How not to miss the budget for the mass production of buildings: 20 examples from the practice of the Bureau of Engineering Design

The publication of only two articles on how to self-assess the cost of production casing for the device ( first and second ) raised the simple wave of a series of inquiries "But how much will it cost our body with a circulation 5-100-1000- ∞ pieces?"

As it turns out in the course of communication, the majority of the requestor is mistaken in estimating the cost of production on the order . I'm not kidding.

However, I could not write a simple instruction (or even simpler to make a calculator) on estimating these costs: for this you will have to take into account too many parameters. Therefore, I will simply show with examples the circulation and price. Yes, you can not accurately assess your project, but it will be clear how much money you need - 100,000 rubles, a million or more.

And if you write in the comments exactly what interests you, I will try to answer with examples: I have a lot of them (from) a great number - from the cases of miniature devices to the cases of machines the size of a house.

Cost of production of small, small and large parts

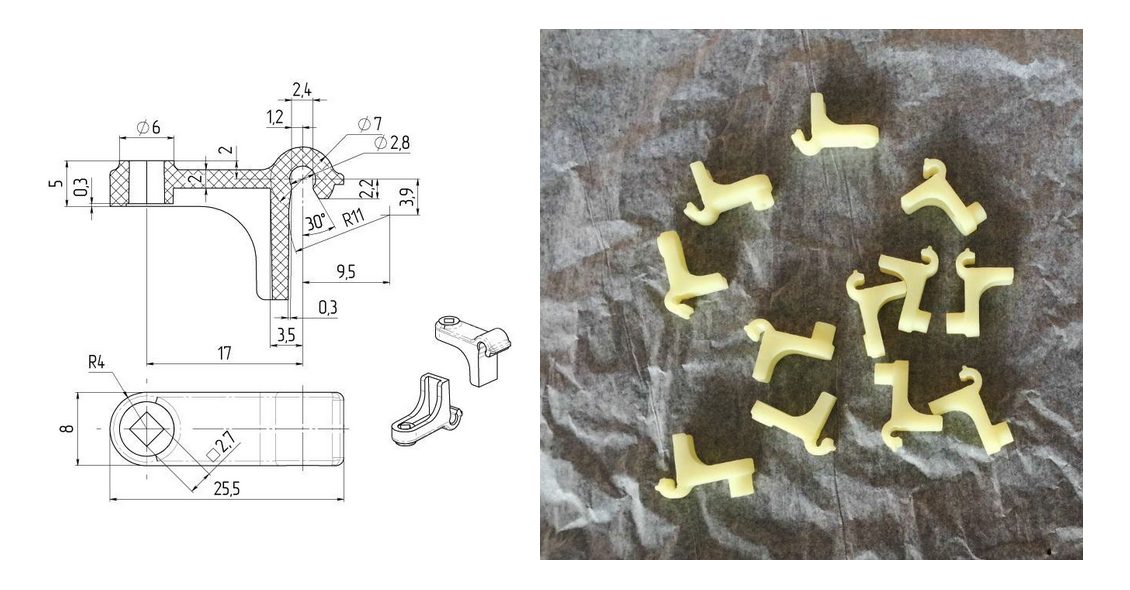

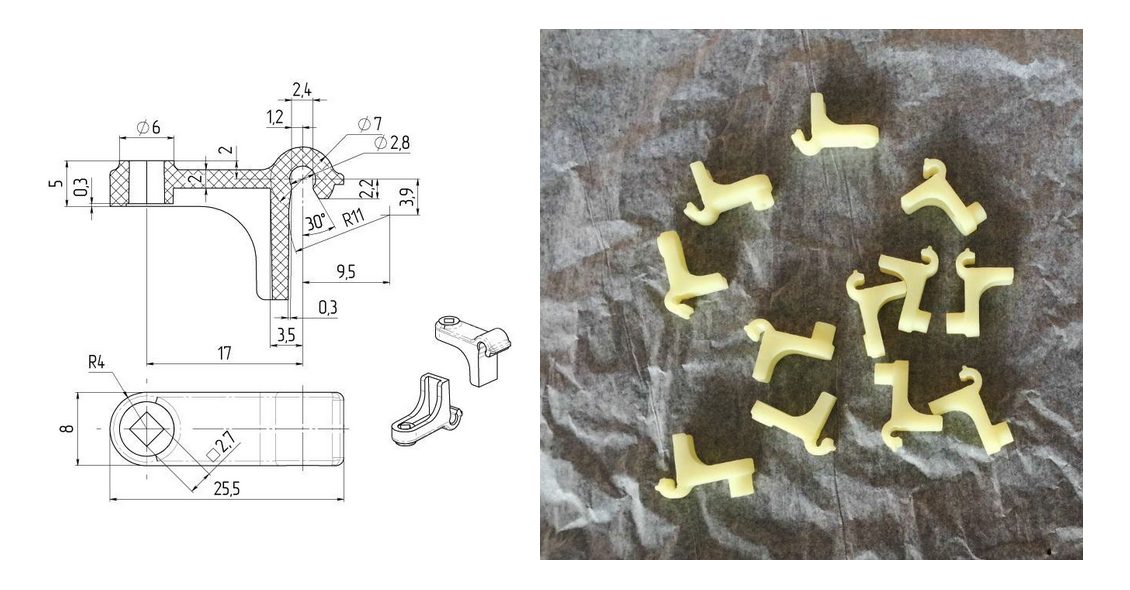

Detail dimensions 25x20 mm

One fastener made of ABS plastic.

The cost of the prototype is $ 60.

Forms cost $ 1,500 (eight-person form).

Resource forms - 300 thousand cycles.

The cost of one part is $ 0.08 with a circulation of 8,000 pieces.

Detail size 150x100 mm

One body part made of ABS plastic.

The cost of the prototype is $ 200.

The cost of the mold is $ 4,300.

Resource forms - 200 thousand cycles

The cost of one part - $ 0.5 with a draw of 1,000 pieces.

Detail with dimensions of 170x170 mm

One body part made of ABS plastic.

The cost of the prototype is $ 230.

Mold cost - $ 5.000

Mold resource - 200 thousand cycles.

The cost of one part is $ 1.1 for a drawing of 10,000 pieces.

Detail dimensions 530x120 mm

Material - ABS-plastic.

The cost of the prototype is $ 350.

The cost of the mold is $ 12,000.

Mold resource - 300 thousand cycles.

The cost of one part is $ 1.4 with a circulation of 10,000 pieces.

Cost of production of small, desktop, wall-mounted, tall and large buildings

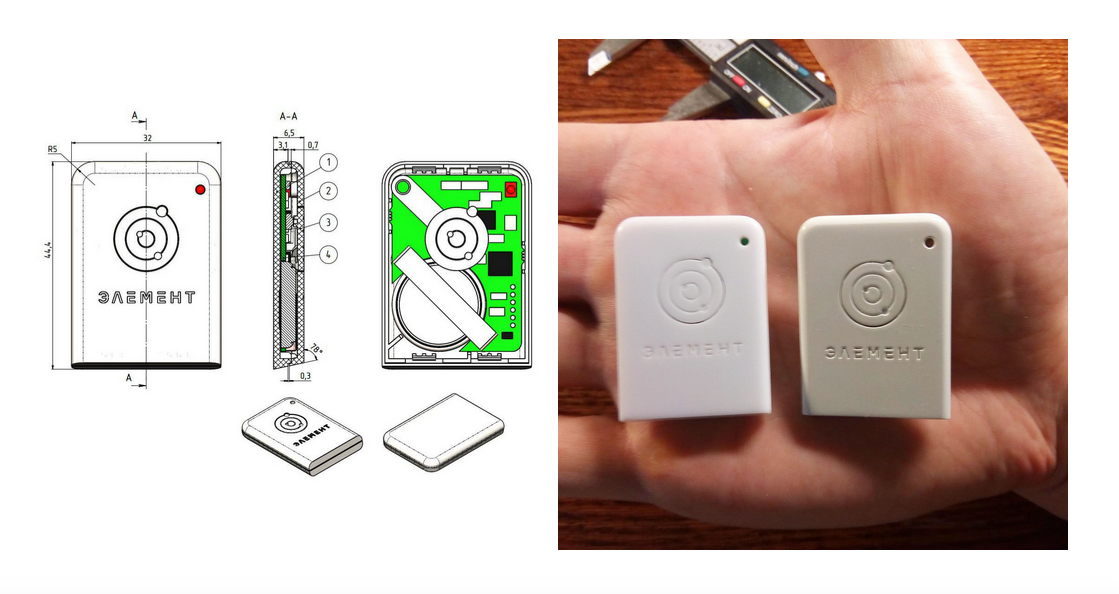

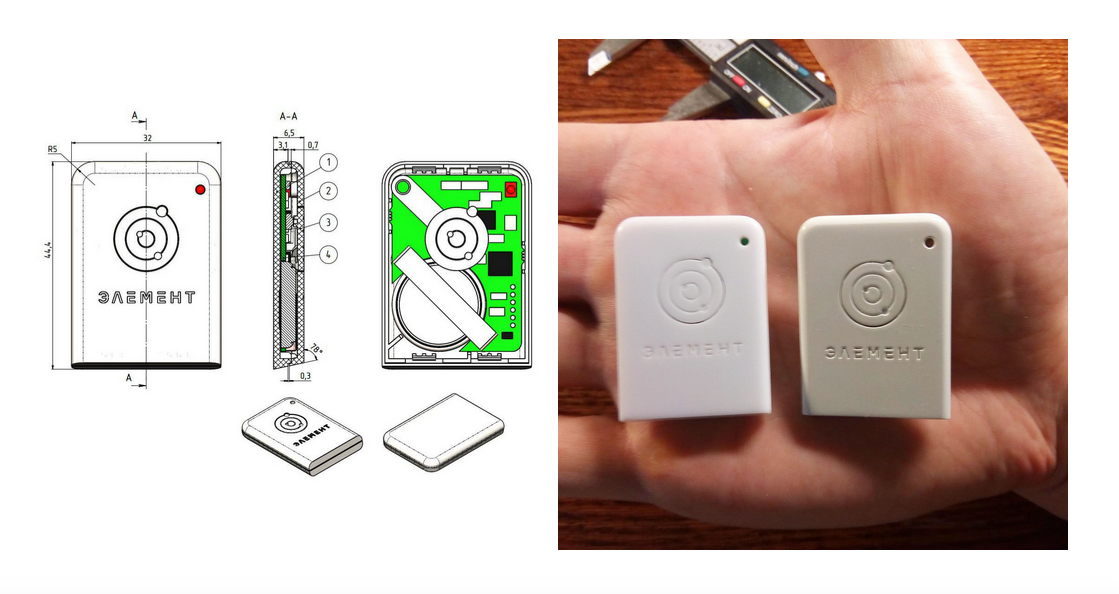

Case size 44x32 mm

Two body parts and one button made of ABS plastic.

The cost of the prototype is $ 150.

The cost of the mold - $ 2,500 (one form for three places).

Mold resource - 50 thousand cycles.

The cost of a set of parts is $ 0.5 with a circulation of 5,000 pieces.

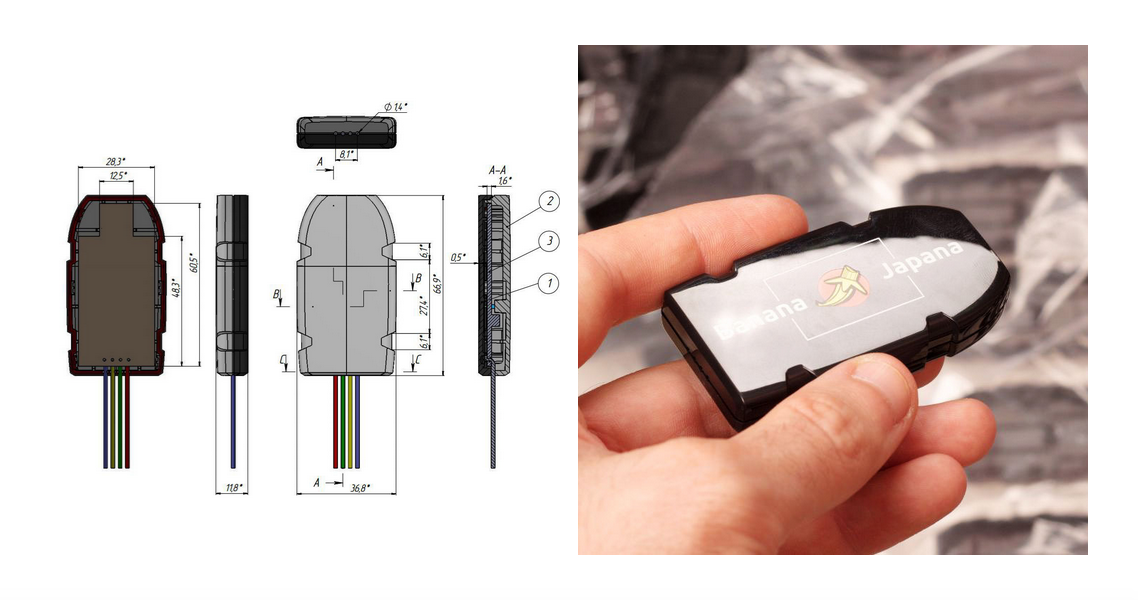

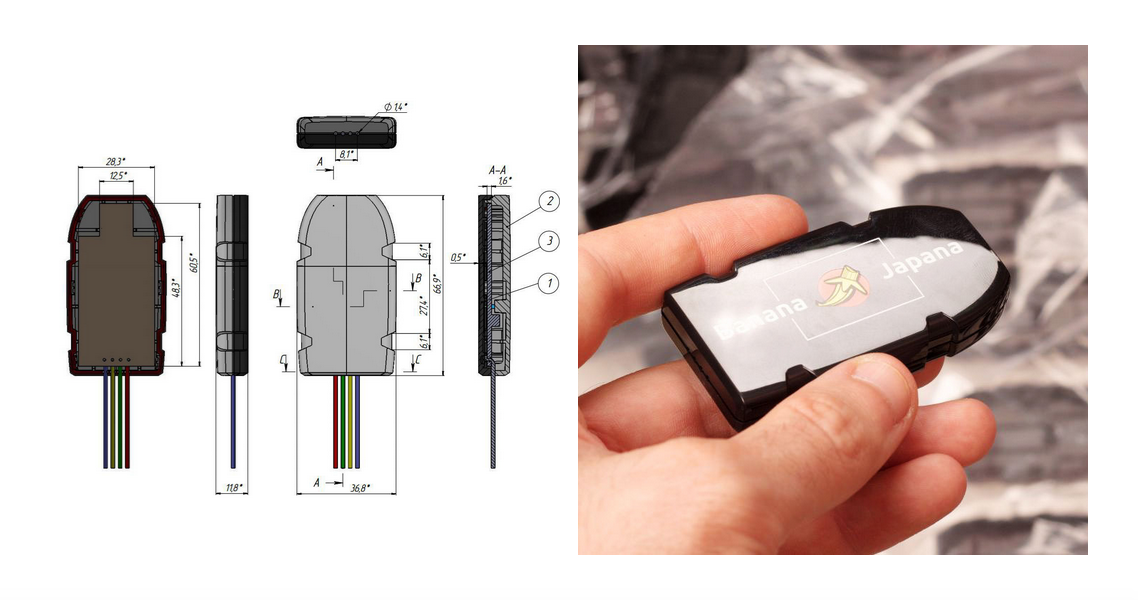

Case dimensions 60x30 mm

Two body parts made of ABS plastic.

The cost of the prototype is $ 200.

The cost of the mold - $ 5,000 (one form for two places).

Resource molds - 50 thousand cycles

The cost of a set of parts - $ 0.8 with circulation of 1,000 pieces.

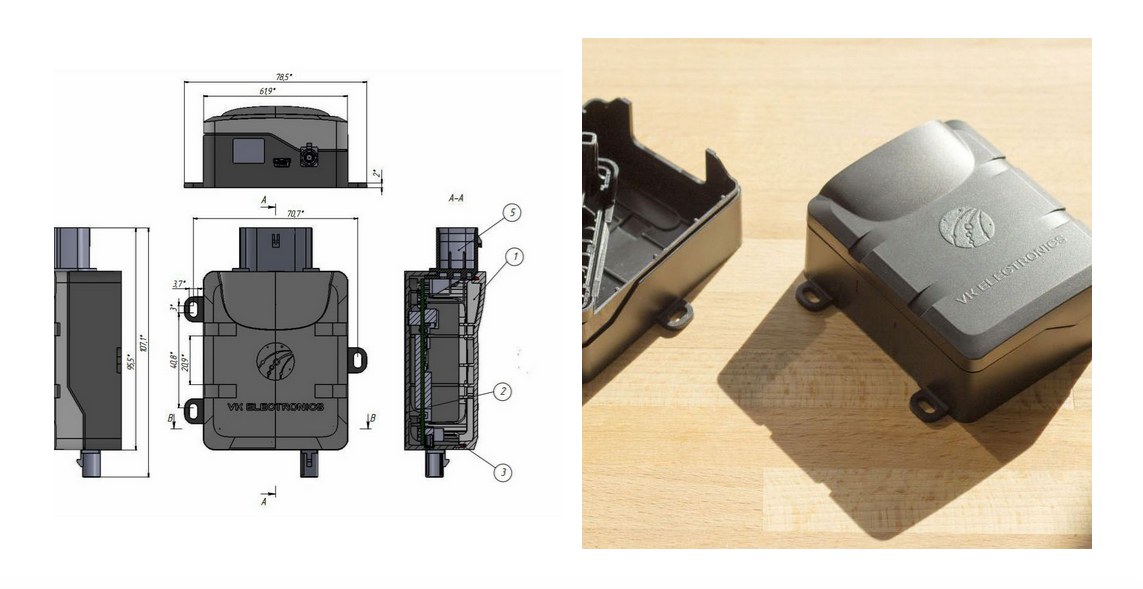

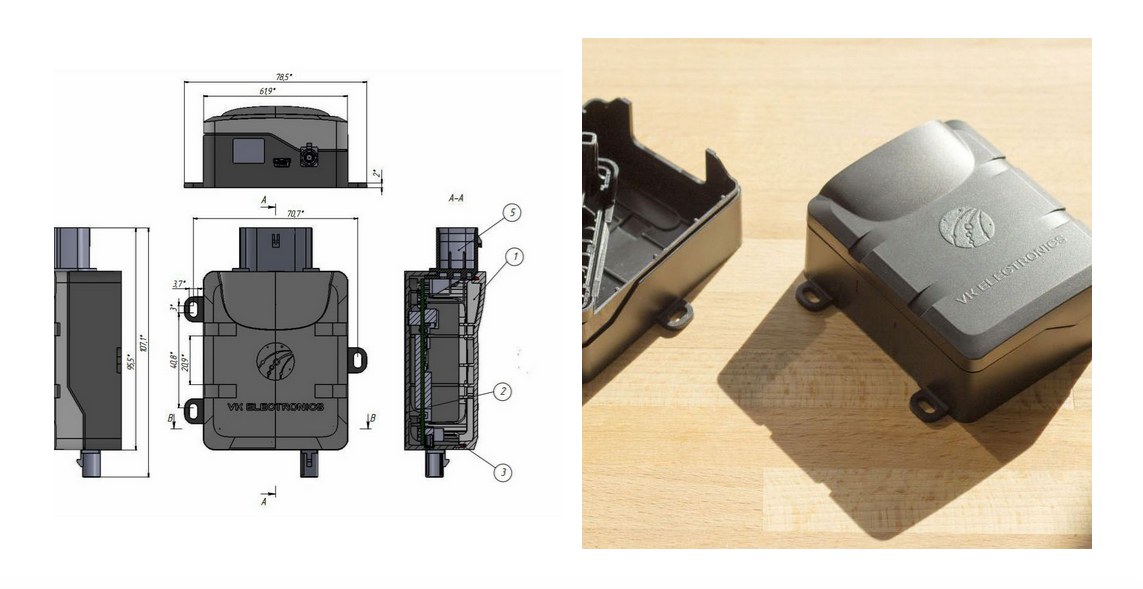

Hermetic (IP-66) case with dimensions of 80x60x30 mm

Two body parts made of ABS plastic and one rubber seal.

The cost of the prototype is $ 280.

The cost of molds - $ 5,500 case (double form) and $ 1,500 - seal.

Resource molds - 50 thousand cycles.

The cost of a set of parts - $ 1.3 when drawing 1,000 pieces.

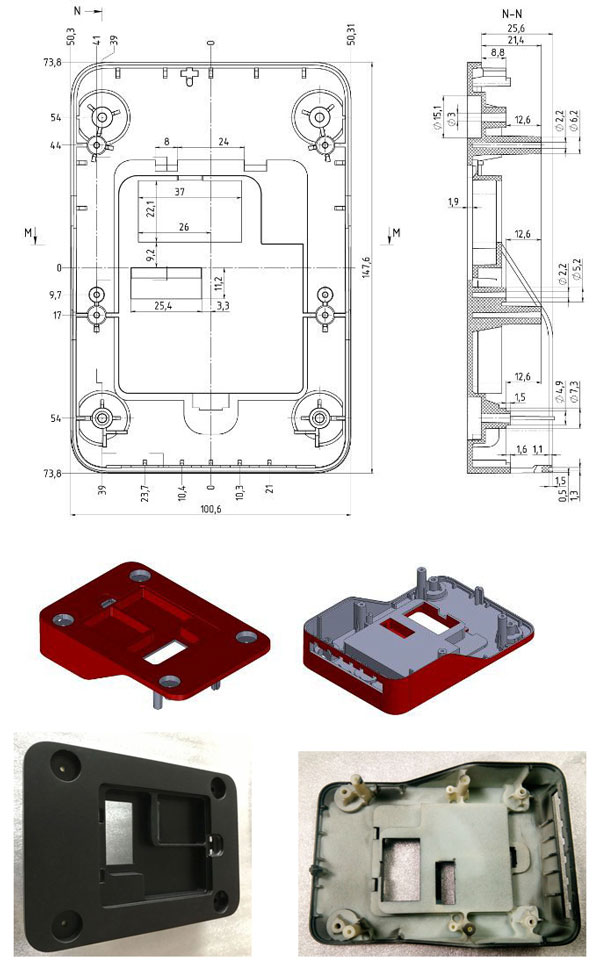

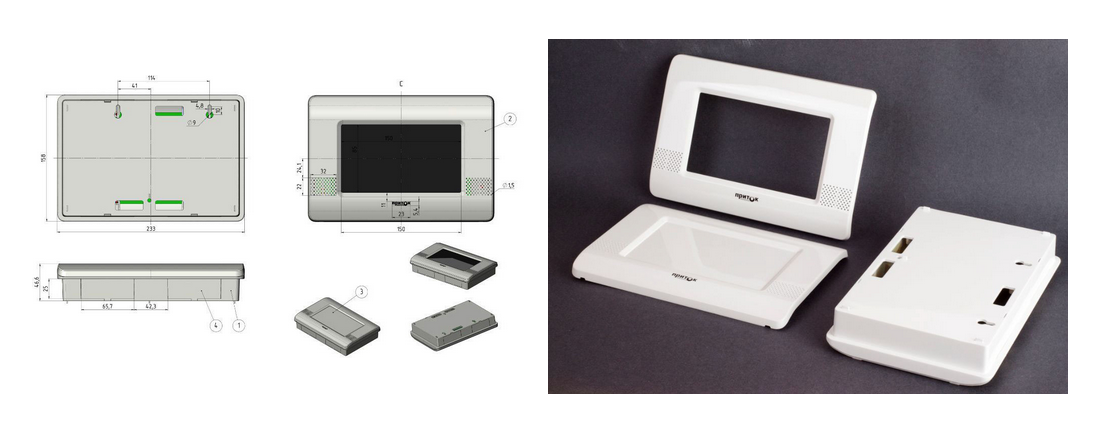

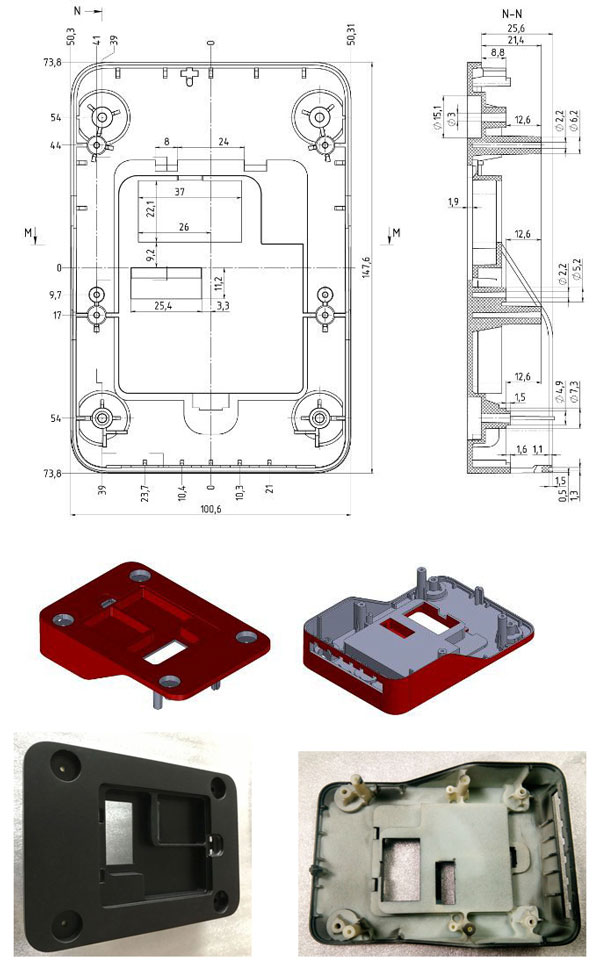

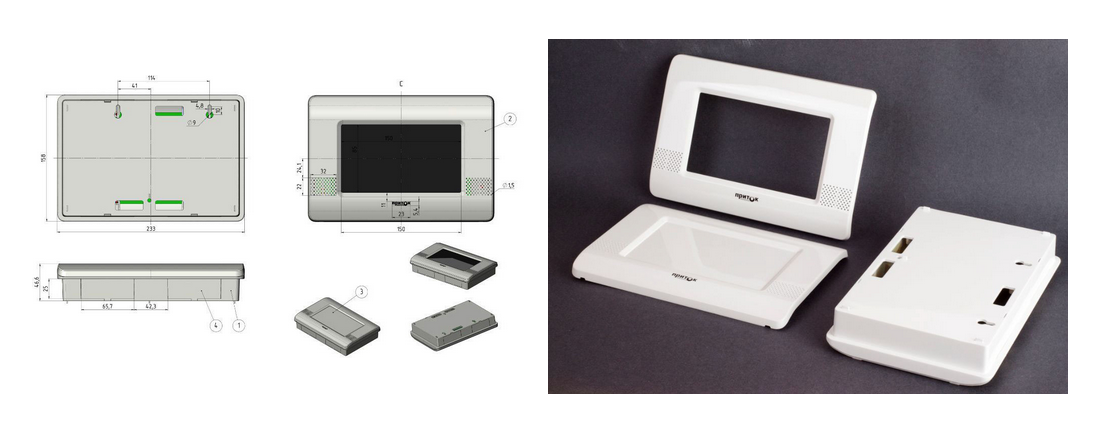

Case with dimensions of 230x160x45 mm

Two body parts made of ABS plastic, three fasteners made of ABS plastic.

The cost of the prototype is $ 750.

The cost of molds is $ 12.000 ($ 5.000 back cover, $ 4.000 front cover for two seats, $ 3.000 cover and hinges for three seats).

Resource forms - 300 thousand cycles.

The cost of a set of parts is $ 3 with a circulation of 5,000 pieces.

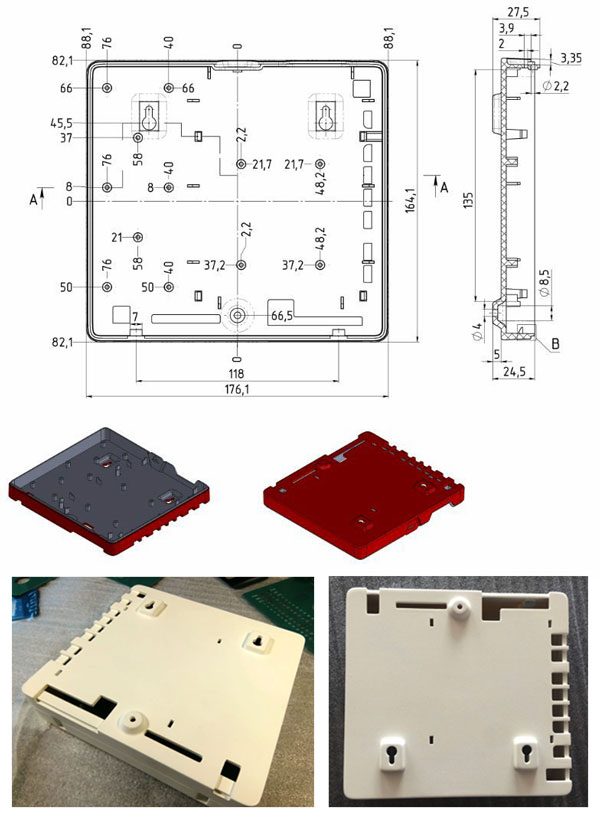

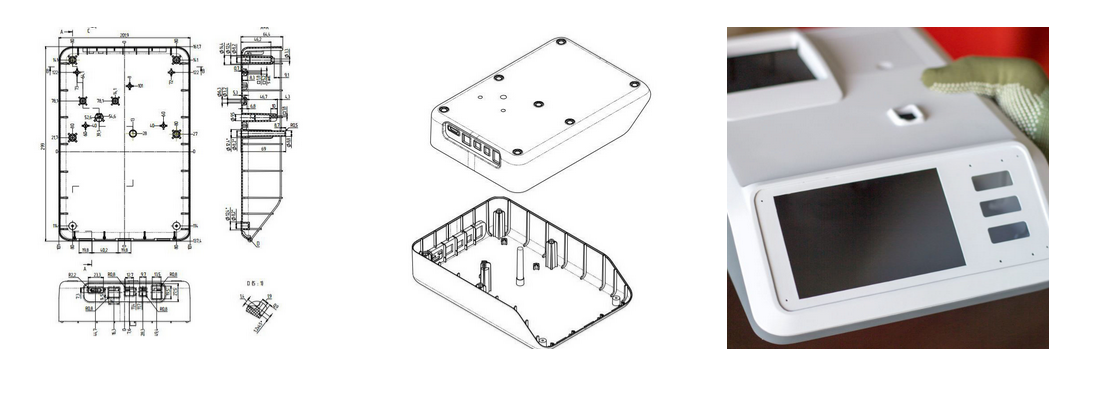

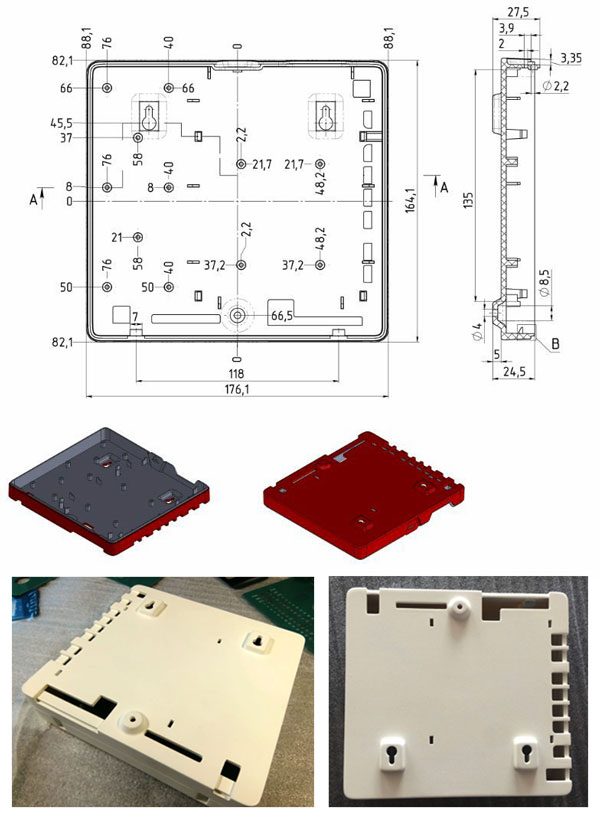

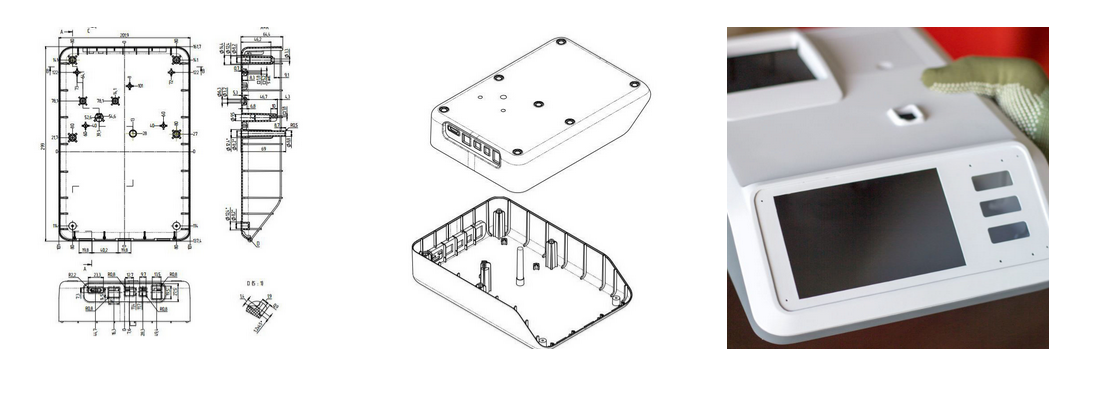

Case dimensions 300x200x65 mm

Two ABS plastic housing parts, one cover, one frame and one set of ABS plastic buttons.

The cost of the prototype is $ 1.200.

The cost of molds is $ 14.000 ($ 7.000 base, $ 4,500 top cover, $ 2,500 cover and buttons).

Resource forms - 500 cycles.

The cost of a set of parts - $ 6 with a draw of 500 pieces.

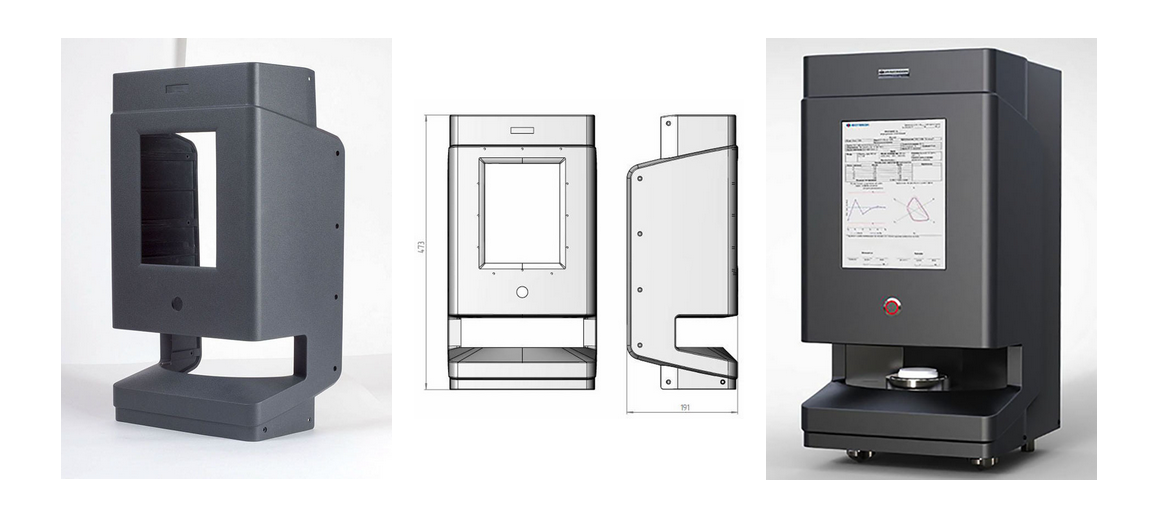

Case dimensions 470x190x250 mm

One case part made of ABS plastic.

The cost of the prototype is $ 2,500.

Mold cost is $ 32,000.

Mold resource - 50 thousand cycles.

The cost of the part is $ 8.2 with a drawing of 1,000 pieces.

Case dimensions 800x800x380 mm

Two body parts made of ABS plastic, a set of blades, frame, clamps

made of ABS plastic.

The cost of the prototype is $ 5,000.

The cost of molds - $ 150.000.

Resource forms - 300 thousand cycles.

The cost of a set of parts is $ 20 for a drawing of 10,000 pieces.

The cost of production of metal enclosures by cutting and bending methods - from small devices to industrial machines.

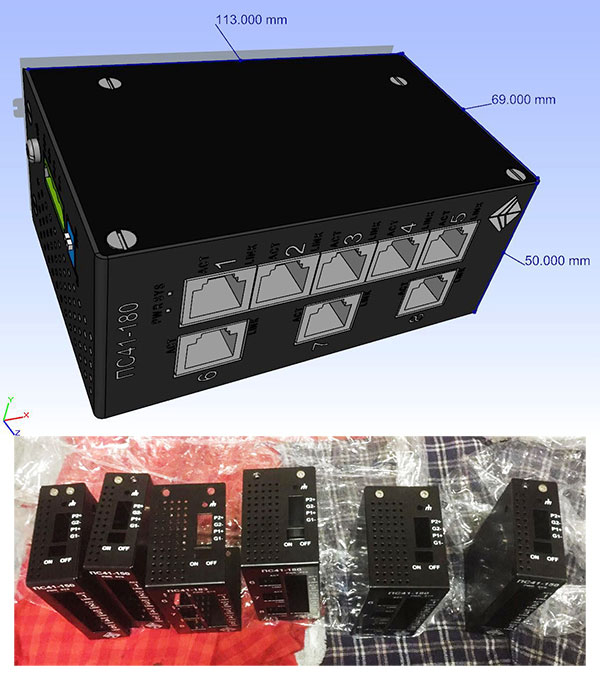

Case dimensions 110x70x50 mm

Two metal parts.

The cost of the prototype - 20 000 rubles.

The cost of a set of parts - 500 rubles. with circulation of 1,000 pieces.

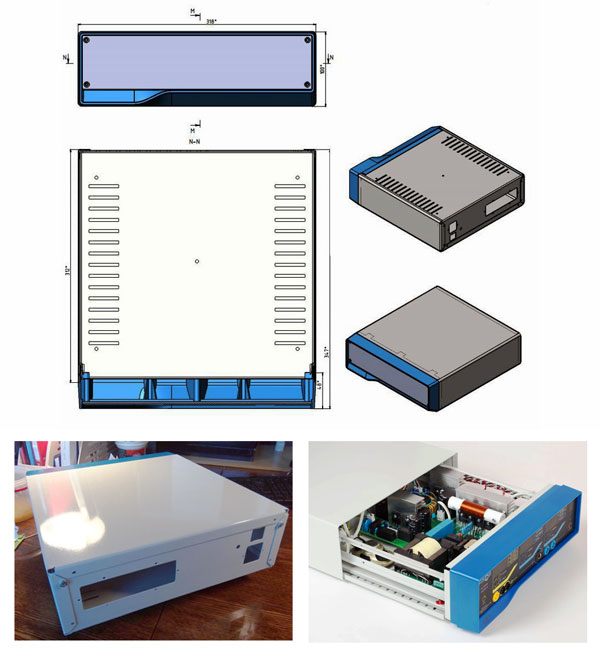

Housing dimensions 350x350x100 mm

One piece - plastic, three parts - metal.

The cost of the prototype (metal) - 20 000 rubles.

The cost of the case - 2 500 rubles. with the circulation of 1.000 pieces.

The cost of the prototype (plastic) - 3 000 rubles.

The cost of a plastic panel - 900 rubles. with circulation of 1,000 pieces.

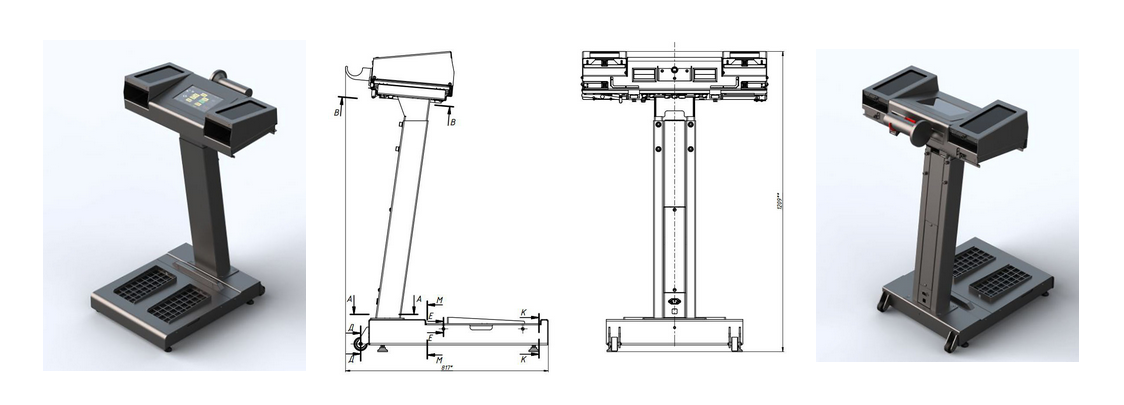

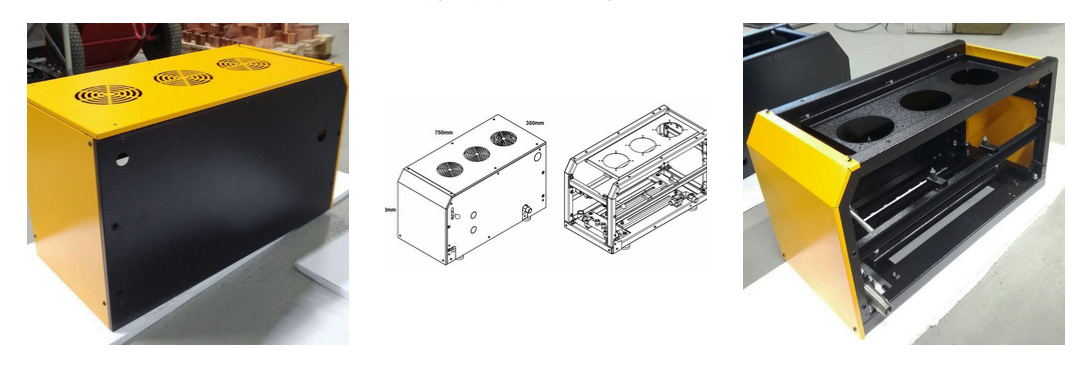

Case dimensions 750x450x350 mm

The cost of the prototype (metal) - 200 000 rubles.

Unit cost - 35,000 rubles. with circulation of 1,000 pieces.

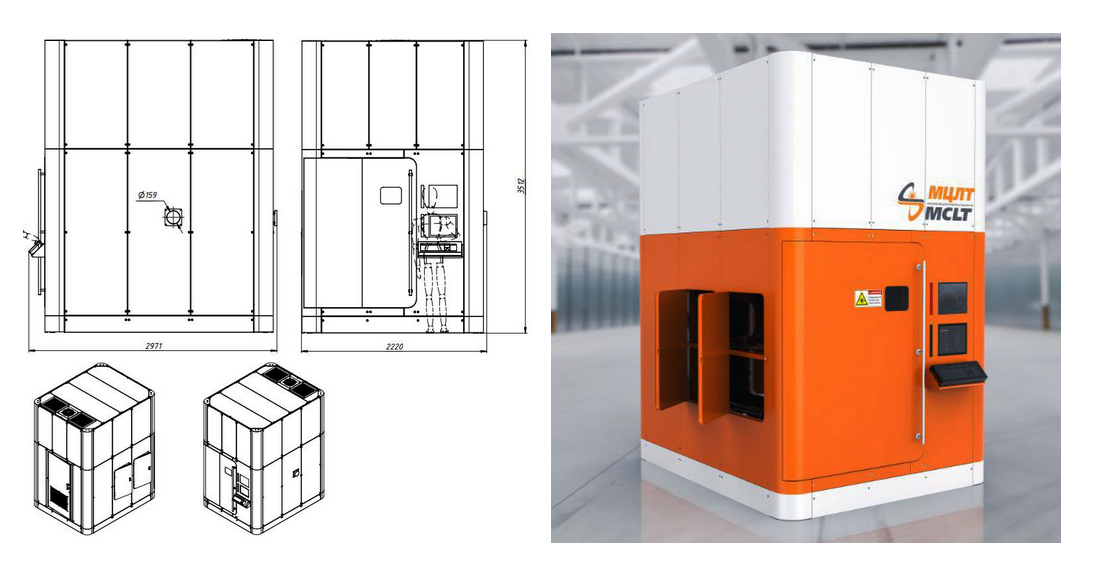

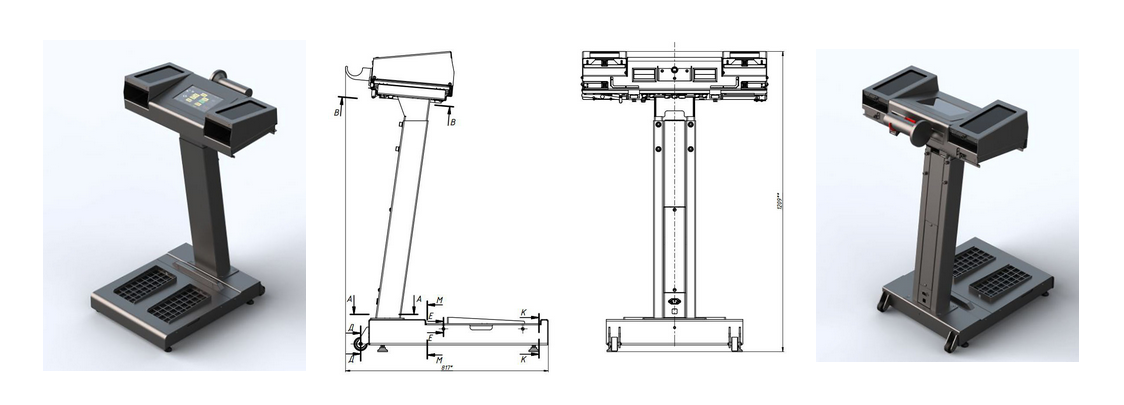

Case dimensions 1300x800x700 mm

The cost of the prototype (metal) - 300 000 rubles.

The cost of the case is 68,000 rubles. with a draw of 50 pieces.

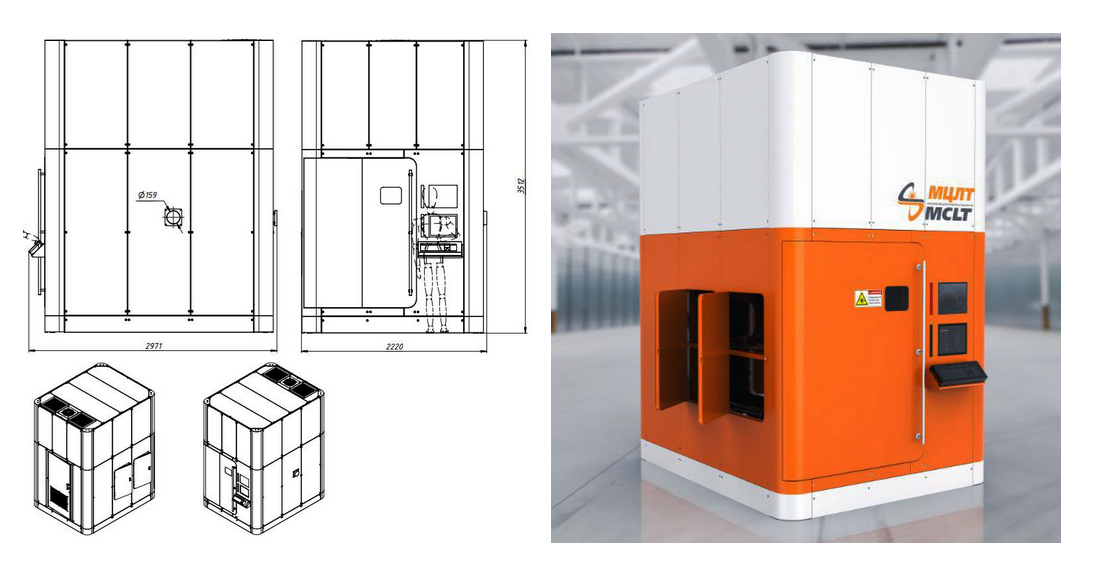

Case dimensions 3500x3000x2200 mm

The cost of the prototype (metal) - 1 300 000 rubles.

The cost of the case is 800,000 rubles. with a draw of 10 pieces.

Cost of production of cases for small devices and devices of medium size

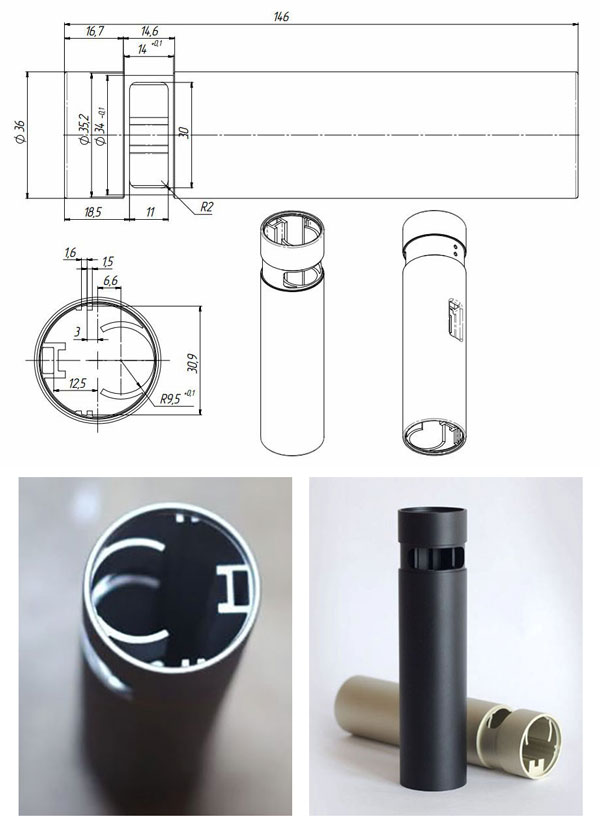

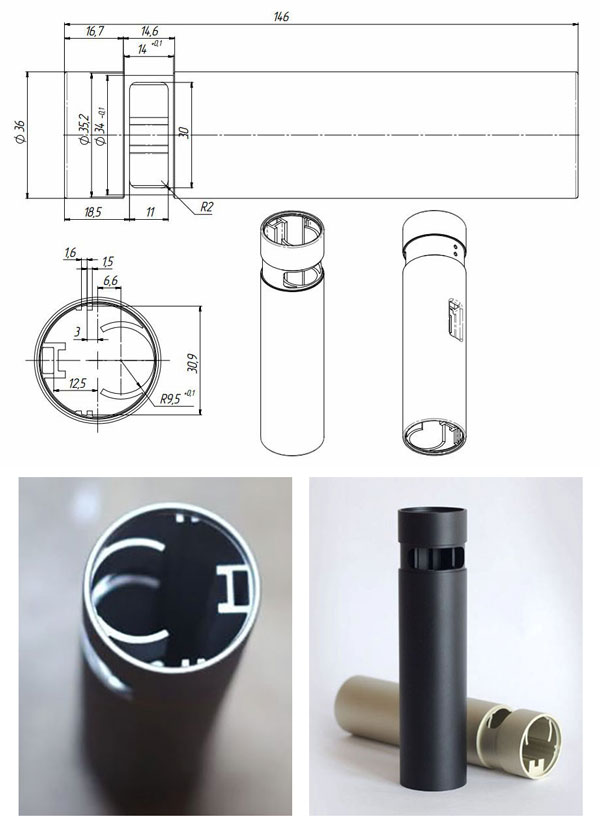

Case with dimensions of 150x35 mm

Technologies: aluminum casting under pressure, aluminum extrusion + milling + anodizing.

The cost of the prototype (metal) - $ 650.

The cost of the die - $ 7.500.

The cost of the case is $ 1.8 with a circulation of 10,000 pieces.

Case dimensions 90x80x29 mm

The cost of the prototype (metal - two aluminum body parts) - $ 700.

The cost of the mold (two seats) - $ 9.000.

Resource forms - 30 thousand cycles.

The cost of the case is $ 3.2 with a draw of 10,000 pieces.

Case dimensions 360x200x80 mm

Technologies: aluminum extrusion + milling, bending and cutting of metal + anodizing.

The cost of the prototype (full body) - $ 800.

The cost of the die - $ 3,000.

The cost of the case is $ 110 with a draw of 500 pieces.

Case dimensions 470x135x125 mm

The cost of the prototype (metal - two aluminum body parts) - $ 2.000.

The cost of the mold (two seats) - $ 42.000.

Resource forms - 150 thousand cycles.

The cost of the case is $ 93 with a circulation of 1,000 pieces.

I will repeat it, because it is important: a simple comparison (“Oh, I have almost the same case, which means it will cost the same!”) on the price. This includes the presence of marks in the mold, and inclines, and unclipped welds, etc. But you can roughly estimate. :)

As it turns out in the course of communication, the majority of the requestor is mistaken in estimating the cost of production on the order . I'm not kidding.

However, I could not write a simple instruction (or even simpler to make a calculator) on estimating these costs: for this you will have to take into account too many parameters. Therefore, I will simply show with examples the circulation and price. Yes, you can not accurately assess your project, but it will be clear how much money you need - 100,000 rubles, a million or more.

And if you write in the comments exactly what interests you, I will try to answer with examples: I have a lot of them (from) a great number - from the cases of miniature devices to the cases of machines the size of a house.

I. Production of plastic parts

Cost of production of small, small and large parts

Detail dimensions 25x20 mm

One fastener made of ABS plastic.

The cost of the prototype is $ 60.

Forms cost $ 1,500 (eight-person form).

Resource forms - 300 thousand cycles.

The cost of one part is $ 0.08 with a circulation of 8,000 pieces.

Detail size 150x100 mm

One body part made of ABS plastic.

The cost of the prototype is $ 200.

The cost of the mold is $ 4,300.

Resource forms - 200 thousand cycles

The cost of one part - $ 0.5 with a draw of 1,000 pieces.

Detail with dimensions of 170x170 mm

One body part made of ABS plastic.

The cost of the prototype is $ 230.

Mold cost - $ 5.000

Mold resource - 200 thousand cycles.

The cost of one part is $ 1.1 for a drawing of 10,000 pieces.

Detail dimensions 530x120 mm

Material - ABS-plastic.

The cost of the prototype is $ 350.

The cost of the mold is $ 12,000.

Mold resource - 300 thousand cycles.

The cost of one part is $ 1.4 with a circulation of 10,000 pieces.

Ii. Production of plastic cases

Cost of production of small, desktop, wall-mounted, tall and large buildings

Case size 44x32 mm

Two body parts and one button made of ABS plastic.

The cost of the prototype is $ 150.

The cost of the mold - $ 2,500 (one form for three places).

Mold resource - 50 thousand cycles.

The cost of a set of parts is $ 0.5 with a circulation of 5,000 pieces.

Case dimensions 60x30 mm

Two body parts made of ABS plastic.

The cost of the prototype is $ 200.

The cost of the mold - $ 5,000 (one form for two places).

Resource molds - 50 thousand cycles

The cost of a set of parts - $ 0.8 with circulation of 1,000 pieces.

Hermetic (IP-66) case with dimensions of 80x60x30 mm

Two body parts made of ABS plastic and one rubber seal.

The cost of the prototype is $ 280.

The cost of molds - $ 5,500 case (double form) and $ 1,500 - seal.

Resource molds - 50 thousand cycles.

The cost of a set of parts - $ 1.3 when drawing 1,000 pieces.

Case with dimensions of 230x160x45 mm

Two body parts made of ABS plastic, three fasteners made of ABS plastic.

The cost of the prototype is $ 750.

The cost of molds is $ 12.000 ($ 5.000 back cover, $ 4.000 front cover for two seats, $ 3.000 cover and hinges for three seats).

Resource forms - 300 thousand cycles.

The cost of a set of parts is $ 3 with a circulation of 5,000 pieces.

Case dimensions 300x200x65 mm

Two ABS plastic housing parts, one cover, one frame and one set of ABS plastic buttons.

The cost of the prototype is $ 1.200.

The cost of molds is $ 14.000 ($ 7.000 base, $ 4,500 top cover, $ 2,500 cover and buttons).

Resource forms - 500 cycles.

The cost of a set of parts - $ 6 with a draw of 500 pieces.

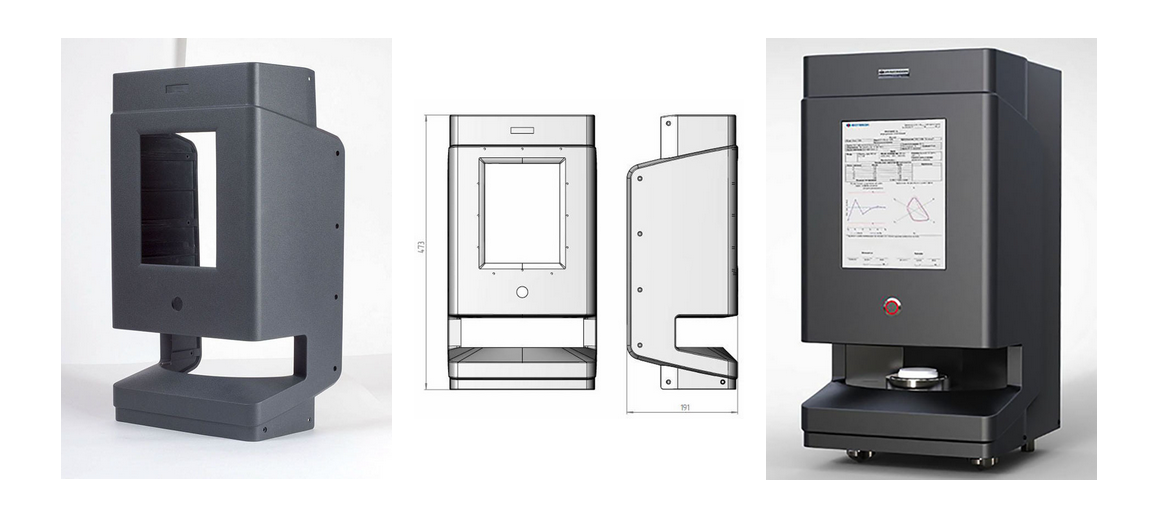

Case dimensions 470x190x250 mm

One case part made of ABS plastic.

The cost of the prototype is $ 2,500.

Mold cost is $ 32,000.

Mold resource - 50 thousand cycles.

The cost of the part is $ 8.2 with a drawing of 1,000 pieces.

Case dimensions 800x800x380 mm

Two body parts made of ABS plastic, a set of blades, frame, clamps

made of ABS plastic.

The cost of the prototype is $ 5,000.

The cost of molds - $ 150.000.

Resource forms - 300 thousand cycles.

The cost of a set of parts is $ 20 for a drawing of 10,000 pieces.

Iii. Sheet Metal Sheet Production

The cost of production of metal enclosures by cutting and bending methods - from small devices to industrial machines.

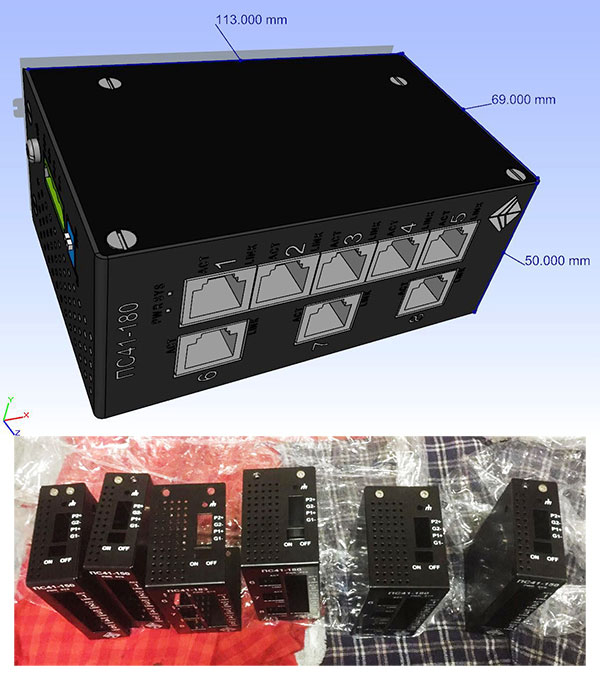

Case dimensions 110x70x50 mm

Two metal parts.

The cost of the prototype - 20 000 rubles.

The cost of a set of parts - 500 rubles. with circulation of 1,000 pieces.

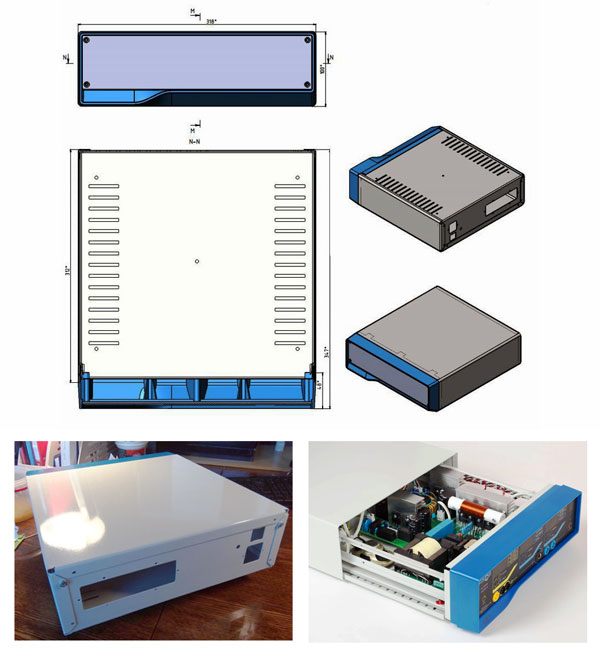

Housing dimensions 350x350x100 mm

One piece - plastic, three parts - metal.

The cost of the prototype (metal) - 20 000 rubles.

The cost of the case - 2 500 rubles. with the circulation of 1.000 pieces.

The cost of the prototype (plastic) - 3 000 rubles.

The cost of a plastic panel - 900 rubles. with circulation of 1,000 pieces.

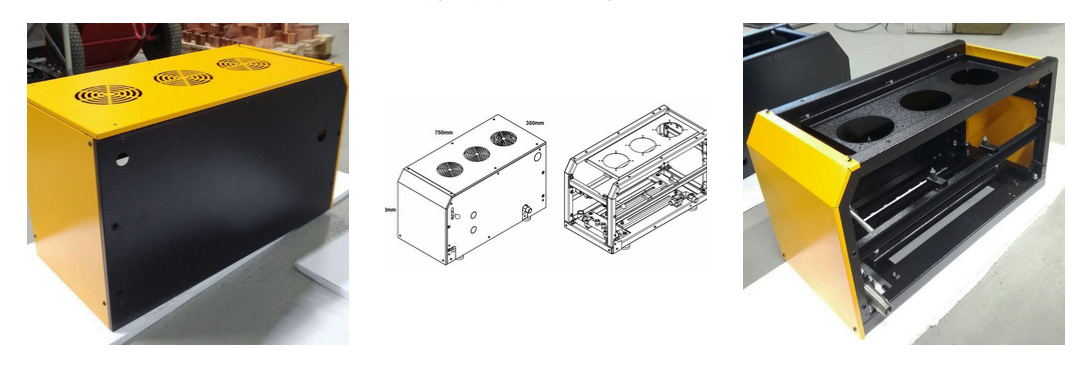

Case dimensions 750x450x350 mm

The cost of the prototype (metal) - 200 000 rubles.

Unit cost - 35,000 rubles. with circulation of 1,000 pieces.

Case dimensions 1300x800x700 mm

The cost of the prototype (metal) - 300 000 rubles.

The cost of the case is 68,000 rubles. with a draw of 50 pieces.

Case dimensions 3500x3000x2200 mm

The cost of the prototype (metal) - 1 300 000 rubles.

The cost of the case is 800,000 rubles. with a draw of 10 pieces.

Iv. Production of metal cases for injection molding technology

Cost of production of cases for small devices and devices of medium size

Case with dimensions of 150x35 mm

Technologies: aluminum casting under pressure, aluminum extrusion + milling + anodizing.

The cost of the prototype (metal) - $ 650.

The cost of the die - $ 7.500.

The cost of the case is $ 1.8 with a circulation of 10,000 pieces.

Case dimensions 90x80x29 mm

The cost of the prototype (metal - two aluminum body parts) - $ 700.

The cost of the mold (two seats) - $ 9.000.

Resource forms - 30 thousand cycles.

The cost of the case is $ 3.2 with a draw of 10,000 pieces.

Case dimensions 360x200x80 mm

Technologies: aluminum extrusion + milling, bending and cutting of metal + anodizing.

The cost of the prototype (full body) - $ 800.

The cost of the die - $ 3,000.

The cost of the case is $ 110 with a draw of 500 pieces.

Case dimensions 470x135x125 mm

The cost of the prototype (metal - two aluminum body parts) - $ 2.000.

The cost of the mold (two seats) - $ 42.000.

Resource forms - 150 thousand cycles.

The cost of the case is $ 93 with a circulation of 1,000 pieces.

I will repeat it, because it is important: a simple comparison (“Oh, I have almost the same case, which means it will cost the same!”) on the price. This includes the presence of marks in the mold, and inclines, and unclipped welds, etc. But you can roughly estimate. :)