5-nm on the way - when to wait for a new process technology

In early October, the Taiwanese chip maker TSMC, which works with companies such as AMD and Apple, made two statements. First, the company managed to improve its 7-nm process technology and manufacture the chip using a new technology. The second - 5-nanometer chip will be released in 2019. About the prospects of these developments - we tell below.

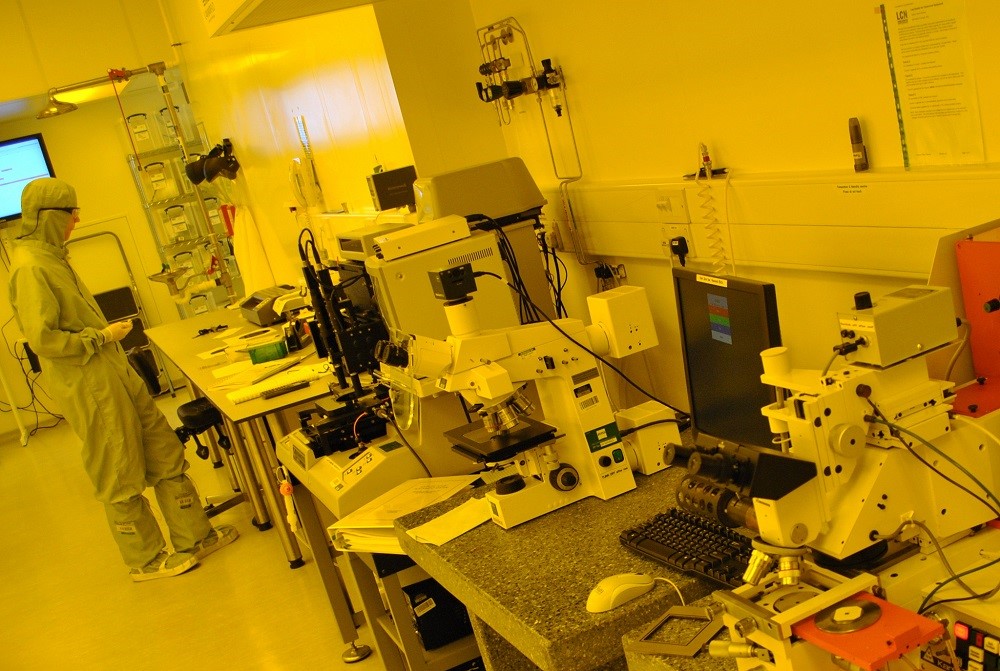

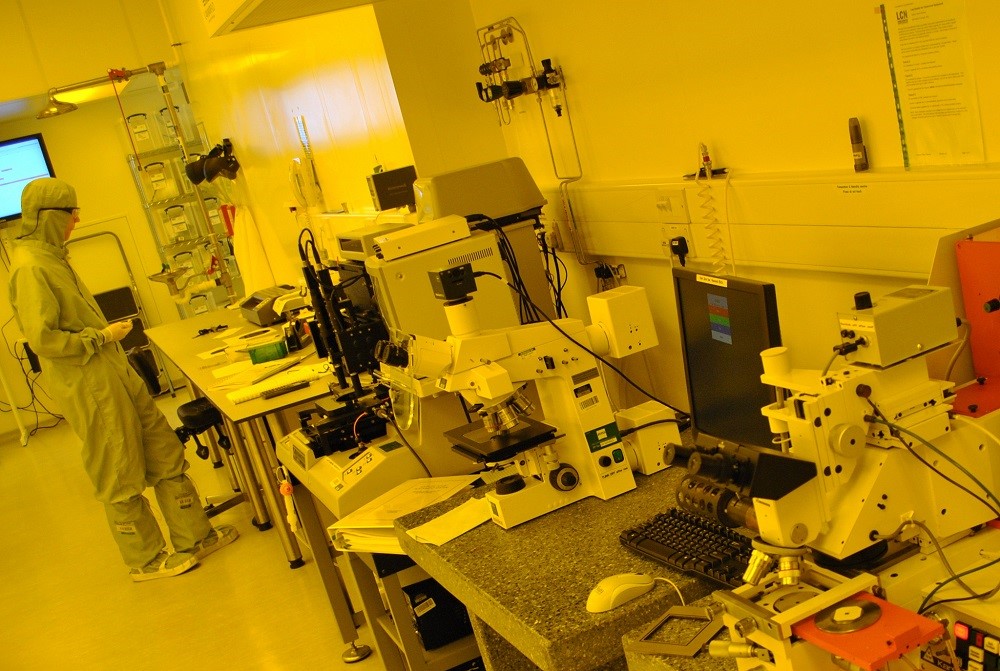

/ photo UCL CC

The chip, printed by TSMC at the beginning of the month, is based on the second-generation 7-nm process technology, which has undergone a number of changes in comparison with its predecessor.

The 7-nm process technology of the first generation TSMC is based on DUV lithography with “deep” ultraviolet radiation. It uses immersion lithography and scanners with a wavelength of 193 nm. The first chip on this technology in the company was printed back in April of this year. And in May, TSMC began to produce 7-nm chips for Apple. New chips provided the system on a chip A12 Bionic. She is already responsible for the work of the latest smartphones of the IT giant: iPhone XR, XS and XS Max.

In total, orders are receivedfrom two dozen companies, including Bitmain, NVIDIA and Qualcomm. AMD is also a major TSMC client - based on the 7-nm process technology, the Vega 20 processors and the Epyc server CPU are built.

Earlier this month, TSMC reported that they were able to improve their 7-nm process technology. Engineers used photolithography in “hard” ultraviolet ( EUV ) to develop chips . In this case, the wavelength is twenty times smaller and amounts to 13.5 nm . The transition to EUV (together with the development of modeling and detection of defects and other processes) reduced the power consumption of microcircuits produced by 8% and increased the density of transistors by 20% compared to the first-generation technology.

So far, with the help of EUV, only four non-critical layers of the chip are realized. First, the company wants to master the technology, and then use it to make large volumes of products (as long as the yield of devices is rather low).

Who was the first customer to receive new chips, the manufacturer did not disclose, but there is an assumption that it was all the same Apple . The company also develops a specialized version of the updated process technology for the automotive industry.

TSMC plans to begin the risk production of 5-nm chips already in 2019. To create 5-nanometer chips, the company uses EUV, but with this photolithography method fourteen chip layers will be made, instead of four.

By that time, the Taiwanese company plans to roll in EUV technology and increase production capacity. The company has already announced the start of construction of a new factory where chips will be created. It will be erected in Taiwan's Southern Science Park.

The 5-nm chips have a number of advantages, compared with the 7-nm. With the same complexity, the density of the transistors in the updated chips will be1.8 times higher, and the clock frequency will increase by 15%. In this case, the 5-nm processor will consume 20% less energy than the 7-nm. However, before starting production, the company needs to solve a number of difficulties.

The first is the lack of development tools. The necessary EDA design package for the 5-nm process technology will be prepared in November of this year. However, libraries for PCIe 4.0 and USB 3.1 units will be ready only in the summer of next year.

Another problem is the high cost of development. According to experts, developing a system on a chip using 7nm technology costssomewhere in the 150 million dollars. In the case of the 5-nm process technology, the cost increases to $ 250 million. This means that the price of finished products will eventually rise, and fewer client companies will be interested in using these chips. Therefore, there are no guarantees that the production of microcircuits using the 5-nm process technology will pay off.

In one of the previous posts, we said that the manufacturer of integrated circuits GlobalFoundries stopped the development of its 7-, 5- and 3-nm process technology due to financial difficulties. Instead, the organization switched to improving the 14-nm and creating embedded storage devices.

/ photo Mr Seb CC / 22nm silicon plate Intel

Intel also loses TSMC in the speed of developing new technical processes. The company again postponed the release of the 10-nm chip, and in September declared that it was returning to 22-nm (albeit for the implementation of the chipsets) in order to “unload” the production capacity. However, it is fair to note that TSMC 7-nm for Intel and 10-nm for Intel are consideredthe same design standards in the context of the density and size of transistors.

The only competitor TSMC on the 7 - and 5-nanometer "field" is still seen Samsung. The launch of 7-nm chips, the South Korean giant has planned for the first half of next year. Microcircuits for design standards 5-nm Samsung will also start producing in 2019, but when their sales start, it is still unknown.

PS About virtual infrastructure and work with PD - in our Telegram-channel :

/ photo UCL CC

7 nm TSMC process technology

The chip, printed by TSMC at the beginning of the month, is based on the second-generation 7-nm process technology, which has undergone a number of changes in comparison with its predecessor.

The 7-nm process technology of the first generation TSMC is based on DUV lithography with “deep” ultraviolet radiation. It uses immersion lithography and scanners with a wavelength of 193 nm. The first chip on this technology in the company was printed back in April of this year. And in May, TSMC began to produce 7-nm chips for Apple. New chips provided the system on a chip A12 Bionic. She is already responsible for the work of the latest smartphones of the IT giant: iPhone XR, XS and XS Max.

In total, orders are receivedfrom two dozen companies, including Bitmain, NVIDIA and Qualcomm. AMD is also a major TSMC client - based on the 7-nm process technology, the Vega 20 processors and the Epyc server CPU are built.

Earlier this month, TSMC reported that they were able to improve their 7-nm process technology. Engineers used photolithography in “hard” ultraviolet ( EUV ) to develop chips . In this case, the wavelength is twenty times smaller and amounts to 13.5 nm . The transition to EUV (together with the development of modeling and detection of defects and other processes) reduced the power consumption of microcircuits produced by 8% and increased the density of transistors by 20% compared to the first-generation technology.

So far, with the help of EUV, only four non-critical layers of the chip are realized. First, the company wants to master the technology, and then use it to make large volumes of products (as long as the yield of devices is rather low).

Who was the first customer to receive new chips, the manufacturer did not disclose, but there is an assumption that it was all the same Apple . The company also develops a specialized version of the updated process technology for the automotive industry.

When to wait for a 5 nm chip

TSMC plans to begin the risk production of 5-nm chips already in 2019. To create 5-nanometer chips, the company uses EUV, but with this photolithography method fourteen chip layers will be made, instead of four.

By that time, the Taiwanese company plans to roll in EUV technology and increase production capacity. The company has already announced the start of construction of a new factory where chips will be created. It will be erected in Taiwan's Southern Science Park.

The 5-nm chips have a number of advantages, compared with the 7-nm. With the same complexity, the density of the transistors in the updated chips will be1.8 times higher, and the clock frequency will increase by 15%. In this case, the 5-nm processor will consume 20% less energy than the 7-nm. However, before starting production, the company needs to solve a number of difficulties.

The first is the lack of development tools. The necessary EDA design package for the 5-nm process technology will be prepared in November of this year. However, libraries for PCIe 4.0 and USB 3.1 units will be ready only in the summer of next year.

Another problem is the high cost of development. According to experts, developing a system on a chip using 7nm technology costssomewhere in the 150 million dollars. In the case of the 5-nm process technology, the cost increases to $ 250 million. This means that the price of finished products will eventually rise, and fewer client companies will be interested in using these chips. Therefore, there are no guarantees that the production of microcircuits using the 5-nm process technology will pay off.

How are other companies doing?

In one of the previous posts, we said that the manufacturer of integrated circuits GlobalFoundries stopped the development of its 7-, 5- and 3-nm process technology due to financial difficulties. Instead, the organization switched to improving the 14-nm and creating embedded storage devices.

/ photo Mr Seb CC / 22nm silicon plate Intel

Intel also loses TSMC in the speed of developing new technical processes. The company again postponed the release of the 10-nm chip, and in September declared that it was returning to 22-nm (albeit for the implementation of the chipsets) in order to “unload” the production capacity. However, it is fair to note that TSMC 7-nm for Intel and 10-nm for Intel are consideredthe same design standards in the context of the density and size of transistors.

The only competitor TSMC on the 7 - and 5-nanometer "field" is still seen Samsung. The launch of 7-nm chips, the South Korean giant has planned for the first half of next year. Microcircuits for design standards 5-nm Samsung will also start producing in 2019, but when their sales start, it is still unknown.

PS About virtual infrastructure and work with PD - in our Telegram-channel :