As we went on an excursion to the KAI Laser

Did you know that in Kazan, with the participation of the world leader in laser technology - IPG Photonics, on December 24, 2013, the regional engineering center for industrial laser technologies KAI-Laser was opened? Members of the delegation of the first private robotic technology park Navigator Campus in Russia and their friends went on an excursion to this center. So, share what we saw.

This is how the entrance group, in which the deputy director of KAI-Laser, Oleg Vladimirovich Zinin, met our delegation. He spoke about existing clients and orders (mainly large industrial and oil enterprises of the Republic of Tatarstan), as well as about the possibilities of technology and the future of lasers in Russia. “What will give us the development of this sphere?” We asked. We were assured that the development of the complex would allow small and medium-sized enterprises to enter the production cycle of large enterprises due to outsourcing work on the production of components and, as a result, the overall economy will increase. Is it so we decided to see for ourselves.

So, let's start with the improvement of this temple of Athena - the goddess of knowledge, arts and crafts. In the center there are 11 complexes based on fiber lasers of various powers, using all types of laser processing of materials - tick and hybrid welding, cutting, surfacing, marking, cleaning, milling of the material. Laser power - from 20 W to 30 kW.

The list and characteristics of the main equipment in the center

full equipment specifications are available here:

439.5 million rubles were spent on equipping the center - 60% of the federal budget, 40% of the budget of the Republic of Tatarstan.

KAI Laser engineers set ambitious plans related to the technological development of the engineering industry of Tatarstan and Russia.

Armed with common sense, versatility and uniqueness of fiber laser technologies, the best minds of Kazan have found them in heavy industry. The use of laser technology will increase efficiency and reduce production costs. Research at the new center will focus on the application of laser technology for the processing of composite materials and the development of laser additive technologies.

For example, the rector of “KNITU-KAI” hinted in one of the interviews that it is planned to develop technologies for processing composite materials and additive technologies in the center - creating parts by building metal from powders (a unique thing for our country!). Laser cutting is characterized by the absence of mechanical impact on the processed material. A powerful laser beam focused at a focal point of 0.1 mm in size of several kW allows you to cut almost any material, regardless of their thermophysical properties.

Laser radiation, due to its versatility, has gained great demand in such types of technological processes as: cutting, welding, heat treatment, alloying, hole piercing, turning, milling. Laser equipment is not limited to this range of work and every day is used in new areas, replacing obsolete equipment. Laser bread slicers are just around the corner, comrades!

The laser today is a proven work tool. The demand for laser technologies is constantly growing mainly because they give results significantly higher compared to traditional methods of processing materials.

So, with what kind of equipment we managed to get acquainted on an excursion:

Laser cutting of blanks: module for laser cutting of pipes based on fiber laser

The module for automatic laser cutting is designed for cutting pipes. The system allows curly cutting of pipes with diameters up to 190 mm and lengths up to 3000 mm.

This machine is equipped with a 6 kW fiber laser with a transport fiber of 100 µm. The essence of technology: a laser beam is formed in a laser source (resonator) and is directed through a mirror or transport fiber to the cutting head of the machine, where it is focused using a lens to a point with a very small diameter and high power. A focused laser beam hits the sheet metal and melts it.

Thanks to these parameters, this module has several advantages over other types of metal cutting:

- clean cut,

- the ability to cut thin-walled pipes,

- high accuracy,

- lack of thermal deformations;

- lack of additional machining of the edges.

Thanks to these advantages, the cut parts can easily be assembled without additional intervention.

Next are automatic profile laser cutting machines.

They allow you to perform curly cutting of any profile with a thickness of up to 200 mm and a length of up to 6000 m. During the cutting process, under the influence of a laser beam, the material melts, ignites, evaporates and is blown out by a gas stream. A cutting width of less than 1 mm allows, with minimal thermal impact on the base material, cutting workpieces with high accuracy.

Next, we got acquainted with the equipment for laser welding, it is performed by the module for laser processing of dimensional products based on fiber laser.

This is manual tick-borne welding with a hydraulic drive.

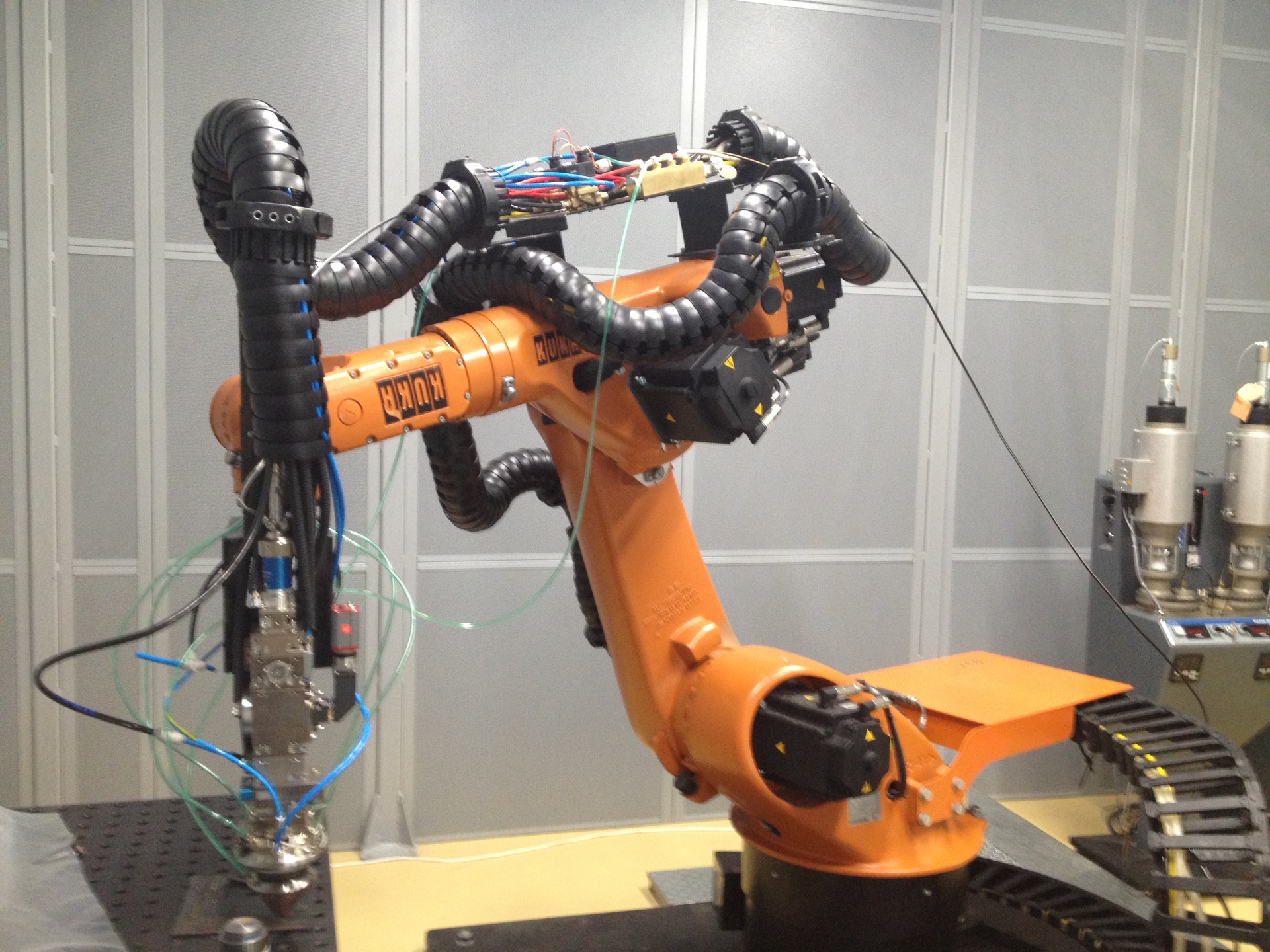

And this is a robotic tick-welding complex.

The LaserWeld 6R60-L6000 installation is intended for automatic laser welding of dimensional products.

The installation is equipped with a 6 kW fiber laser produced by NTO "IRE-Polyus" to ensure the laser welding process. Machine control is carried out using a specialized control panel that provides the entire cycle of machine control.

Compared to arc welding, laser welding has several advantages:

- deep penetration with the effect of "dagger penetration",

- allows you to process products with a thickness of up to 10 mm without cutting edges for welding;

- welding is carried out in one pass;

- welding is carried out with minimal geometric deformations and stresses due to minimal thermal impact;

- increased welding speed (from 1 to 10 m / min).

Laser welding provides high productivity, process efficiency and technology competitiveness compared to other welding methods. Laser welding technology is universal and suitable for welding a wide range of materials and thicknesses.

The installation uses a highly efficient ytterbium fiber laser with a power of up to 6 kW, laser efficiency of more than 40%. Laser radiation is transmitted to the welding head via a separate flexible transport fiber cable up to 15 m long.

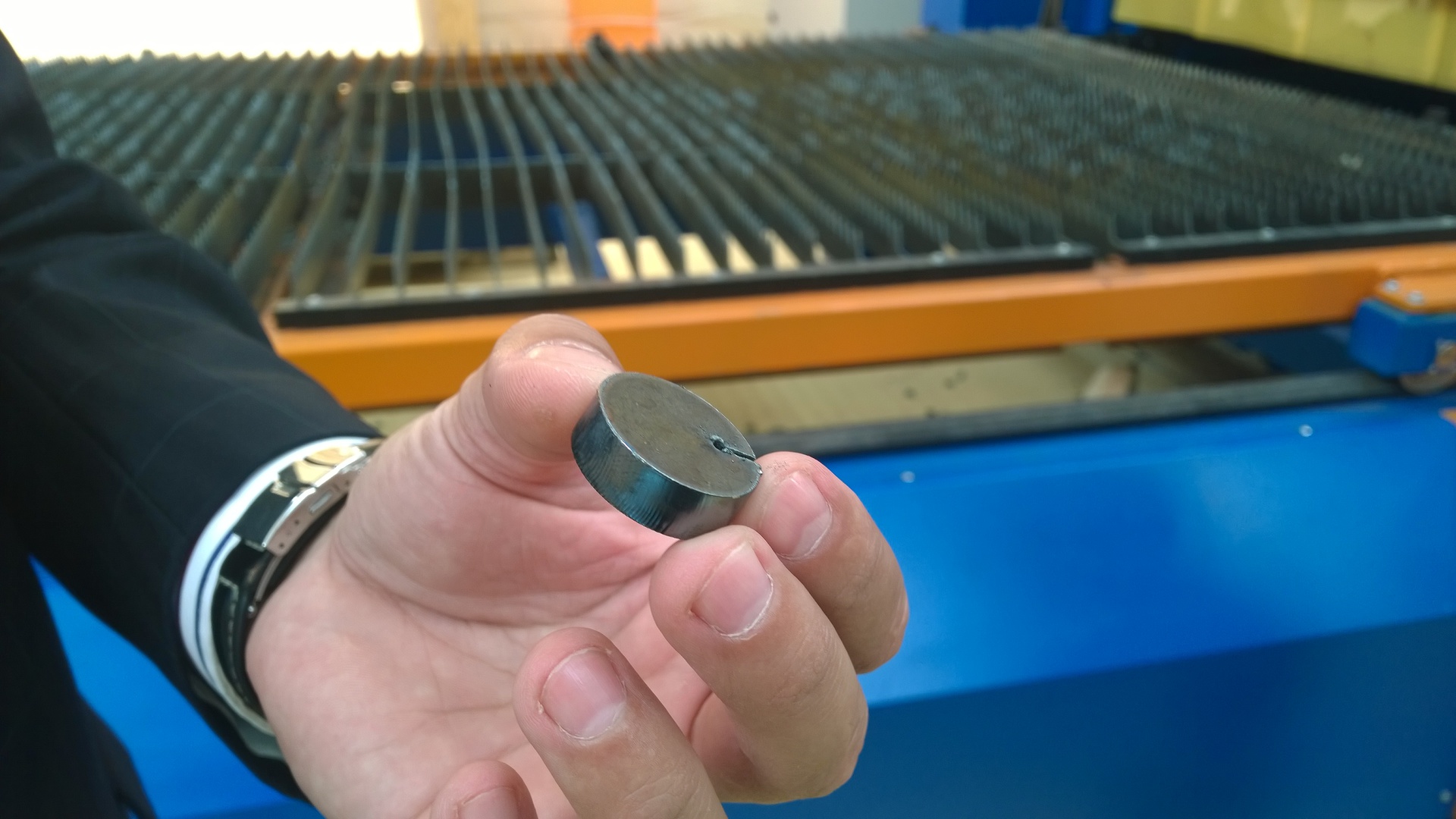

And the last, most “spectacular” exhibit - laser cutting of mounting holes in the finished product - a module for laser processing of complex parts (5D) based on a fiber laser.

Someone called it “Autobot”, this module impressed us the most! The Bumblebee's younger brother can not only turn everything around into a flame, and then into dust, but also cuts voluminous parts of complex geometric shapes with a vertical axis of rotation (axis of geometric symmetry or axis of assembly of the part). The maximum overall dimensions of the part are 2000 mm in diameter and 550 mm in height.

This module is equipped with a 5 kW fiber laser, which allows laser cutting with high quality edges of a wide range of materials and thicknesses.

The automatic cutting module comes with a protective cab. To monitor the laser cutting process, protective transparent windows from laser radiation are installed.

And all these treasures lie "at hand" for Tatarstan engineers and businessmen! The largest enterprises of the Republic of Tatarstan are already using it, and Navigator Campus plans to cooperate with KAI Laser in the implementation of its upcoming large projects.

This is how the entrance group, in which the deputy director of KAI-Laser, Oleg Vladimirovich Zinin, met our delegation. He spoke about existing clients and orders (mainly large industrial and oil enterprises of the Republic of Tatarstan), as well as about the possibilities of technology and the future of lasers in Russia. “What will give us the development of this sphere?” We asked. We were assured that the development of the complex would allow small and medium-sized enterprises to enter the production cycle of large enterprises due to outsourcing work on the production of components and, as a result, the overall economy will increase. Is it so we decided to see for ourselves.

So, let's start with the improvement of this temple of Athena - the goddess of knowledge, arts and crafts. In the center there are 11 complexes based on fiber lasers of various powers, using all types of laser processing of materials - tick and hybrid welding, cutting, surfacing, marking, cleaning, milling of the material. Laser power - from 20 W to 30 kW.

The list and characteristics of the main equipment in the center

full equipment specifications are available here:

439.5 million rubles were spent on equipping the center - 60% of the federal budget, 40% of the budget of the Republic of Tatarstan.

KAI Laser engineers set ambitious plans related to the technological development of the engineering industry of Tatarstan and Russia.

Armed with common sense, versatility and uniqueness of fiber laser technologies, the best minds of Kazan have found them in heavy industry. The use of laser technology will increase efficiency and reduce production costs. Research at the new center will focus on the application of laser technology for the processing of composite materials and the development of laser additive technologies.

For example, the rector of “KNITU-KAI” hinted in one of the interviews that it is planned to develop technologies for processing composite materials and additive technologies in the center - creating parts by building metal from powders (a unique thing for our country!). Laser cutting is characterized by the absence of mechanical impact on the processed material. A powerful laser beam focused at a focal point of 0.1 mm in size of several kW allows you to cut almost any material, regardless of their thermophysical properties.

Laser radiation, due to its versatility, has gained great demand in such types of technological processes as: cutting, welding, heat treatment, alloying, hole piercing, turning, milling. Laser equipment is not limited to this range of work and every day is used in new areas, replacing obsolete equipment. Laser bread slicers are just around the corner, comrades!

The laser today is a proven work tool. The demand for laser technologies is constantly growing mainly because they give results significantly higher compared to traditional methods of processing materials.

So, with what kind of equipment we managed to get acquainted on an excursion:

Laser cutting of blanks: module for laser cutting of pipes based on fiber laser

The module for automatic laser cutting is designed for cutting pipes. The system allows curly cutting of pipes with diameters up to 190 mm and lengths up to 3000 mm.

This machine is equipped with a 6 kW fiber laser with a transport fiber of 100 µm. The essence of technology: a laser beam is formed in a laser source (resonator) and is directed through a mirror or transport fiber to the cutting head of the machine, where it is focused using a lens to a point with a very small diameter and high power. A focused laser beam hits the sheet metal and melts it.

Thanks to these parameters, this module has several advantages over other types of metal cutting:

- clean cut,

- the ability to cut thin-walled pipes,

- high accuracy,

- lack of thermal deformations;

- lack of additional machining of the edges.

Thanks to these advantages, the cut parts can easily be assembled without additional intervention.

Next are automatic profile laser cutting machines.

They allow you to perform curly cutting of any profile with a thickness of up to 200 mm and a length of up to 6000 m. During the cutting process, under the influence of a laser beam, the material melts, ignites, evaporates and is blown out by a gas stream. A cutting width of less than 1 mm allows, with minimal thermal impact on the base material, cutting workpieces with high accuracy.

Next, we got acquainted with the equipment for laser welding, it is performed by the module for laser processing of dimensional products based on fiber laser.

This is manual tick-borne welding with a hydraulic drive.

And this is a robotic tick-welding complex.

The LaserWeld 6R60-L6000 installation is intended for automatic laser welding of dimensional products.

The installation is equipped with a 6 kW fiber laser produced by NTO "IRE-Polyus" to ensure the laser welding process. Machine control is carried out using a specialized control panel that provides the entire cycle of machine control.

Compared to arc welding, laser welding has several advantages:

- deep penetration with the effect of "dagger penetration",

- allows you to process products with a thickness of up to 10 mm without cutting edges for welding;

- welding is carried out in one pass;

- welding is carried out with minimal geometric deformations and stresses due to minimal thermal impact;

- increased welding speed (from 1 to 10 m / min).

Laser welding provides high productivity, process efficiency and technology competitiveness compared to other welding methods. Laser welding technology is universal and suitable for welding a wide range of materials and thicknesses.

The installation uses a highly efficient ytterbium fiber laser with a power of up to 6 kW, laser efficiency of more than 40%. Laser radiation is transmitted to the welding head via a separate flexible transport fiber cable up to 15 m long.

And the last, most “spectacular” exhibit - laser cutting of mounting holes in the finished product - a module for laser processing of complex parts (5D) based on a fiber laser.

Someone called it “Autobot”, this module impressed us the most! The Bumblebee's younger brother can not only turn everything around into a flame, and then into dust, but also cuts voluminous parts of complex geometric shapes with a vertical axis of rotation (axis of geometric symmetry or axis of assembly of the part). The maximum overall dimensions of the part are 2000 mm in diameter and 550 mm in height.

This module is equipped with a 5 kW fiber laser, which allows laser cutting with high quality edges of a wide range of materials and thicknesses.

The automatic cutting module comes with a protective cab. To monitor the laser cutting process, protective transparent windows from laser radiation are installed.

And all these treasures lie "at hand" for Tatarstan engineers and businessmen! The largest enterprises of the Republic of Tatarstan are already using it, and Navigator Campus plans to cooperate with KAI Laser in the implementation of its upcoming large projects.