How we did the right production

By the way, it took six years of research.

Obviously, if you produce something (or carry out projects, this is not so important), then you really, really want to do it:

- quickly

- efficiently

- on time

- with minimal cost (investment)

This means that must be found some kind of solution that allows you to do just that.

But there is a nuance. Any multi-user environment does not accept complex solutions. Or you will have to go broke on training and advanced training, bringing the level of education of employees to candidates of science.

We began our research in this part in the year 2006, believing that the best production solution is MRP. In 2010, after some implementation experiments, we realized that MRP does not lead to increased efficiency. The number of orders made on time is not increasing, stocks are not decreasing, production speed is not growing. And often even the opposite. I wrote an article about this. Pretty emotional. Apparently seriously hitting those who earn on the implementation of MRP. But the goal of introducing any management system should be to increase efficiency, isn't it? Many people forget about this, as well as the fact that the goal of business is to make money. Therefore, the implementation of MRP most often turns simply into a project to implement MRP, and not into a project to improve production efficiency.

In 2009, we found the right solution. This is Theory of Constraints (TOC), which by that time had been actively spreading in the West for about 10-15 years (Hitachi, Boing, GM, P&G, ABB, Philips, etc.). But in Russia, as is often the case with innovation, almost no one has heard of it. Constraint Theory offers algorithms for both production management and project management. We made a bias towards production, but we did not forget about the projects.

I read the book “That Purpose” and realized that the Theory of Constraints allows you to produce and execute projects (this is another book, “The Critical Chain”) in accordance with the four points that are written about at the beginning of this article. Reading a book, you understand that this is what you need. But how to turn words into software ???

We need algorithms, but they were not. Finding people who know TOC well was almost unbelievable. I went to courses, but there was either a banal retelling of the book, or simply calculations that were removed from life. And I needed to understand how to issue production tasks, how to build a production schedule, how to determine the importance of a project task, etc.

And we started our own research and started trying to develop software. They began to actively talk about it. And then people appeared who were also interested in it. Meetings began, an exchange of experience. We collected information bit by bit, modeled, there were already implementations, after which we introduced adjustments to the algorithms. And so, in 2013, we did what we intended.

Theory of Constraints says: in a company there is always only one place that limits the productivity of the entire enterprise. And the productivity of the entire enterprise is strictly equal to the productivity of this particular place.

You can invest in new machines (or other objects) as much as you like, but if they are not a bottleneck, you will not get a productivity increase for the whole enterprise. This is an easy digression for those who want to evaluate the effectiveness of investments. The efficiency of investments in non-narrow places is at best equal to zero, and maybe negative, if you invest in new equipment to a bottleneck and do not agree on capacity. At the same time, investments in bottlenecks are the most effective because they can increase the productivity of the entire company.

1. Identify the narrow link.

2. Use its capabilities to the maximum.

3. Agree on the power of all other sections with a weak link (restriction).

4. Increase the performance of a narrow link.

5. Return to step number 1.

The systematic implementation of these steps will inevitably lead to an increase in the productivity of the entire company.

Stop.

How to find a narrow link? And how to use its capabilities to the maximum? And how to coordinate the capacity of other sites?

So we asked ourselves these questions over the years and looked for answers to them.

And after much research, the answers were found and translated into software observational algorithms.

So, first a little philosophy. You have clients, they need something from you. You must do what they need in a strictly set time frame and then customers will be loyal and will order more. Fulfilling orders (projects) on time is one way to increase sales. And if you do it fast

too , then ... Goldratt proceeded from this rule. Everything should be subordinate to the achievement of this particular task. Fulfillment of the order / project on time is the main task, and the work of the company should be built in accordance with it. That is, all parts of the enterprise — procurement, production, and fulfillment of tasks — must work to fulfill this task. Then the goal of the business - to make money - will be achieved.

1. The need is determined to produce what the customer ordered. Is there any need to do this? If the order is secured by stocks, it is not necessary to produce it. But that can change very quickly. The need to produce a product from each order is determined at any change in the situation. Example for illustrative purposes: a

customer called you and ordered goods number 1 in the amount of 3 pieces and asked him to provide it by 05/31/2013. If you have 3 pieces in stock, then you do not need to produce anything. Or if you have a production task in which such a product is made with some stock and this stock is enough.

But tomorrow another customer called you and asked for exactly the same product, also in the amount of 3 pcs., But by May 15th.

Question: under what order to produce?

Answer: of course, under the first, although yesterday there was nothing to be done under it.

Thus, the need for production for a particular order is determined at any change in the situation in the company relating to this product.

Then the system according to the same scheme determines the need for the production of nodes of various levels in your product and the need for the purchase of components. And as a result, two date-consistent lists are built. The so-called "to do sheet."

Both sheets are “live” and change whenever the situation changes.

But that is not enough. It’s not enough to understand what you have to buy. It is necessary to determine when to purchase it and when to produce it. If you have a need to buy a product, this does not mean that you need to buy it now. You buy / produce too early - you will spend precious working capital, which will then “lie” in the warehouse. And you take resources that could take something more priority.

You buy / produce too late - you will break the final deadlines. For this, the Theory of Constraints suggests using the so-called time buffers, which we also built into to do lists.

Prioritization! That is what matters! It is important to understand what is most important at the moment. What to do now, and what to do later. The same goes for project management tasks. It is important to understand what is the most important task in the implementation of the project. And the importance of the task is determined precisely by the state of the project time buffer. The less buffer left in the project, the higher the level of the task.

2. To achieve maximum production speed, each production site must do exactly those tasks that have the highest priority in terms of solving the main problem. The main task is to complete the order on time. For this, the system builds a production line, where each record has its own priority. Each entry is a name. This is not necessarily the name that the client ordered from you. Rather, it is definitely there, but there can be others besides it. For example, the intermediate nodes of your manufactured product. The priority is determined by the degree of approximation of the hour X. The closer the hour X, the higher the priority. Thus, each site receives those tasks that are most important. The production queues use the same time buffers, which I wrote about a little higher.

3. But even this is not enough. The points described above do not solve the problem of subordinating all production sites to a bottleneck. If this is not done, then there is every chance of organizing a traffic jam in production. In order not to “fall asleep” a narrow link, tasks should be issued strictly at the speed that the narrow link is able to “digest”.

And for this we came up with the so-called traffic light. Before issuing a task to the site, the dispatcher looks at the indications of the traffic light. If the traffic light is red, it means, most likely, it is impossible to issue a task. But it all depends on the specifics of production. If the bottleneck operates 24/7 (maximum use of the resources of the narrow link, step No. 2), then in the evening some queue may accumulate in front of it, which will be eliminated in the morning, because narrow places, for example, work only during the day.

In short, the traffic light helps the dispatcher make the right decision whether to issue tasks to the sections or not, thereby coordinating the performance of all sections with a bottleneck. By the way, the traffic light also helps to identify a bottleneck. The bottleneck is the one that is most often “red”, that is, it is constantly late in time. It is not always obvious, therefore the help of the “traffic light” is needed.

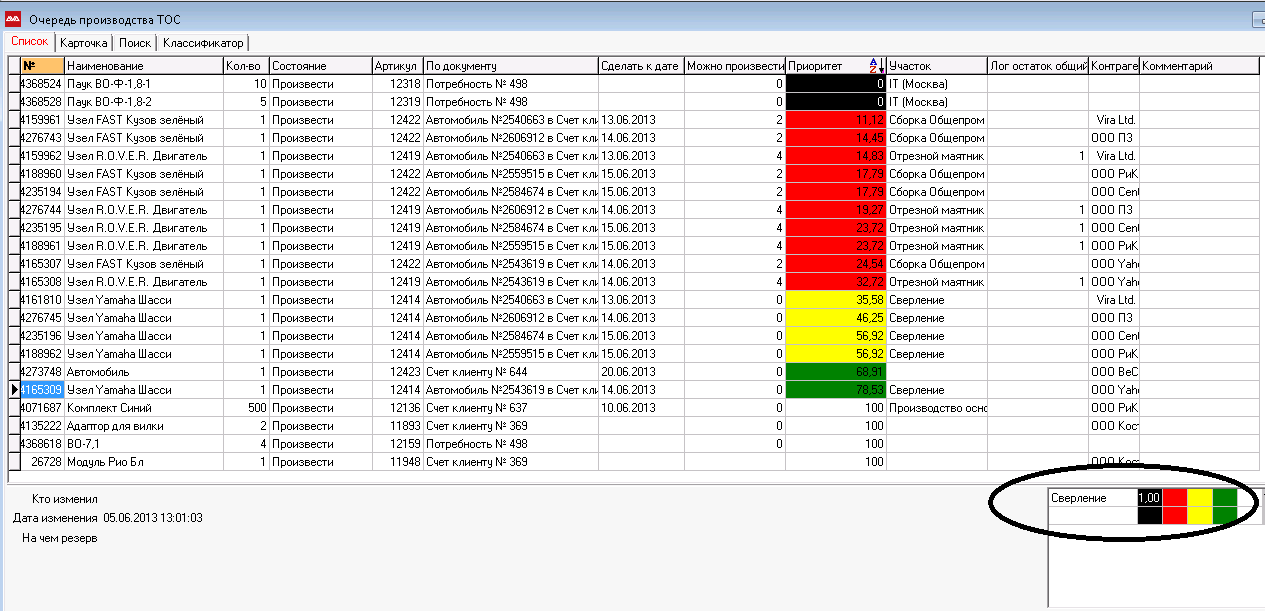

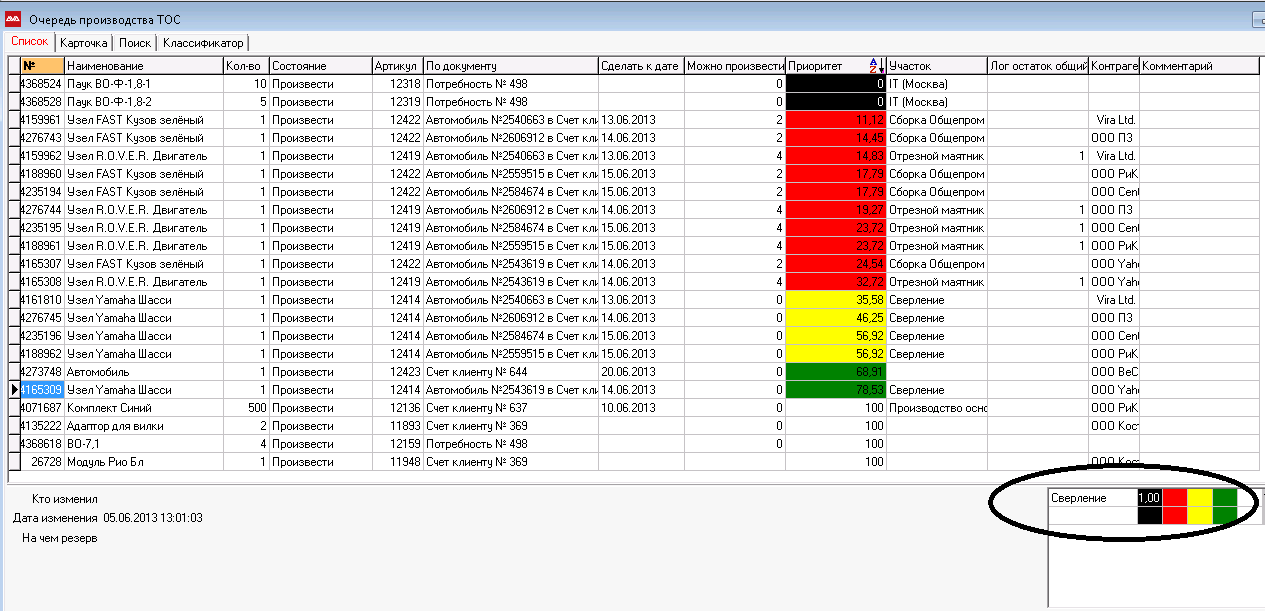

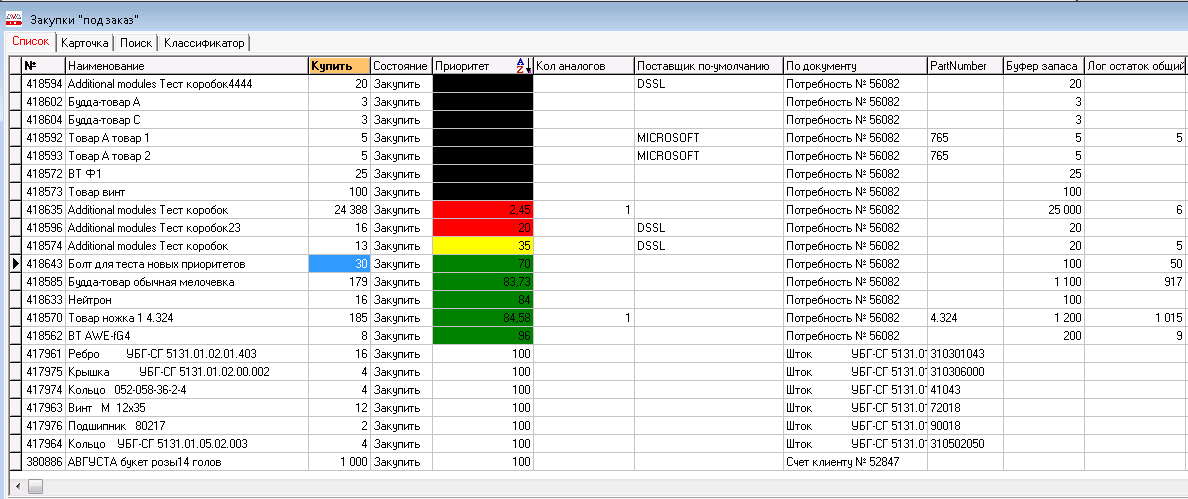

This is how the dispatcher’s workplace looks:

Now imagine the purchasing department at the factory. This is very often a pattern of chaos. The purchasing department not only does not know what it should buy, it does not know how much and when .

Such is the nature of man, that he cannot at one and the same moment engage in two things. A procurement manager can only do one thing at a time. Question: what should he do right now?

If he cannot unambiguously answer this question, then he will definitely buy the wrong and the wrong one. How this will affect the execution of the order is not for me to tell you.

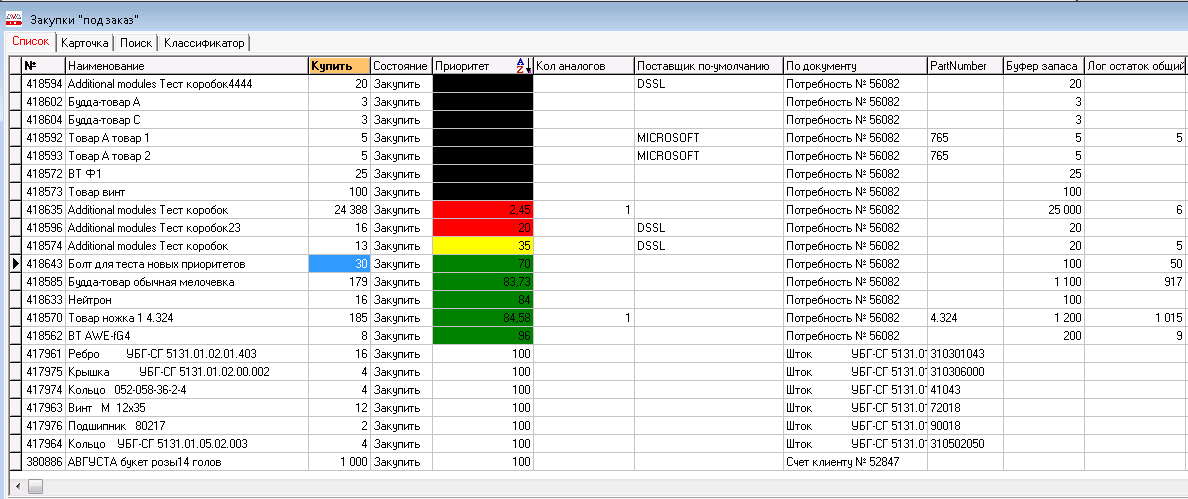

Therefore, the workplace of the sales manager looks like this:

That's it. This is a clear answer to the question "what should I do in the first place, and what in the second." A person is fully focused on what is more important right now. Buy from top to bottom.

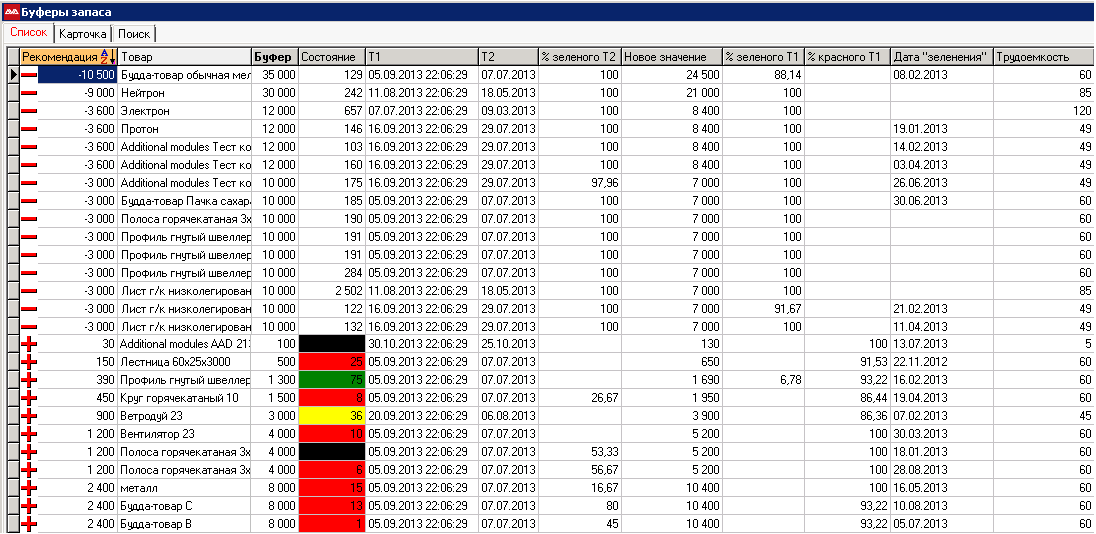

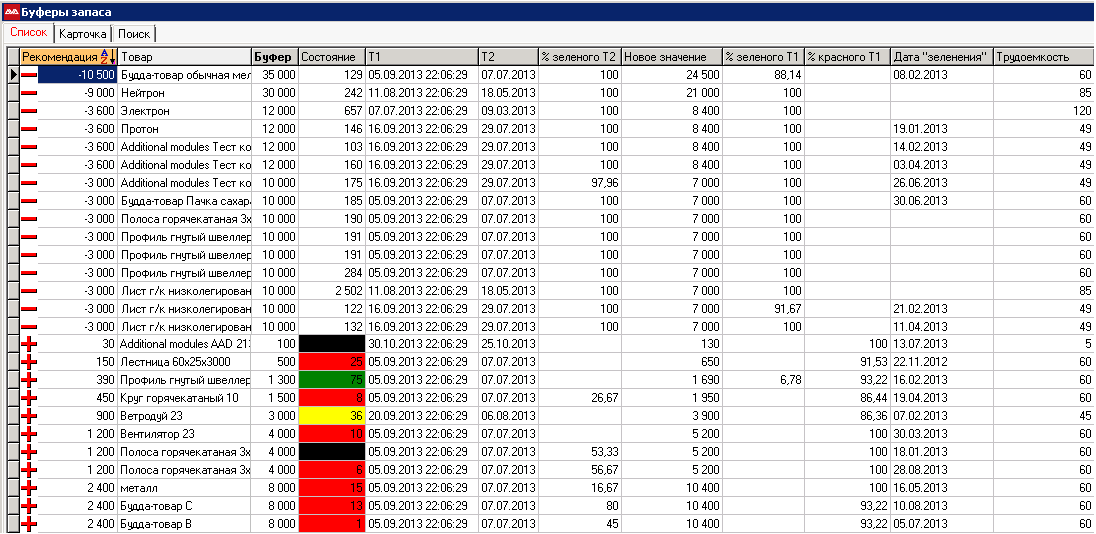

Well, in parallel, a responsible citizen is making decisions in the field of optimizing stock levels.

Constantly regulating them. The system unambiguously answers the question about the level of optimal reserves for each item.

Almost everyone knows what traffic jams are. They arise either in the place where a sharp narrowing occurs, or when an obstacle occurs. As a result of the occurrence of plugs, the total flow rate decreases sharply, sometimes almost to zero. If the road will always have a constant width and all cars will move at a constant speed, without constant braking and acceleration, there will be no traffic jams and the flow rate will be much higher than the flow rate with traffic jams.

The same thing happens in production. The task is very simple - to make sure that production is constantly maintained speed. This can only be done if this speed is maintained at the speed of a narrow link. And only after that it is possible to proceed to step No. 4 of the Theory of Constraints, that is, to increase the throughput of the weak link, thereby increasing the throughput of the entire production.

Well, then step number 5 :-)

Good luck with the implementation of TOC.

UPD At the insistent request of commentators, he added pictures to the text.

Obviously, if you produce something (or carry out projects, this is not so important), then you really, really want to do it:

- quickly

- efficiently

- on time

- with minimal cost (investment)

This means that must be found some kind of solution that allows you to do just that.

But there is a nuance. Any multi-user environment does not accept complex solutions. Or you will have to go broke on training and advanced training, bringing the level of education of employees to candidates of science.

We began our research in this part in the year 2006, believing that the best production solution is MRP. In 2010, after some implementation experiments, we realized that MRP does not lead to increased efficiency. The number of orders made on time is not increasing, stocks are not decreasing, production speed is not growing. And often even the opposite. I wrote an article about this. Pretty emotional. Apparently seriously hitting those who earn on the implementation of MRP. But the goal of introducing any management system should be to increase efficiency, isn't it? Many people forget about this, as well as the fact that the goal of business is to make money. Therefore, the implementation of MRP most often turns simply into a project to implement MRP, and not into a project to improve production efficiency.

In 2009, we found the right solution. This is Theory of Constraints (TOC), which by that time had been actively spreading in the West for about 10-15 years (Hitachi, Boing, GM, P&G, ABB, Philips, etc.). But in Russia, as is often the case with innovation, almost no one has heard of it. Constraint Theory offers algorithms for both production management and project management. We made a bias towards production, but we did not forget about the projects.

I read the book “That Purpose” and realized that the Theory of Constraints allows you to produce and execute projects (this is another book, “The Critical Chain”) in accordance with the four points that are written about at the beginning of this article. Reading a book, you understand that this is what you need. But how to turn words into software ???

We need algorithms, but they were not. Finding people who know TOC well was almost unbelievable. I went to courses, but there was either a banal retelling of the book, or simply calculations that were removed from life. And I needed to understand how to issue production tasks, how to build a production schedule, how to determine the importance of a project task, etc.

And we started our own research and started trying to develop software. They began to actively talk about it. And then people appeared who were also interested in it. Meetings began, an exchange of experience. We collected information bit by bit, modeled, there were already implementations, after which we introduced adjustments to the algorithms. And so, in 2013, we did what we intended.

Theory of Constraints says: in a company there is always only one place that limits the productivity of the entire enterprise. And the productivity of the entire enterprise is strictly equal to the productivity of this particular place.

You can invest in new machines (or other objects) as much as you like, but if they are not a bottleneck, you will not get a productivity increase for the whole enterprise. This is an easy digression for those who want to evaluate the effectiveness of investments. The efficiency of investments in non-narrow places is at best equal to zero, and maybe negative, if you invest in new equipment to a bottleneck and do not agree on capacity. At the same time, investments in bottlenecks are the most effective because they can increase the productivity of the entire company.

Five fundamental steps of the Theory of Constraints.

1. Identify the narrow link.

2. Use its capabilities to the maximum.

3. Agree on the power of all other sections with a weak link (restriction).

4. Increase the performance of a narrow link.

5. Return to step number 1.

The systematic implementation of these steps will inevitably lead to an increase in the productivity of the entire company.

Stop.

How to find a narrow link? And how to use its capabilities to the maximum? And how to coordinate the capacity of other sites?

So we asked ourselves these questions over the years and looked for answers to them.

And after much research, the answers were found and translated into software observational algorithms.

So, first a little philosophy. You have clients, they need something from you. You must do what they need in a strictly set time frame and then customers will be loyal and will order more. Fulfilling orders (projects) on time is one way to increase sales. And if you do it fast

too , then ... Goldratt proceeded from this rule. Everything should be subordinate to the achievement of this particular task. Fulfillment of the order / project on time is the main task, and the work of the company should be built in accordance with it. That is, all parts of the enterprise — procurement, production, and fulfillment of tasks — must work to fulfill this task. Then the goal of the business - to make money - will be achieved.

The basics of our algorithm

1. The need is determined to produce what the customer ordered. Is there any need to do this? If the order is secured by stocks, it is not necessary to produce it. But that can change very quickly. The need to produce a product from each order is determined at any change in the situation. Example for illustrative purposes: a

customer called you and ordered goods number 1 in the amount of 3 pieces and asked him to provide it by 05/31/2013. If you have 3 pieces in stock, then you do not need to produce anything. Or if you have a production task in which such a product is made with some stock and this stock is enough.

But tomorrow another customer called you and asked for exactly the same product, also in the amount of 3 pcs., But by May 15th.

Question: under what order to produce?

Answer: of course, under the first, although yesterday there was nothing to be done under it.

Thus, the need for production for a particular order is determined at any change in the situation in the company relating to this product.

Then the system according to the same scheme determines the need for the production of nodes of various levels in your product and the need for the purchase of components. And as a result, two date-consistent lists are built. The so-called "to do sheet."

- What should we buy

- What should we produce

Both sheets are “live” and change whenever the situation changes.

But that is not enough. It’s not enough to understand what you have to buy. It is necessary to determine when to purchase it and when to produce it. If you have a need to buy a product, this does not mean that you need to buy it now. You buy / produce too early - you will spend precious working capital, which will then “lie” in the warehouse. And you take resources that could take something more priority.

You buy / produce too late - you will break the final deadlines. For this, the Theory of Constraints suggests using the so-called time buffers, which we also built into to do lists.

Prioritization! That is what matters! It is important to understand what is most important at the moment. What to do now, and what to do later. The same goes for project management tasks. It is important to understand what is the most important task in the implementation of the project. And the importance of the task is determined precisely by the state of the project time buffer. The less buffer left in the project, the higher the level of the task.

2. To achieve maximum production speed, each production site must do exactly those tasks that have the highest priority in terms of solving the main problem. The main task is to complete the order on time. For this, the system builds a production line, where each record has its own priority. Each entry is a name. This is not necessarily the name that the client ordered from you. Rather, it is definitely there, but there can be others besides it. For example, the intermediate nodes of your manufactured product. The priority is determined by the degree of approximation of the hour X. The closer the hour X, the higher the priority. Thus, each site receives those tasks that are most important. The production queues use the same time buffers, which I wrote about a little higher.

3. But even this is not enough. The points described above do not solve the problem of subordinating all production sites to a bottleneck. If this is not done, then there is every chance of organizing a traffic jam in production. In order not to “fall asleep” a narrow link, tasks should be issued strictly at the speed that the narrow link is able to “digest”.

And for this we came up with the so-called traffic light. Before issuing a task to the site, the dispatcher looks at the indications of the traffic light. If the traffic light is red, it means, most likely, it is impossible to issue a task. But it all depends on the specifics of production. If the bottleneck operates 24/7 (maximum use of the resources of the narrow link, step No. 2), then in the evening some queue may accumulate in front of it, which will be eliminated in the morning, because narrow places, for example, work only during the day.

In short, the traffic light helps the dispatcher make the right decision whether to issue tasks to the sections or not, thereby coordinating the performance of all sections with a bottleneck. By the way, the traffic light also helps to identify a bottleneck. The bottleneck is the one that is most often “red”, that is, it is constantly late in time. It is not always obvious, therefore the help of the “traffic light” is needed.

This is how the dispatcher’s workplace looks:

Now imagine the purchasing department at the factory. This is very often a pattern of chaos. The purchasing department not only does not know what it should buy, it does not know how much and when .

Such is the nature of man, that he cannot at one and the same moment engage in two things. A procurement manager can only do one thing at a time. Question: what should he do right now?

If he cannot unambiguously answer this question, then he will definitely buy the wrong and the wrong one. How this will affect the execution of the order is not for me to tell you.

Therefore, the workplace of the sales manager looks like this:

That's it. This is a clear answer to the question "what should I do in the first place, and what in the second." A person is fully focused on what is more important right now. Buy from top to bottom.

Well, in parallel, a responsible citizen is making decisions in the field of optimizing stock levels.

Constantly regulating them. The system unambiguously answers the question about the level of optimal reserves for each item.

Why you need to subordinate narrow places to a bottleneck.

Almost everyone knows what traffic jams are. They arise either in the place where a sharp narrowing occurs, or when an obstacle occurs. As a result of the occurrence of plugs, the total flow rate decreases sharply, sometimes almost to zero. If the road will always have a constant width and all cars will move at a constant speed, without constant braking and acceleration, there will be no traffic jams and the flow rate will be much higher than the flow rate with traffic jams.

The same thing happens in production. The task is very simple - to make sure that production is constantly maintained speed. This can only be done if this speed is maintained at the speed of a narrow link. And only after that it is possible to proceed to step No. 4 of the Theory of Constraints, that is, to increase the throughput of the weak link, thereby increasing the throughput of the entire production.

Well, then step number 5 :-)

Good luck with the implementation of TOC.

UPD At the insistent request of commentators, he added pictures to the text.