3D printing lessons. Effective support and changing the height of the layers in practice from the company 3Dtool

Good day! In addition to the usual tests and experiments, we spend a lot of time trying 3D printing. Usually, parts for test printing are of the same type and uninteresting. But there are also instances such as: a handle with a bas-relief for the wardrobe. Why - no one knows, the customer said to print in order to understand the capabilities of the Hercules 2018 3D printer .

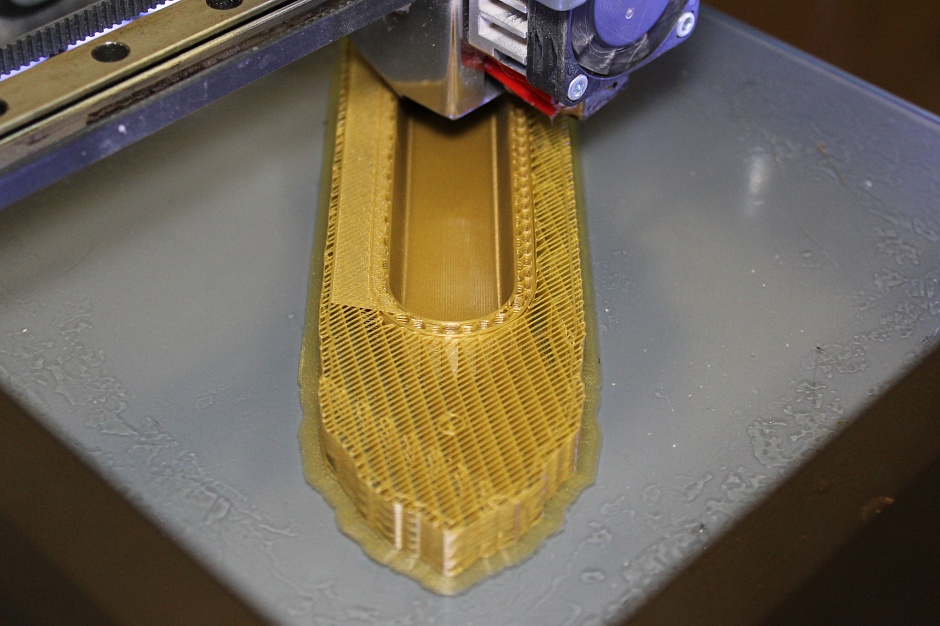

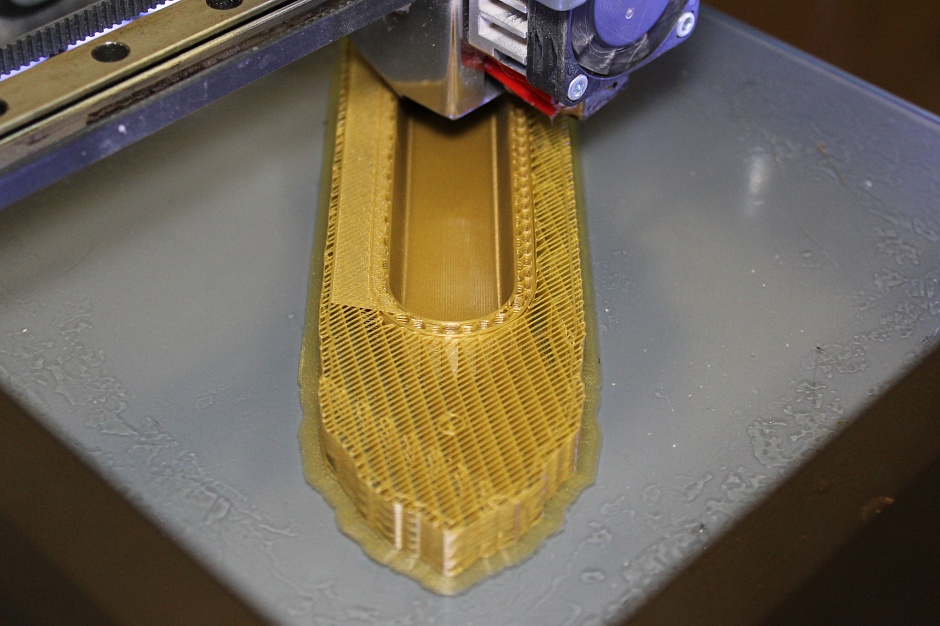

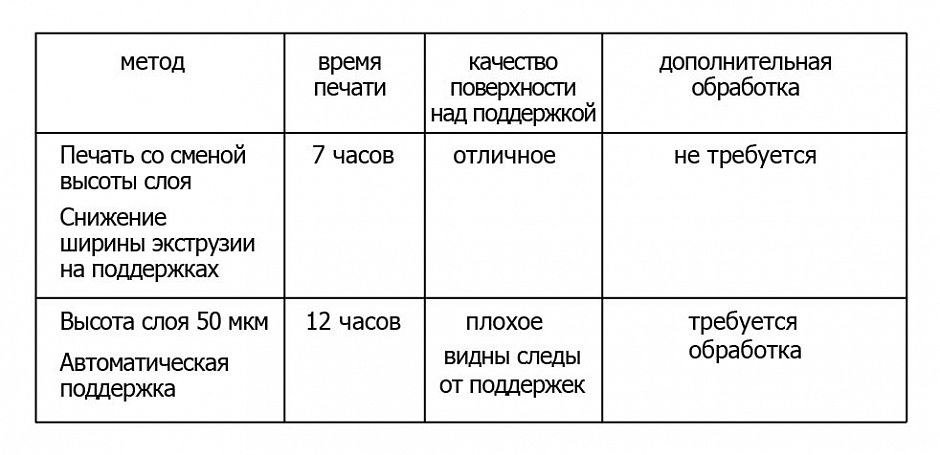

Material PLA Esun gold, nozzle diameter 0.3 mm. Printing occurred with a change in the height of the layer; prior to the beginning of the bas-relief, the layer height was 0.2 mm, the height of the bas-relief layer was 0.05 mm. Printing time is 7 hours. Slicer - Slic3r.

The extruder / table temperature is 205/65 degrees. Blowing 100%. The handle was printed lying on the table fully supported.

Printing process:

The extrusion width of the supports is 0.2 mm. To save time, the support comes in 3 mm increments, then 2 intermediate layers in 1 mm increments so that the first layers of the handle do not hang down. The support is printed closest in XY to the first layer of the pen, despite this it does not burn to the first layer.

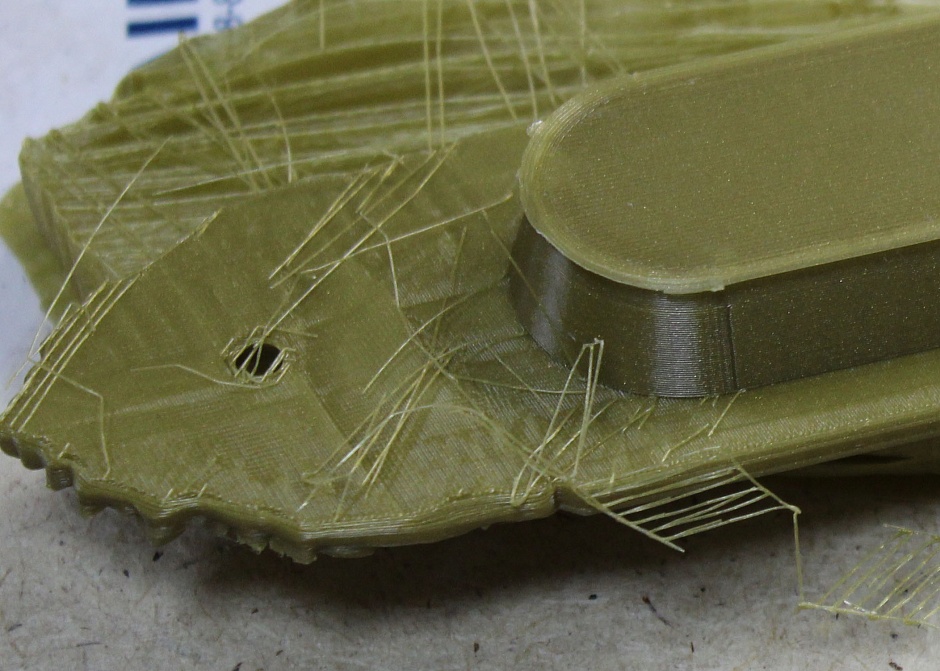

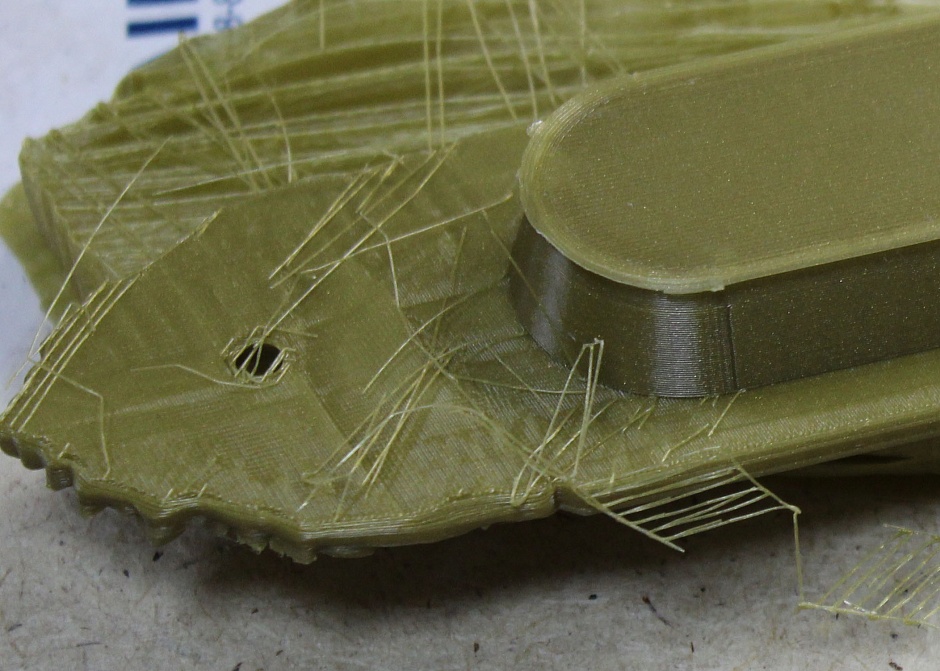

Remove from the table:

All the bottom in support.

After removing the parts, the support pieces were easily removed by hand, the surface turned out to be smooth and almost without any trace of support.

Remove the support with your hands, the knife is not needed at all. Previously, it would take an hour and a half to remove the supports and clean the surface, but traces would be visible anyway. No more than two minutes were spent here, and the surface quality is several times better.

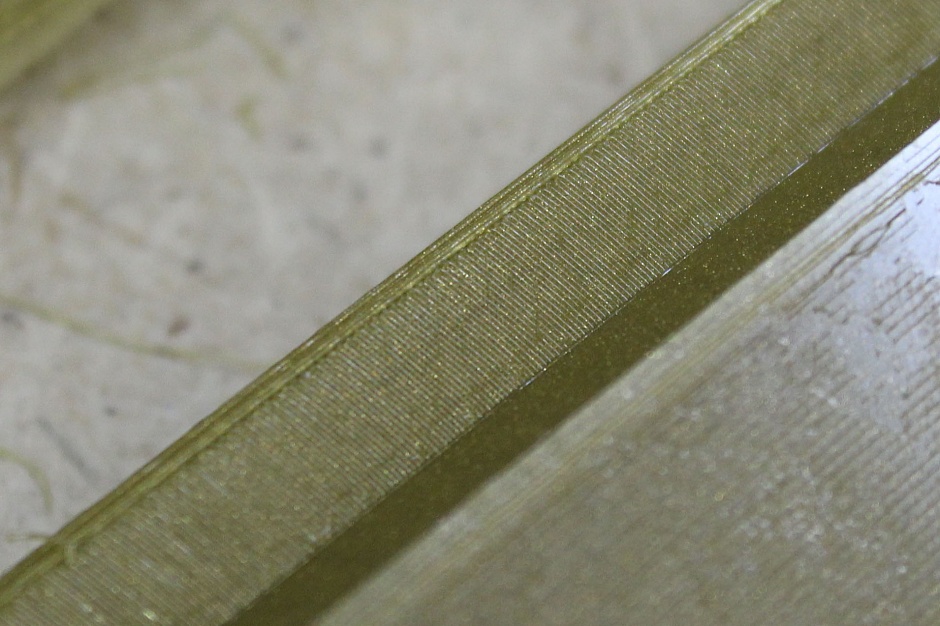

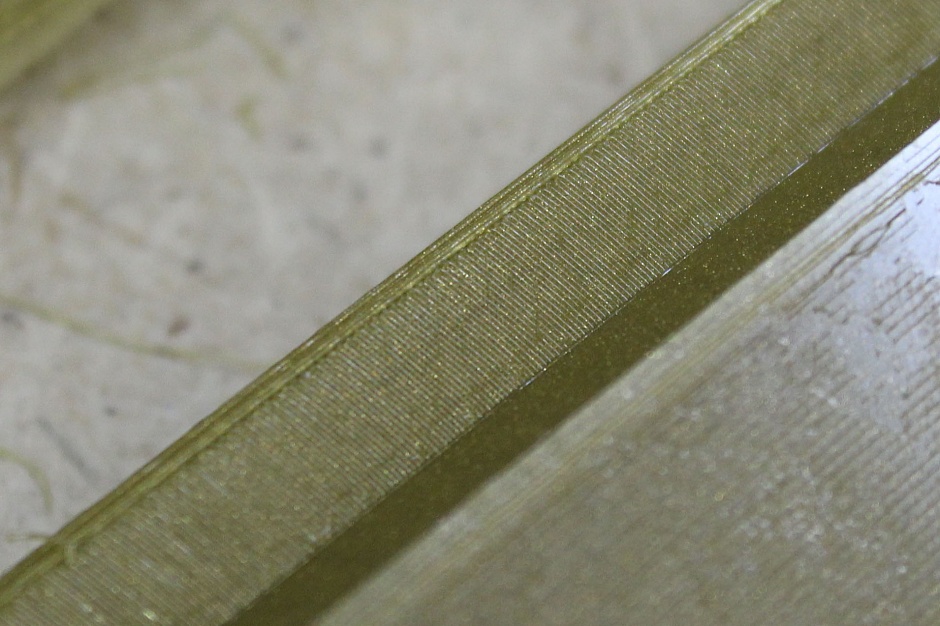

The surface that was printed over the support.

After treatment with dichloroethane:

It seems to us that it looked prettier before treatment. But this is also an experiment, where without them.

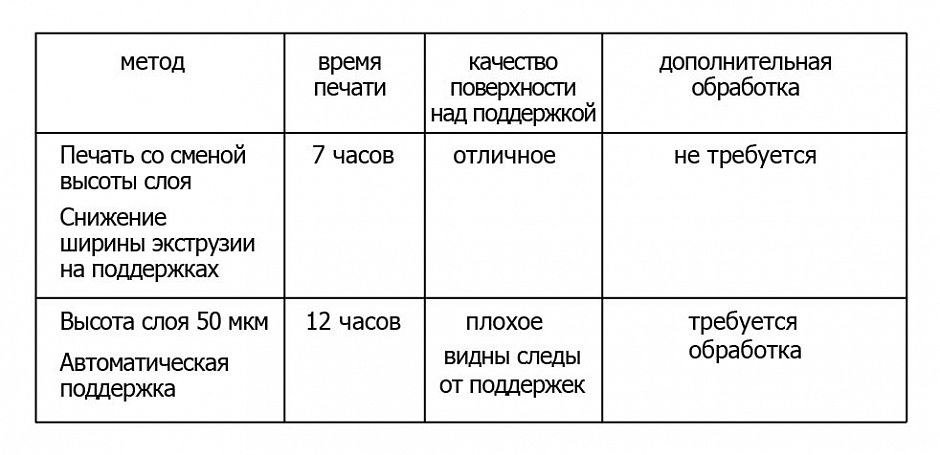

The handle is interesting because the previously described methods were used in the preparation of the code: changing the layer height and printing easily detachable supports. Both methods work, once again tested in practice.

Conclusion: 50% of success depends on properly prepared code.

Good luck to everyone in 3D printing.

→ Catalog of 3D printers

Do not forget to subscribe to our YouTube channel (new videos are released every week).

Material PLA Esun gold, nozzle diameter 0.3 mm. Printing occurred with a change in the height of the layer; prior to the beginning of the bas-relief, the layer height was 0.2 mm, the height of the bas-relief layer was 0.05 mm. Printing time is 7 hours. Slicer - Slic3r.

The extruder / table temperature is 205/65 degrees. Blowing 100%. The handle was printed lying on the table fully supported.

Printing process:

The extrusion width of the supports is 0.2 mm. To save time, the support comes in 3 mm increments, then 2 intermediate layers in 1 mm increments so that the first layers of the handle do not hang down. The support is printed closest in XY to the first layer of the pen, despite this it does not burn to the first layer.

Remove from the table:

All the bottom in support.

After removing the parts, the support pieces were easily removed by hand, the surface turned out to be smooth and almost without any trace of support.

Remove the support with your hands, the knife is not needed at all. Previously, it would take an hour and a half to remove the supports and clean the surface, but traces would be visible anyway. No more than two minutes were spent here, and the surface quality is several times better.

The surface that was printed over the support.

After treatment with dichloroethane:

It seems to us that it looked prettier before treatment. But this is also an experiment, where without them.

The handle is interesting because the previously described methods were used in the preparation of the code: changing the layer height and printing easily detachable supports. Both methods work, once again tested in practice.

Conclusion: 50% of success depends on properly prepared code.

Good luck to everyone in 3D printing.

→ Catalog of 3D printers

Do not forget to subscribe to our YouTube channel (new videos are released every week).