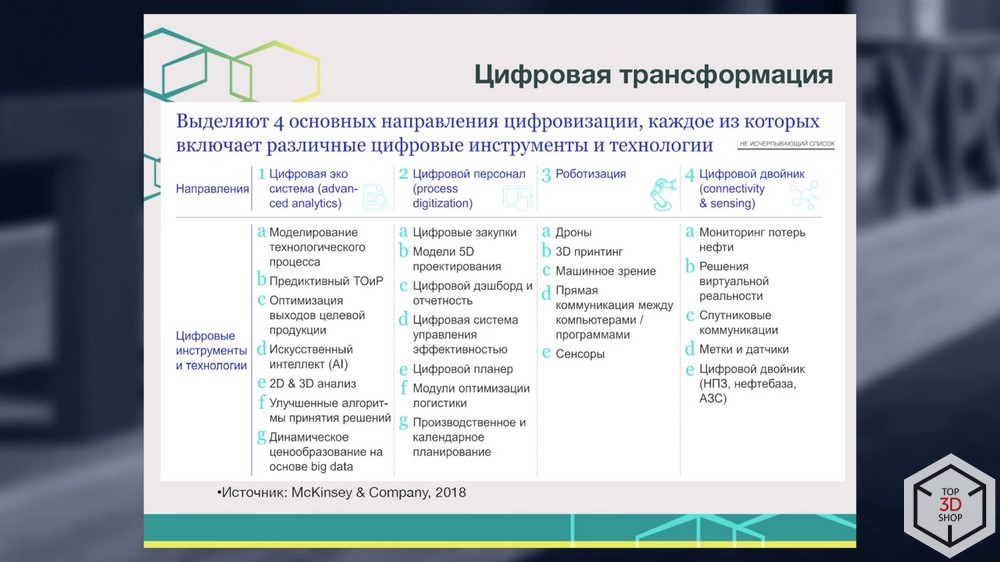

This is a digital transformation presentation for one of our largest oil and gas companies. She has commissioned a digital transformation consultancy and is looking at where to invest money in terms of developing her competencies. There are even areas such as digital staff, 3D printing, VR solutions and a bunch of other chips that are associated with industry 4.0. This confirms that all the same education will be engaged in learning these tools.

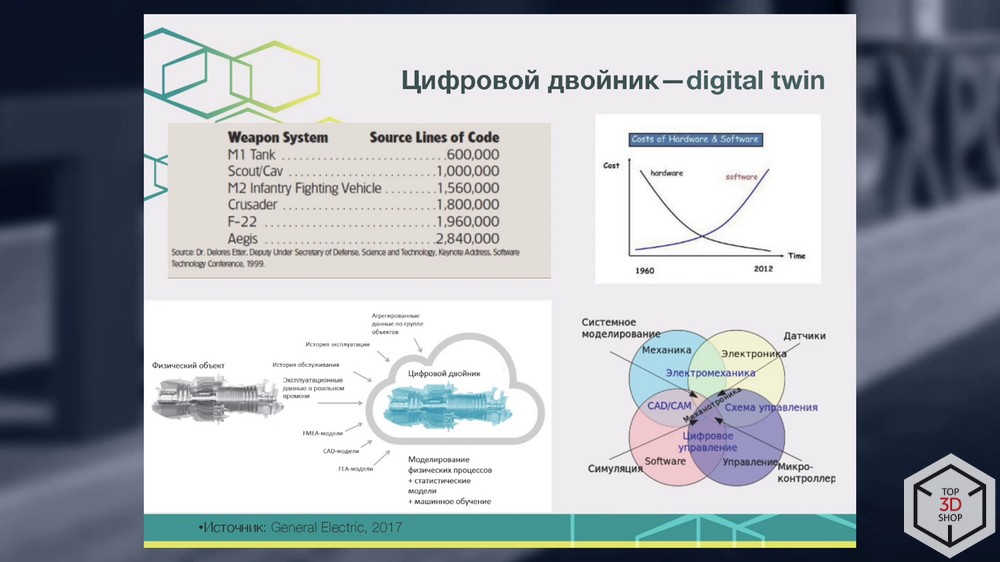

In terms of virtual reality, everything actually revolves around the term digital twin. This term has not yet been settled and every company, in this case, General Electric, understands something of its own as a digital twin. It includes both CAD-models, and engineering calculations, and predictive analysis of the service, and control software, which is now more and more in any engineering product. But there is no common understanding of what to teach. When meeting with different educational organizations, we do not see an understanding of which way to go. Although, if we talk about the fullness of modern engineering devices, I recently read about a Porsche car - there are about 120 processors and several thousand lines of code. In this case, the digital twin is not an engineering model of this car, but its control code.

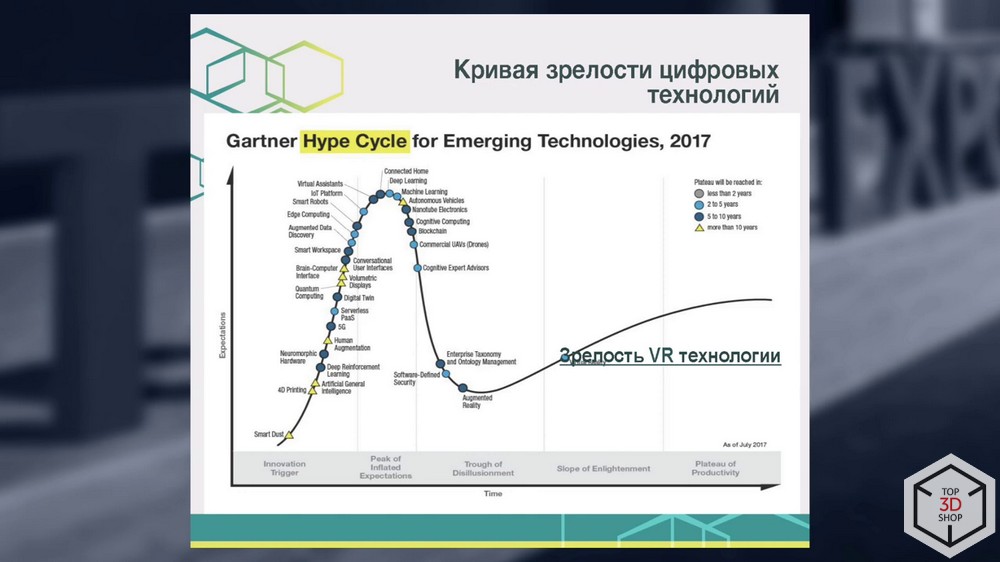

There is a fairly well-known schedule of the company Gartner on the maturity of technology. They are trying to predict which technologies have reached their maturity and will gradually be introduced into industry and education in the near future - ten years, two years, five years. Accordingly, this is the schedule for 2017.

Virtual reality, in their opinion, is on the way - within two to five years it will begin to be implemented more or less en masse. But, you can remember the schedule of the fifteenth year. If I am not mistaken, there, just in the place of virtual reality, was 3D printing.

What is VR and AR

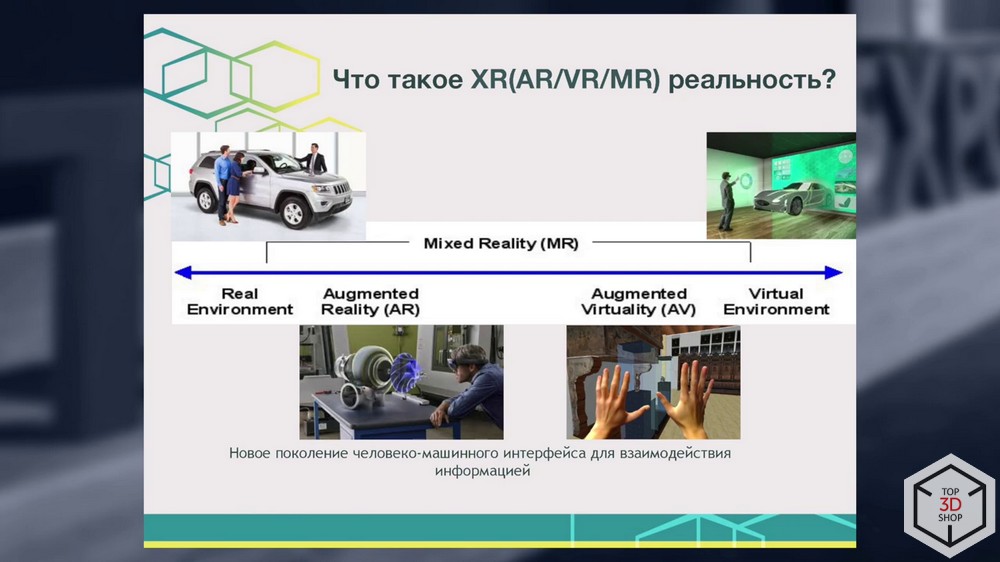

Many have a standard question: what is virtual reality? Because the terminology is new. There is a terminology XR, AR, MR and so on. Virtual reality, VR is what is completely generated on the computer. Accordingly, augmented reality, AR, is something generated on a computer and superimposed on the surrounding reality.

Application

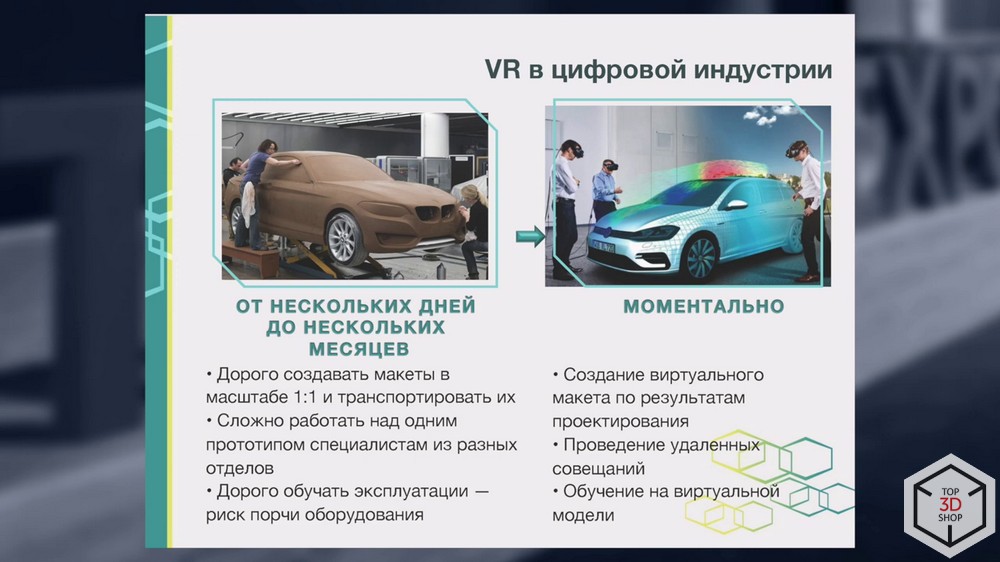

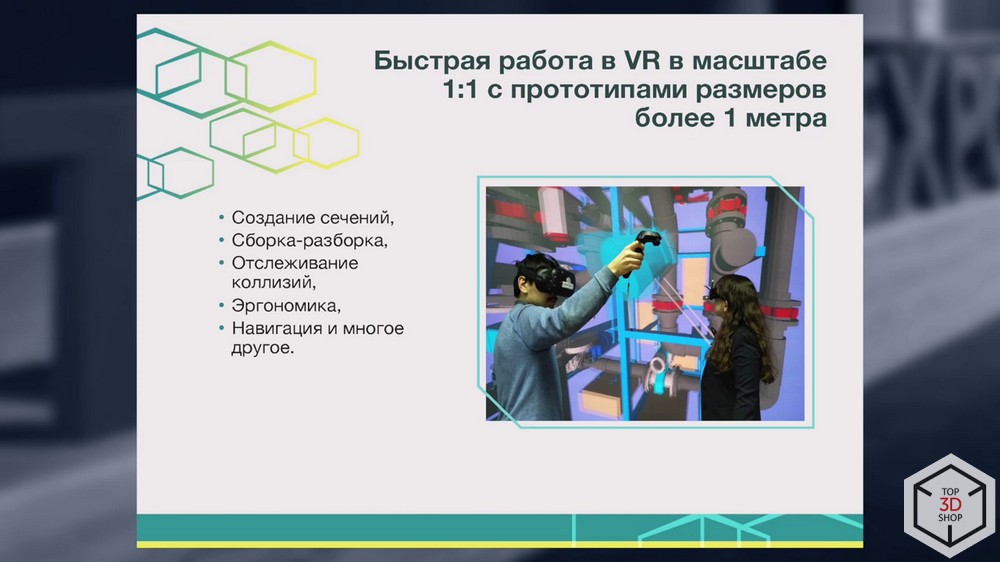

How is VR used in the digital industry, respectively, in education? In VR, you can perceive an object with which you are working, on a 1: 1 scale or any convenient one. Previously, for this purpose, full-scale or semi-gadget layouts were used, or, for example, something printed on a 3D printer. As a VR object, there may be a car, there may be a building. You can work with him collectively, but at the same time wearing VR helmets, perceiving everything in volume. As a matter of fact, this is the main effect that allows replacing physical mock-ups, physical prototypes.

VR equipment

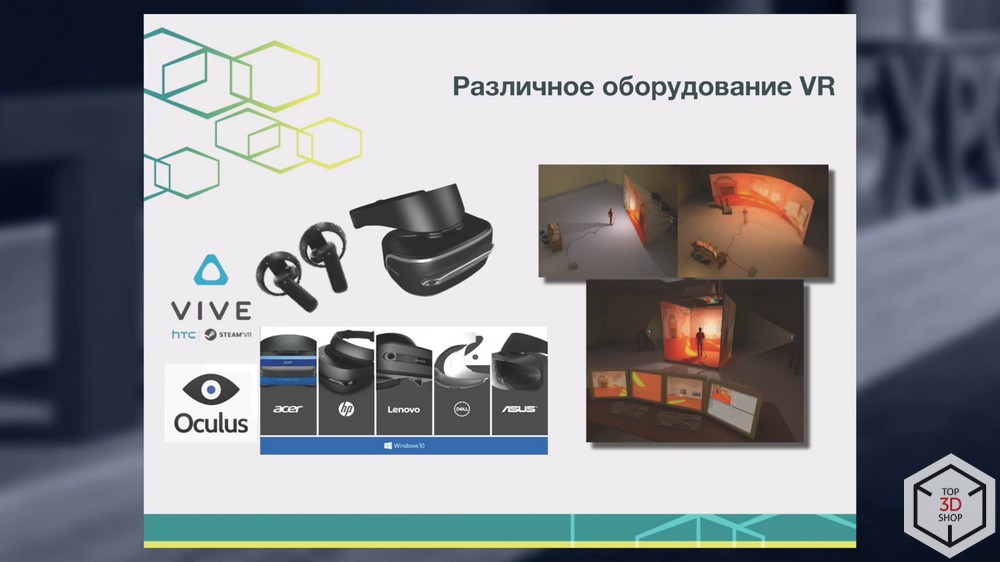

Different VR equipment is used - well-known virtual reality helmets from various manufacturers, which are now quite a lot on the market. Basically, of course, these helmets are used for gaming tasks. But no one bothers to use them for training or for real work in the design bureau. There are also professional systems, so-called VR rooms, “cadwalls”, panoramic systems. These are quite specific devices that are used mainly in some large organizations that make the final assembly of complex products, for example, a submarine or an airplane.

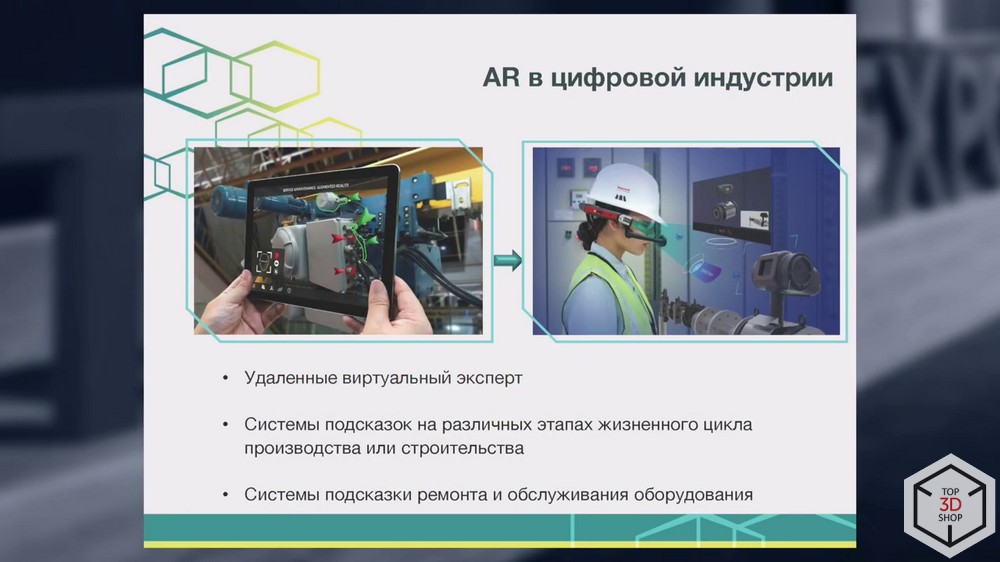

On the Gartner graph, augmented reality is drawn, the technology is still quite young, let's say - green, but it is being actively used in education and in the real industry. This technology, which allows you to impose on the surrounding reality of some kind of computer graphics. With the help of this graphic it is possible to suggest something, teach, move in the direction of the virtual assistant. There are still no significant industrial solutions, but the technology promises to be quite promising.

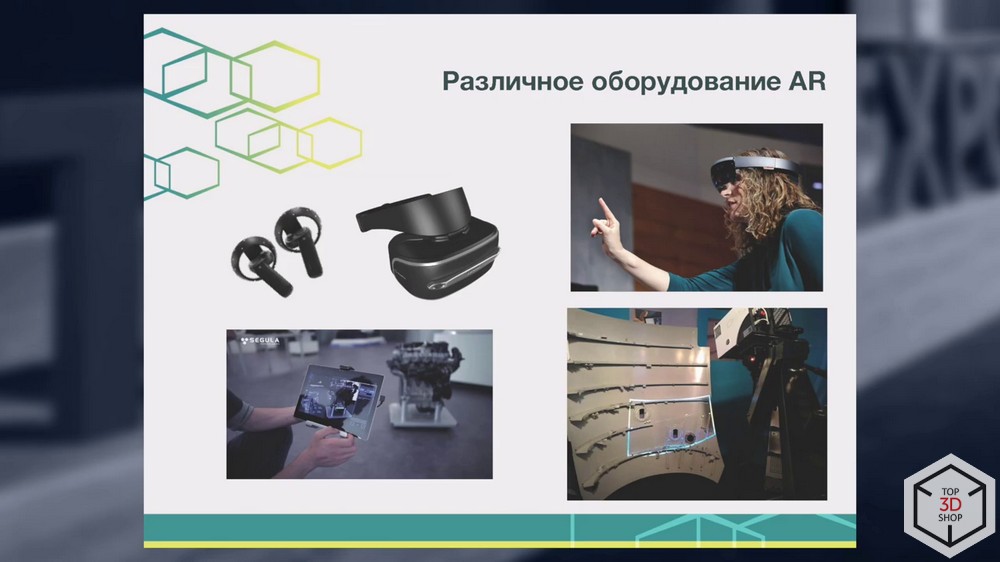

AR equipment

Different augmented reality equipment is also used. Including standard helmets that are sold for gaming tasks. You can use built-in camera helmets. There are a number of augmented reality helmets: Microsoft Hololens, A-DATA, and so on. There are, again, similar devices made on the basis of industrial laptops, industrial touchpads and completely industrial systems, as in the picture - these are industrial projectors that allow you to make a hint to workers - how to lay out or what to do for large surfaces.

Pluses for education

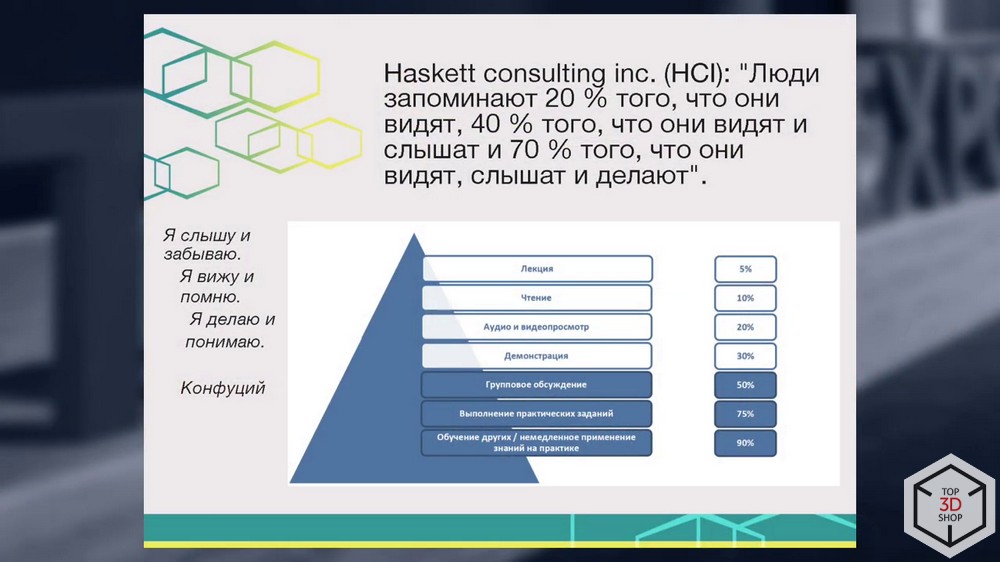

If we talk about education, there is a fairly well-known study on the recallability of Haskett Consulting International. That is, what type of presentation of information is best absorbed. In the first place the lecture is about five percent, in the second - reading, in the third - audio and video, in the fourth - a demonstration of something, the fifth is a group discussion, group interaction, when a person already remembers almost 50 percent of the material provided. In the sixth place is the implementation of some practical classes - 75 percent is memorable and, accordingly, when a person already teaches others, this is the maximum memorability - about 90 percent. Naturally, everyone wants from a tool that is used in education, the maximum effect - maximum memorization.

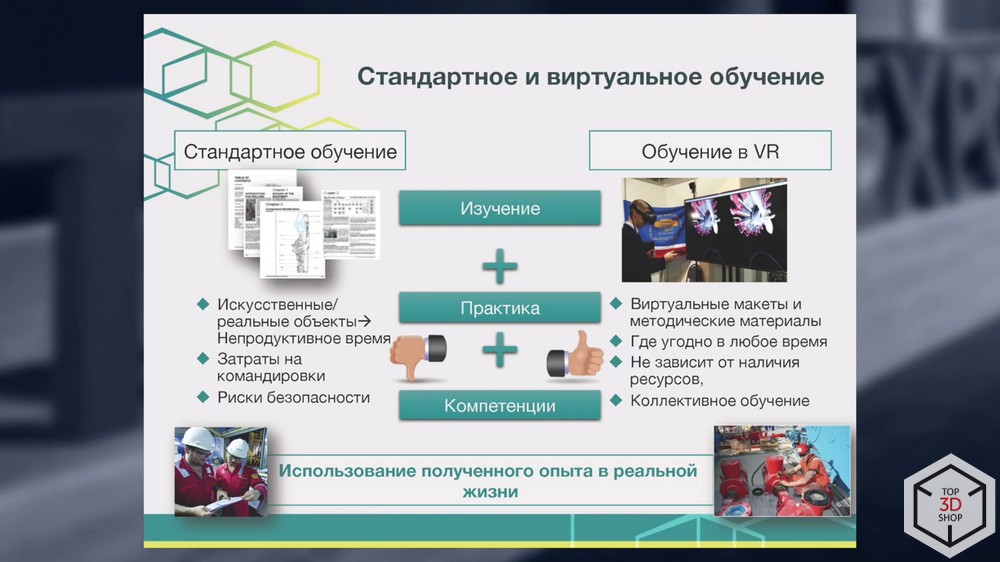

You can compare standard learning tools and learning in VR. In VR, you can conduct practical and theoretical studies simultaneously. Standard training is standard books and classes, and in the case of industrial enterprises it is a business trip. If training takes place on real objects, there is always the risk of injury to the employee or damage to equipment. In VR, there are no such problems, because you can simply make virtual layouts, some teaching materials, it is absolutely safe to conduct training.

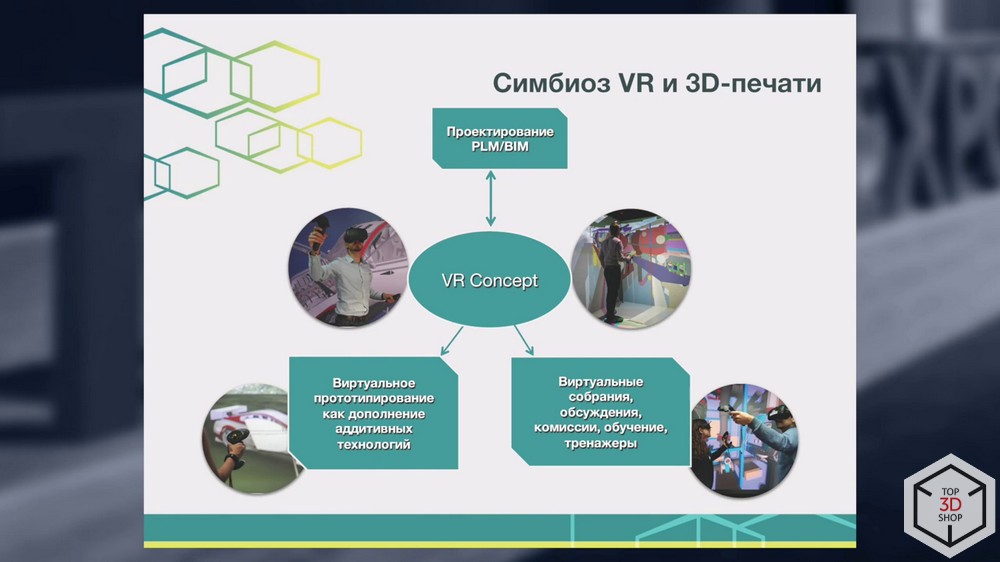

Virtual reality and 3D printing complement each other: in engineering and architectural-construction education, the design tools used for quite a long time are: CAD, PLM, BIM, whose files can be used as source material for creating a virtual digital double, and further, already in virtual reality, using our software, or the software of our competitors, to complement the existing cycle associated with additive technologies. Or use it differently - to hold some kind of virtual meetings, discussions, regular meetings of the mockup commission, train and do some kind of simulators.

Creating full-sized physical prototypes of large objects, from a meter or more, on a one-to-one scale, is usually not economically feasible, and sometimes impossible, for various reasons. VR is well suited for projects involving large equipment such as pumps and compressors, industrial equipment and buildings. That is, those cases where you need to work with the prototype, discuss or study it, but make the physical model for a long and expensive. In such cases, we can perform any necessary operations with the virtual model.

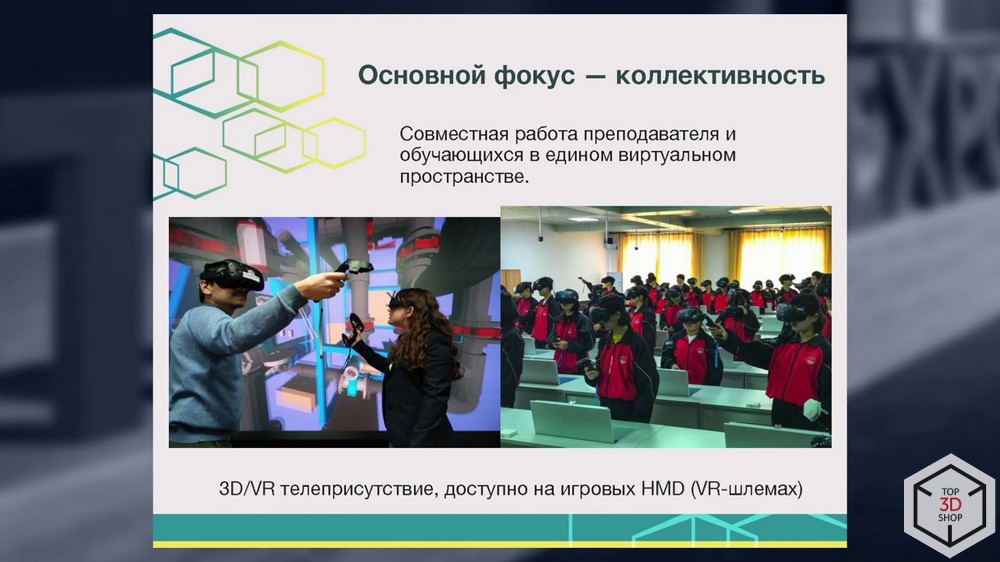

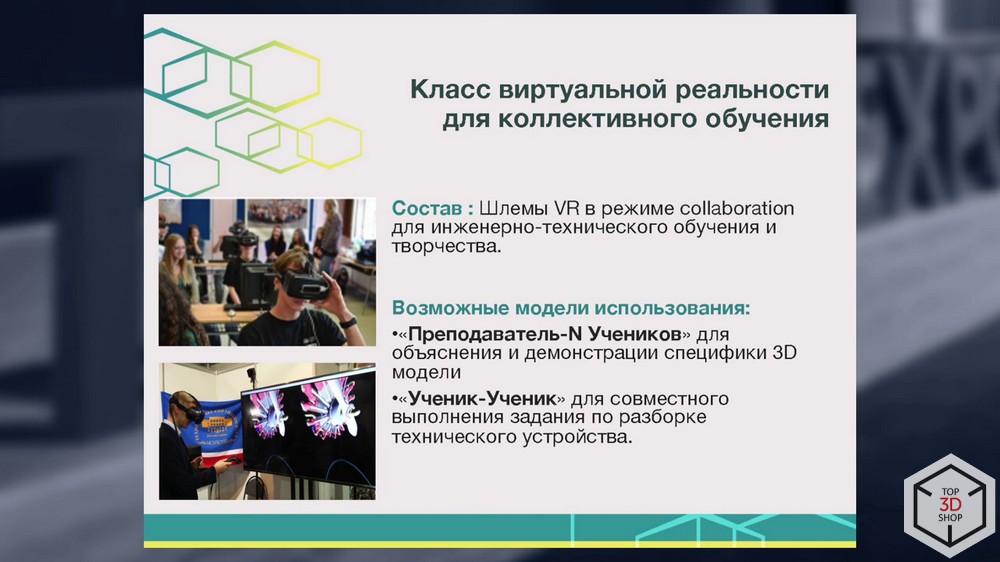

Another important advantage of VR is the possibility of teamwork, because while working in a team you can transfer your knowledge. On the slide - real photos of real projects of class equipment in a regular school. There is an elaboration of methods of using virtual reality for collective learning - from the school level to the professional.

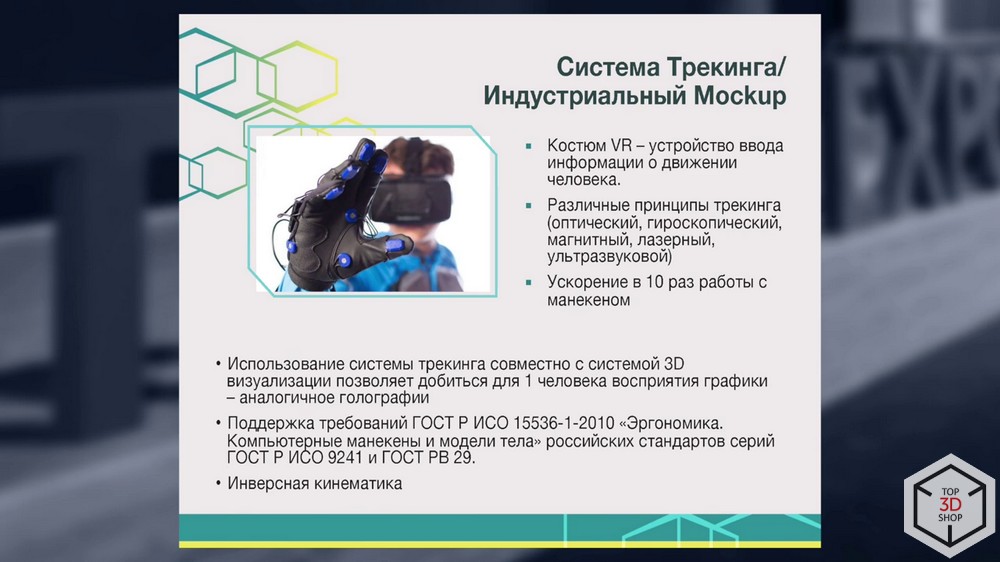

Quite inexpensive tracking systems already exist that allow these solutions to be used to create a virtual avatar. That is, in fact, in real time to capture the movement of a person, a teacher or a student, and send them to a three-dimensional scene. It was previously used for professional tasks, for practicing ergonomics. Now it is very well suited for learning.

Accordingly, such virtual reality classes are now being launched. This year we have already done several projects. In the following we expect much more.

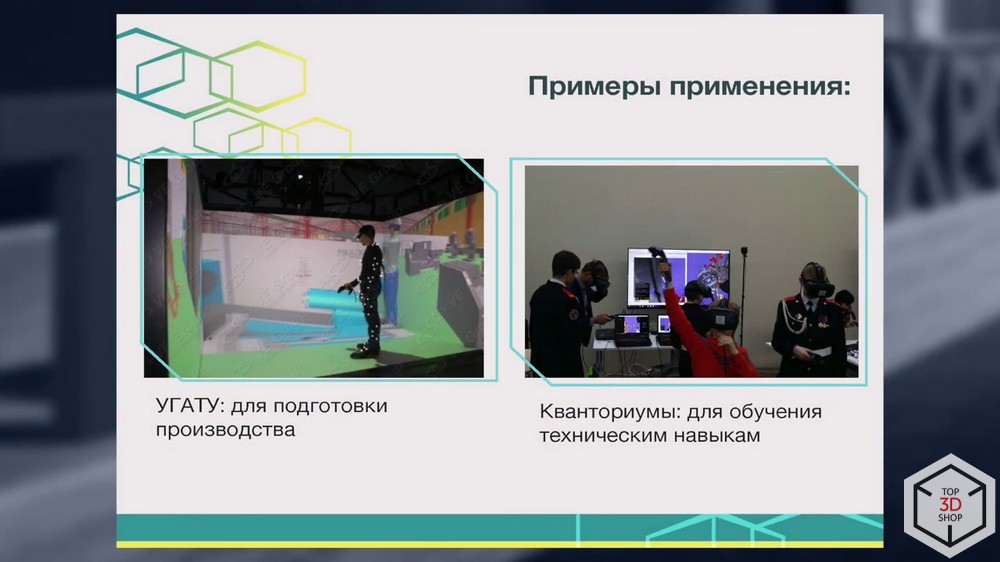

Examples: USATU University - a virtual reality room for the preparation of the process of production of engines.

Benefits for technical training

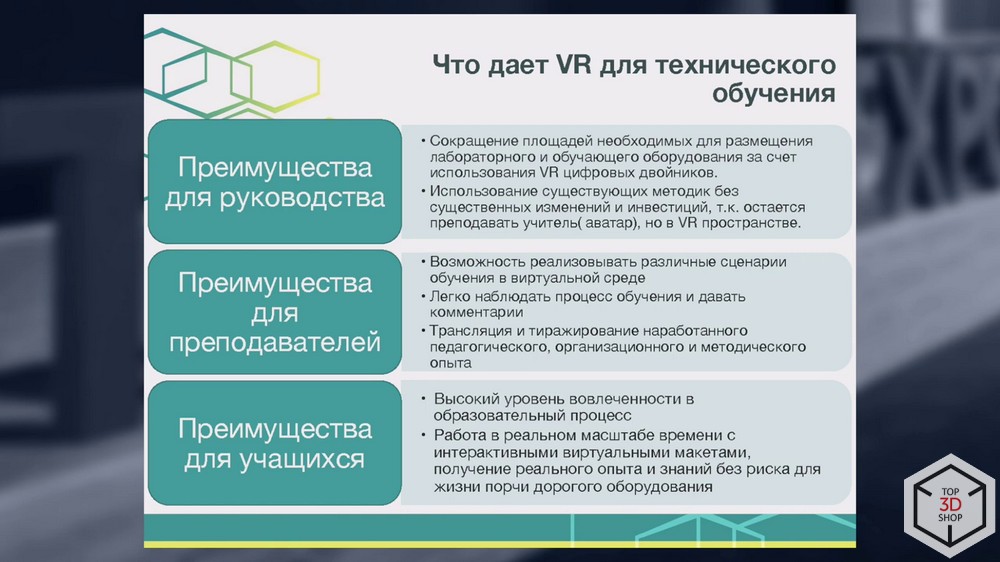

How is VR useful for technical training? We brainstormed and tried to identify benefits for those involved in the learning process.

- VR allows you to reduce the area if you are learning with the help of large full-scale layouts. In a number of universities, the jet engine is given in section. Naturally, now the industry no longer conveys real objects in such numbers as in Soviet times. That is, they are often simply not there, and there is no place for them.

- With collective learning in VR, it is not necessary to significantly change the current methods by which the teacher works, to write any special programs.

- The ability to implement any scenarios where three-dimensional layouts and three-dimensional CAD data are involved. All this fits into existing teaching methods quite easily, and it is quite simple to replicate.

- For students, this is a higher involvement and a greater opportunity to perceive information, because the information is provided on a one-to-one scale is very realistic.

Total

The virtual reality tool is quite new, it is literally several years old. In 2016, available virtual reality helmets came out, before they were more expensive, cost tens of thousands of dollars. Now it is more accessible and understandable to most tools, but the techniques and the material itself are still few. A lot of experiments, trial launches of such projects. There is a great interest on the part of real enterprises and universities to this technology. Even in schools, TSMITs, fab labs and vocational schools, pilot projects are now underway.

We can say that the process is just beginning. And now, while the “pilots” are going, it is difficult to talk about mass implementation - this is a fairly distant future business.

The point of view of the lecturer may not coincide with the position of the editorial board.

Order equipment and creationIntegrated VR and AR systems for learning and working you can in Top 3D Shop.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks: