Fancy DIY materials. Dentistry + electronics =? Part 1

There is nothing more beautiful than sitting in a laboratory and stroking a thick bald rat in search of inspiration.

So, today we will have a slightly unusual DIY post. We will not do anything with our hands. Arduino and 30 line firmware on Brainfuck will not be either. We will try to look at familiar things from an unusual angle.

We are all accustomed to classical materials for this area, such as textolite, tin solder and other joys of lovers tocut with a jigsawpoison boards. In this article, we will try to find interesting alternatives to the usual technological processes in a somewhat unusual field - dentistry. Dental technicians and dentists work with a whole bunch of polymers, composites and much more. I will not give specific recipes for use, but simply give a general direction for independent experiments.

In today's program:

Materials

In the next part:

Materials

Equipment and tools

Disclaimer: I’m not promoting anyone’s interests and all of the links to dental material stores that I selected were selected by the Korean random for illustrative purposes.

To begin, let's decide what materials we are interested in and how to get them.

Firstly, the materials vary greatly in price. There are 80 rubles a bucket of some rubbish like Unifas-cement. There are 7000 for 2 ml of a very tricky adhesive. We are interested in low-budget options, although, perhaps, someone will find use in more expensive things.

Secondly, points of sale are not at all obvious. Here the same principle works as in the accessories for professional furniture makers, specialized pet food stores for possums and the like. Such stores do not spend money on a beautiful display case and usually nest in city hives among hundreds of Vector-Plus LLCs, because of cheap rent. A typical example in Krasnodar:

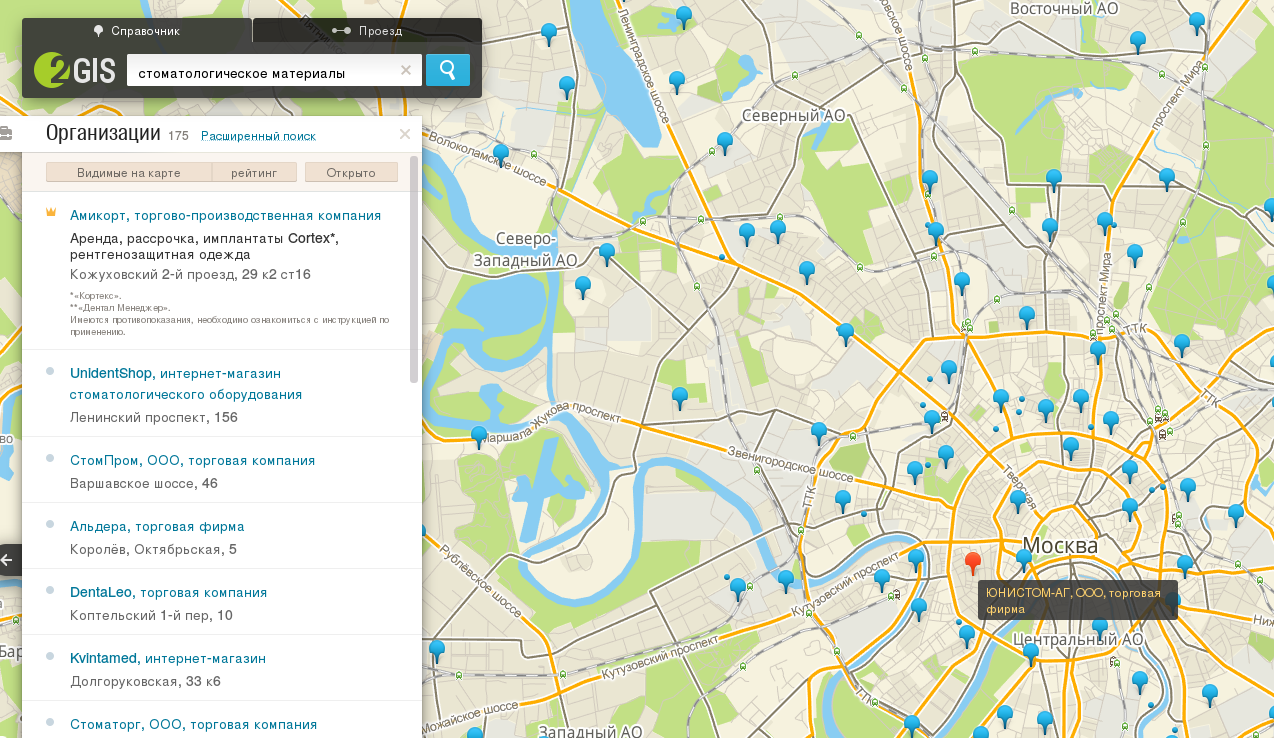

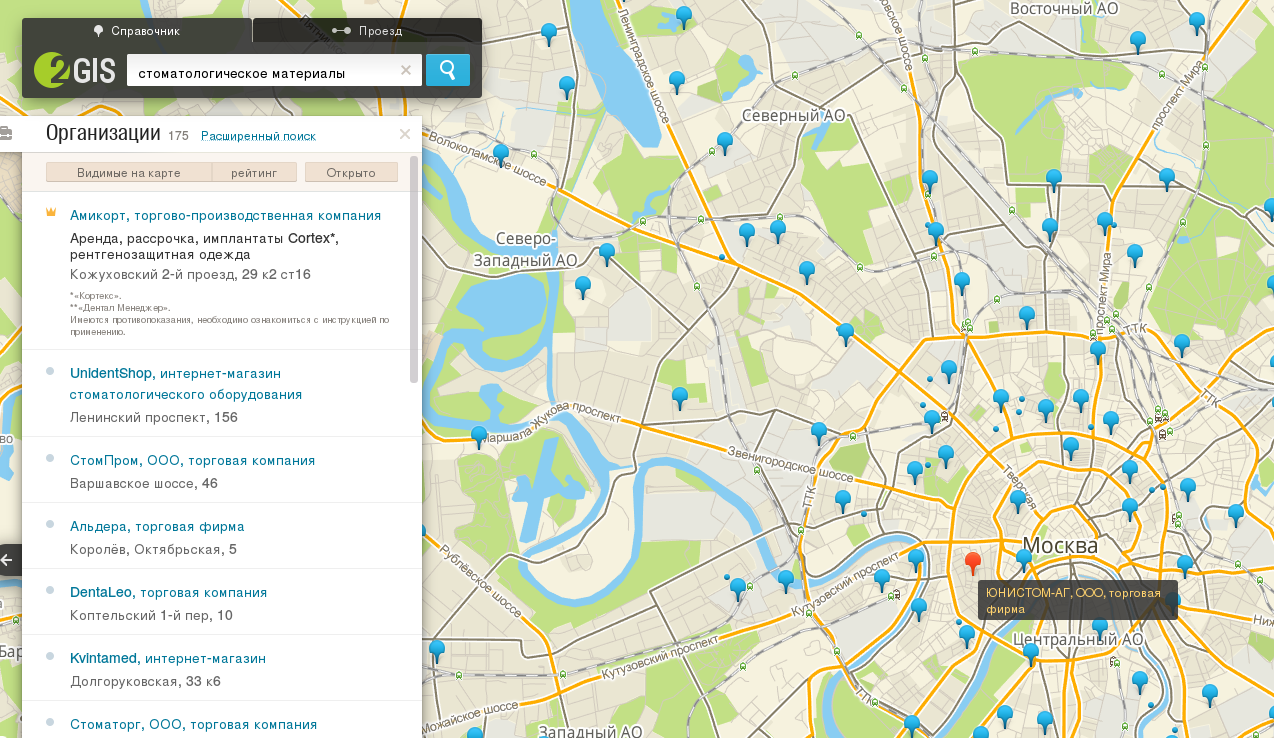

The question immediately arises, but how to find these disguised shelters with cunning materials? The answer is pretty obvious. 2GIS is our best assistant in this situation. I take this opportunity to convey many thanks to the employees of pilikoff , jetfreeman and everyone else. Dentists themselves do not have time to follow the endless movements of these stores. Take, for example, Moscow, as one of the most relevant for the audience. The correct variant of the request is “dental materials”.

It is especially convenient to do this directly from the phone, combining the search with a call to the subject of the presence of interesting positions. Now we can go directly to the materials.

Dentists very often take impressions. Once this was done with gypsum, which is fragile and removing it with a whole piece from the oral cavity is impossible in principle. Then I had to glue the impression and several pieces. Moreover, the impression was also heated during crystallization ... Also, a pleasant bonus was the ability to leave part of the teeth directly in the impression. Today, everything has changed and the main working materials for the doctor are alginate masses and C- and A-silicones.

Alginates are good for their very low price. For example, Hydrogum Soft costs about 200 rubles per half-kilogram package. Sold in the form of colored powder and mixed in distilled (preferably) water.

Very important! Always read the instructions carefully. The manufacturer is not in vain gives the exact proportions by weight and volume. It is also very important to maintain time standards for kneading and imprinting. More expensive alginates are color-coded for polymerization and kneading quality. They change color depending on their state, for example, from purple to yellow. Alginates have one big minus - they give wild shrinkage already in 2-3 hours after creating a cast. In a day you will not recognize the model. Therefore, it is necessary to cast immediately.

Dry alginic acid powder is potentially harmful to health. Avoid spraying or inhaling.

To work with alginates, you will need several things:

Rubber flask

Costs no more than 50 rubles. It is also very convenient to knead gypsum.

Putty knife.

It can also be metal.

Optionally - scales or measuring spoon.

Not all measuring containers are placed in all alginate masses, but I strongly advise against mixing “by eye”.

Work process:

Measure out the right amount of powder and pour it into the flask. Then add the required amount of coldwater. Start stirring with a spatula. When the mass becomes homogeneous, it can be applied to the surface. In the case of dentistry, this is an impression spoon for the oral cavity, in ours - you will need to come up with something depending on the goals. Finally, a little twitchy video showing a semi-automatic kneading system.

Much more interesting materials, but also cost significantly more. However, among them there are some low-budget representatives. A-silicones give less shrinkage and higher accuracy of the reproduction of the relief. C-silicones are simpler, but also cheaper. Consider one of these budget representatives with a price of around 1300 rubles - Zetaplus from Zhermack.

As you can see in the figure, the basic set consists of three components. This is the base material in a large bucket (often called Putty), fluid silicone in a tube labeled Oranwash L (also often called soft or light), and a tube with a catalyst. The basic principle of working with silicones is to create two-component impressions. The first layer of the print is removed by a viscous base mass, then the second is a corrective fluid mass, which gives a particularly accurate representation of the details. Consider in practice:

First, mixing the base mass with the right amount of catalyst. We place our clay-like mass in the impression spoon or its analogue and press it to the removed part.

We try on an impression of why we are taking it, most likely it will not sit down, since there are undercuts, we cut off what prevents the impression from sitting down. This space will be filled with liquid silicone.

Pour the liquid silicone mixed with the catalyst into the processed mold and again press it to the part, carefully squeezing the mass. Important! This blue rubbish is not categorically washed. Liquid silicone impregnates the fabric and then solidifies forever with a hydrophobic stain.

We get an accurate impression of the model being shot.

Of other silicones, you can also pay attention to Speedex. It is also inexpensive. In addition to the direct purpose for prints, silicones can be used as sealants, as well as to create any temporary structures. I often make sealing-holding stands for laboratory equipment out of it. Shrinkage is not as severe as that of alginates. It is believed that the cast can be cast within 24 hours while maintaining accuracy. For various kinds of temporary structures, the life span is almost unlimited.

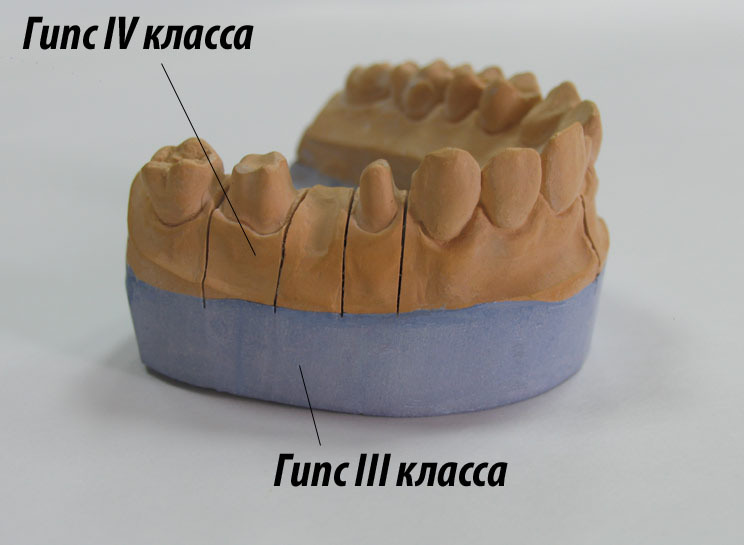

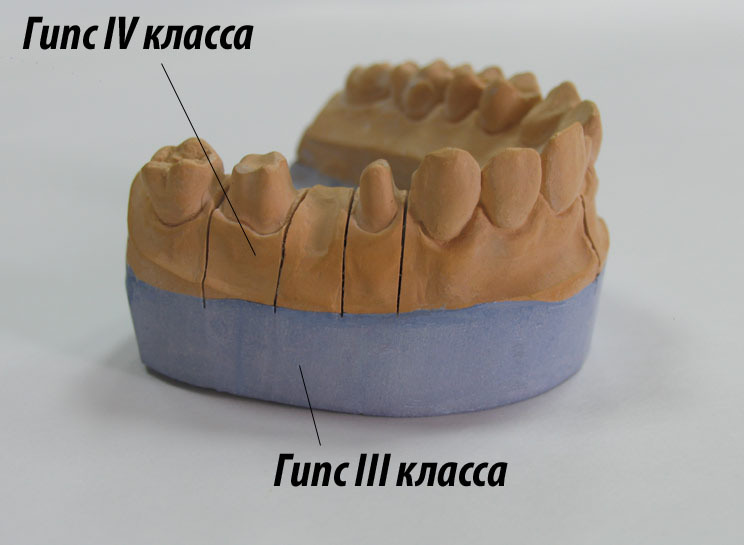

Super gypsum is distinguished by ordinary building alabaster with high purity, uniform particle size and tricky additives that can reduce the expansion coefficient. The strength of the final product is also higher. Prices for it from 500 rubles. Plaster material is very moody and the creation of high-quality models from it requires a fair amount of training.

Classification:

Grade I - a rare muck and is not used by normal laboratories.

Grade II - in dentistry it is mainly used for plastering models into an occluder or articulator, and plastering ditches for cooking. Strength is low.

Grade III is one of the most popular in dental laboratories. Almost all models of jaws pour out of it for various works, with the exception of collapsible models. This dental gypsum is strong enough to not break when removing the model from the cast. Universal plaster, a kind of middle ground between price, quality and durability.

Grade IV - heavy-duty gypsum, which is almost impossible to process without the use of high-speed tools. Use it for casting the working part of collapsible models. To use it for other purposes is quite expensive, since it is very expensive.

V class - incredibly durable and virtually non-shrinkable gypsum. The strength and other properties of gypsum are achieved through the use of various synthetic components in the manufacturing process. The price is absolutely inhumane.

To obtain a gypsum model, we need:

Remember that in normal dental laboratories there are traps of gypsum particles in the drains. In the apartment, you run the risk of clogging the sewer if you drain the spent mass directly into the sink.

Gypsum is mixed strictly according to the proportions specified by the manufacturer. It is best to weigh, then the result will be clean and predictable. First, gypsum is poured, then the right amount of water is poured. Knead quickly, rubbing the lumps on the walls of the flask until a perfectly homogeneous mass is obtained. Vacuum mixers at home will be too expensive, although they give an ideal result. Pour the resulting creamy mass onto the print, trying to prevent the presence of air bubbles. The use of a vibrating table for accurate spilling of all parts will be correct. If it is not possible to act by vibration, tap the impression on the edge of the table during the casting process. Each bubble will give a cavity on the final model.

Possible applications are prototyping, creating copies of prototypes, preparing molds for future molding from plastic, metal and other materials.

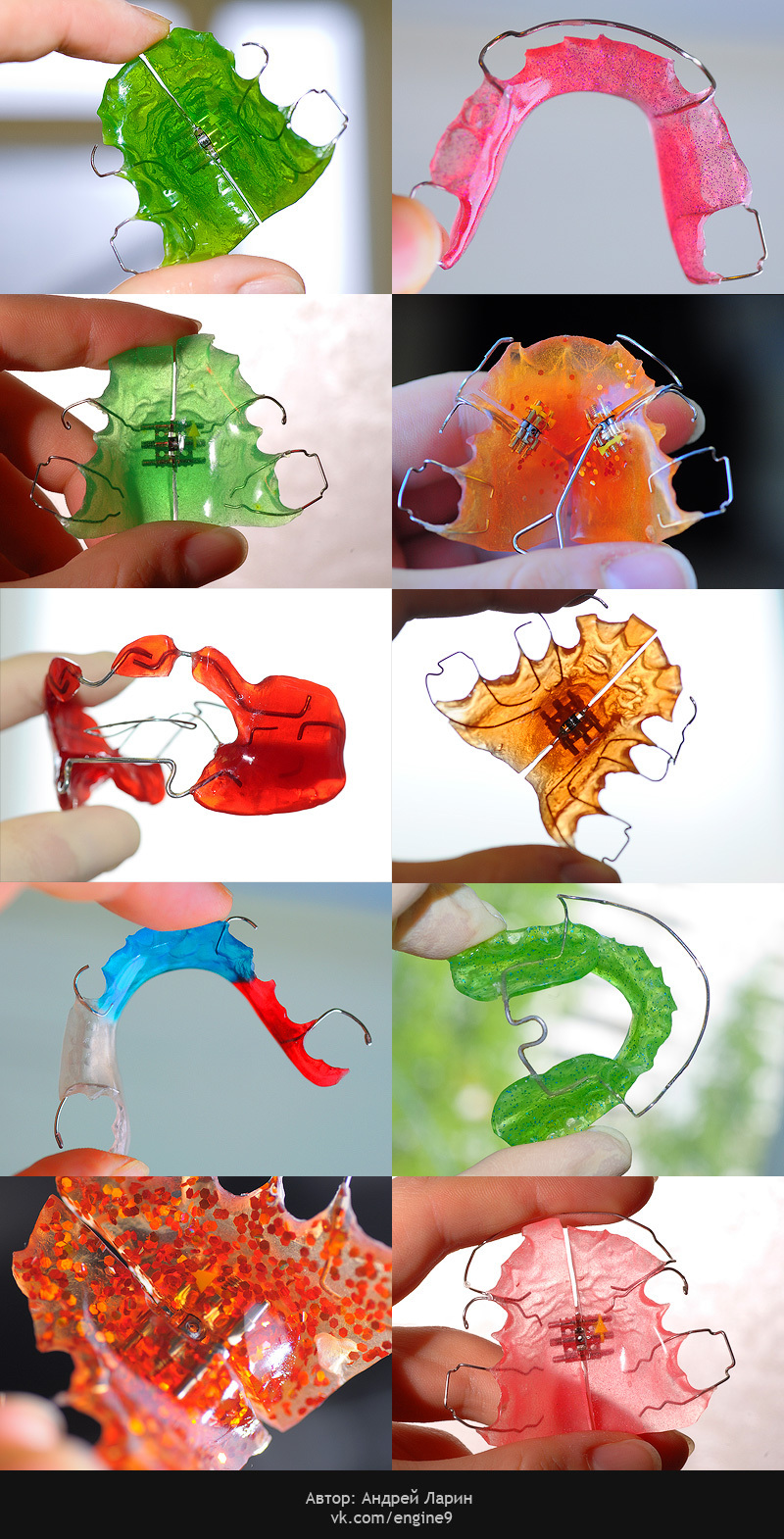

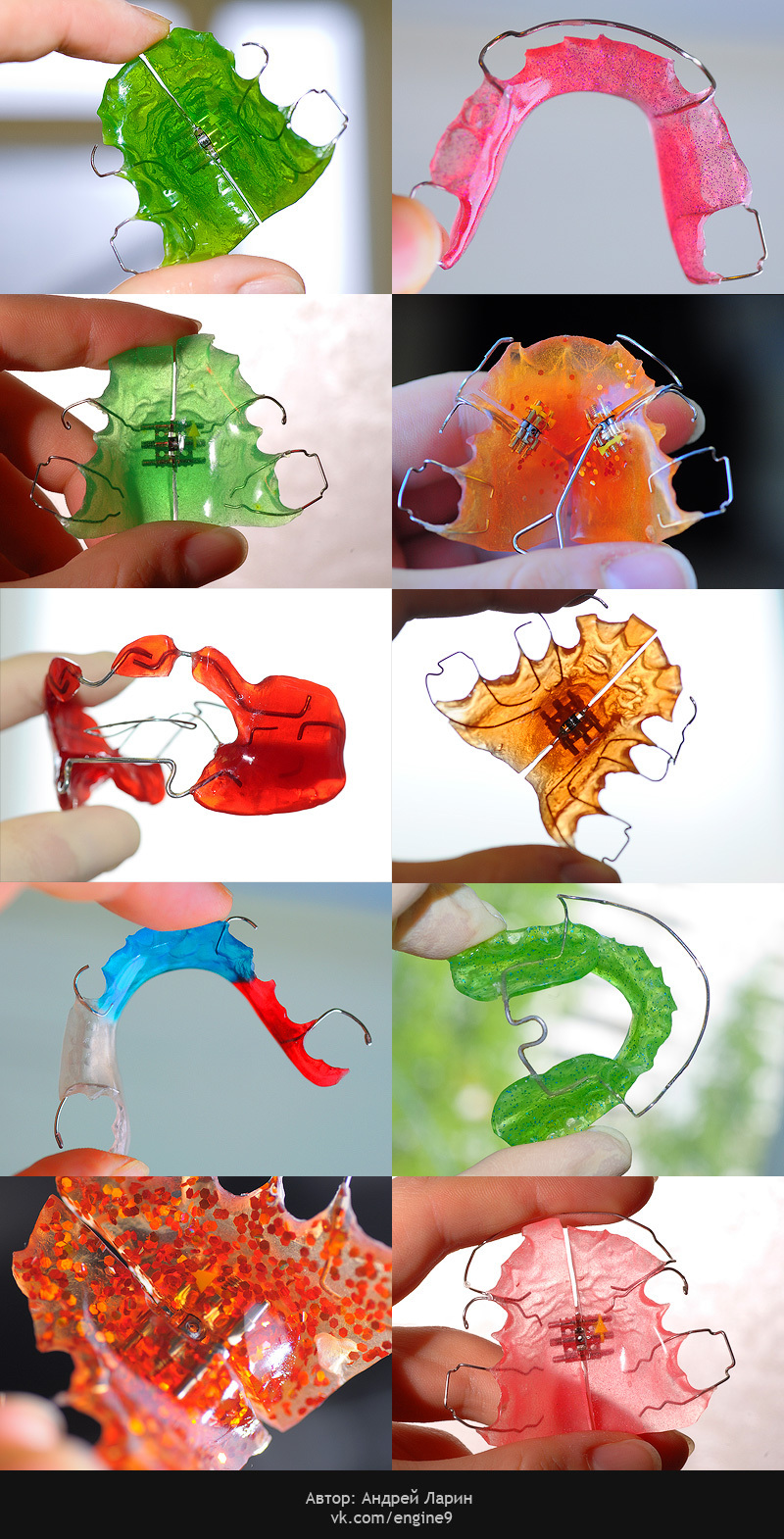

Very tasty group of materials. They can cure at home at room temperature. Color options - from mysteriously pink to transparent. For our tasks, plastics produced in the CIS are best suited. They are significantly cheaper. For example, Redont Kolir is a self-hardening plastic for the manufacture of orthodontic appliances (150 g of powder, 100 g of liquid, 3x15 g of dyes red, blue, yellow). The price is about 400 rubles.

Representatives: Protacryl-M, Redont-01, Redont-02, Redont-03, Stadont, Carboplast, Acryloxide, Chromazit, Futura Zelier, Probase Cold ”,“ CP-3/60 Quinn ”,“ Spectra Trey ”,“ SR-Ivolen ”,“ Protemp ”.

The rules for working with each plastic are very different - you need to consult the manufacturer's recommendations. Remember safety precautions. Almost all monomers are poisonous, often have evaporating fractions that are unhealthy.

Working methods:

Polymerization occurs upon the initiating effect of the redox system, the initiator-activator system. The polymerization rate depends on the amount and nature of the activator and initiator, the ambient temperature, the dispersion of the powder and the nature of the monomer. At temperatures above 30 ° C, rapid polymerization occurs, and at negative temperatures it stops. General technology: plastic dough is prepared in glass or porcelain dishes. First, the monomer is poured, and then the powder is poured using measurers for this. The mixture is thoroughly stirred and the vessel is tightly closed. In this state, the plastic dough should be aged 30 to 40 minutes. Ripened plastic dough (stage 3) is used for packaging.

The polymerization process of the polymer-monomer mixture of cold curing is exothermic. After mixing the original components, the mass swells. Then comes the induction period, in which the mass retains its plasticity, and its temperature does not rise yet. Subsequently, the polymerization period begins, and at this time the temperature rises rapidly to its maximum value. After the polymerization period, the temperature drops due to the end of the reaction and the transfer of heat to the environment. The resulting polymer chains are shorter than during thermal polymerization. Plastic is considered ripe if a significant portion of the monomer is absorbed by the polymer particles. In the phase of stretching threads, plastic is packaged.

At first I wanted to make one article, but then I realized that the volume is too large for this. Therefore there will be a series. Unfortunately, I am now wildly limited in time due to intensive work in the laboratory and cannot promise that I will publish the article very often. If you have questions, I will answer with pleasure.

UPD

As it turned out on Habré also there are my colleagues-dentists. In particular, Budda40rightly reproached me for several factual errors, for which many thanks to him. In particular, I confused in a hurry the concept of a mold / impression and a model. The model is a positive display of the subject, and the cast is negative. Actually, you need to sleep more. In my defense, I can say that I have not been practicing for a long time. Now my main area of activity is genetic and tissue engineering. I also give his complement on plastics:

UPD2

Plastics can be very diverse. Some are extremely beautiful, especially those designed for children. In the photo of the work of the engine9 haraler :

So, today we will have a slightly unusual DIY post. We will not do anything with our hands. Arduino and 30 line firmware on Brainfuck will not be either. We will try to look at familiar things from an unusual angle.

We are all accustomed to classical materials for this area, such as textolite, tin solder and other joys of lovers to

In today's program:

Materials

- Silicones. Like silicon, only more interesting.

- Super gypsum. Gypsum of all gypsum.

- Plastics. Great pink color.

In the next part:

Materials

- Photocomposites. 3D printer myself.

- Phosphoric acid for pickling

Equipment and tools

- Diamond and carbide burs

- Portable micromotors. Replacing Dremel

- Reverse tweezers, probes and other trifles

Disclaimer: I’m not promoting anyone’s interests and all of the links to dental material stores that I selected were selected by the Korean random for illustrative purposes.

Our goal

To begin, let's decide what materials we are interested in and how to get them.

Firstly, the materials vary greatly in price. There are 80 rubles a bucket of some rubbish like Unifas-cement. There are 7000 for 2 ml of a very tricky adhesive. We are interested in low-budget options, although, perhaps, someone will find use in more expensive things.

Secondly, points of sale are not at all obvious. Here the same principle works as in the accessories for professional furniture makers, specialized pet food stores for possums and the like. Such stores do not spend money on a beautiful display case and usually nest in city hives among hundreds of Vector-Plus LLCs, because of cheap rent. A typical example in Krasnodar:

How to find a store

The question immediately arises, but how to find these disguised shelters with cunning materials? The answer is pretty obvious. 2GIS is our best assistant in this situation. I take this opportunity to convey many thanks to the employees of pilikoff , jetfreeman and everyone else. Dentists themselves do not have time to follow the endless movements of these stores. Take, for example, Moscow, as one of the most relevant for the audience. The correct variant of the request is “dental materials”.

It is especially convenient to do this directly from the phone, combining the search with a call to the subject of the presence of interesting positions. Now we can go directly to the materials.

Silicone and alginate masses

Dentists very often take impressions. Once this was done with gypsum, which is fragile and removing it with a whole piece from the oral cavity is impossible in principle. Then I had to glue the impression and several pieces. Moreover, the impression was also heated during crystallization ... Also, a pleasant bonus was the ability to leave part of the teeth directly in the impression. Today, everything has changed and the main working materials for the doctor are alginate masses and C- and A-silicones.

Alginates

Alginates are good for their very low price. For example, Hydrogum Soft costs about 200 rubles per half-kilogram package. Sold in the form of colored powder and mixed in distilled (preferably) water.

Very important! Always read the instructions carefully. The manufacturer is not in vain gives the exact proportions by weight and volume. It is also very important to maintain time standards for kneading and imprinting. More expensive alginates are color-coded for polymerization and kneading quality. They change color depending on their state, for example, from purple to yellow. Alginates have one big minus - they give wild shrinkage already in 2-3 hours after creating a cast. In a day you will not recognize the model. Therefore, it is necessary to cast immediately.

Dry alginic acid powder is potentially harmful to health. Avoid spraying or inhaling.

To work with alginates, you will need several things:

Rubber flask

Costs no more than 50 rubles. It is also very convenient to knead gypsum.

Putty knife.

It can also be metal.

Optionally - scales or measuring spoon.

Not all measuring containers are placed in all alginate masses, but I strongly advise against mixing “by eye”.

Work process:

Measure out the right amount of powder and pour it into the flask. Then add the required amount of coldwater. Start stirring with a spatula. When the mass becomes homogeneous, it can be applied to the surface. In the case of dentistry, this is an impression spoon for the oral cavity, in ours - you will need to come up with something depending on the goals. Finally, a little twitchy video showing a semi-automatic kneading system.

Silicones

Much more interesting materials, but also cost significantly more. However, among them there are some low-budget representatives. A-silicones give less shrinkage and higher accuracy of the reproduction of the relief. C-silicones are simpler, but also cheaper. Consider one of these budget representatives with a price of around 1300 rubles - Zetaplus from Zhermack.

As you can see in the figure, the basic set consists of three components. This is the base material in a large bucket (often called Putty), fluid silicone in a tube labeled Oranwash L (also often called soft or light), and a tube with a catalyst. The basic principle of working with silicones is to create two-component impressions. The first layer of the print is removed by a viscous base mass, then the second is a corrective fluid mass, which gives a particularly accurate representation of the details. Consider in practice:

First, mixing the base mass with the right amount of catalyst. We place our clay-like mass in the impression spoon or its analogue and press it to the removed part.

We try on an impression of why we are taking it, most likely it will not sit down, since there are undercuts, we cut off what prevents the impression from sitting down. This space will be filled with liquid silicone.

Pour the liquid silicone mixed with the catalyst into the processed mold and again press it to the part, carefully squeezing the mass. Important! This blue rubbish is not categorically washed. Liquid silicone impregnates the fabric and then solidifies forever with a hydrophobic stain.

We get an accurate impression of the model being shot.

Of other silicones, you can also pay attention to Speedex. It is also inexpensive. In addition to the direct purpose for prints, silicones can be used as sealants, as well as to create any temporary structures. I often make sealing-holding stands for laboratory equipment out of it. Shrinkage is not as severe as that of alginates. It is believed that the cast can be cast within 24 hours while maintaining accuracy. For various kinds of temporary structures, the life span is almost unlimited.

Super gypsum and casting models

Super gypsum is distinguished by ordinary building alabaster with high purity, uniform particle size and tricky additives that can reduce the expansion coefficient. The strength of the final product is also higher. Prices for it from 500 rubles. Plaster material is very moody and the creation of high-quality models from it requires a fair amount of training.

Classification:

Grade I - a rare muck and is not used by normal laboratories.

Grade II - in dentistry it is mainly used for plastering models into an occluder or articulator, and plastering ditches for cooking. Strength is low.

Grade III is one of the most popular in dental laboratories. Almost all models of jaws pour out of it for various works, with the exception of collapsible models. This dental gypsum is strong enough to not break when removing the model from the cast. Universal plaster, a kind of middle ground between price, quality and durability.

Grade IV - heavy-duty gypsum, which is almost impossible to process without the use of high-speed tools. Use it for casting the working part of collapsible models. To use it for other purposes is quite expensive, since it is very expensive.

V class - incredibly durable and virtually non-shrinkable gypsum. The strength and other properties of gypsum are achieved through the use of various synthetic components in the manufacturing process. The price is absolutely inhumane.

To obtain a gypsum model, we need:

- Rubber flask

- Super gypsum

- Metal spatula for kneading

Remember that in normal dental laboratories there are traps of gypsum particles in the drains. In the apartment, you run the risk of clogging the sewer if you drain the spent mass directly into the sink.

Gypsum is mixed strictly according to the proportions specified by the manufacturer. It is best to weigh, then the result will be clean and predictable. First, gypsum is poured, then the right amount of water is poured. Knead quickly, rubbing the lumps on the walls of the flask until a perfectly homogeneous mass is obtained. Vacuum mixers at home will be too expensive, although they give an ideal result. Pour the resulting creamy mass onto the print, trying to prevent the presence of air bubbles. The use of a vibrating table for accurate spilling of all parts will be correct. If it is not possible to act by vibration, tap the impression on the edge of the table during the casting process. Each bubble will give a cavity on the final model.

Possible applications are prototyping, creating copies of prototypes, preparing molds for future molding from plastic, metal and other materials.

Plastics cold polymerization

Very tasty group of materials. They can cure at home at room temperature. Color options - from mysteriously pink to transparent. For our tasks, plastics produced in the CIS are best suited. They are significantly cheaper. For example, Redont Kolir is a self-hardening plastic for the manufacture of orthodontic appliances (150 g of powder, 100 g of liquid, 3x15 g of dyes red, blue, yellow). The price is about 400 rubles.

Representatives: Protacryl-M, Redont-01, Redont-02, Redont-03, Stadont, Carboplast, Acryloxide, Chromazit, Futura Zelier, Probase Cold ”,“ CP-3/60 Quinn ”,“ Spectra Trey ”,“ SR-Ivolen ”,“ Protemp ”.

The rules for working with each plastic are very different - you need to consult the manufacturer's recommendations. Remember safety precautions. Almost all monomers are poisonous, often have evaporating fractions that are unhealthy.

Working methods:

Polymerization occurs upon the initiating effect of the redox system, the initiator-activator system. The polymerization rate depends on the amount and nature of the activator and initiator, the ambient temperature, the dispersion of the powder and the nature of the monomer. At temperatures above 30 ° C, rapid polymerization occurs, and at negative temperatures it stops. General technology: plastic dough is prepared in glass or porcelain dishes. First, the monomer is poured, and then the powder is poured using measurers for this. The mixture is thoroughly stirred and the vessel is tightly closed. In this state, the plastic dough should be aged 30 to 40 minutes. Ripened plastic dough (stage 3) is used for packaging.

The polymerization process of the polymer-monomer mixture of cold curing is exothermic. After mixing the original components, the mass swells. Then comes the induction period, in which the mass retains its plasticity, and its temperature does not rise yet. Subsequently, the polymerization period begins, and at this time the temperature rises rapidly to its maximum value. After the polymerization period, the temperature drops due to the end of the reaction and the transfer of heat to the environment. The resulting polymer chains are shorter than during thermal polymerization. Plastic is considered ripe if a significant portion of the monomer is absorbed by the polymer particles. In the phase of stretching threads, plastic is packaged.

Instead of an epilogue

At first I wanted to make one article, but then I realized that the volume is too large for this. Therefore there will be a series. Unfortunately, I am now wildly limited in time due to intensive work in the laboratory and cannot promise that I will publish the article very often. If you have questions, I will answer with pleasure.

UPD

As it turned out on Habré also there are my colleagues-dentists. In particular, Budda40rightly reproached me for several factual errors, for which many thanks to him. In particular, I confused in a hurry the concept of a mold / impression and a model. The model is a positive display of the subject, and the cast is negative. Actually, you need to sleep more. In my defense, I can say that I have not been practicing for a long time. Now my main area of activity is genetic and tissue engineering. I also give his complement on plastics:

I want to add the cold polymerization plastics in this section, since now trading in this class of materials has become quite hemorrhoidal since last year, since the polymerization fluid contains methamphetamine precursors - methyl methacrylates. Now it is sold upon presentation of a passport, and storage requires a safe and documentation, in general, you should not buy them, although plastics without precursors have recently appeared, for example, Rebase II from Tokuyama Dental.

UPD2

Plastics can be very diverse. Some are extremely beautiful, especially those designed for children. In the photo of the work of the engine9 haraler :

Only registered users can participate in the survey. Please come in.

Should the series continue?

- 92.8% Yes, the topic is interesting 2101

- 7.1% No, except rosin and tin solder nothing is needed! 162