How to test nuclear power plants

We have become accustomed to the fact that tests are launched by pressing a single button. Checks take place automatically at every commit, statistics are collected without a tester, and bugs are started up in a semi-automatic mode. In general, we are used to applying software and system engineering technologies to our software projects. Now imagine that your task is to test the operation of a nuclear power plant. It is necessary not only to test its software, but also to test all its components.

Of course, no one can first build a station and then move the supporting wall due to the fact that the ventilation system can not be installed in the current configuration. Therefore, the processes of the real world more and more go to the "figure." How do you like the comment to the commit "Moving the main wall 2 meters north"? When designing and testing nuclear power plants, a fully digital approach is used: an information model is created, the classical V-model of life cycle management is applied to it. Thus, the NPP is transformed into a replicable and fully digital object. Testing and launching of modern nuclear power plants takes place in digital form, and only after that builders start installation using the same digital models.

From this article you will learn about what is a modern information system, how the development and testing of "capital" objects on the example of nuclear power plants.

The material is based on the interpretation of the report by Vyacheslav Alenkov , Director of Systems Engineering and Information Technologies of the Atomstroyexport engineering company (ASE) from our December conference Heisenbug 2017 Moscow.

In this article I will talk about how we use information management technologies, testing various kinds of processes in the construction of large capital facilities (in our case, these are nuclear power plants). Considering the fact that global introduction of digital technologies is underway in capital construction and these technologies are increasingly penetrating various industries, including those related to the physical world, IT-related technologies are also actively included in this area.

A little introduction: Atomstroyexport (ASE)- is a company that is an engineering division of the state corporation Rosatom. We are responsible for the design, procurement / supply and construction of virtually all nuclear power plants in Russia and abroad, in more than 15 countries of the world. More than 90% of our projects are the construction and design of stations abroad, and in this regard we absorb the best requirements, the best practices from international regulators setting standards and rules from international customers.

In many countries, the topic of requirements for the "figure" is very high. Many customers already need not only a built object in concrete / iron, which - here it is, stands in the field. Now you need to pass a digital modelfacility, which will live then throughout the life cycle of the nuclear power plant. The station is under construction for 5-10 years, then it is operated for 60 and more years, that is, everything that we have done (taking into account decommissioning up to 100 years) will then be used and live on the corresponding facility. At the same time, as you understand, almost every year in IT from the point of view of technology, something drastically changes, and how to predict it for 100 years is, of course, a big problem.

The nuclear power plant is, to date, probably one of the most complex objects that humanity builds in terms of the complexity of the object, the number of participants, and the safety of these objects. Therefore, without digital technology, these objects are almost impossible to build. Now the customers (despite the fact that the object is complex) each time make demands to build an object “even faster” and “even cheaper”, while we simultaneously build and design 30 such complex objects in different countries of the world, and manage such an array of information without digital technology is impossible. For example, the basic parameters are hundreds of thousands of positions of different equipment, and each position itself is a complex engineering object. These are tens of thousands of unique classes of equipment, Tens and hundreds of thousands of digital requirements at the entrance (I’ll talk about this in more detail later), this is an information model containing hundreds of thousands, sometimes millions of elements interconnected with each other - and this is not the final product: the model is still “flowing”, it is changing, a huge number of participants simultaneously work with this digital information, a large number of collisions arise between them, and it is very important to manage the whole process in an interconnected way so that it does not go away. Of course, there are issues related to the preparation of "containers" for storing this information, creating links between elements, for accepting / checking / testing everything that happens in the design process. At the design stage, the most information about the object arises, and only then, at the construction stage, it changes.

One of the first stages is the creation of an information model , which, of course, includes the concept of 3D. (The 3D model is easier to understand, because everything is presented visually.) We are talking about the information model, because 3D is part of the information: there is a large amount of various mathematical data and attributes. Take an element, for example, a pump (of which, as I said, hundreds of thousands): each of them has some set of attributes that are characteristic of this pump, and these attributes change throughout the entire life cycle. This information model is actually a single source of truth, to which everyone turns, takes this information and uses it in its activities when designing such large objects as a nuclear power plant.

Accordingly, a single information space is created around the information model , which allows all participants to gain access there, track changes that he makes himself or some other project participants who are geographically distributed, and the only thing that brings them together is this informational model.

An important point is the requirements management processes and configuration management processes . Most of these processes at one time came just from the management of projects that migrated from software engineering, moved to system engineering (this is about the large engineering objects created in the physical world).

Probably everyone is familiar with the concept of "V-model" - in fact, the software is also developed in accordance with the V-model: requirements are formed, the next stage is the architecture, then the design process (design, engineering design) then the implementation stage creating an object. And then there is a reverse-upstream process, when you need to test, carry out various processes associated with verification, with acceptance, with verification and ultimately hand over to the customer, who must make sure that he received exactly what he had in mind. Therefore, there are two processes - verification and acceptance. I think everyone knows how they differ. Verification is a formal compliance with the technical assignment: you had 500 wishes - we ticked each one, and then, we fulfilled 500formal answers. And the acceptance also includes satisfactionthe customer, i.e., not only you have completed everything formally , but he really got what he wanted. Therefore, both processes are important.

The V-model is so wide, because in the modern world no one waits for one stage to complete (for example, the requirements development stage), and design and manufacturing begin. If you look at the cut (t, time), then the vertical straight red line just shows that the project is simultaneously in several stages of the life cycle, that is, somewhere else, perhaps, the customer is determined with the requirements, somewhere the project development is already in full swing, and somewhere, roughly speaking, they began to dig a pit (because everything is clear about it, there is already a project, etc.) d.). Thus, in this regard, there are even greater requirements for the coordination of project participants, because you do not expect the end of the stage. Actually, these topics related to agile approaches with Agile - they are now actively used during the construction phase,

What is the meaning of the horizontal red oval: in fact, the whole value of project management (a large project including even, maybe, first of all) is concentrated just inside this oval. All that is higher is the role of the customer.: he forms an idea, sometimes very abstract, sometimes formalized, and he then takes the product to his operation, as a result. All that is below the oval can be various contractors, participants, suppliers, some partners. The center of the oval is the main feature, i.e. need to be able to talk with the customer and correctly formulate the requirements; it is necessary to decompose them correctly, to make sure that they are all equally understood by everyone (there are formal criteria for how to test and take this requirement into work); one must be able to assign the task to the lower layer of participants (for example, all contractors or software developers) so that it is clearly formulated and nothing is lost. And on the right side, you should be able to do everything the other way around, that is, to accept work, test for compliance with those requirements,

Another such general, theoretical, perhaps aspect: probably everyone is familiar with the classic project management triangle, when it is necessary to provide three parameters - time, cost and quality in the project. Standard joke: “choose two any”. In terms of time management and cost management, all technologies have long been invented, i.e. take, apply best practices, learn technologies, techniques. But the main problems that arise in the project are always associated with quality.. From my experience (and I have quite a lot of experience in different directions and industries): there is always some problem with the formulation of requirements, which then pops up at the end of the project, or something someone did wrong, checked incorrectly, tested, and This has emerged in the next stage. Therefore, the main focus when working on a project now needs to be done on quality. You can work with quality; international standards (ISO 9000, etc.) have standardized documentation describing the concept of quality.

But there are two more technologies that say: you need to manage requirements and configuration. It is very important to have these two practices in good quality and to track them, especially when it comes to large projects. These design and configuration processes are actually the quality management of the entire project.

For capital construction projects, for example, a nuclear power plant, it is very important that you have a detailed information model, i.e. almost everything is now transferred to the figure: if you did something not in digital technologies, then with a high degree of probability an error will occur at the construction stage. For example, any ventilation pipe and a pipe connected with a fire extinguishing will intersect somewhere, and you will find it not in a computer where it was possible very cheaply and to fix quickly.and then, when all this is already welded, screwed, real money is spent, and you will need to break something, redesign, sometimes even something will need to be changed in terms of project approvals - this immediately affects the cost, the deadlines. Therefore, it is very important to test many things in a virtual environment . In fact, when we build / create an object, we test it twice: for the first time we completely do the digital double in the information environment and check the operation of the systems, the work related to the construction and the design; the second time when the first check is passed is in the real physical world. This is a very important point, because now it is the most important trend from the point of view of “physics”: a lot is being done in the computer.

Previously, for example, how the plane was made: designed, then a huge number of full-scale tests were carried out (aerotube, huge mock-ups), it was all blown out, then the plane was built, it was tested - it took many years ... The task was set - could it be done in virtual environment, i.e. so that the first built aircraft would take off at once and fly according to the characteristics set. This task has now been solved: most of the aircraft are designed entirely in a computer and are tested there as well, until all the flight characteristics are tested and only then the correct production task is given , done the manufacturing process monitoredso that everything corresponds to the virtual models, - and the very first built aircraft flies according to the characteristics (it is clear that some fine tweaks are underway, but there is not as much criticism as it was before).

A similar situation is happening now in capital construction: almost everything should be done in a virtual environment, and only then during the construction phase the main task should be to check that the real building corresponds to what you drew in the computer and that everything is done exactly for this technology. As an example, there are so-called technological schemes : we model physicalthe processes of the equipment, we see how it will behave in a particular environment, how it will pump liquid / gas, etc. - all this is simulated in a computer related to 3D.

It is very important that you do not lose anything in 3D, in this information model: you draw a diagram, it works for you in a certain way, and then the computer checks that you don’t really forget some kind of valve or some piece of pipe that you must be in terms of process technology. Now the computer checks a lot of things for the designer. You can say "lay me, please, the pipe from here to that angle," and a computer with certain rules laid in it lay the pipeline. Maybe from science fiction films, remember how the design of objects is shown there: a large flat screen is hung out, and there a person designs a few skyscrapers with several signs - we are in fact close to these technologies, the very principle of generating design corresponds to this in many ways. Important,

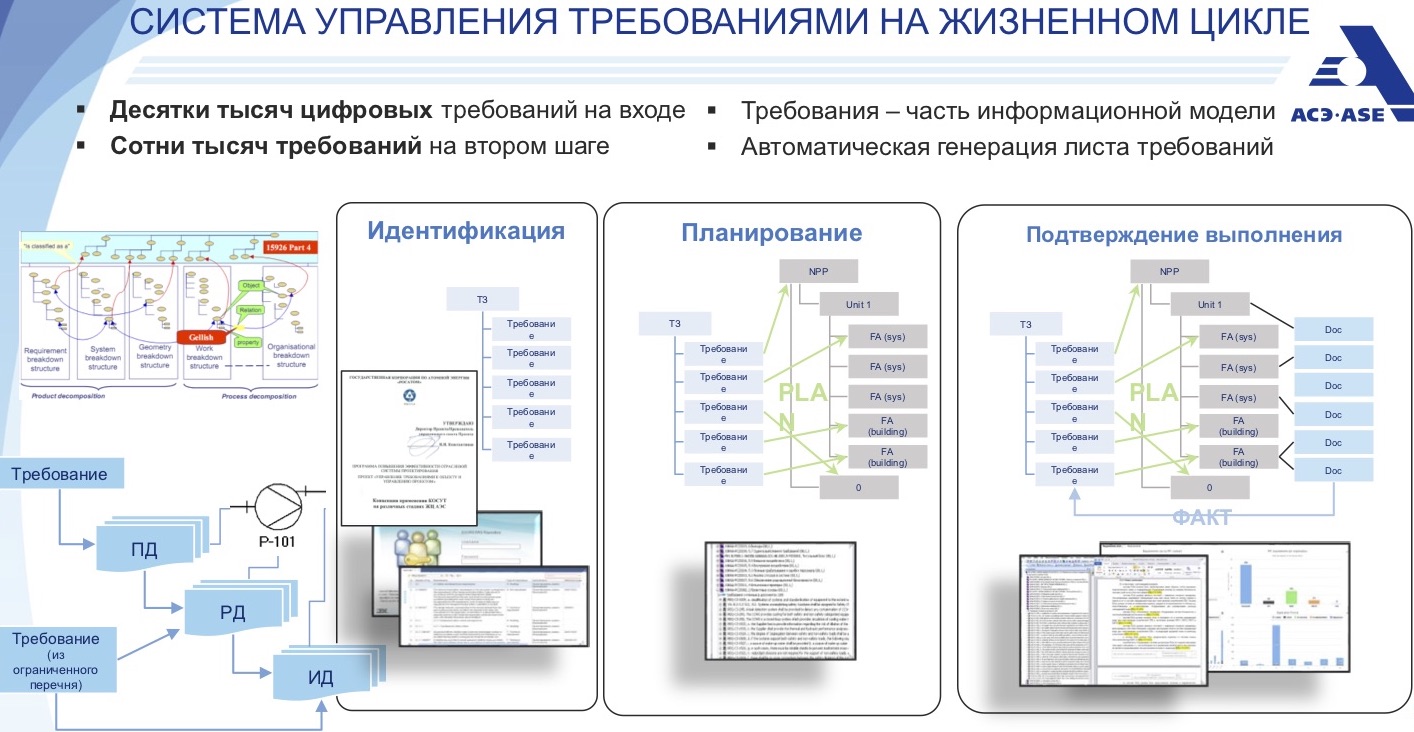

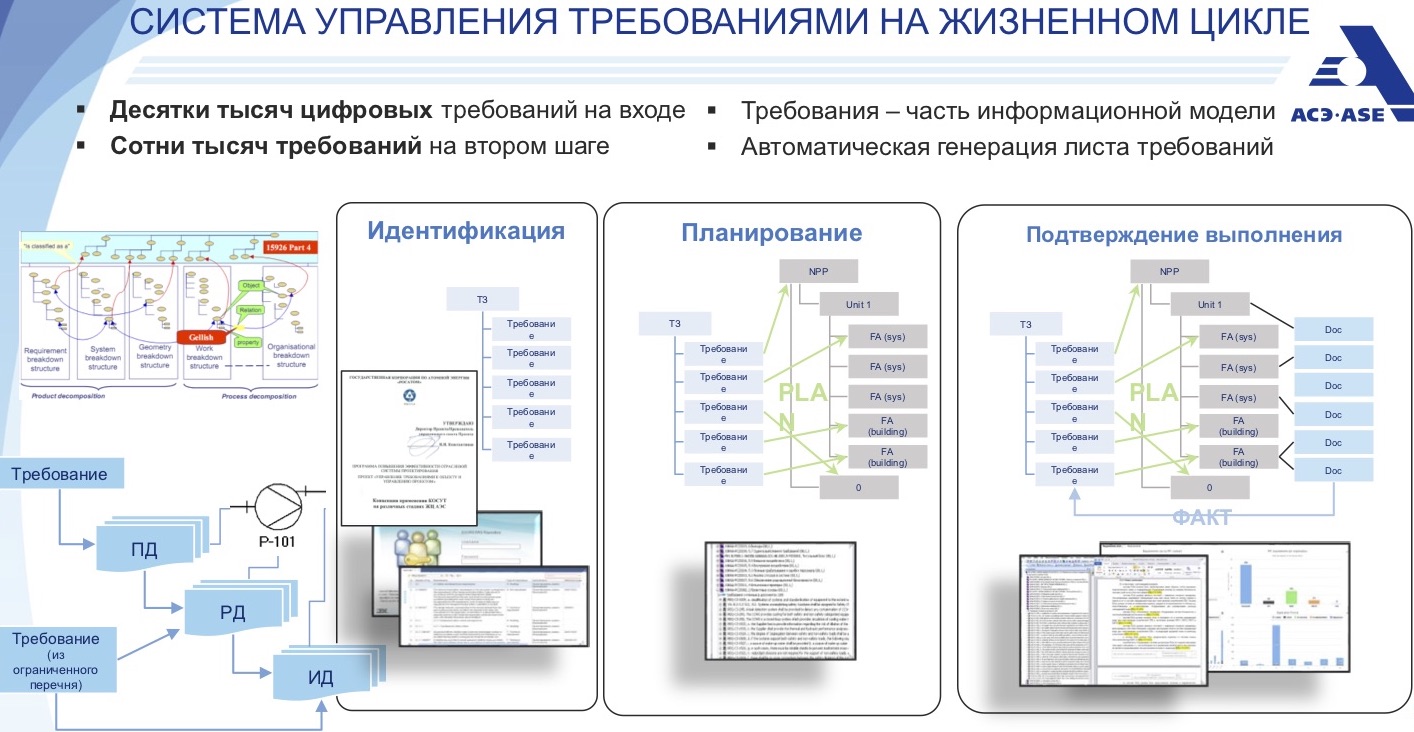

An important process, as I said, is requirements management . At the “entrance”, when a customer comes to us, especially a qualified one, he gives us not a classical technical task (Talmud on paper “to assemble a station”), but a database of digital requirements . These are approximately 15-20 thousand requirements, each of which has a formalized look, and the task is to ensure that these requirements are met during the project, i.e. The project will be checked for compliance with these requirements. And the customer says: “At the stage of everythingthe process of creating an object, designing an object, every time you prove to me that you are doing this object in the name of fulfilling the requirements, and do not invent something to bring a non-compliant project in five years. You must have an information system, in which I can go at any time and see that all the actions you are doing are somehow related to the fulfillment of the requirements that I initially set for you. ”

It is important that these 15-20 thousand - this is not the final requirements. Yes, very often they seem to sound rude, very simple - for example, “to fulfill such a standard”. But in fact, this standard in itself represents a huge array of requirements of the next level, and one of the first tasks is to reach the last final requirement, which can already be calculated / measured. And very quickly, these 15-20 thousand turn into hundreds of thousands. You understand that without information technology it is almost impossible to do.

Moreover, for each requirement, you need to have a test program, a testing methodology, a huge number of project participants are participating, distributed geographically, and this is exactly (when we talk about the horizontal red oval on the V-model) there is the main value of quality project management.

All this happens, first of all, through the technology of working with requirements - they live throughout the entire life cycle. The first time you check the requirements when you perform information models, develop project-working documentation - you say: "Look, we have made a digital model of the object, and it meets your requirements." At this stage, there is testing, acceptance, verification - the customer says: "Yes, great!". Then the second stage, when you start purchasing equipment and also put the corresponding set of requirements to manufacturers, equipment suppliers (already about a specifica piece of iron that will stand in this project), and check that they actually make it at the factory as you designed it in your model so that it meets the basic requirements. At the next stage, the construction process occurs, when all these glands, pumps, valves come to the object, and you collect a complex object from them, as from a large constructor. But there are hundreds of thousands of such elements, and all of them must be somehow connected, checked. And already at this stage the manufacturing technology is checked , the technological process itself is being tested. When the object is already built, you are testing - and does it work as you originally designed in the information model?

Next comes the process, let's say, of the next level in complexity - this is the process of configuration management . It is actually very simple. In terms of ideology, there are three entities that you manage in the project:

The configuration management standard says a simple thing: you must ensure that all these three elements match each other at any time. Then it turns out that you built an object qualitatively, in accordance with the requirements, described what you actually did and did what you actually described. But when, as I said, you have hundreds of thousands of requirements, millions of elements in a project, thousands of participants, then managing this process and ensuring that the elements match each other turns into a mega-complex task, which in terms of information technology has only recently been approached from a practical point of view. : after all, it should not be a scientific thing, but a practical one; ordinary people, simple designers, installers should use this technology. We now have this technology,

Here is the tag- this is the central element of the system, the design position (in other words, the pump, the valve), in fact, what your object consists of. In our case, these are hundreds of thousands of elements - each of them is networked with some set of characteristics, attributes, i.e. it has properties related to physics (heavy, light, red, white, etc.), with its parameters (how fast it pumps the fluid), in general, what this object does. He has a description so that you can make a purchase. At first, you do not even know what kind of pump it is and what kind of plant it will produce - you just know that it must pump the liquid from one place to another. This is a characteristic feature. And only then it becomes overgrown with some elements showing that this is a specific product. You should understand where this element is located:physically - on which floor, in which engineering system, in which building, i.e., this is also a set of parameters that determine geography, position. There are many such parameters. A network of semantically interconnected various attributes arises , which are laid into the data model, which then allows all project participants to manage configuration processes.

The picture below shows an example: at first you think that this is some kind of “thing” (as the designer thinks: “There must be some kind of thing pumping fluid from this point to this point with some kind of speed”). At the second step, a set of parameters appears (examples in the picture are highlighted in orange). Then you move on to the next stage of the project life cycle, where you understand that there should actually be two pieces, because you need a reserve (if one breaks, the second must turn on), etc. There is a logical scheme: there is still a set of parameters that are characteristic of this element at this stage. Then you move to the next stage, where you say: "Yes, now I understand that you are in fact a pump, not a valve, you have such and such characteristics, and I can start buying." And in the end, you buy a specific element, a specific piece of hardware arrives with a serial number, which says, “I'm not just a teapot - I'm a teapot maker at this and that number” - and this is another characteristic. This is an example of the movement of a single element along a life cycle.

As I have already said, there are hundreds of thousands of such elements that simultaneously live some kind of life of their own, and it means that at some point you look at this huge information model as an elephant - on the one hand you saw the tail, on the other - trunk, and everyone sees this model from its bell tower. It is very important to reconcile everyone with each other and say: “At the moment, such a slice of this model is important for us.” There are so-called configuration linesi.e. you say: in spite of the fact that we have a million elements here, today these 25,000 are important for us - and we are tracking them, we want them not to violate their parameters. And the following elements arise only at the next stage, otherwise this process will be simply uncontrollable. Configuration lines are exactly what allows you to keep such a large amount of data in your head at the same time.

For example, about a nuclear power plant, we say that it has an information model, and we keep in mind one thing: then this facility will be operated, it has existing operational and technological processes (it must generate electrical energy, work according to certain principles) . Accordingly, there is a control information system , which will then manage this object. In the process of designing and creating the object itself, in parallel with the V-model, you design and create an automated process control system for the object.that you build. This system also goes through the relevant stages of the life cycle. The atomic station is equipped with a huge number of sensors that generate various information, they are interconnected into a computer network, and, accordingly, you also need to design an object and test it: are there really any control signals going to these actuators as you intended in the computer? ; Will it not happen later that by pressing the button you will not open something, but close it. This element is tested in a computer, as a classic object, then each engineering system is tested separately, and then the whole object as a whole, and a multi-step approach to the acceptance of the results of the work performed is obtained. And at the same time it is very important that most of the testing should take place in the computer,

The picture shows an example: a fragment of the control panel of a nuclear power plant. This is a model in which the work of all the algorithms that will then stand on a real object is mathematically protected - and you test in advance the performance of these elements. Moreover, since the object is very complex, the whole service operation (people who will then sit here and make decisions) in advance to work off all their skills, practices, reactions to some events, like at the simulator level computer game (but only real). This is also an element of testing, because people are tested on how they react to relevant events. Thus, very much initially occurs in the virtual world.

The next stage is the construction stage, the creation of the object itself, when you are already entering the field, you start digging, pouring concrete, boiling metal, etc. There is a very important point here: you should also simulate many things in the computer in advance: you should see the sequence of operations , understand that this big pump really fits into this opening, into this door (and not as it actually happens: you brought it, but it can not be dragged, because there are smaller doors). An everyday example: a piano was brought to your home, but it did not fit into the door. When you build a nuclear power plant, in principle , this should not be, although you have such “pianos” hundreds of thousands, and it is clear that without computer modeling, checking all routes, sequences of operations, it is almost impossible to do. This means that the facility will need to make some non-standard decisions (which is not correct), therefore, we have developed a technology for modeling the construction process .

In the picture, cranes, machines and mechanisms are not images, but kinematic models.and they have a mathematician inside, which shows that he has given this crane, whether he really will lift this dimensional load on this outreach of the arrow and bring it where it needs to. In fact, all technologies are related to computer games, they have long been used in the practical field. In this case, for example, we are testing the location of the equipment on the site, because if it is put incorrectly, then it is months of rework. This is a huge iron mechanisms, they must immediately be properly arranged.

Similarly, from the point of view of the sequence of operations: who, what for, does, we first cook one pipe or another - the entire sequence must be tested. This is done by various organizations, so if you have not done this in a centralized way (in a computer system), then a great number of contradictions arise between them.

The picture is shallow, but the meaning is as follows: bottom right is actually the programming of the installer’s work to perform a particular operation, the sequence of what he should do (up to schedule by day, sometimes by the hour). But when you have a horizon of 5 years, day planning is a fairly detailed planning. In fact, we are programming the work process of installers at the site, and it must also be verified in the computer environment.

In fact, the trend is such that more and more things will be replaced, including robots. If you look at the BMW plant, which makes the car - there are almost no people. Even a certain number of years ago it was impossible. How does this happen? From my point of view, this became possible only due to the fact that all this was digitized. If a computer can play chess, then it’s no problem to make a machine for him, if everything is digitized correctly, it is algorithmic and checked.

There is a similar trend in capital construction technology. For many years, there have been 3D printers that print at home while simple, although there was a high, multi-storey one. It is clear that this cannot be done on the example of a nuclear power plant, but this is the trend. This is how it begins: the computer has learned to play checkers, after a certain number of years has learned to play chess, i.e. The trend is inevitable - the more you introduce digital technologies, you set up processes and algorithms, the greater the likelihood that less intelligent work will be performed by a computer.

In the picture one of the examples: in fact, we are programming the work of installers at the site - there are appropriate tools, IT mechanisms. As an example (bottom left), something similar to a mobile payment terminal is such an anti-vandal kiosk that stands right in the foundation pit or on the object in concrete, in metal, all in dust, with appropriate protection. Any installer can go to him, enter his password, see the three-dimensional model of the object that he has to do now, print or copy the task to himself on the tablet, go to do this work, note what he has done, go back and hand over the work. Previously, for this, he had to go, for example, to headquarters, which is located a kilometer from the object, - now everything happens directly on the site. And it's getting closer and closer: soon these monitors will not be needed, the person will receive all this right on the tablet. While we are putting such things, because there is a lot of concrete and metal there, modern communication networks do not always work, and there are no restrictions anymore. The younger generation now, in principle, does not exist without a smartphone or tablet. Those who are now becoming builders are already quietly working with computer technologies in the database, in principle, they will no longer need graphics, maybe there will be enough simulator in a computer that shows what, where and why a person should do. It is faster than drawing graphics in the old fashioned way. who are now becoming builders, they are already quietly working with computer technologies in the database, in principle, they will no longer need graphics, maybe there will be enough simulator in a computer that shows what, where and why a person should do. It is faster than drawing graphics in the old fashioned way. who are now becoming builders, they are already quietly working with computer technologies in the database, in principle, they will no longer need graphics, maybe there will be enough simulator in a computer that shows what, where and why a person should do. It is faster than drawing graphics in the old fashioned way.

Moreover, if we move further, here is an example from the Rostov station, which we started to put into operation in the so-called visual modeling studio. In fact, this is such an engineering 3D cinema, when you put on glasses and find yourself, roughly speaking, inside a nuclear power plant - you can see pipes around yourself, you can even move them, reschedule (several people do it at the same time), you can see the sequence of operations, test whether will pass this or that element. Various complex meetings are held here: instead of going to an object that is being built, for example, in Bangladesh, all specialists can connect remotely and see the current situation at the facility, compare it with the virtual model and suggest some solutions to the team that the moment is on the court. This is a distributed virtual reality, also an element of a computer game, but transferred into engineering, practical activity. You do not just live in a computer game - you really create some kind of value, building a serious large object, applying absolutely the same skills that you used, for example, when programming or computer modeling.

For example, the picture shows the installation of the reactor vessel, one of the main elements of the nuclear power plant. All that to the right and below is a virtual simulation . The body weighs about 330 tons, is a rather heavy element, you need to mount it to the nearest millimeter, and it should not be distorted in any way. Then huge pipelines are connected to it, in which the degrees of all angles of connection are also regulated, otherwise everything will not go according to the project. And, of course, all this is simulated in a computer: operations, cranes are modeled, and then the object is installed at the required place, where, for example, laser scanning is being tested, are we really fulfilled all the parameters that we originally laid in the project? ?

In the picture - one more example: at some stage of the construction to monitor the progress of construction, in the computer information model you mark points that you want to track in terms of the progress of work. And then a very simple technology - in these points a spherical photo is made at 360 degrees (this also doesn’t surprise anyone now), it is combined with a point from the 3D model (you can turn around yourself, scroll, look), and on the right you can to see that, from the point of view of the model, at this point in time had to be done, and on the left you see a real photo of what actually happens at the moment at the construction site. And you can very quickly compare, according to the plan, all this is going on or not according to plan, there are deviations or no deviations. Previously, you had to carry out a huge number of comparative operations - see the documents, compare them with the schedule - and now very quickly, in a matter of minutes, you can see the project’s movement, and remotely, that is, you don’t need to physically go to this object, you are watching how things really happen. Below - the slider in time, if you scroll through it, then you will have a “movie” about what is happening - both in the model and in real life.

Accordingly, as I have already said, the important point is not only modeling, but also verification upon completion of work. Many things are not done "by eye" when you came and saw - yes, you really put the equipment or poured concrete, but you do not have the means of formal control. Now there are such tools - you can scan the object with a laser, see that it really did not deviate from any of its axes. Moreover, now it can be done with the help of drones, if we speak about objects not inside the building, but on the site. The technology is actively developing: a person does not even need to walk and waste time if the object is large. You can regularly, moreover - in the automated mode, fill in, launch, using some algorithm, drones that will scan and in fact provide information on whether there are any deviations from what is in your model at the current time. There are corresponding other controls inside the object, the same spherical panoramas - so you actually make a slice of the automated control system (automatic control, testing, speaking your language) whether or not what you originally programmed as a project, in form of information model.

In conclusion, I would like to say that given the total digitalization of the physical world (and the trend is becoming more and more visible), the skills that are now developed in the IT industry, including testing, are becoming more and more active in penetrating the real physical industry. And in this regard, I would like, perhaps, to even unleash the potential of technology. For example, when we take on employees, we take many engineering positions, but from the IT industry, because sometimes it is easier to make an engineer from an IT specialist than to transfer the skills of this culture, flexible approaches, etc. to some engineers, although this Of course, not always the case.

Of course, no one can first build a station and then move the supporting wall due to the fact that the ventilation system can not be installed in the current configuration. Therefore, the processes of the real world more and more go to the "figure." How do you like the comment to the commit "Moving the main wall 2 meters north"? When designing and testing nuclear power plants, a fully digital approach is used: an information model is created, the classical V-model of life cycle management is applied to it. Thus, the NPP is transformed into a replicable and fully digital object. Testing and launching of modern nuclear power plants takes place in digital form, and only after that builders start installation using the same digital models.

From this article you will learn about what is a modern information system, how the development and testing of "capital" objects on the example of nuclear power plants.

The material is based on the interpretation of the report by Vyacheslav Alenkov , Director of Systems Engineering and Information Technologies of the Atomstroyexport engineering company (ASE) from our December conference Heisenbug 2017 Moscow.

In this article I will talk about how we use information management technologies, testing various kinds of processes in the construction of large capital facilities (in our case, these are nuclear power plants). Considering the fact that global introduction of digital technologies is underway in capital construction and these technologies are increasingly penetrating various industries, including those related to the physical world, IT-related technologies are also actively included in this area.

A little introduction: Atomstroyexport (ASE)- is a company that is an engineering division of the state corporation Rosatom. We are responsible for the design, procurement / supply and construction of virtually all nuclear power plants in Russia and abroad, in more than 15 countries of the world. More than 90% of our projects are the construction and design of stations abroad, and in this regard we absorb the best requirements, the best practices from international regulators setting standards and rules from international customers.

In many countries, the topic of requirements for the "figure" is very high. Many customers already need not only a built object in concrete / iron, which - here it is, stands in the field. Now you need to pass a digital modelfacility, which will live then throughout the life cycle of the nuclear power plant. The station is under construction for 5-10 years, then it is operated for 60 and more years, that is, everything that we have done (taking into account decommissioning up to 100 years) will then be used and live on the corresponding facility. At the same time, as you understand, almost every year in IT from the point of view of technology, something drastically changes, and how to predict it for 100 years is, of course, a big problem.

The nuclear power plant is, to date, probably one of the most complex objects that humanity builds in terms of the complexity of the object, the number of participants, and the safety of these objects. Therefore, without digital technology, these objects are almost impossible to build. Now the customers (despite the fact that the object is complex) each time make demands to build an object “even faster” and “even cheaper”, while we simultaneously build and design 30 such complex objects in different countries of the world, and manage such an array of information without digital technology is impossible. For example, the basic parameters are hundreds of thousands of positions of different equipment, and each position itself is a complex engineering object. These are tens of thousands of unique classes of equipment, Tens and hundreds of thousands of digital requirements at the entrance (I’ll talk about this in more detail later), this is an information model containing hundreds of thousands, sometimes millions of elements interconnected with each other - and this is not the final product: the model is still “flowing”, it is changing, a huge number of participants simultaneously work with this digital information, a large number of collisions arise between them, and it is very important to manage the whole process in an interconnected way so that it does not go away. Of course, there are issues related to the preparation of "containers" for storing this information, creating links between elements, for accepting / checking / testing everything that happens in the design process. At the design stage, the most information about the object arises, and only then, at the construction stage, it changes.

Information model and V-model

One of the first stages is the creation of an information model , which, of course, includes the concept of 3D. (The 3D model is easier to understand, because everything is presented visually.) We are talking about the information model, because 3D is part of the information: there is a large amount of various mathematical data and attributes. Take an element, for example, a pump (of which, as I said, hundreds of thousands): each of them has some set of attributes that are characteristic of this pump, and these attributes change throughout the entire life cycle. This information model is actually a single source of truth, to which everyone turns, takes this information and uses it in its activities when designing such large objects as a nuclear power plant.

Accordingly, a single information space is created around the information model , which allows all participants to gain access there, track changes that he makes himself or some other project participants who are geographically distributed, and the only thing that brings them together is this informational model.

An important point is the requirements management processes and configuration management processes . Most of these processes at one time came just from the management of projects that migrated from software engineering, moved to system engineering (this is about the large engineering objects created in the physical world).

Probably everyone is familiar with the concept of "V-model" - in fact, the software is also developed in accordance with the V-model: requirements are formed, the next stage is the architecture, then the design process (design, engineering design) then the implementation stage creating an object. And then there is a reverse-upstream process, when you need to test, carry out various processes associated with verification, with acceptance, with verification and ultimately hand over to the customer, who must make sure that he received exactly what he had in mind. Therefore, there are two processes - verification and acceptance. I think everyone knows how they differ. Verification is a formal compliance with the technical assignment: you had 500 wishes - we ticked each one, and then, we fulfilled 500formal answers. And the acceptance also includes satisfactionthe customer, i.e., not only you have completed everything formally , but he really got what he wanted. Therefore, both processes are important.

The V-model is so wide, because in the modern world no one waits for one stage to complete (for example, the requirements development stage), and design and manufacturing begin. If you look at the cut (t, time), then the vertical straight red line just shows that the project is simultaneously in several stages of the life cycle, that is, somewhere else, perhaps, the customer is determined with the requirements, somewhere the project development is already in full swing, and somewhere, roughly speaking, they began to dig a pit (because everything is clear about it, there is already a project, etc.) d.). Thus, in this regard, there are even greater requirements for the coordination of project participants, because you do not expect the end of the stage. Actually, these topics related to agile approaches with Agile - they are now actively used during the construction phase,

What is the meaning of the horizontal red oval: in fact, the whole value of project management (a large project including even, maybe, first of all) is concentrated just inside this oval. All that is higher is the role of the customer.: he forms an idea, sometimes very abstract, sometimes formalized, and he then takes the product to his operation, as a result. All that is below the oval can be various contractors, participants, suppliers, some partners. The center of the oval is the main feature, i.e. need to be able to talk with the customer and correctly formulate the requirements; it is necessary to decompose them correctly, to make sure that they are all equally understood by everyone (there are formal criteria for how to test and take this requirement into work); one must be able to assign the task to the lower layer of participants (for example, all contractors or software developers) so that it is clearly formulated and nothing is lost. And on the right side, you should be able to do everything the other way around, that is, to accept work, test for compliance with those requirements,

Another such general, theoretical, perhaps aspect: probably everyone is familiar with the classic project management triangle, when it is necessary to provide three parameters - time, cost and quality in the project. Standard joke: “choose two any”. In terms of time management and cost management, all technologies have long been invented, i.e. take, apply best practices, learn technologies, techniques. But the main problems that arise in the project are always associated with quality.. From my experience (and I have quite a lot of experience in different directions and industries): there is always some problem with the formulation of requirements, which then pops up at the end of the project, or something someone did wrong, checked incorrectly, tested, and This has emerged in the next stage. Therefore, the main focus when working on a project now needs to be done on quality. You can work with quality; international standards (ISO 9000, etc.) have standardized documentation describing the concept of quality.

But there are two more technologies that say: you need to manage requirements and configuration. It is very important to have these two practices in good quality and to track them, especially when it comes to large projects. These design and configuration processes are actually the quality management of the entire project.

For capital construction projects, for example, a nuclear power plant, it is very important that you have a detailed information model, i.e. almost everything is now transferred to the figure: if you did something not in digital technologies, then with a high degree of probability an error will occur at the construction stage. For example, any ventilation pipe and a pipe connected with a fire extinguishing will intersect somewhere, and you will find it not in a computer where it was possible very cheaply and to fix quickly.and then, when all this is already welded, screwed, real money is spent, and you will need to break something, redesign, sometimes even something will need to be changed in terms of project approvals - this immediately affects the cost, the deadlines. Therefore, it is very important to test many things in a virtual environment . In fact, when we build / create an object, we test it twice: for the first time we completely do the digital double in the information environment and check the operation of the systems, the work related to the construction and the design; the second time when the first check is passed is in the real physical world. This is a very important point, because now it is the most important trend from the point of view of “physics”: a lot is being done in the computer.

Previously, for example, how the plane was made: designed, then a huge number of full-scale tests were carried out (aerotube, huge mock-ups), it was all blown out, then the plane was built, it was tested - it took many years ... The task was set - could it be done in virtual environment, i.e. so that the first built aircraft would take off at once and fly according to the characteristics set. This task has now been solved: most of the aircraft are designed entirely in a computer and are tested there as well, until all the flight characteristics are tested and only then the correct production task is given , done the manufacturing process monitoredso that everything corresponds to the virtual models, - and the very first built aircraft flies according to the characteristics (it is clear that some fine tweaks are underway, but there is not as much criticism as it was before).

A similar situation is happening now in capital construction: almost everything should be done in a virtual environment, and only then during the construction phase the main task should be to check that the real building corresponds to what you drew in the computer and that everything is done exactly for this technology. As an example, there are so-called technological schemes : we model physicalthe processes of the equipment, we see how it will behave in a particular environment, how it will pump liquid / gas, etc. - all this is simulated in a computer related to 3D.

It is very important that you do not lose anything in 3D, in this information model: you draw a diagram, it works for you in a certain way, and then the computer checks that you don’t really forget some kind of valve or some piece of pipe that you must be in terms of process technology. Now the computer checks a lot of things for the designer. You can say "lay me, please, the pipe from here to that angle," and a computer with certain rules laid in it lay the pipeline. Maybe from science fiction films, remember how the design of objects is shown there: a large flat screen is hung out, and there a person designs a few skyscrapers with several signs - we are in fact close to these technologies, the very principle of generating design corresponds to this in many ways. Important,

Requirements Management

An important process, as I said, is requirements management . At the “entrance”, when a customer comes to us, especially a qualified one, he gives us not a classical technical task (Talmud on paper “to assemble a station”), but a database of digital requirements . These are approximately 15-20 thousand requirements, each of which has a formalized look, and the task is to ensure that these requirements are met during the project, i.e. The project will be checked for compliance with these requirements. And the customer says: “At the stage of everythingthe process of creating an object, designing an object, every time you prove to me that you are doing this object in the name of fulfilling the requirements, and do not invent something to bring a non-compliant project in five years. You must have an information system, in which I can go at any time and see that all the actions you are doing are somehow related to the fulfillment of the requirements that I initially set for you. ”

It is important that these 15-20 thousand - this is not the final requirements. Yes, very often they seem to sound rude, very simple - for example, “to fulfill such a standard”. But in fact, this standard in itself represents a huge array of requirements of the next level, and one of the first tasks is to reach the last final requirement, which can already be calculated / measured. And very quickly, these 15-20 thousand turn into hundreds of thousands. You understand that without information technology it is almost impossible to do.

Moreover, for each requirement, you need to have a test program, a testing methodology, a huge number of project participants are participating, distributed geographically, and this is exactly (when we talk about the horizontal red oval on the V-model) there is the main value of quality project management.

All this happens, first of all, through the technology of working with requirements - they live throughout the entire life cycle. The first time you check the requirements when you perform information models, develop project-working documentation - you say: "Look, we have made a digital model of the object, and it meets your requirements." At this stage, there is testing, acceptance, verification - the customer says: "Yes, great!". Then the second stage, when you start purchasing equipment and also put the corresponding set of requirements to manufacturers, equipment suppliers (already about a specifica piece of iron that will stand in this project), and check that they actually make it at the factory as you designed it in your model so that it meets the basic requirements. At the next stage, the construction process occurs, when all these glands, pumps, valves come to the object, and you collect a complex object from them, as from a large constructor. But there are hundreds of thousands of such elements, and all of them must be somehow connected, checked. And already at this stage the manufacturing technology is checked , the technological process itself is being tested. When the object is already built, you are testing - and does it work as you originally designed in the information model?

Configuration management

Next comes the process, let's say, of the next level in complexity - this is the process of configuration management . It is actually very simple. In terms of ideology, there are three entities that you manage in the project:

- what you wanted to do, i.e. the original idea, the requirements, all the basic messages that appeared before you started creating your object;

- what you think and do, i.e. all that describes your object: drawings, information models, documentation - a virtual description of a physical object;

- in fact, the object you built in concrete or in metal.

The configuration management standard says a simple thing: you must ensure that all these three elements match each other at any time. Then it turns out that you built an object qualitatively, in accordance with the requirements, described what you actually did and did what you actually described. But when, as I said, you have hundreds of thousands of requirements, millions of elements in a project, thousands of participants, then managing this process and ensuring that the elements match each other turns into a mega-complex task, which in terms of information technology has only recently been approached from a practical point of view. : after all, it should not be a scientific thing, but a practical one; ordinary people, simple designers, installers should use this technology. We now have this technology,

Here is the tag- this is the central element of the system, the design position (in other words, the pump, the valve), in fact, what your object consists of. In our case, these are hundreds of thousands of elements - each of them is networked with some set of characteristics, attributes, i.e. it has properties related to physics (heavy, light, red, white, etc.), with its parameters (how fast it pumps the fluid), in general, what this object does. He has a description so that you can make a purchase. At first, you do not even know what kind of pump it is and what kind of plant it will produce - you just know that it must pump the liquid from one place to another. This is a characteristic feature. And only then it becomes overgrown with some elements showing that this is a specific product. You should understand where this element is located:physically - on which floor, in which engineering system, in which building, i.e., this is also a set of parameters that determine geography, position. There are many such parameters. A network of semantically interconnected various attributes arises , which are laid into the data model, which then allows all project participants to manage configuration processes.

The picture below shows an example: at first you think that this is some kind of “thing” (as the designer thinks: “There must be some kind of thing pumping fluid from this point to this point with some kind of speed”). At the second step, a set of parameters appears (examples in the picture are highlighted in orange). Then you move on to the next stage of the project life cycle, where you understand that there should actually be two pieces, because you need a reserve (if one breaks, the second must turn on), etc. There is a logical scheme: there is still a set of parameters that are characteristic of this element at this stage. Then you move to the next stage, where you say: "Yes, now I understand that you are in fact a pump, not a valve, you have such and such characteristics, and I can start buying." And in the end, you buy a specific element, a specific piece of hardware arrives with a serial number, which says, “I'm not just a teapot - I'm a teapot maker at this and that number” - and this is another characteristic. This is an example of the movement of a single element along a life cycle.

As I have already said, there are hundreds of thousands of such elements that simultaneously live some kind of life of their own, and it means that at some point you look at this huge information model as an elephant - on the one hand you saw the tail, on the other - trunk, and everyone sees this model from its bell tower. It is very important to reconcile everyone with each other and say: “At the moment, such a slice of this model is important for us.” There are so-called configuration linesi.e. you say: in spite of the fact that we have a million elements here, today these 25,000 are important for us - and we are tracking them, we want them not to violate their parameters. And the following elements arise only at the next stage, otherwise this process will be simply uncontrollable. Configuration lines are exactly what allows you to keep such a large amount of data in your head at the same time.

Testing in practice

For example, about a nuclear power plant, we say that it has an information model, and we keep in mind one thing: then this facility will be operated, it has existing operational and technological processes (it must generate electrical energy, work according to certain principles) . Accordingly, there is a control information system , which will then manage this object. In the process of designing and creating the object itself, in parallel with the V-model, you design and create an automated process control system for the object.that you build. This system also goes through the relevant stages of the life cycle. The atomic station is equipped with a huge number of sensors that generate various information, they are interconnected into a computer network, and, accordingly, you also need to design an object and test it: are there really any control signals going to these actuators as you intended in the computer? ; Will it not happen later that by pressing the button you will not open something, but close it. This element is tested in a computer, as a classic object, then each engineering system is tested separately, and then the whole object as a whole, and a multi-step approach to the acceptance of the results of the work performed is obtained. And at the same time it is very important that most of the testing should take place in the computer,

The picture shows an example: a fragment of the control panel of a nuclear power plant. This is a model in which the work of all the algorithms that will then stand on a real object is mathematically protected - and you test in advance the performance of these elements. Moreover, since the object is very complex, the whole service operation (people who will then sit here and make decisions) in advance to work off all their skills, practices, reactions to some events, like at the simulator level computer game (but only real). This is also an element of testing, because people are tested on how they react to relevant events. Thus, very much initially occurs in the virtual world.

The next stage is the construction stage, the creation of the object itself, when you are already entering the field, you start digging, pouring concrete, boiling metal, etc. There is a very important point here: you should also simulate many things in the computer in advance: you should see the sequence of operations , understand that this big pump really fits into this opening, into this door (and not as it actually happens: you brought it, but it can not be dragged, because there are smaller doors). An everyday example: a piano was brought to your home, but it did not fit into the door. When you build a nuclear power plant, in principle , this should not be, although you have such “pianos” hundreds of thousands, and it is clear that without computer modeling, checking all routes, sequences of operations, it is almost impossible to do. This means that the facility will need to make some non-standard decisions (which is not correct), therefore, we have developed a technology for modeling the construction process .

In the picture, cranes, machines and mechanisms are not images, but kinematic models.and they have a mathematician inside, which shows that he has given this crane, whether he really will lift this dimensional load on this outreach of the arrow and bring it where it needs to. In fact, all technologies are related to computer games, they have long been used in the practical field. In this case, for example, we are testing the location of the equipment on the site, because if it is put incorrectly, then it is months of rework. This is a huge iron mechanisms, they must immediately be properly arranged.

Similarly, from the point of view of the sequence of operations: who, what for, does, we first cook one pipe or another - the entire sequence must be tested. This is done by various organizations, so if you have not done this in a centralized way (in a computer system), then a great number of contradictions arise between them.

The picture is shallow, but the meaning is as follows: bottom right is actually the programming of the installer’s work to perform a particular operation, the sequence of what he should do (up to schedule by day, sometimes by the hour). But when you have a horizon of 5 years, day planning is a fairly detailed planning. In fact, we are programming the work process of installers at the site, and it must also be verified in the computer environment.

Digitized construction

In fact, the trend is such that more and more things will be replaced, including robots. If you look at the BMW plant, which makes the car - there are almost no people. Even a certain number of years ago it was impossible. How does this happen? From my point of view, this became possible only due to the fact that all this was digitized. If a computer can play chess, then it’s no problem to make a machine for him, if everything is digitized correctly, it is algorithmic and checked.

There is a similar trend in capital construction technology. For many years, there have been 3D printers that print at home while simple, although there was a high, multi-storey one. It is clear that this cannot be done on the example of a nuclear power plant, but this is the trend. This is how it begins: the computer has learned to play checkers, after a certain number of years has learned to play chess, i.e. The trend is inevitable - the more you introduce digital technologies, you set up processes and algorithms, the greater the likelihood that less intelligent work will be performed by a computer.

In the picture one of the examples: in fact, we are programming the work of installers at the site - there are appropriate tools, IT mechanisms. As an example (bottom left), something similar to a mobile payment terminal is such an anti-vandal kiosk that stands right in the foundation pit or on the object in concrete, in metal, all in dust, with appropriate protection. Any installer can go to him, enter his password, see the three-dimensional model of the object that he has to do now, print or copy the task to himself on the tablet, go to do this work, note what he has done, go back and hand over the work. Previously, for this, he had to go, for example, to headquarters, which is located a kilometer from the object, - now everything happens directly on the site. And it's getting closer and closer: soon these monitors will not be needed, the person will receive all this right on the tablet. While we are putting such things, because there is a lot of concrete and metal there, modern communication networks do not always work, and there are no restrictions anymore. The younger generation now, in principle, does not exist without a smartphone or tablet. Those who are now becoming builders are already quietly working with computer technologies in the database, in principle, they will no longer need graphics, maybe there will be enough simulator in a computer that shows what, where and why a person should do. It is faster than drawing graphics in the old fashioned way. who are now becoming builders, they are already quietly working with computer technologies in the database, in principle, they will no longer need graphics, maybe there will be enough simulator in a computer that shows what, where and why a person should do. It is faster than drawing graphics in the old fashioned way. who are now becoming builders, they are already quietly working with computer technologies in the database, in principle, they will no longer need graphics, maybe there will be enough simulator in a computer that shows what, where and why a person should do. It is faster than drawing graphics in the old fashioned way.

Moreover, if we move further, here is an example from the Rostov station, which we started to put into operation in the so-called visual modeling studio. In fact, this is such an engineering 3D cinema, when you put on glasses and find yourself, roughly speaking, inside a nuclear power plant - you can see pipes around yourself, you can even move them, reschedule (several people do it at the same time), you can see the sequence of operations, test whether will pass this or that element. Various complex meetings are held here: instead of going to an object that is being built, for example, in Bangladesh, all specialists can connect remotely and see the current situation at the facility, compare it with the virtual model and suggest some solutions to the team that the moment is on the court. This is a distributed virtual reality, also an element of a computer game, but transferred into engineering, practical activity. You do not just live in a computer game - you really create some kind of value, building a serious large object, applying absolutely the same skills that you used, for example, when programming or computer modeling.

For example, the picture shows the installation of the reactor vessel, one of the main elements of the nuclear power plant. All that to the right and below is a virtual simulation . The body weighs about 330 tons, is a rather heavy element, you need to mount it to the nearest millimeter, and it should not be distorted in any way. Then huge pipelines are connected to it, in which the degrees of all angles of connection are also regulated, otherwise everything will not go according to the project. And, of course, all this is simulated in a computer: operations, cranes are modeled, and then the object is installed at the required place, where, for example, laser scanning is being tested, are we really fulfilled all the parameters that we originally laid in the project? ?

In the picture - one more example: at some stage of the construction to monitor the progress of construction, in the computer information model you mark points that you want to track in terms of the progress of work. And then a very simple technology - in these points a spherical photo is made at 360 degrees (this also doesn’t surprise anyone now), it is combined with a point from the 3D model (you can turn around yourself, scroll, look), and on the right you can to see that, from the point of view of the model, at this point in time had to be done, and on the left you see a real photo of what actually happens at the moment at the construction site. And you can very quickly compare, according to the plan, all this is going on or not according to plan, there are deviations or no deviations. Previously, you had to carry out a huge number of comparative operations - see the documents, compare them with the schedule - and now very quickly, in a matter of minutes, you can see the project’s movement, and remotely, that is, you don’t need to physically go to this object, you are watching how things really happen. Below - the slider in time, if you scroll through it, then you will have a “movie” about what is happening - both in the model and in real life.

Accordingly, as I have already said, the important point is not only modeling, but also verification upon completion of work. Many things are not done "by eye" when you came and saw - yes, you really put the equipment or poured concrete, but you do not have the means of formal control. Now there are such tools - you can scan the object with a laser, see that it really did not deviate from any of its axes. Moreover, now it can be done with the help of drones, if we speak about objects not inside the building, but on the site. The technology is actively developing: a person does not even need to walk and waste time if the object is large. You can regularly, moreover - in the automated mode, fill in, launch, using some algorithm, drones that will scan and in fact provide information on whether there are any deviations from what is in your model at the current time. There are corresponding other controls inside the object, the same spherical panoramas - so you actually make a slice of the automated control system (automatic control, testing, speaking your language) whether or not what you originally programmed as a project, in form of information model.

In conclusion, I would like to say that given the total digitalization of the physical world (and the trend is becoming more and more visible), the skills that are now developed in the IT industry, including testing, are becoming more and more active in penetrating the real physical industry. And in this regard, I would like, perhaps, to even unleash the potential of technology. For example, when we take on employees, we take many engineering positions, but from the IT industry, because sometimes it is easier to make an engineer from an IT specialist than to transfer the skills of this culture, flexible approaches, etc. to some engineers, although this Of course, not always the case.

If you liked this report, please note: December 6-7, Heisenbug comes to Moscow again. There will be useful tips, amazing stories, and the worlds of testers and developers again come into contact. You can always see the current status of the program (and, if desired, purchase a ticket) on the conference website .