Wiren Board Smart Home Batch Production Experience

Brief Background

Based on our Wiren Board platform (a compact industrial computer with Linux and different interfaces), we made a sophisticated controller for home automation Wiren Board Smart Home, to which you can connect a bunch of wired and wireless devices from different systems and manufacturers. The device has ARM9 64MB RAM, GSM / GPRS, Ethernet, Wi-Fi, USB, 2xRS-485 / Modbus, CAN, 2 relays, ASK / FSK radio module 433MHz, NRF24L01 - a full description is here .

At the end of February, we presented a prototype and opened a pre-order for the controller. How the pre-order went, how we made a batch of devices and what we will do next - read under the cut.

Preorder

To start selling devices on pre-order was a very difficult decision for us. Users have to buy the device without seeing it live, we have to try very hard to justify the huge trust. To convince future buyers of the device’s capabilities, we even shot a video about its operation.

The second option to launch the device, which we considered, was pre-order without payment - once we already completed it when we launched the usual Wiren Board. In theory, this method allows you to estimate the demand and the required volume of the party. But this method is very inaccurate - the last time the number of real buyers was less than a third, so this time we decided to check the real demand.

In general, we were very worried, but the result was not bad - we collected more than a hundred paid (!) Pre-orders, and decided to prepare a batch of 200 devices.

Party launch

This was not the first time we organized the production of a batch - before we had already collected 55 pieces of Wiren Board rev. 2.8. But then the task was much simpler: although the boards were assembled at the factory, they were manually assembled; processor modules we generally bought ready-made. This time we assembled the entire device ourselves, with automatic installation.

Components

The first thing to do was to purchase components and order printed circuit boards.

Most of the components were purchased in Elitan, a little in China, memory chips and modems in MT-Systems. Processors had to be purchased from abroad. And with them our biggest miscalculation happened - the managers of the usually perfectly working Farnell company at first were unable to place an order for processors that were subject to minimum export restrictions, and during the approval of all authorization papers they either went on vacation or simply did not answer. Having tormented with them an extra month, we placed an order for Digikey, signed all the papers in a day, and on the third day our order flew from the United States to Russia.

It was the unpleasant story with the processors that served as the main reason for the disruption of the shipment dates - during the pre-order we promised to send the first devices in early May, but we could only do this at the end of the month.

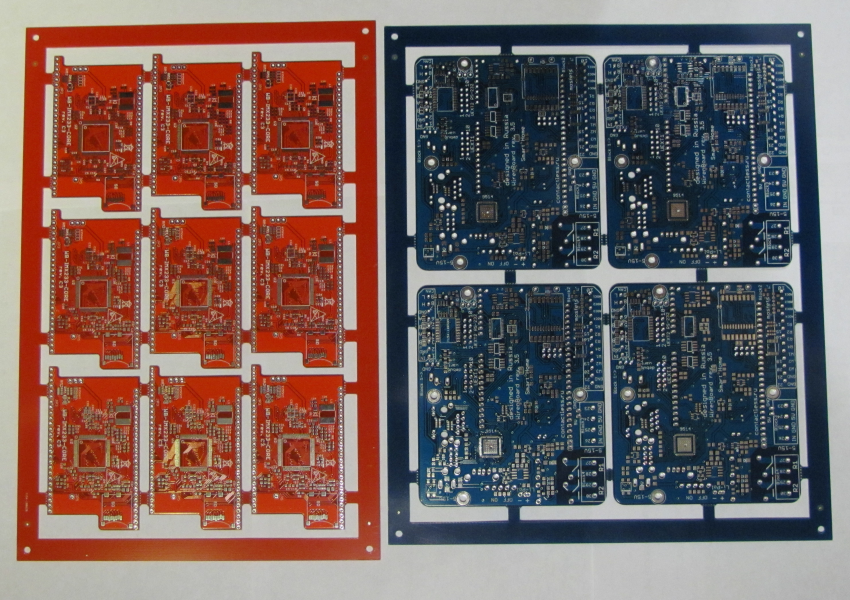

Fees

Printed circuit boards ordered at HQEW . Prior to that, they had not been ordered from them, but the COOLRF comrades wrote about them well . Judging by the status of orders on their website, they made them quickly, and then delayed the shipment rather unreasonably. I had to write angry letters to managers both on mail and on Skype, which they all ignored (it should be noted that before we paid them the money, they answered instantly).

In the end, they still answered, apologized and sent the order.

Board Quality

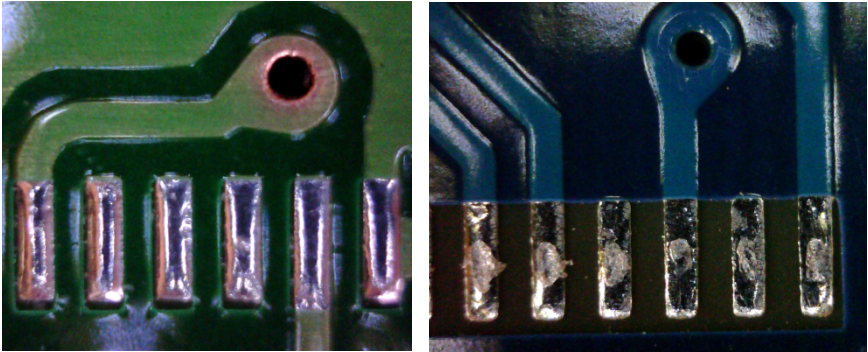

The site claimed a very high manufacturing accuracy. But in fact, for some reason, they removed the mask between the pads with a pitch of 0.5 mm (0.15 mm mask bridge) - although the same Rezonit and Seeed Studio did them. This did not cause big problems with the installation, but the sediment remained.

On the left is a board from Rezonit, on the right - from China. Pay attention to the removed solder mask around the pads in the second photo.

Mounting

Automatic installation was done in Tula - MT-electro . They asked to mount faster - they did it very quickly, although this affected the cost.

Initial installation was first done by the forces of its employee - it took only 20 minutes to pay. But he quickly got tired of this business, and he had to hire a third-party installer.

Housing

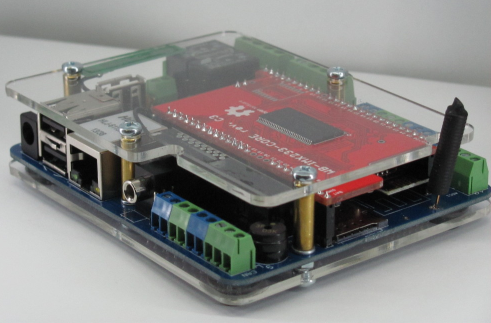

A dozen cases in the desktop version were made of two plexiglass plates on racks (the first photo in the article). Used laser cutting services at Seeed Studio.

A plastic case on a DIN rail was bought standard - Gainta D6MG. It required a little refinement - we needed slots for a SIM and microSD card, a button, and a little trim for a USB connector. It was possible to order a revision, but why? If in the corner cnc machine dust gathers dust :). We set the spindle horizontally, make stops for the body - and mill the neat holes.

Testing

To test the assembled devices, we wrote a script that interrogated the chips, clicked on the reels, checked the data transfer via RS-485, etc. It turned out that in the batch of RS-485 transceivers up to 20% of the marriage (and there are two of such transceivers on the board). It was lucky that the defective chips were in the SOIC-8 package and it was easy and quick to change them.

We bought these transceivers in Platan, they never answered our angry letter. There were no such problems with other components.

Production stages with deadlines

- March 1 ordered boards

- March 20, fees arrived at the border intermediary

- May 5 delivered to us

- May 7 sent for installation

- On May 17, collected fees were received.

- May 25, sending devices began

- Pre-order mailing finished on June 15

Before production

In the process of testing the samples, a couple of serious bugs were discovered:

- The processor modules sometimes did not pass the memory test.

The problem was solved by correctly setting timings for memory. They searched for the problem for a very long time (more than a week) and because of this they delayed the order of the boards. It was aggravated by the fact that errors in the test sometimes appeared after dozens of minutes of testing and everything affected these errors in general, so initially we sinned on some kind of interference. It turned out that the new model of memory chips has slightly different timings, and we need to fix them in the code. - The controller rebooted every 7 hours.

We replaced the LTC4002 power chip with a nearly full Chinese analogue EUP8207, which works the same way, but turns off every 7 hours :). According to the documentation, the LTC4002 also turns off every three hours (battery charging cycle), but these shutdowns do not affect the operation ( the chip turns off, the output voltage drops to 4.0 V and the chip restarts the cycle). The Chinese clone turned off completely, and slowed down with the inclusion (almost a hundred milliseconds). Dancing with a tambourine and capacitors did not help, I had to return to the previous version. - And after receiving the batch, we discovered a very “wonderful” bug: When the controller was turned on using the button with some probability (from 10 to 95% for different boards), the processor hung up.

Moreover, this has never been observed if you plug in the power plug.

This revealed a well-known problem of the IMX233 processor - moodiness to food.

When the button was turned on, there was a small interference on the 5V line, which caused it to hang. The problem was easily solved by replacing the capacitor from 10 μF to 1 μF in the right place, but, as they say, the precipitate remained.

Now

The first buyers have already managed to work with the controllers - we can say that with the iron part it turned out more or less good.

With software, it’s so far worse: until support “out of the box” for external devices on Modbus is ready, different devices Oregon Scientific and Noolite devices are supported from 433 MHz radio devices. The controller has a native simple web interface where you can control connected devices and watch sensor readings. In addition, a gate to the Ninja Blocks cloud system works, where you can create scripts and rules, watch history, etc.

We are going to complete the support of a local (not cloud) system with rules and history soon, first of all, work with Domoticz will be implemented.

What's next

We get invaluable help from our users on the forum, who are testing updates, and have helped us with device support for radio dumps.

But, unfortunately, although all the software we have is open, none of the users has yet participated in the software development.

Now we have some problem in implementing and testing the operation of the device with all kinds of peripherals ourselves. We are constantly working on this, but we hope for help from the habrasociety.