LUT on vinyl or home Arduino Mini

Hello, the article was originally conceived as a review of the Oracal 651 plotter vinyl as a replacement for toner transfer photo paper. However, as an example, I chose the self-made version of the Arduino Mini ( ATMega8 ) and decided to bring the article to its logical conclusion.

Vinyl compares favorably with photo paper and various kinds of substrates - the process of making a circuit board becomes less time-consuming and more economical, you can read about LUT here .

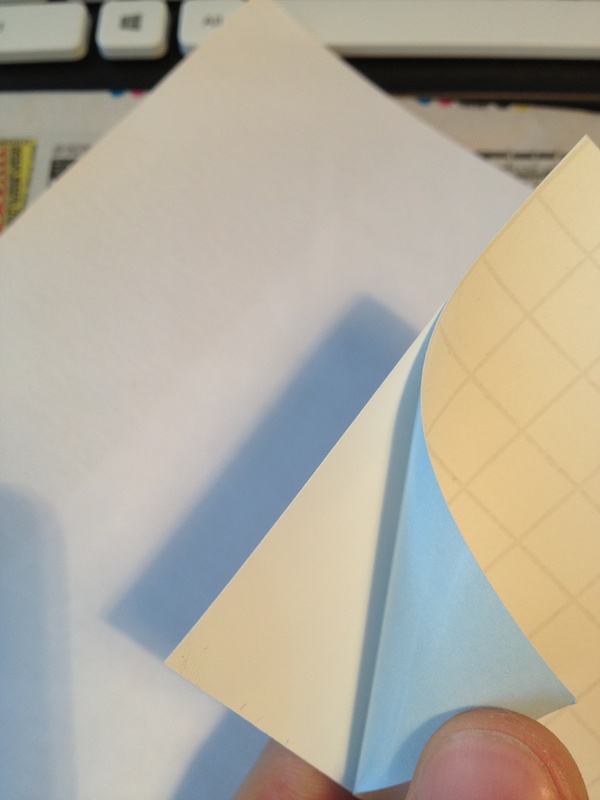

To transfer toner to the board, I will use Oracal 651 vinyl (spied here ). Oracal is already known among hams for its basis for self-adhesive film, it is also suitable for LUT and has similar properties.

This material can be bought at companies involved in vinyl printing (advertising agencies, stickers, etc.), or ordered on ibei .

The most important plus of this material is that it is self-adhesive .

This property allows us to use exactly as much vinyl as we need, without the need to throw out small trimmings, and also does not require tricky manipulations to feed the printer.

As a result, we can safely produce single devices of a small size without worrying about material consumption.

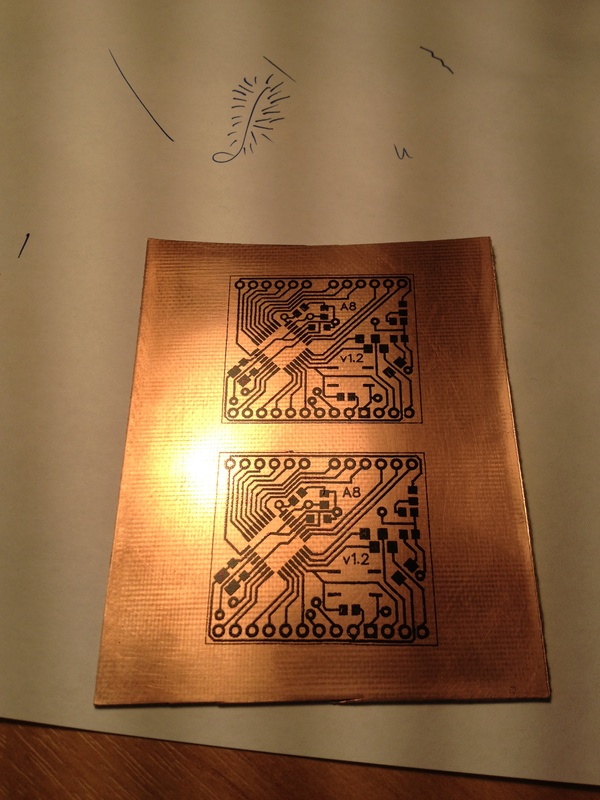

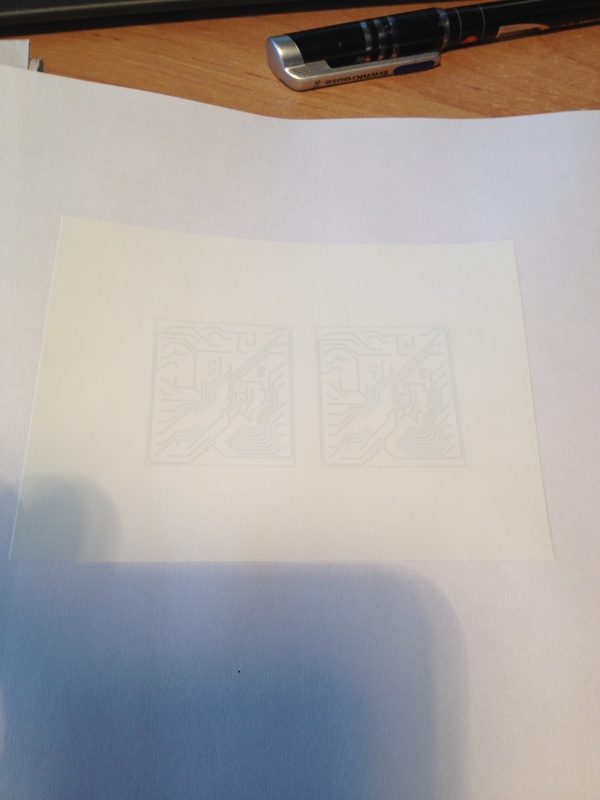

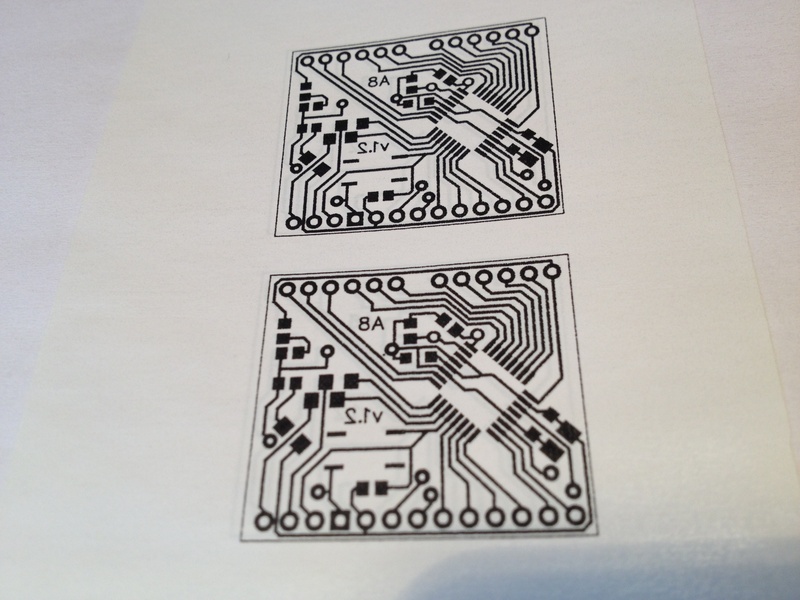

To get started, I print the board on plain A4 paper, then focusing on the lumen I paste a piece of vinyl.

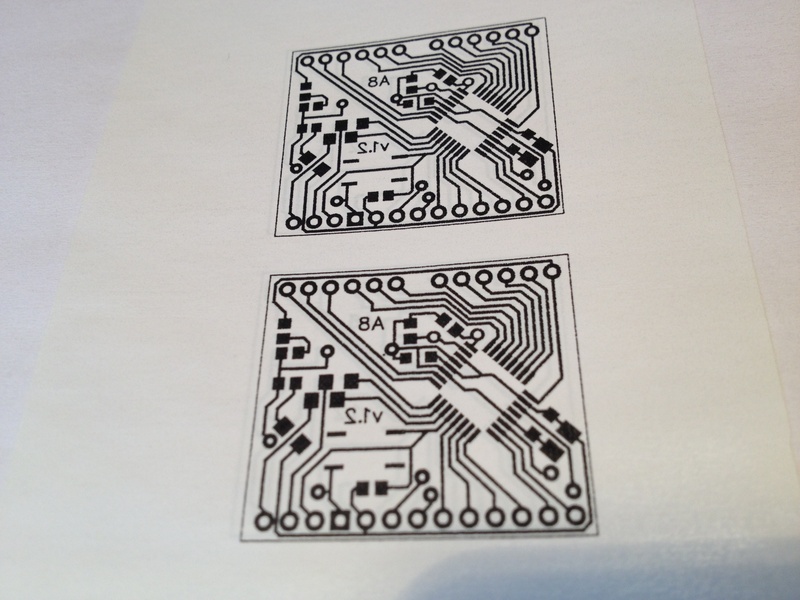

And print again (do not forget to turn off all toner saving options).

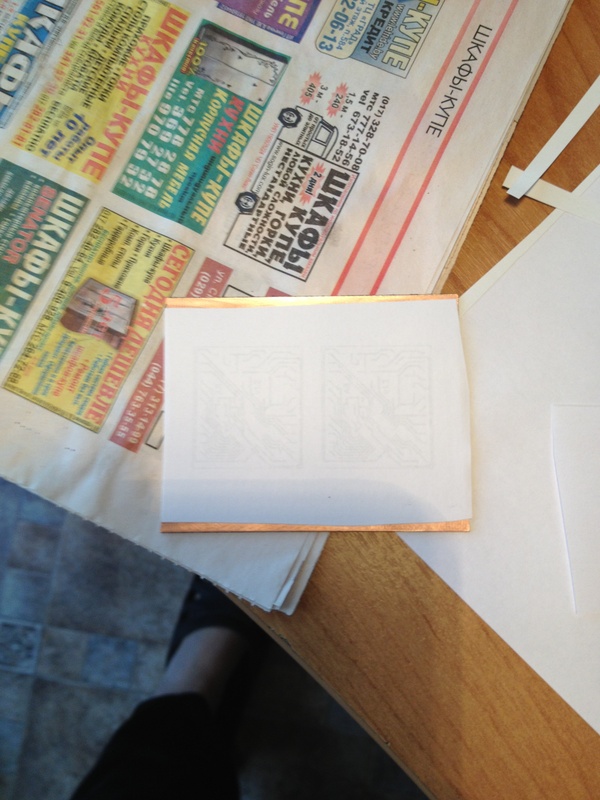

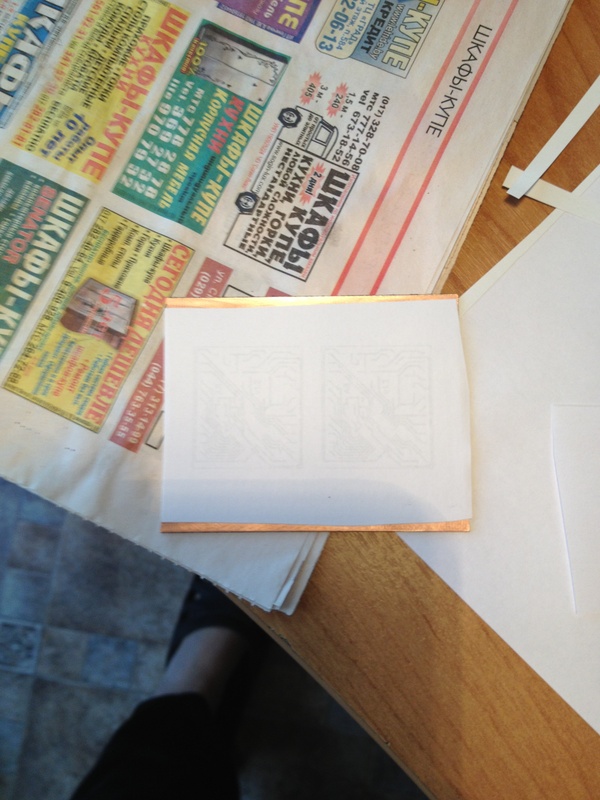

We clean the printed circuit board and impose the printed image.

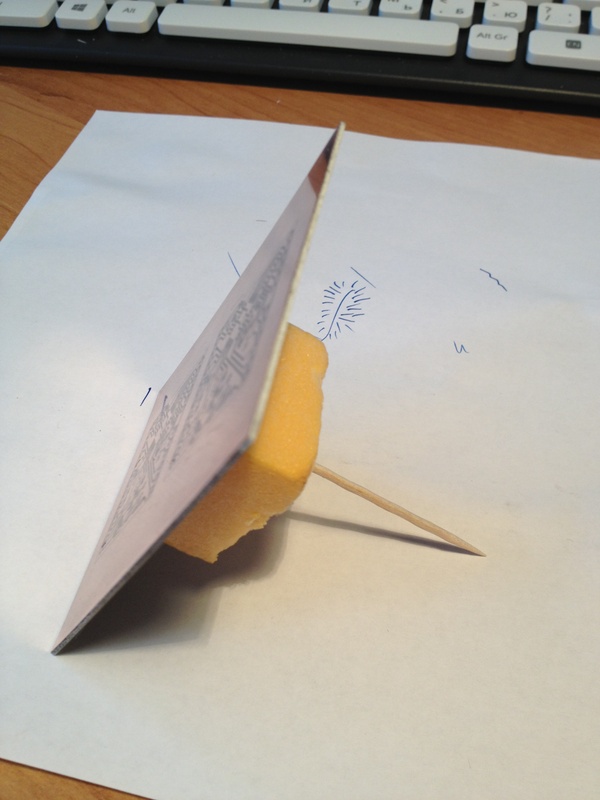

Iron is used to transfer the toner according to the standard scheme: the board is inserted into a paper “envelope” for pressure distribution, it makes sense to place a metal object under the cover to remove heat, then we simply press the hot duck (I set the temperature to maximum) to the board for 10-15 seconds , gently smooth the edges of the board and you're done.

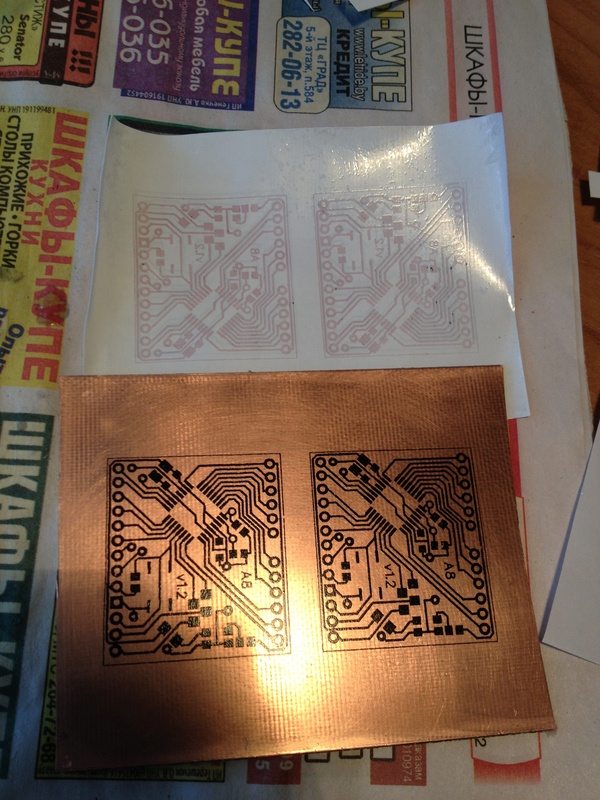

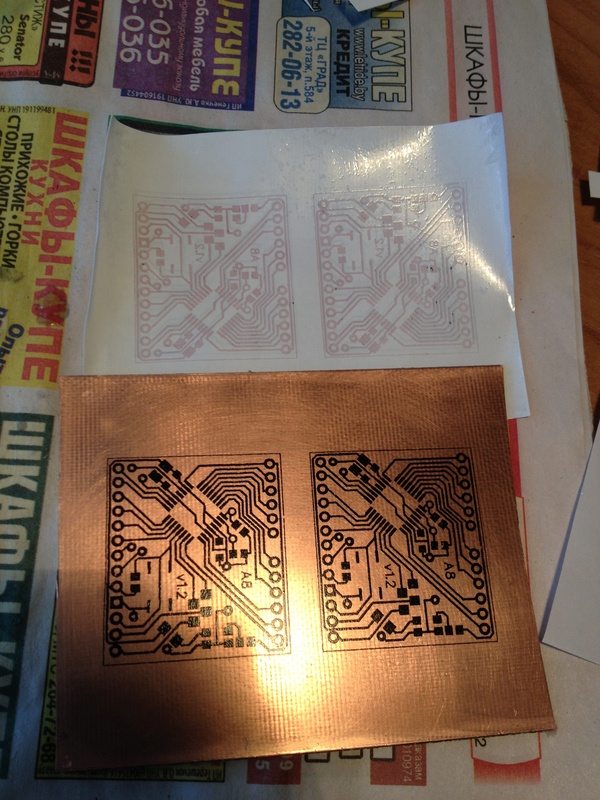

The blank should be cooled in cold or warm water, this will help soften the paper used as a substrate.

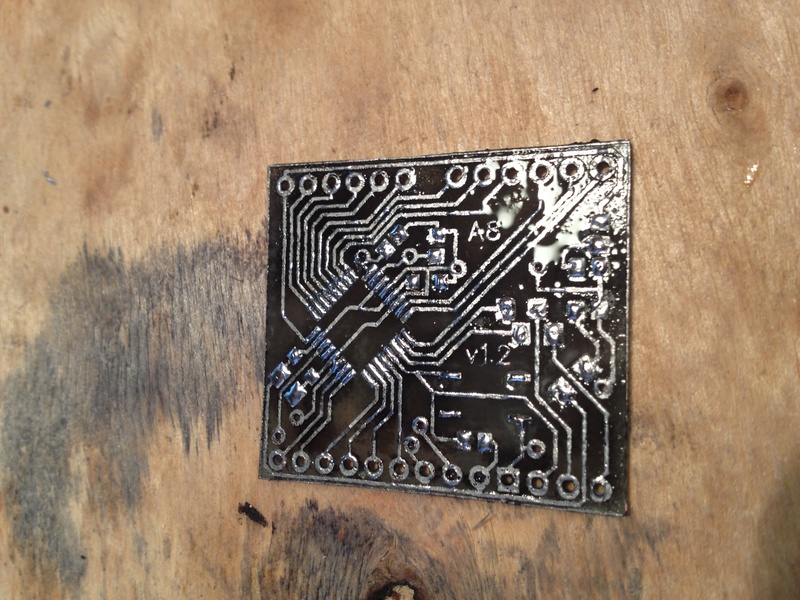

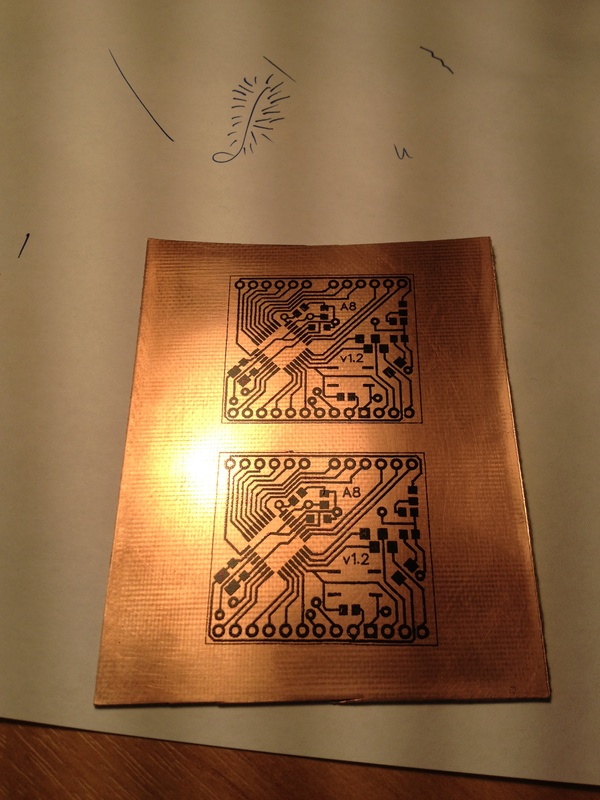

Further, fans of typing with photo paper will be very pleased - there is no need to pore for a few minutes over the board by erasing pieces of paper and cleaning the tracks, the vinyl is removed meekly and leaves no residue. The first time I was even surprised at such a black toner. :)

To retouch poorly translated tracks, I use an ordinary gel pen. A permanent marker for these purposes is much better suited, but with a pen it turns out more accurately (even tracks of 0.3-0.2 mm are tinted without problems). The peculiarity of this method is that the gel dries for a long time, so either wait or look for a hair dryer. :)

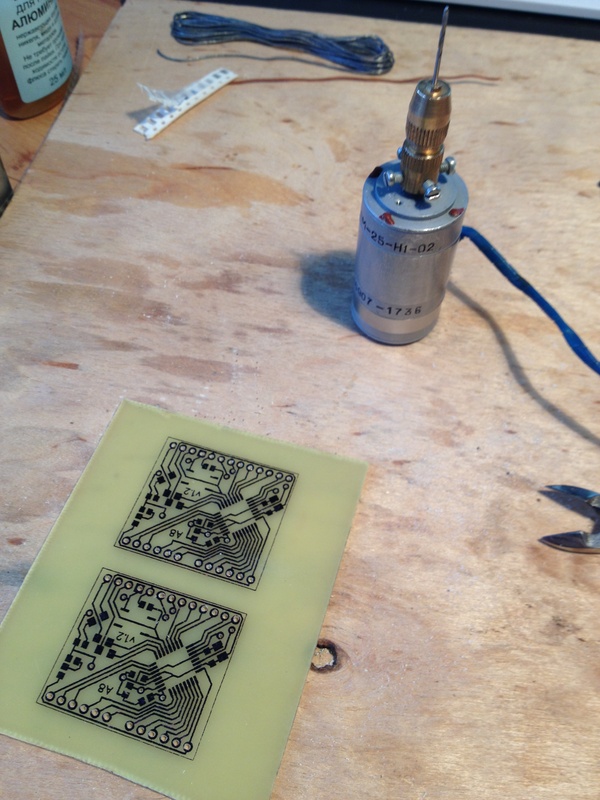

Heated ferric chloride is used as a solution; the board is located “face down”. To speed up the etching process, the workpiece should be shaken periodically. Previously, a vibration motor from a Nokia phone did this work for me, but, in my negligence, he died the death of the brave and disappeared .

During etching, it is worth tidying up the workplace and preparing for soldering and drilling.

It turned out to be problematic to find 24 volts for the motor at home, I had to overclock the standard 5 using the MC34063 chip (more on easyelectronics.ru ).

The teskolit is quite thin, easy to cut with scissors.

Either because of the poor solvent or because of the properties of the PCB (which is more likely) I couldn’t wash the toner without leaving any stains on the board, it looks very messy and leaves an unpleasant feeling in my soul. After much thought, I decided not to fight the problem, but to use it for my own good. We paint the board with a marker not suitable for tinting tracks. After we wash off the excess with acetone.

For tinning, we need a thick sting and a lot of flux. :)

There are many ways to solder SMD components (with a simple soldering iron, in the oven, on a searchlight, etc.), I prefer to use a hairdryer (since you can buy a good soldering station without any problems and for a little money).

Using a thin beveled sting we will apply a little solder to the places where our components will be located. In fact, this is a simple replacement for solder paste.

With tweezers we place the components in the places they put.

We heat the board with a hairdryer, help the components to look in the right direction with tweezers.

As jumpers I use a twisted pair wire, it is not very thick and holds its shape well.

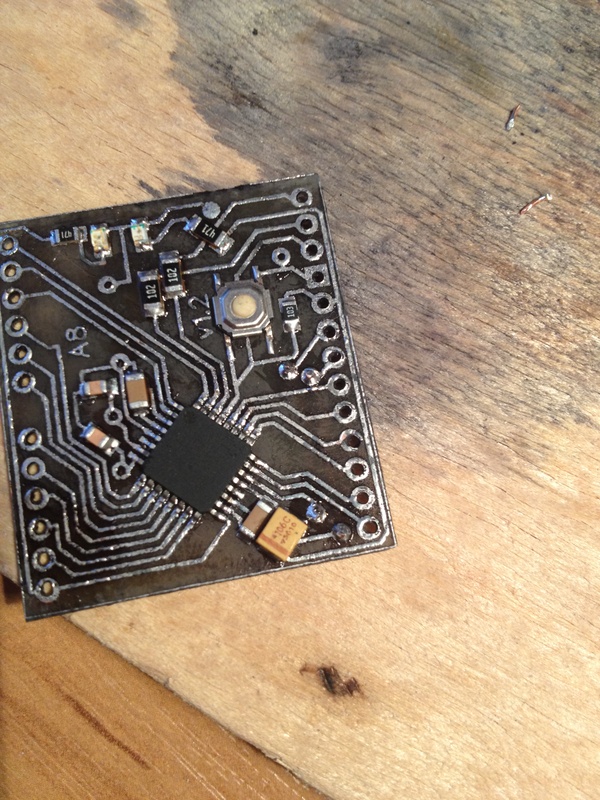

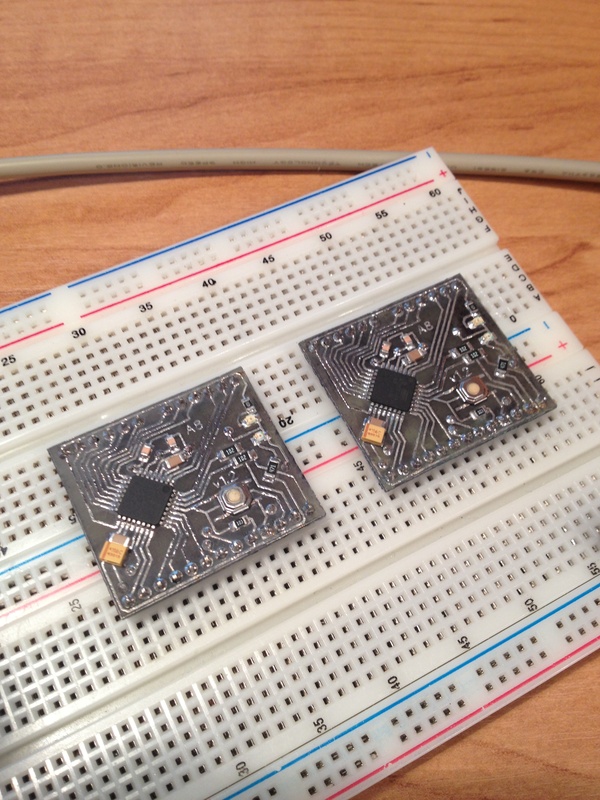

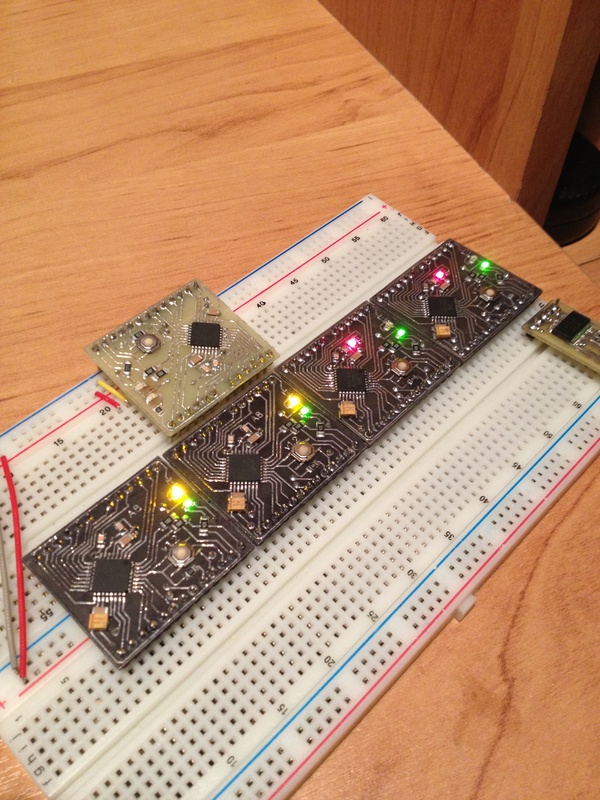

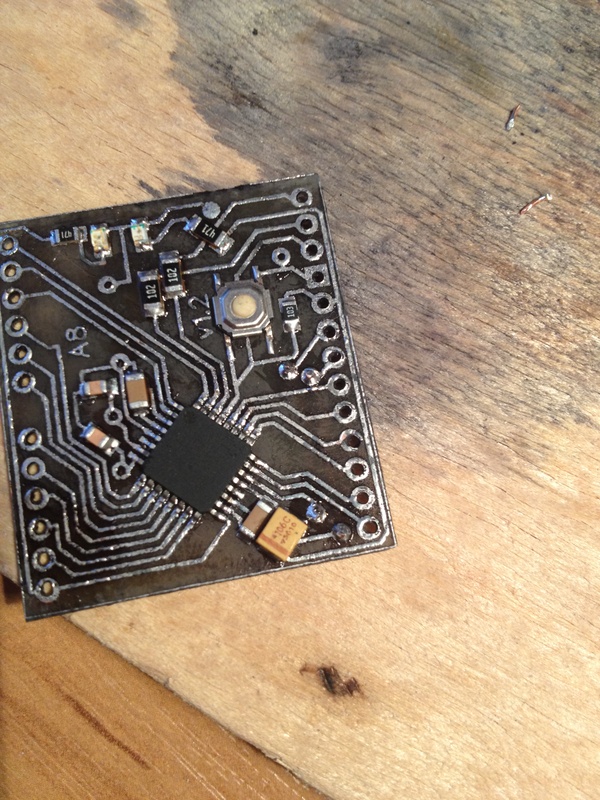

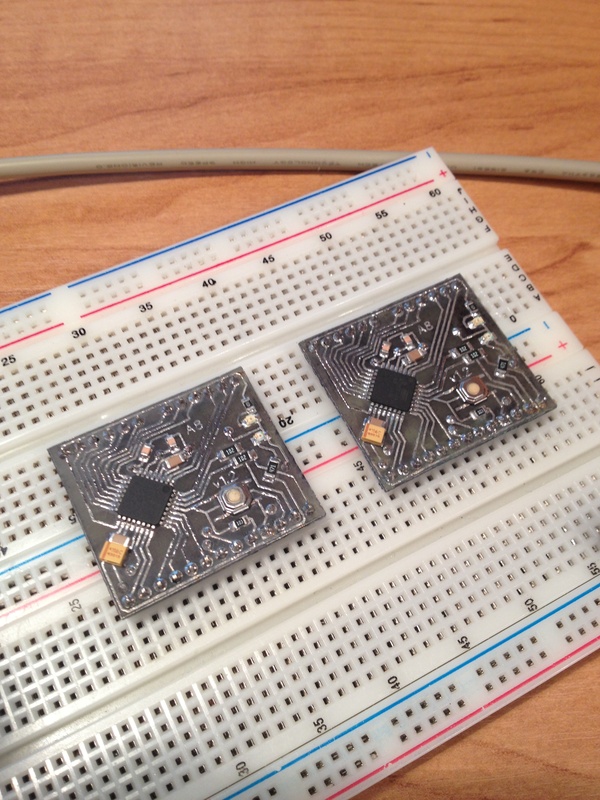

Almost finished product, it remains to solder the legs. In order to eliminate distortions in the future, the board can be installed on the breadboard and solder the side leads.

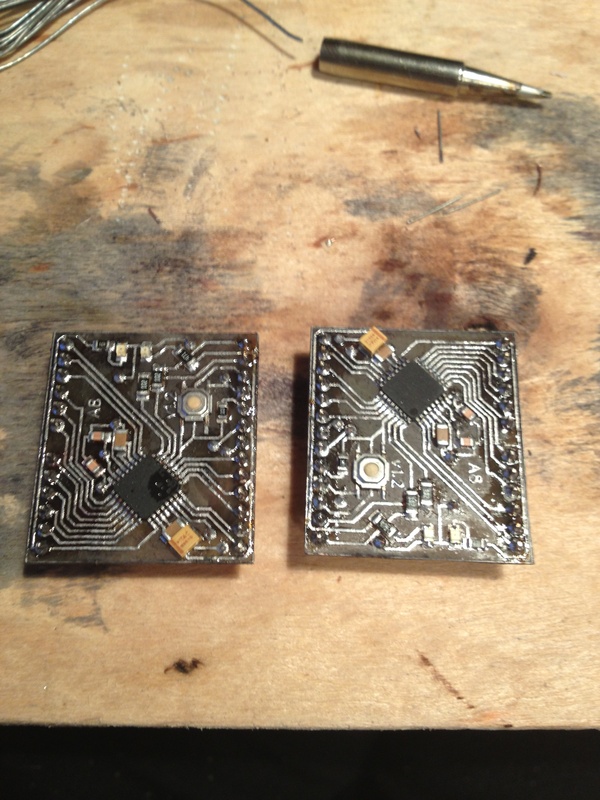

Done, the “dirty” work is behind, now the boards need to be washed and flashed.

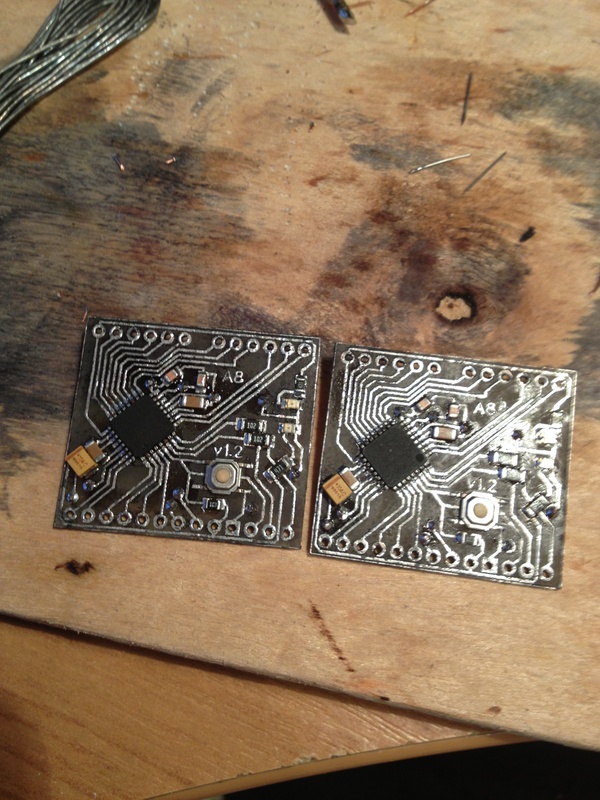

I use a conductive flux, it can be washed off with a toothbrush under a stream of warm water, or you can throw the boards in an ultrasonic bath and go to drink tea (the two lower boards were made earlier, I decided that an extra bath would not harm them).

In order to turn the microcontroller on a piece of textolite into a full-fledged Arduin, we need to flash the bootloader, for this you can use any programmer, but for the sake of a single operation I take Arduin herself and the ArduinoISP sketch.

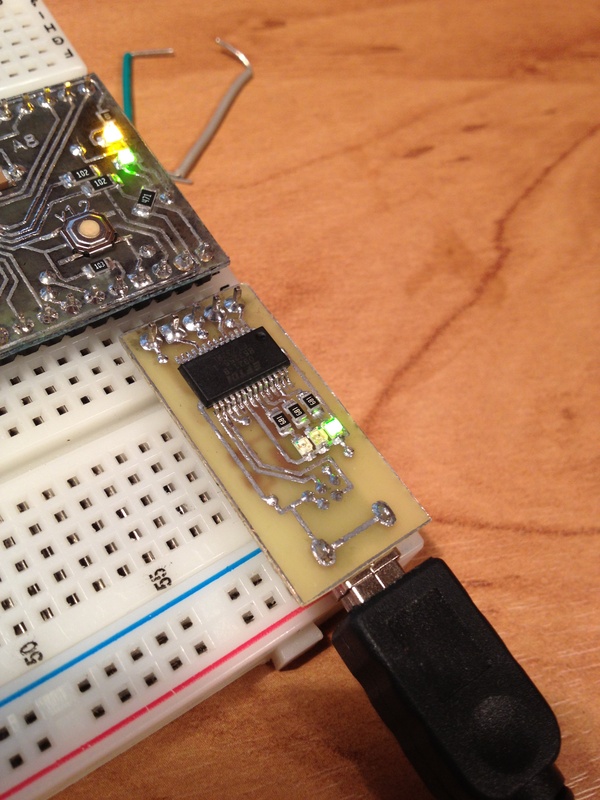

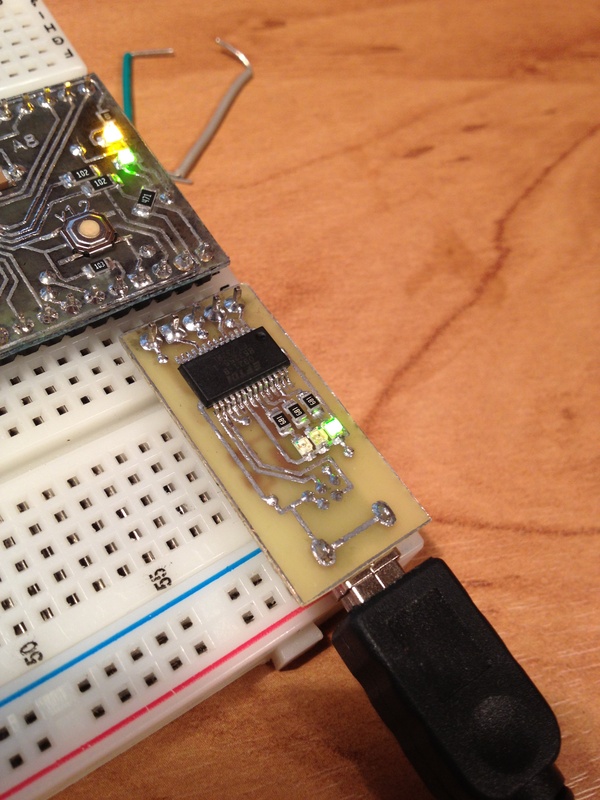

Any USB-UART adapter is suitable for downloading sketches, I personally soldered my own with the reset line (the board will reboot itself during the download of the sketch).

The adapter is based on FT232, the board is double-sided. Made the first time using the same vinyl (you need to combine patterns in the gap and glue the edges).

During washing and other operations, part of the black coating was washed off, so I repeated the painting already on the finished board.

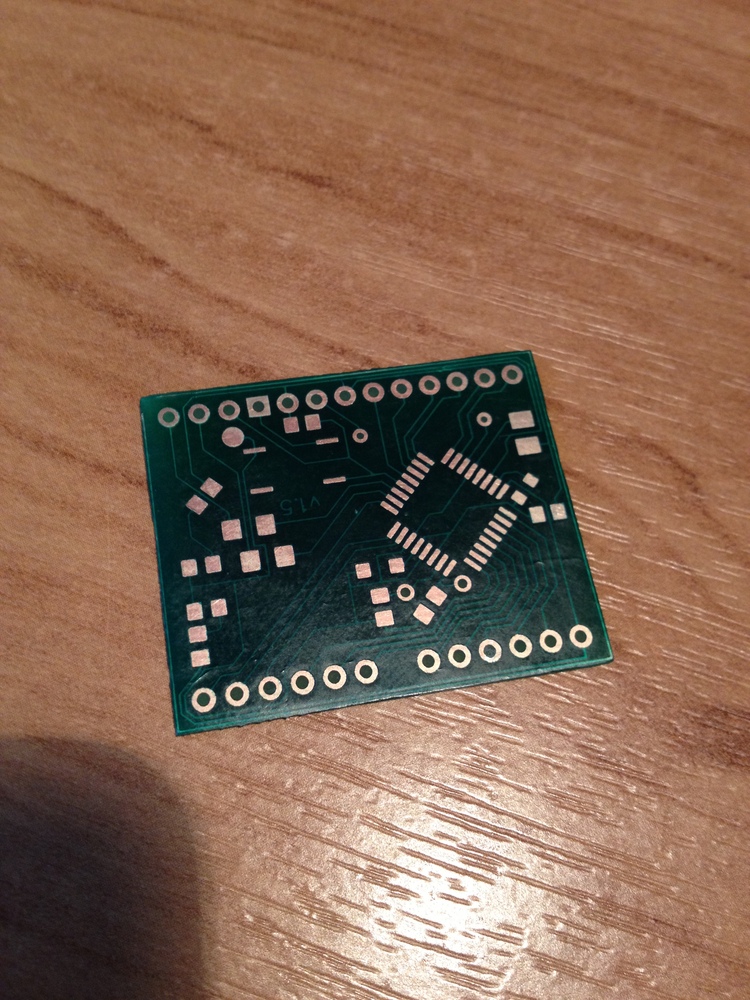

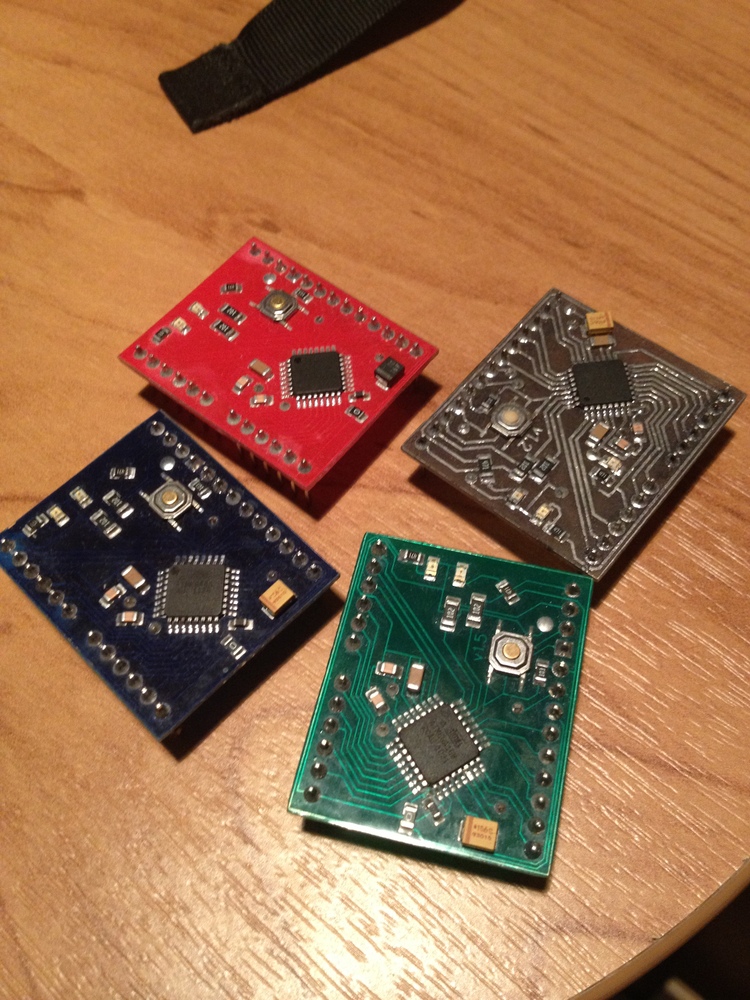

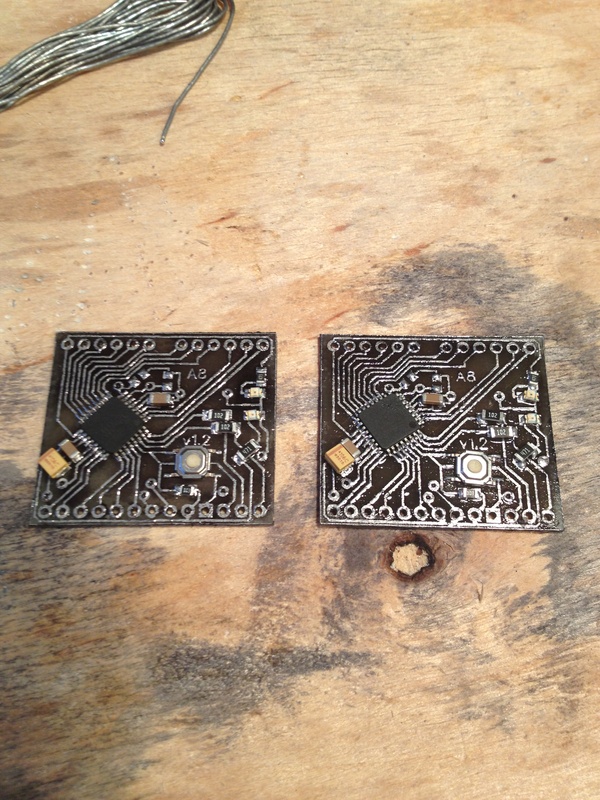

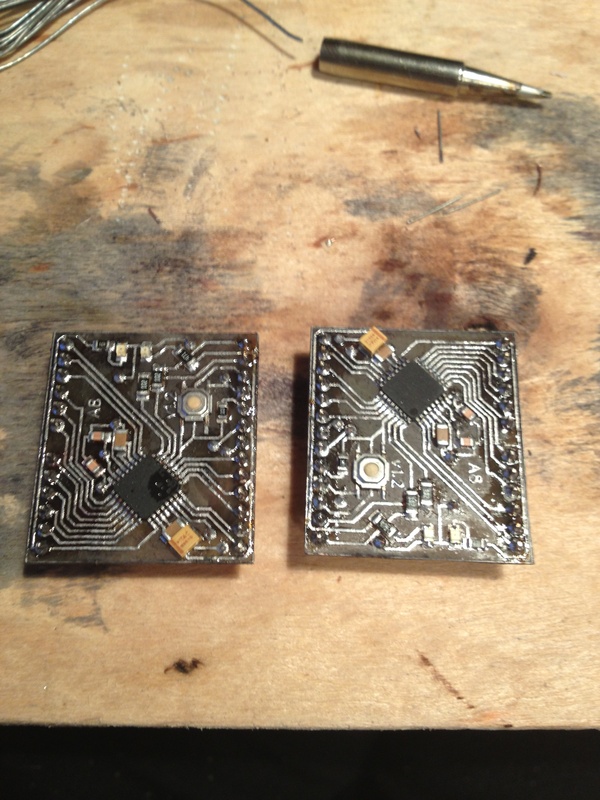

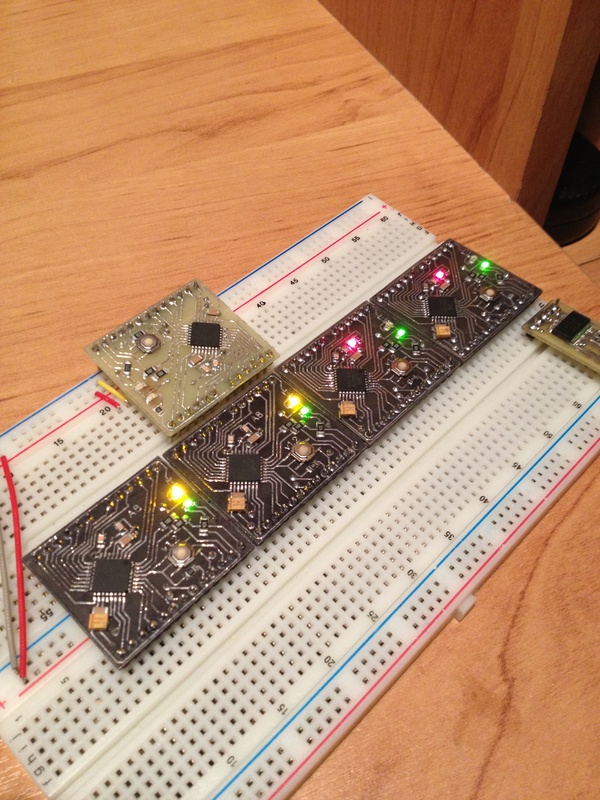

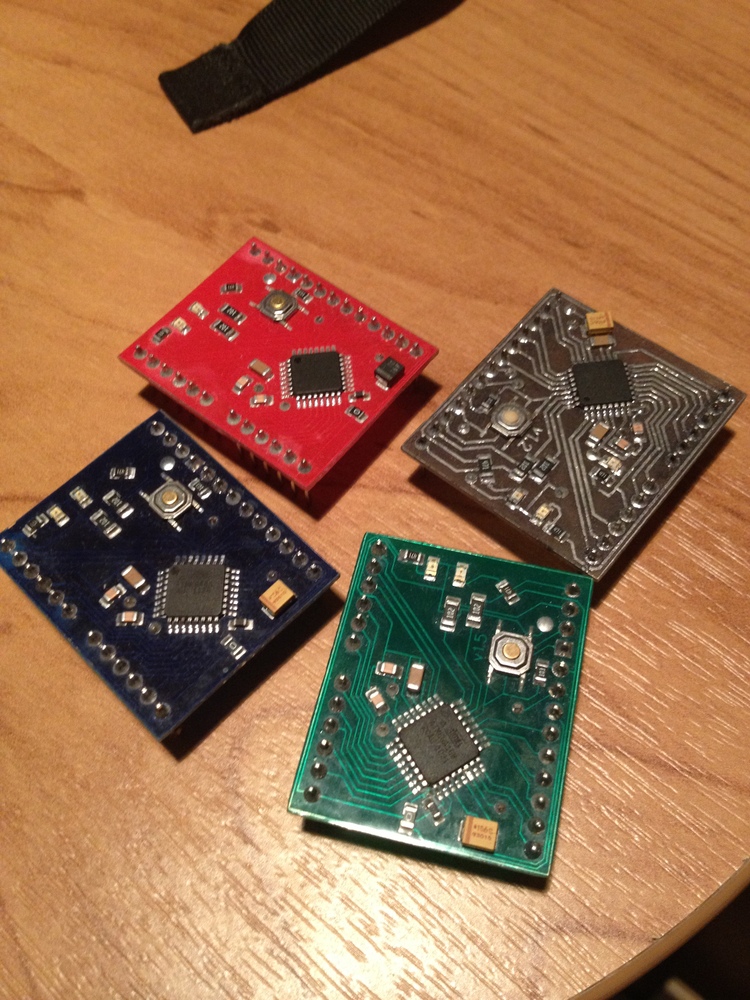

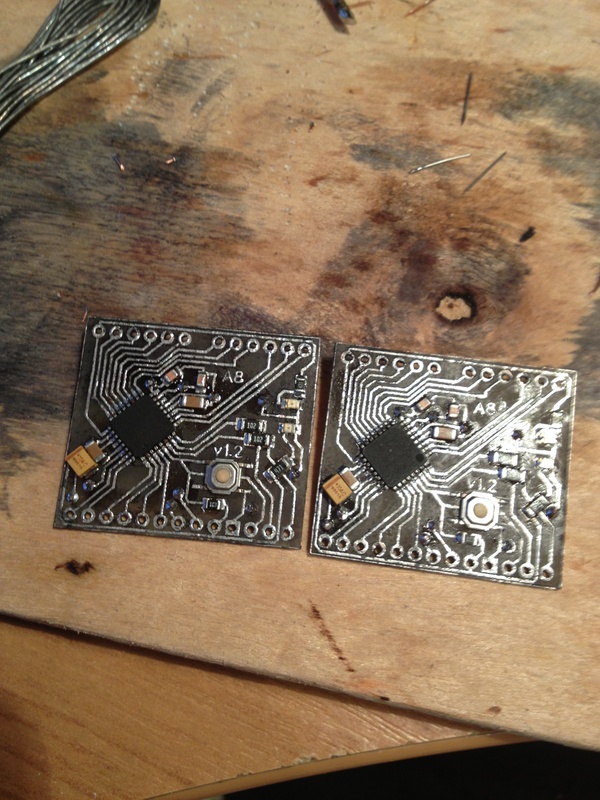

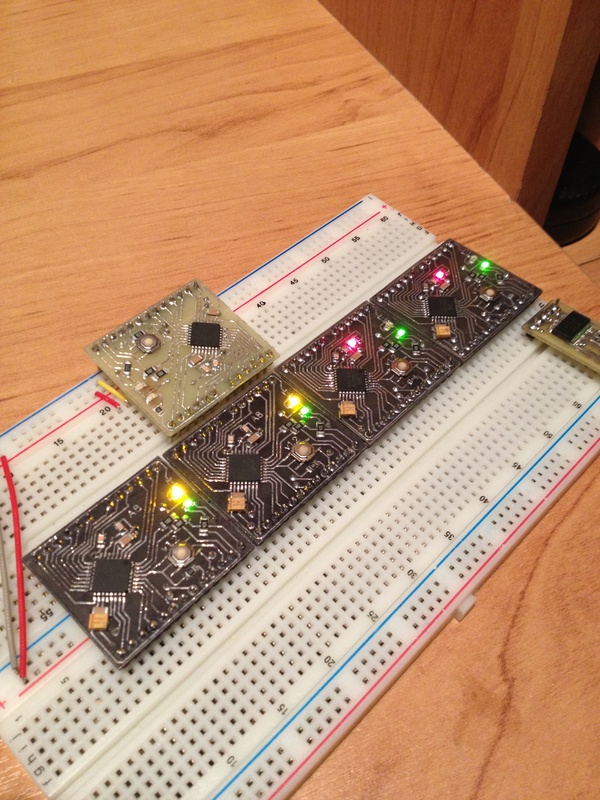

Finished product: on the left are two boards on the ATMega8 , on the right are two on the ATMega16 (the difference is in the additional LED on the 5 (PWM) leg, you can smoothly adjust the brightness). The white crow on top is the very first version of the board.

The thickness of the tracks is 0.33 mm, the outer boundary is 0.1 mm. The cost of one board in the region of 2 dollars can be safely left in the finished device.

DipTrace versions of

P.S. boards For versions with ATMega168 , ATMega328 and higher, it is worth adding a throttle to the AVCC foot, for ATMega8 this is useless, because the internal resistance between AVCC and VCC is about 6 ohms.

Using photoresistive technology and a one-component mask with eBay, you can achieve better results:

Vinyl compares favorably with photo paper and various kinds of substrates - the process of making a circuit board becomes less time-consuming and more economical, you can read about LUT here .

Content

- Board printing

- Board etching (briefly)

- Drilling, cutting, "painting"

- Tinning (short)

- Soldering SMD Components

- Programming

- Dokraska

- Source code

⇑ Print board

To transfer toner to the board, I will use Oracal 651 vinyl (spied here ). Oracal is already known among hams for its basis for self-adhesive film, it is also suitable for LUT and has similar properties.

This material can be bought at companies involved in vinyl printing (advertising agencies, stickers, etc.), or ordered on ibei .

The most important plus of this material is that it is self-adhesive .

This property allows us to use exactly as much vinyl as we need, without the need to throw out small trimmings, and also does not require tricky manipulations to feed the printer.

As a result, we can safely produce single devices of a small size without worrying about material consumption.

To get started, I print the board on plain A4 paper, then focusing on the lumen I paste a piece of vinyl.

And print again (do not forget to turn off all toner saving options).

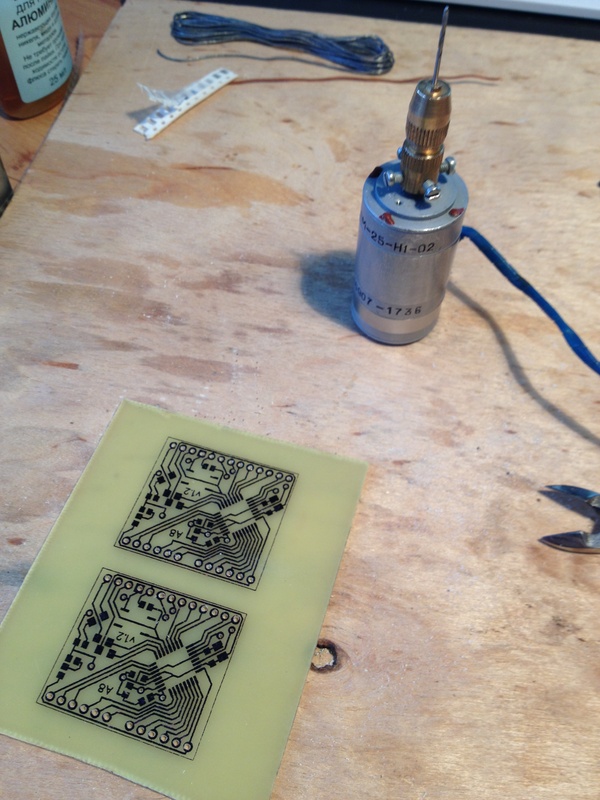

We clean the printed circuit board and impose the printed image.

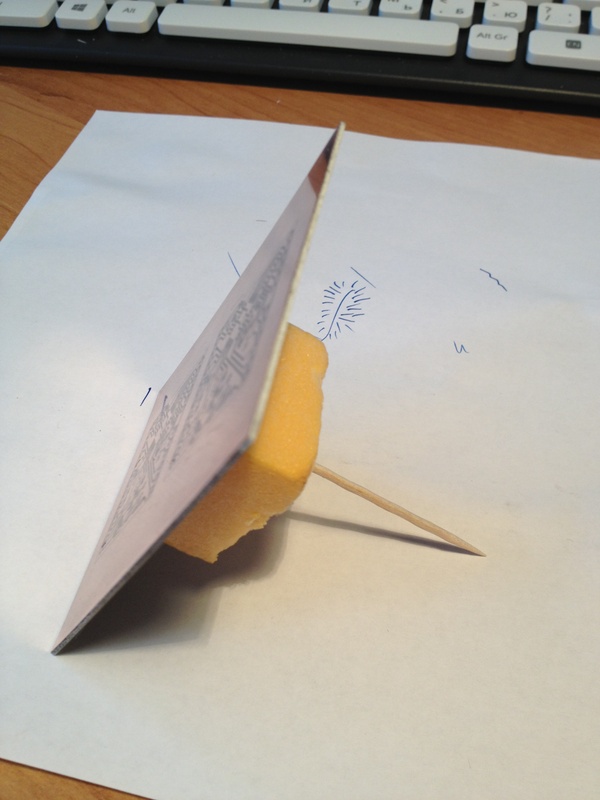

Iron is used to transfer the toner according to the standard scheme: the board is inserted into a paper “envelope” for pressure distribution, it makes sense to place a metal object under the cover to remove heat, then we simply press the hot duck (I set the temperature to maximum) to the board for 10-15 seconds , gently smooth the edges of the board and you're done.

The blank should be cooled in cold or warm water, this will help soften the paper used as a substrate.

Further, fans of typing with photo paper will be very pleased - there is no need to pore for a few minutes over the board by erasing pieces of paper and cleaning the tracks, the vinyl is removed meekly and leaves no residue. The first time I was even surprised at such a black toner. :)

To retouch poorly translated tracks, I use an ordinary gel pen. A permanent marker for these purposes is much better suited, but with a pen it turns out more accurately (even tracks of 0.3-0.2 mm are tinted without problems). The peculiarity of this method is that the gel dries for a long time, so either wait or look for a hair dryer. :)

⇑ Etched circuit board

Heated ferric chloride is used as a solution; the board is located “face down”. To speed up the etching process, the workpiece should be shaken periodically. Previously, a vibration motor from a Nokia phone did this work for me, but, in my negligence, he died the death of the brave and disappeared .

During etching, it is worth tidying up the workplace and preparing for soldering and drilling.

⇑ Drilling, cutting, “painting”

It turned out to be problematic to find 24 volts for the motor at home, I had to overclock the standard 5 using the MC34063 chip (more on easyelectronics.ru ).

The teskolit is quite thin, easy to cut with scissors.

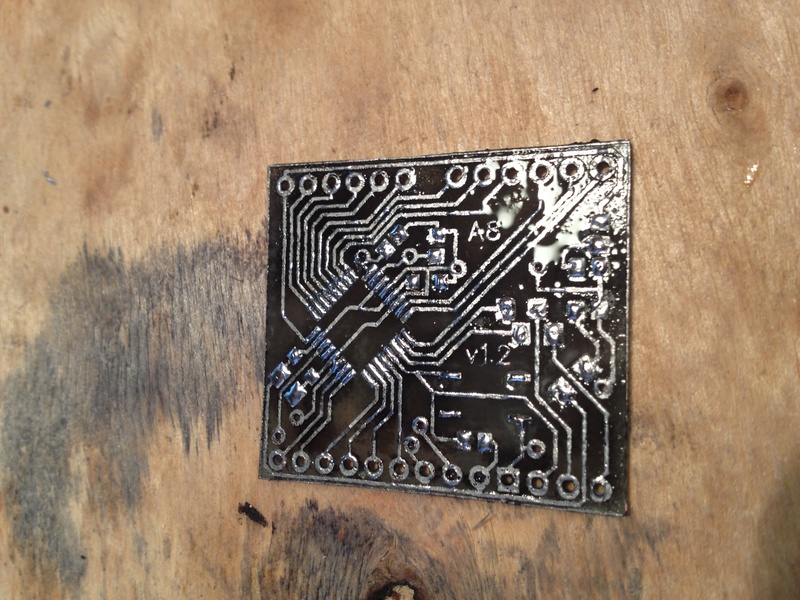

Either because of the poor solvent or because of the properties of the PCB (which is more likely) I couldn’t wash the toner without leaving any stains on the board, it looks very messy and leaves an unpleasant feeling in my soul. After much thought, I decided not to fight the problem, but to use it for my own good. We paint the board with a marker not suitable for tinting tracks. After we wash off the excess with acetone.

⇑ Tinning

For tinning, we need a thick sting and a lot of flux. :)

⇑ Soldering SMD components

There are many ways to solder SMD components (with a simple soldering iron, in the oven, on a searchlight, etc.), I prefer to use a hairdryer (since you can buy a good soldering station without any problems and for a little money).

Using a thin beveled sting we will apply a little solder to the places where our components will be located. In fact, this is a simple replacement for solder paste.

With tweezers we place the components in the places they put.

We heat the board with a hairdryer, help the components to look in the right direction with tweezers.

As jumpers I use a twisted pair wire, it is not very thick and holds its shape well.

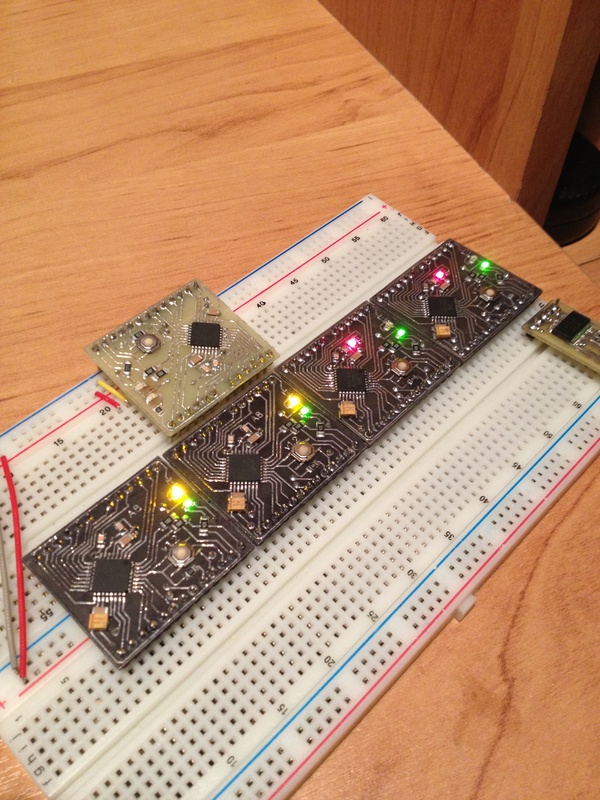

Almost finished product, it remains to solder the legs. In order to eliminate distortions in the future, the board can be installed on the breadboard and solder the side leads.

Done, the “dirty” work is behind, now the boards need to be washed and flashed.

I use a conductive flux, it can be washed off with a toothbrush under a stream of warm water, or you can throw the boards in an ultrasonic bath and go to drink tea (the two lower boards were made earlier, I decided that an extra bath would not harm them).

⇑ Programming

In order to turn the microcontroller on a piece of textolite into a full-fledged Arduin, we need to flash the bootloader, for this you can use any programmer, but for the sake of a single operation I take Arduin herself and the ArduinoISP sketch.

Any USB-UART adapter is suitable for downloading sketches, I personally soldered my own with the reset line (the board will reboot itself during the download of the sketch).

The adapter is based on FT232, the board is double-sided. Made the first time using the same vinyl (you need to combine patterns in the gap and glue the edges).

⇑ Step back

During washing and other operations, part of the black coating was washed off, so I repeated the painting already on the finished board.

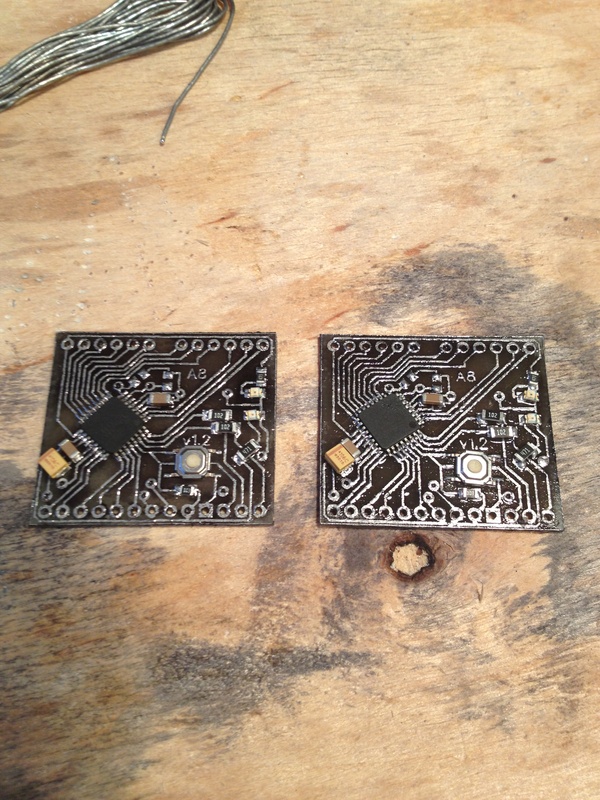

⇑ End

Finished product: on the left are two boards on the ATMega8 , on the right are two on the ATMega16 (the difference is in the additional LED on the 5 (PWM) leg, you can smoothly adjust the brightness). The white crow on top is the very first version of the board.

The thickness of the tracks is 0.33 mm, the outer boundary is 0.1 mm. The cost of one board in the region of 2 dollars can be safely left in the finished device.

DipTrace versions of

P.S. boards For versions with ATMega168 , ATMega328 and higher, it is worth adding a throttle to the AVCC foot, for ATMega8 this is useless, because the internal resistance between AVCC and VCC is about 6 ohms.

UPD 04/21/2013

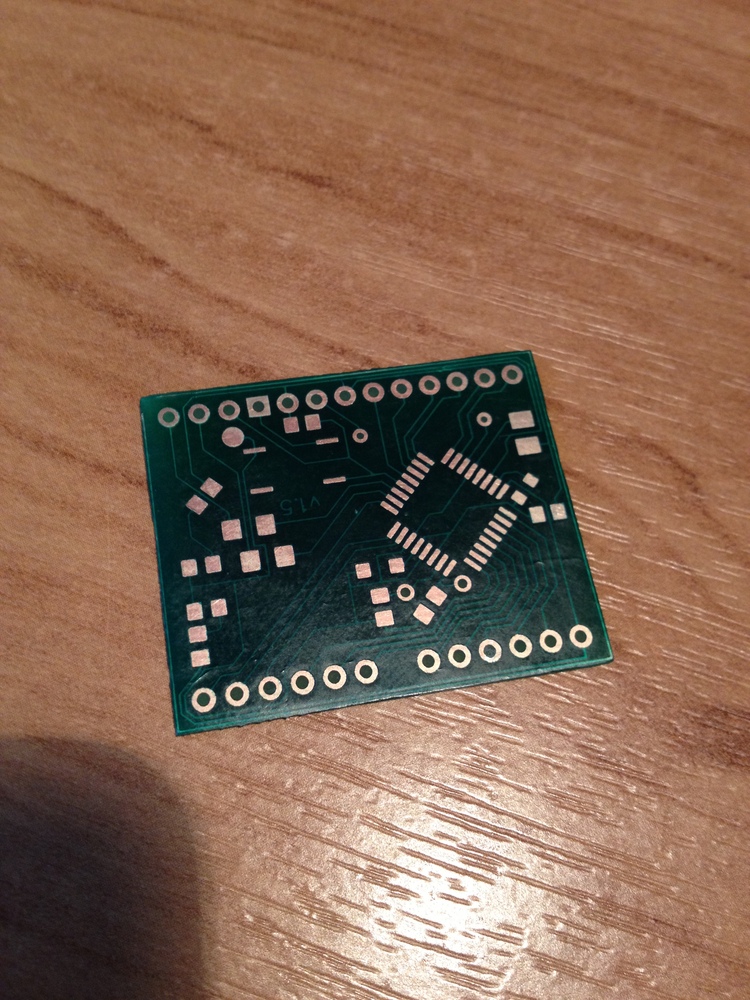

Using photoresistive technology and a one-component mask with eBay, you can achieve better results: