Winchester watches in a couple of hours

In 2009, on Habré, I saw a photo with a clock from a Winchester for $ 60 . Since I just stick out from the glands, I like to squeeze and look at them, and the brilliance of pancakes from the HDD simply fascinates me, I liked the thingy and after some time I repeated someone else’s experience as I was able to. Ahead of the holidays, weekends and, perhaps, someone wants to do the same needlework. Moreover, all this is very simple. Further traffic and pictures.

I had three dead hard drives in my household. Patients and conventional tools when assembling watches:

A screwdriver with a set of interchangeable bits, superglue and a Chinese magnifier with backlight with BuySKU for $ 14 , helping my decrepit vision, are especially useful . A set of star keys was needed, because in the new hard drives, manufacturers liked to use such screws, rather than ordinary, Phillips screws. Moreover, these new screws easily lick and it is almost impossible to unscrew them. This was the patient on the right who grunted the WD drive from the Apple iMac.

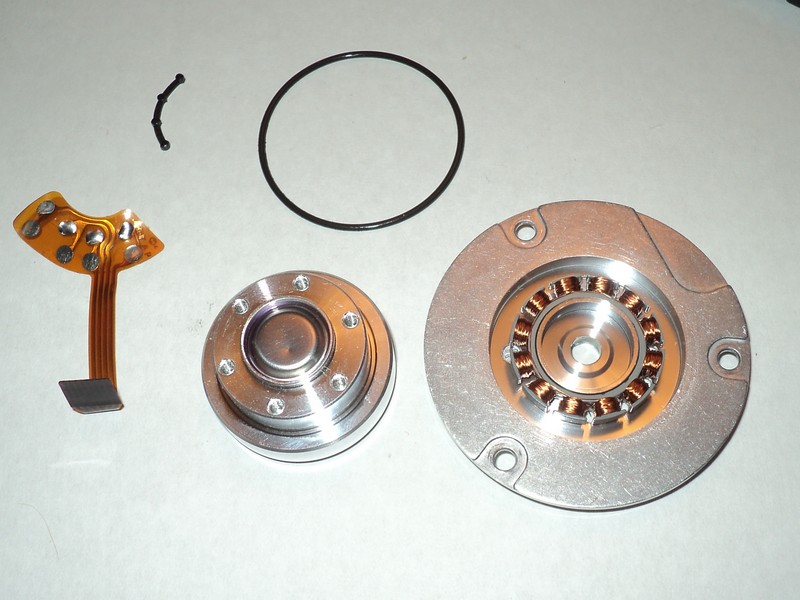

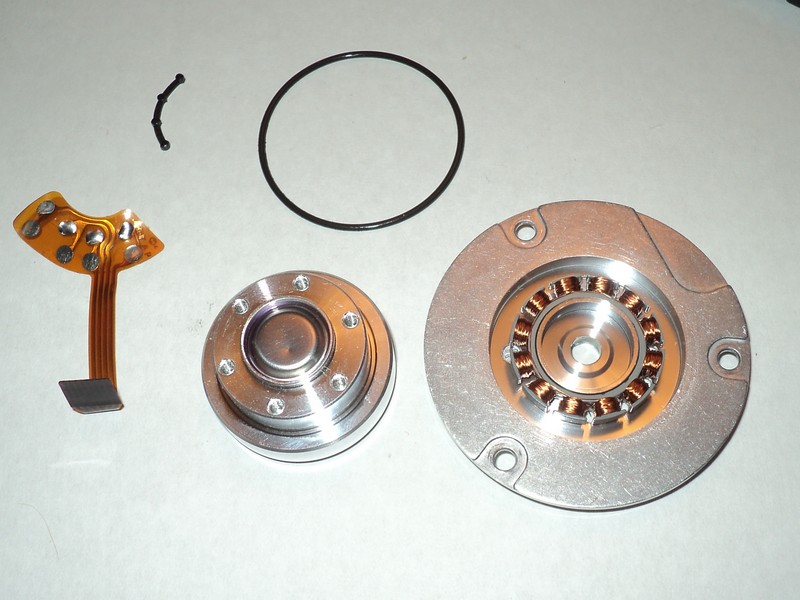

We analyze patients as much as possible, analyze the contents.

The far left, the ancient Fudjitsu, turned out to be the thinnest, and therefore the most convenient in my case. The fact is that the Winchester platform serves as the basis for the watch and you need to somehow place the clockwork on it. For me, the preferred option is always to put the clockwork in the back. Some authors cut a hole in the case to the size of the clockwork and somehow match them. The extreme option on the right (the most modern screw) turned out to be unsuitable at the moment. Firstly, the hexagonal slots on the screws licked from him, and secondly, the clock mechanism would have to be placed on the front side of the proposed watch, sticking out a pancake that would most likely hide part of the excellent mechanism for moving the heads. Compare the thickness of the cases, Fudjitsu, Samsung and WD:

No. 2 and 3 will wait until better times. Customize other key components. An donor alarm clock for 70 rubles from Auchan (his insides lie nearby), as well as a clock mechanism for needlewomen from Leonardo for 135 rubles.

It is worth noting that the idea of saving, having bought a cheap donor, was unsuccessful: the height of the turntable, on which the hands are mounted, was excessively small and it is more difficult to assemble a clock on such a mechanism, since it will need to fit literally in a fraction of a millimeter. What to do - the manufacturer was counting on a thin paper dial. Compare the height yourself:

Also pay attention to the arrows. Huge arrows on the left were bought in the same Leonardo for 75 rubles. A little expensive for a few drops of painted aluminum, but they are ideally suited to their clockwork. And at the same time they are completely unsuitable for watches from the Winchester, since they are excessively large. I’ll just cut them off until I find more suitable ones. The hands on the right are pulled out of the donor and, alas, are suitable only for its clockwork. Put off.

Also, in my farm there is already a stock of pancakes from different hard drives, in different shades and thicknesses:

As I said above, the mounting options for the clock mechanism can vary depending on the format of the hard drive, the type of clock mechanism used, the hands, the desired result and other restrictions due to the quirks and decisions of the body manufacturer.

In my case, I decided to place the running gear behind, pass the rack for the arrows through the engine plate, after knocking the engine out of it. Sometimes it is possible to keep the motor in place by knocking out the spindle. Then the pancake put back looks more esthetically. As an option - you can drill the spindle or use for decoration very sympathetic pressure plate-plates of pancakes. This fuss was useless to me because of the designated time limit. So, carefully dismantle and knock out the engine:

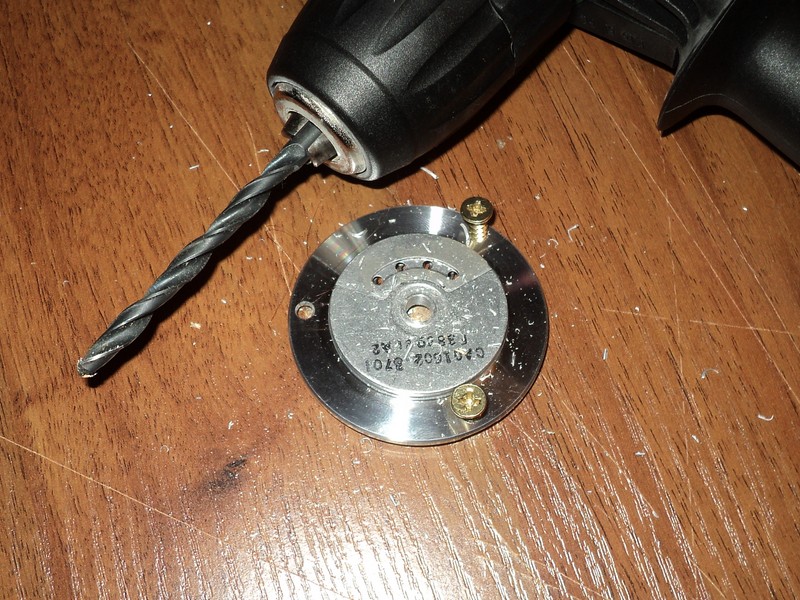

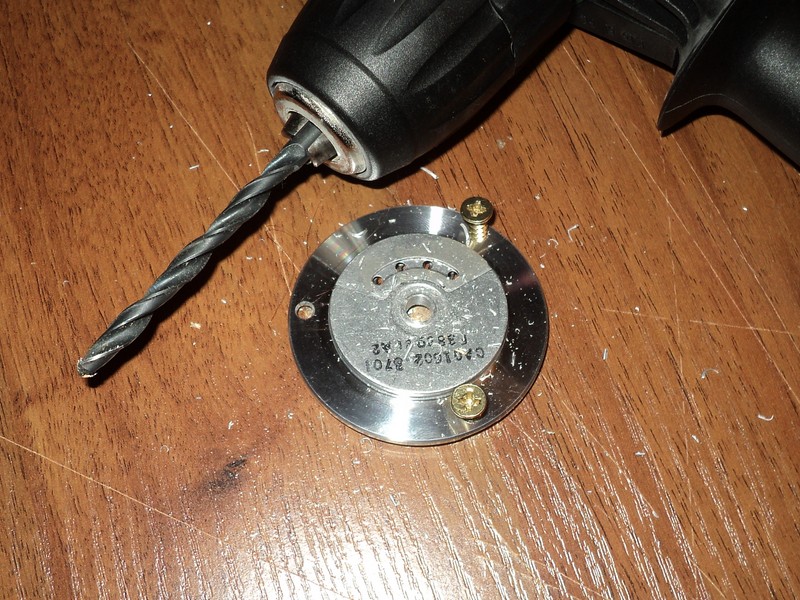

The hole in the center was too narrow; I had to expand it with a drill. I do not hold a vise in the apartment, therefore their role is played by the on-duty piece of chipboard and self-tapping screws, which fix the part. This is necessary, since it gets very hot during drilling, and it can just fly to the side, causing injuries:

The hole is widened, we are trying on. We fasten the plate in place, insert the mechanism at the back, and we see that in this version of the thread, which will be above the shiny pancake, it is not enough to fix the mechanism with a nut because of the sticking out screw caps:

The solution comes quickly: we unscrew the screws, and glue the plate on superglue, since the parts fit perfectly and fit perfectly together. Hats removed, win the required millimeter. As an option, it was possible to glue the clockwork mechanism back to the same superglue or double-sided tape and not use a nut. But I prefer to assemble so that the product can later be disassembled without tearing anything.

We fix the pancake, press it with a rubber washer and nut to the mechanism, tighten it to full fixation.

Proponents of aesthetics (and I) prefer more technologically advanced and beautiful solutions, but I have a time limit. So that the pancake does not loose, I fix it with three drops of superglue directly to the body of the screw.

Side view:

We hoist the pre-cut arrows and previously removed for convenience parts of the head positioning mechanism. It turned out to be somewhatbastardly unusual, but there are no suitable arrows, therefore, we grind our teeth with teeth.

A look falls on the remaining screw cap. Without thinking twice, we fasten it from behind, closing the clockwork and giving the structure weight. Wall mounting is provided by a hole drilled in the cover for ordinary wall nails and dowels:

We put in the phone a reminder that you need to buy fluorescent paint and cover it with arrows and, possibly, some other gizmos.

Minimum set of materials and tools

- Winchester (better faulty)

- Clockwork (maybe not everyone will do)

- Set of hands (hour, minute, second)

- Super glue

- Double-sided tape or such thick adhesive tape

- Winchester disassembly screwdriver

- Drill or other metal processing tools

I had three dead hard drives in my household. Patients and conventional tools when assembling watches:

A screwdriver with a set of interchangeable bits, superglue and a Chinese magnifier with backlight with BuySKU for $ 14 , helping my decrepit vision, are especially useful . A set of star keys was needed, because in the new hard drives, manufacturers liked to use such screws, rather than ordinary, Phillips screws. Moreover, these new screws easily lick and it is almost impossible to unscrew them. This was the patient on the right who grunted the WD drive from the Apple iMac.

We analyze patients as much as possible, analyze the contents.

The far left, the ancient Fudjitsu, turned out to be the thinnest, and therefore the most convenient in my case. The fact is that the Winchester platform serves as the basis for the watch and you need to somehow place the clockwork on it. For me, the preferred option is always to put the clockwork in the back. Some authors cut a hole in the case to the size of the clockwork and somehow match them. The extreme option on the right (the most modern screw) turned out to be unsuitable at the moment. Firstly, the hexagonal slots on the screws licked from him, and secondly, the clock mechanism would have to be placed on the front side of the proposed watch, sticking out a pancake that would most likely hide part of the excellent mechanism for moving the heads. Compare the thickness of the cases, Fudjitsu, Samsung and WD:

No. 2 and 3 will wait until better times. Customize other key components. An donor alarm clock for 70 rubles from Auchan (his insides lie nearby), as well as a clock mechanism for needlewomen from Leonardo for 135 rubles.

It is worth noting that the idea of saving, having bought a cheap donor, was unsuccessful: the height of the turntable, on which the hands are mounted, was excessively small and it is more difficult to assemble a clock on such a mechanism, since it will need to fit literally in a fraction of a millimeter. What to do - the manufacturer was counting on a thin paper dial. Compare the height yourself:

Also pay attention to the arrows. Huge arrows on the left were bought in the same Leonardo for 75 rubles. A little expensive for a few drops of painted aluminum, but they are ideally suited to their clockwork. And at the same time they are completely unsuitable for watches from the Winchester, since they are excessively large. I’ll just cut them off until I find more suitable ones. The hands on the right are pulled out of the donor and, alas, are suitable only for its clockwork. Put off.

Also, in my farm there is already a stock of pancakes from different hard drives, in different shades and thicknesses:

Next is the most interesting.

As I said above, the mounting options for the clock mechanism can vary depending on the format of the hard drive, the type of clock mechanism used, the hands, the desired result and other restrictions due to the quirks and decisions of the body manufacturer.

In my case, I decided to place the running gear behind, pass the rack for the arrows through the engine plate, after knocking the engine out of it. Sometimes it is possible to keep the motor in place by knocking out the spindle. Then the pancake put back looks more esthetically. As an option - you can drill the spindle or use for decoration very sympathetic pressure plate-plates of pancakes. This fuss was useless to me because of the designated time limit. So, carefully dismantle and knock out the engine:

The hole in the center was too narrow; I had to expand it with a drill. I do not hold a vise in the apartment, therefore their role is played by the on-duty piece of chipboard and self-tapping screws, which fix the part. This is necessary, since it gets very hot during drilling, and it can just fly to the side, causing injuries:

The hole is widened, we are trying on. We fasten the plate in place, insert the mechanism at the back, and we see that in this version of the thread, which will be above the shiny pancake, it is not enough to fix the mechanism with a nut because of the sticking out screw caps:

The solution comes quickly: we unscrew the screws, and glue the plate on superglue, since the parts fit perfectly and fit perfectly together. Hats removed, win the required millimeter. As an option, it was possible to glue the clockwork mechanism back to the same superglue or double-sided tape and not use a nut. But I prefer to assemble so that the product can later be disassembled without tearing anything.

We fix the pancake, press it with a rubber washer and nut to the mechanism, tighten it to full fixation.

Proponents of aesthetics (and I) prefer more technologically advanced and beautiful solutions, but I have a time limit. So that the pancake does not loose, I fix it with three drops of superglue directly to the body of the screw.

Side view:

We hoist the pre-cut arrows and previously removed for convenience parts of the head positioning mechanism. It turned out to be somewhat

A look falls on the remaining screw cap. Without thinking twice, we fasten it from behind, closing the clockwork and giving the structure weight. Wall mounting is provided by a hole drilled in the cover for ordinary wall nails and dowels:

We hang on the wall:

We put in the phone a reminder that you need to buy fluorescent paint and cover it with arrows and, possibly, some other gizmos.