Moon bricks from the solar furnace

At best, the person’s return to the moon remains years - the first manned flight to the lunar orbital station Lunar Orbital Platform-Gateway is expected not earlier than the mid-2020s, and even the approximate dates for the construction of the lunar base are still unknown. However, we need to develop the technologies that we need on the Moon right now, because they cannot reach maturity instantly. And one of the places to develop such technologies is the Spaceship EAC division in the astronaut training center of the European Space Agency, Cologne, Germany. For several years now, there has been exploring the possibility of obtaining building material from the lunar regolith, baking volcanic rocks in a hybrid of a 3D printer and a solar furnace, and not only that.

3D-printing of the protective dome of the lunar base in the view of the European Space Agency

The surface of the moon is an inhospitable place. Without an atmosphere, even a small meteor becomes dangerous; in the absence of a magnetic field, nothing stops solar radiation. Even the temperature challenges the technology, because during the day the surface heats up to + 127 ° С, and at night it cools down to -173 ° С. Need some kind of protection. But it is very expensive to carry it with you from the Earth, therefore, for example, in historical projects of the lunar bases it was often suggested to bury them deeper. Now the European Space Agency has a different approach, outlined in the conceptual video for 2014.

A self-propelled bulldozer with a 3D printer will have to rake the regolith with a blade and then form a dome on the principle of bird bone — with solid structural elements holding the load and large volumes filled with loose regolith between them. The concept was not created from scratch, in 2013, using a 3D printer, one and a half tons of walls were made from a simulator of lunar soil.

Photo by ESA

Initially, judging by the concept, the 3D printer had a reagent tank, and the formation of solid parts had to take place chemically. But other options are also being considered.

Since the sun heats the lunar surface so much, its light energy can be used directly without conversion into electricity and back into heat.

The photograph shows the solar furnace of the German Aerospace Center in Cologne. 147 rotating mirrors provide temperatures up to 2500 ° C and energy density up to 5 megawatts per square meter. Since it is not always sunny in Europe, the furnace has a backup light source from xenon lamps. In 2017, this furnace was connected to a 3D printer that prints a lunar regolith simulator.

The printer printed in layers of 0.1 mm and heated the regolith simulator to 1000 ° C. It took about five hours for a brick of 20x10x3 cm, and the resulting material had a gypsum hardness.

Top view, ESA photo.

Side view.

The resulting bricks are far from ideal - layering is visible, a bend (warping) is noticeable along the edges, and the hardness is not that big. But engineers are full of optimism - at the level of experimental verification of the concept, the problem is solved, and with violations of geometry one can fight by changing the printing speed.

In August 2017, the concept of a movable printhead, which does not require a separate building of the solar furnace, was successfully tested on the simulator of the lunar regolith and ordinary sand.

The RegoLight project, within which this head was developed, was launched in 2015 and completed in 2017, but in general the work did not stop, of course.

As already mentioned, experiments on the construction of local resources were carried out on the simulator of the lunar soil. What it is? Both on the Earth and on the Moon, rocks of volcanic origin can be found. On the moon, they are destroyed by exposure to temperature, solar and cosmic rays, as well as meteorite impacts. The result is silty sand, which is called regolith. And about Cologne 45 million years ago there were volcanic eruptions that ejected basalts, very similar to similar rocks from the moon. You only need to grind them into dust of the required size. Under the name EAC-1, they are used as a simulator of lunar soil in the EAC Spaceship.

Of course, the rocks on Earth and on the Moon were in different conditions, and, for example, the effect of oxygen could not leave its mark. Randomly selected stones will give only a rough similarity, and it is necessary to investigate both lunar and terrestrial rocks in order to improve the quality of the simulator. For example, moon dust has an electric charge. To reproduce these properties of the simulator, the particles were milled even more, they got close electrostatic properties, but they lost the properties of the surface, so the work must continue.

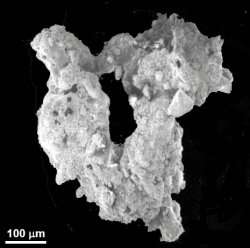

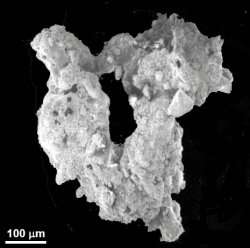

Another feature of the regolith is its extremely high abrasiveness. Unlike terrestrial conditions, there were no erosion processes on the moon that would smooth the surface, and a real moon grain of sand looks something like this.

ESA Photos

Such sharp and small particles are dangerous not only for technology, but also for people - all 12 astronauts who walked on the surface of the moon, noted "lunar allergy" - sore throat, eyes, runny nose, sneezing, which passed after a few days. But for people who will work on the surface for weeks and months, abrasive dust can pose a direct threat to health, damaging lung cells and spreading through the body, even the brain. And here the simulator also still does poorly - mechanical grinding of volcanic rocks forms sand with a polished surface, it is necessary to improve the production methods of the simulator.

But the lunar regolith has potentially beneficial properties. For example, it contains up to 40% oxygen, which theoretically can be mined and used. In general, no long-term settlement on the Moon (or Mars, whatever) can not do without using local resources. And the students working now in Spaceship EAC may well see the implementation at a serious level of technology, which the experiments that are currently under way have given rise to.

3D-printing of the protective dome of the lunar base in the view of the European Space Agency

Problems and ideas

The surface of the moon is an inhospitable place. Without an atmosphere, even a small meteor becomes dangerous; in the absence of a magnetic field, nothing stops solar radiation. Even the temperature challenges the technology, because during the day the surface heats up to + 127 ° С, and at night it cools down to -173 ° С. Need some kind of protection. But it is very expensive to carry it with you from the Earth, therefore, for example, in historical projects of the lunar bases it was often suggested to bury them deeper. Now the European Space Agency has a different approach, outlined in the conceptual video for 2014.

A self-propelled bulldozer with a 3D printer will have to rake the regolith with a blade and then form a dome on the principle of bird bone — with solid structural elements holding the load and large volumes filled with loose regolith between them. The concept was not created from scratch, in 2013, using a 3D printer, one and a half tons of walls were made from a simulator of lunar soil.

Photo by ESA

Initially, judging by the concept, the 3D printer had a reagent tank, and the formation of solid parts had to take place chemically. But other options are also being considered.

Piping hot

Since the sun heats the lunar surface so much, its light energy can be used directly without conversion into electricity and back into heat.

The photograph shows the solar furnace of the German Aerospace Center in Cologne. 147 rotating mirrors provide temperatures up to 2500 ° C and energy density up to 5 megawatts per square meter. Since it is not always sunny in Europe, the furnace has a backup light source from xenon lamps. In 2017, this furnace was connected to a 3D printer that prints a lunar regolith simulator.

The printer printed in layers of 0.1 mm and heated the regolith simulator to 1000 ° C. It took about five hours for a brick of 20x10x3 cm, and the resulting material had a gypsum hardness.

Top view, ESA photo.

Side view.

The resulting bricks are far from ideal - layering is visible, a bend (warping) is noticeable along the edges, and the hardness is not that big. But engineers are full of optimism - at the level of experimental verification of the concept, the problem is solved, and with violations of geometry one can fight by changing the printing speed.

In August 2017, the concept of a movable printhead, which does not require a separate building of the solar furnace, was successfully tested on the simulator of the lunar regolith and ordinary sand.

The RegoLight project, within which this head was developed, was launched in 2015 and completed in 2017, but in general the work did not stop, of course.

Good imitator

As already mentioned, experiments on the construction of local resources were carried out on the simulator of the lunar soil. What it is? Both on the Earth and on the Moon, rocks of volcanic origin can be found. On the moon, they are destroyed by exposure to temperature, solar and cosmic rays, as well as meteorite impacts. The result is silty sand, which is called regolith. And about Cologne 45 million years ago there were volcanic eruptions that ejected basalts, very similar to similar rocks from the moon. You only need to grind them into dust of the required size. Under the name EAC-1, they are used as a simulator of lunar soil in the EAC Spaceship.

Of course, the rocks on Earth and on the Moon were in different conditions, and, for example, the effect of oxygen could not leave its mark. Randomly selected stones will give only a rough similarity, and it is necessary to investigate both lunar and terrestrial rocks in order to improve the quality of the simulator. For example, moon dust has an electric charge. To reproduce these properties of the simulator, the particles were milled even more, they got close electrostatic properties, but they lost the properties of the surface, so the work must continue.

Another feature of the regolith is its extremely high abrasiveness. Unlike terrestrial conditions, there were no erosion processes on the moon that would smooth the surface, and a real moon grain of sand looks something like this.

ESA Photos

Such sharp and small particles are dangerous not only for technology, but also for people - all 12 astronauts who walked on the surface of the moon, noted "lunar allergy" - sore throat, eyes, runny nose, sneezing, which passed after a few days. But for people who will work on the surface for weeks and months, abrasive dust can pose a direct threat to health, damaging lung cells and spreading through the body, even the brain. And here the simulator also still does poorly - mechanical grinding of volcanic rocks forms sand with a polished surface, it is necessary to improve the production methods of the simulator.

But the lunar regolith has potentially beneficial properties. For example, it contains up to 40% oxygen, which theoretically can be mined and used. In general, no long-term settlement on the Moon (or Mars, whatever) can not do without using local resources. And the students working now in Spaceship EAC may well see the implementation at a serious level of technology, which the experiments that are currently under way have given rise to.