Disposal of CRT monitors and TVs

Many of us still remember those recent times when monitors with a cathode ray tube (CRT) were used to visualize information on a PC, and CRT televisions can still be found in almost every home. Nevertheless, the century of picture tubes came to an end, and replaced by more advanced liquid crystal and plasma displays. The flip side of this progress was an unusually large number of unnecessary CRT monitors and televisions. According to some estimates, from several thousand to one million monitors and TVs are thrown out in different countries every year, and the total amount of obsolete equipment that is still stored in the owners' houses can be in the millions. It is predicted that the flow of this "electronic garbage" will run out only by 2020-2025. However, the main problem is

To answer this question, let's look at the device of technology with a CRT and the kinescope itself, as well as the materials that are used for its manufacture.

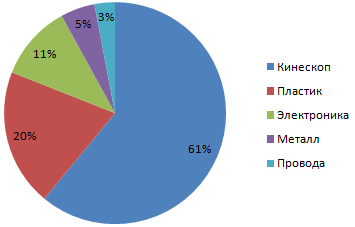

The main components of a computer monitor or TV are a kinescope, a plastic case, printed circuit boards, wires, a deflecting system, and protective elements. A kinescope makes up about two-thirds of the mass fraction of the entire monitor or TV, as can be seen from the pie chart below.

Fractional composition of a CRT monitor or TV

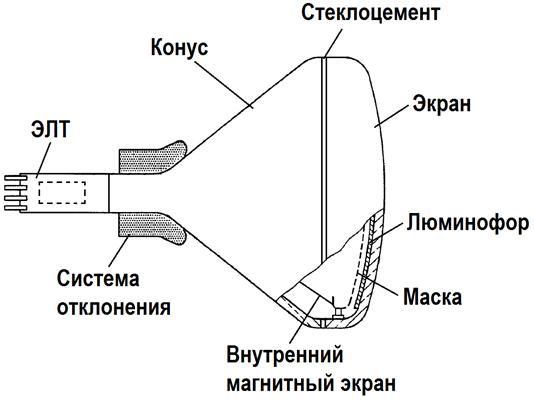

In turn, the main structural elements of a kinescope are a CRT, a cone, a screen and an internal magnetic screen with a mask.

A simplified schematic image of a kinescope The

fractional composition of a kinescope in mass percent is as follows:

Kinescope fractional composition The

inner surface of the screen is covered with four layers. The first layer is a carbon coating with various additives of surfactants. The second layer forms a coating of phosphors, on which a wax-like layer is applied to level and protect the surface. The aluminum coating forms the fourth layer, applied to increase brightness. In the case of a kinescope cone, its inner side is covered with a layer of iron oxide, and the outer one is covered with graphite. The screen and the kinescope cone are interconnected using glass cement.

It is widely known that the kinescope is made of glass, the chemical composition of which varies depending on the functions performed by the elements of the kinescope. One of the main functions of glass is X-ray protection. To do this, about 34 wt.% PbO is usually introduced into the glass of the electron gun. A slightly smaller amount of lead oxide contains the tube cone (22 wt.% PbO). In the case of a kinescope screen, its glass is specially made of a greater thickness to absorb dangerous x-ray radiation. In addition, this glass must have good optical properties, so it is made from barium-strontium glass (it absorbs x-ray radiation about one and a half times worse than lead glass). Note that the color TV screens released before 1995 used glass containing up to 5 wt.% PbO. However, thanks to the efforts of the German Central Association of the Electrical and Electronic Industry (ZVEI) to increase the utilization of picture tubes, most manufacturers since 1996 completely switched to the production of screens without the use of lead oxide. This example just did not follow the American manufacturers Corning and Corning Asahi Video (Thompson RCA moved in 1998).

In black and white televisions, the screen and tube cone are made of one type of glass, which, as a rule, contains up to 4 wt.% PbO. This difference in the chemical composition of glasses of different types of TVs is due to more powerful x-ray radiation in color TVs due to an increase in the accelerating voltage to 20-30 kV against 10-20 kV for a black and white TV. The average chemical composition of the tubes of the tube is shown in the table below (depending on the manufacturer, the composition of the glass may vary slightly).

As the reader probably already guessed, the main environmental hazard is lead oxide, which is part of the tubes of the tube. The amount of lead oxide in one picture tube depends on its size and can vary from 0.5 to 2.9 kg with an increase in its measurements from 13 to 32 inches, respectively.

The content of lead (II) oxide depending on the picture tube size.

A feature of these glasses is that lead ions are relatively easy to leach out of the glass and enter the environment. For example, with improper disposal of the tube, leaching of lead ions can occur under the influence of organic acids, which are formed at the landfill for household waste. Of all the lead-containing components of the tube, the most easily leached is from glass cement.

Lead, like its compounds, is a toxicant with a pronounced cumulative effect, causing changes in the nervous system, blood and blood vessels. This circumstance suggests the need for proper disposal of picture tubes by their disposal at special landfills or recycling.

Consider the existing methods of disposal of picture tubes.

As a rule, the recycling process begins with the manual dismantling of televisions or computer monitors. In this operation, the case, printed circuit boards, speakers, wires, a protective metal casing, a deflecting system and an electronic gun are dismantled. Also, for safety reasons, in this operation, the vacuum is bleed from the tube by making holes in the place of the high-voltage output or through the neck of the electron gun. The protective iron clamp over the connection of the kinescope cone with the screen is also cut off. All these components are sent for further processing. As a result, there remains only a kinescope, which must be divided into a cone and a screen due to their different chemical composition, which is important for their subsequent disposal.

In practice, the separation of the cone and the screen is most often performed using a diamond saw, a hot nichrome wire or a laser. After that, an internal magnetic screen with a mask is removed from the cut-off tube and the screen is sent to a chamber in which a phosphor is collected using a vacuum cleaner (stored at a special polygon). Thus, two types of glass are obtained at the output — lead and barium-strontium.

This process is presented in the video below.

There is also a slightly different way of separating lead and barium-strontium glasses. This method consists of the following technological operations: crushing of picture tubes, separation of the magnetic fraction, mechanical removal of coatings, washing the glass with water, drying, and, finally, separation into lead, barium-strontium and mixed glasses using special analyzers (X-ray fluorescence or ultraviolet) and air guns . Note that in this technology, water is used in a closed cycle, and the amount of waste is 0.5% (glass dust, phosphor, coatings). This method of glass separation is used by Swissglas AG (Switzerland), RTG GmbH (Germany), SIMS (Great Britain).

We now turn to the most important issue - the disposal of lead and barium-strontium glass. Until recently, these glasses were mainly sent to factories for the manufacture of new picture tubes. However, with the advent of liquid crystal and plasma displays, the production of picture tubes ceased, which made this processing method practically irrelevant. Nevertheless, there are three enterprises in China (Shaanxi IRICO Electronic Glass, Henan AnCai Hi-Tech and Henan AnFei Electronic Glass), which can use up to 100 thousand tons of glass per year, which is only a small part of the total (5.2 million tons according to the Qinghua University report).

It should be noted that barium-strontium glass has found application in the production of building materials due to the low leachability of barium and strontium ions, the concentration of which does not exceed permissible norms. Therefore, further we will focus only on the disposal of lead glass.

Today, the only and most widespread method for processing lead glass is to use it as a recyclable material to produce lead. For this, metallurgical melting furnaces for lead are used, in which the flux is partially replaced by lead glass. However, the number of furnaces that use lead glass in their technological process is rather small for the whole world. For example, Doe Run (USA), Xstrata and Teck Cominco (Canada), Boliden Rönnskär Smelter (Sweden), Metallo-Chimique (Belgium).

Due to the small number of furnaces and the high cost of transporting recyclables to them, this made it easier to send lead glass to the landfill. However, some companies involved in the disposal of "electronic garbage" have chosen a different path.

For example, to solve this problem, SWEEEP Kuusakoski Ltd. (Great Britain) together with Nulife Glass, the University of Sheffield and Aalto University developed and put into operation on November 30, 2012 a furnace for producing lead from glass. The furnace is heated by electricity, and lead glass (crushed up to 3 mm in size) is preliminarily ground and mixed with a reducing agent. After the recovery process at 1200 oWith the output get lead granules and glass. This furnace can process up to 10 tons of glass or up to 2 thousand large TVs per day.

Opening Ceremony Report

Alternative methods for recycling lead glass have also been proposed. In general, they all come down to the idea of using glass for the manufacture of building materials (foam glass, for example) or as an additive in such building materials as brick, concrete, cement, decorative tile, etc. Building materials with a high content of lead glass can be used to protect against x-ray radiation. It has also been proposed to use lead glass in the ceramic industry to create glazes that are resistant to leaching.

The main disadvantage of building materials with additives of lead glass is a decrease in their mechanical properties. In addition, the results of the leach tests performed showed that the concentration of lead ions in most cases exceeds the permissible norms (according to American standards, the concentration of lead ions should not exceed 5 mg / l). Also note that in many countries the use of toxic substances in building materials is prohibited by law.

The above problem can be solved by special chemical processing of glass, the essence of which is the preliminary leaching of lead. In this method, leaching is usually carried out using nitric acid for one hour, followed by washing and drying the ground glass. Next, the leach products are sent to a chemical plant for further processing, and the resulting glass chips can be used in building materials. This lead glass recycling method is used in Hong Kong.

In conclusion, it should be said that the problem of recycling old televisions and monitors with CRT will be relevant for at least another decade. The situation with the solution of this problem may differ significantly in different countries of the world, which is primarily due to the lack or availability of technologies and processing plants, state support, and recycling culture. In the CIS countries, as well as in Ukraine, the state of affairs in this regard can be said to be in a deplorable state. Only in many cases, picture tubes are at special testing sites, and you only have to dream about their processing.