Building effective business systems. Chapter 2.2 Business Processes: Local Optimization

At the moment, we have done tremendous work, identifying the main flows of the company, and arranging them in perfect order. I say “we”, because I believe that you are building this scheme with me, and you understand it completely. If this is not the case, then it may make sense to go back to the beginning of the document. If this does not clarify, then ask questions to the author.

But, let's leave for a while complex schemes and return to simple examples. A streamlined approach to organizing a business allows us to apply simple technical laws to our company, drawing from this many useful lessons.

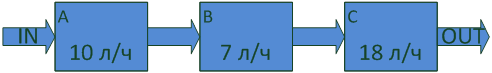

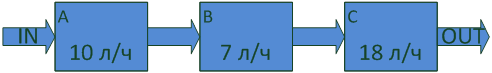

For example, consider a simple system of three tanks and connecting pipes:

Figure 6. The simplest flow system with limited throughput.

Suppose that water must be driven through this system. And the more water we drive, the better. As we see, each of the reservoirs has its own limitation. Tank A only allows 10 liters per hour, B 7 liters per hour, and C 18 liters per hour. Assume that at the beginning of the experiment all the tanks are empty. We deliver water to the IN pipe at a pressure of 18 l / h. Attention, question:

At what speed will water flow out of the OUT pipe?

There are several ways to get the answer: calculate the average of all tanks, take the largest number, take the smallest number, and other arithmetic operations. There is only one correct answer - 7 liters per hour. An old saying goes, “A chain is as strong as its weakest link.” (Remember the conclusion about the laws that are common to all systems?) Water will pass through the system at the speed with which the slowest tank can pass it, which means 7 liters per hour. What do you think will happen if you continue to supply water with a pressure greater than 7 l / h? If you have never "drowned" the neighbors, then I inform you: either it will break the pipe, or it will break the tank.

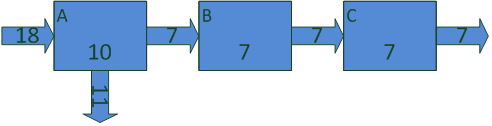

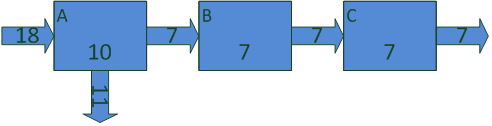

To avoid tragedy, we add a branch pipe, which will discharge excess water. In the diagram, we denote the actual speed of water passage through the system:

Figure 7. Actual speed of water passage.

The diagram shows that 11 liters per hour flows from the system to nowhere. I think, colleagues, you have already drawn analogies between this simple picture and our company flow chart. Imagine that this diagram depicts three departments of our company: "Sales - Production Managers - Workshop". No matter how much effort sellers spend on strengthening the incoming stream, the more “slowest” of the departments will work more than will not go through the company.

Let's look at another simple example. We will build a flow diagram of the assembly of a certain product, consisting of three posts and a conveyor belt between them.

Figure 8. Production flow.

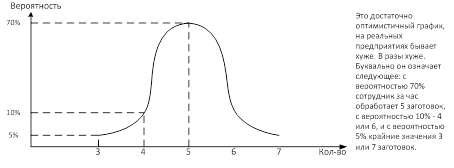

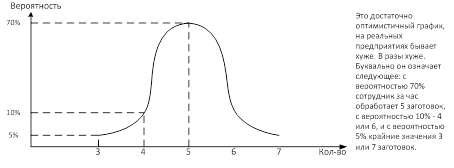

5 billets are fed to the production line, which must be processed to obtain 5 finished products. But at the same time, it should be remembered that living people are at the posts and sometimes they are distracted, tired or just lazy. In such cases, they process up to 3 in an hour instead of 5 blanks. But then they realize that they are behind the plan and quickly catch up, making up to 7 blanks. To be fair, we distribute the probability of processing so that the average output remains at level 5:

Figure 9. The probability of processing a different number of blanks.

And, of course, the question:

How many units of finished products will be produced in a forty-hour working week?

Production managers are required to consider this every day in the mind and very quickly. Try it and you, first count, and then look back.

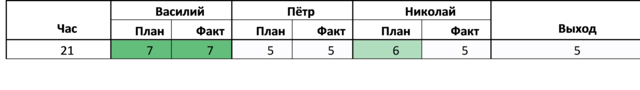

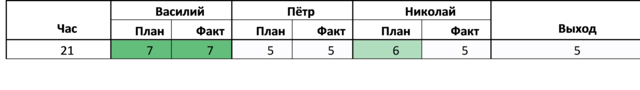

Table 1. Actual production chain production.

Let me remind you that the production plan for all is five, and the table shows what the employee planned for himself. Apparently, we lost 10% of productivity only on the fact that workers sometimes deviate from the norm of production! Let’s see how it turned out

Table 2. Actual production chain production (Fragment 1).

For example, in the first hour, Vasily processed four instead of the prescribed five pieces. Of course, after two hours, he caught up with the backlog, having made six instead of five, but in the first hour he transferred only four to the next post. What was happening at the second post at this time? Peter, acting in normal mode, was forced to periodically wait for work, because Vasily did not give it fast enough. Thus, from Peter to Nicholas also took four blanks instead of five, and the output in the first hour amounted to four units of production.

Table 3. Actual production chain production (Fragment 2).

I remind you again that live people are standing at the conveyor. All of them want to get paid, to please their children and live comfortably. Therefore, at the third hour, the situation may well look like this:

Peter, remembers that he is already lagging behind the norm of production, and decided to catch up with the lag, and also do a little for the future. For this reason, he planned to work as fast as possible and make 7 blanks. But Vasily had important things to do and, thinking about them, he did even less than the first hour. What do you think, how polite will Peter be with Vasily for the whole hour, which he will be forced to work under intense conditions, but at the same time systematically lose his work? And given that this is not the first time?

Every time you see conflicts in the company on the topic “What the hell is it for so long !?”, you observe the local Vasily and Peter.

In both examples considered, the first link performs less than planned, so the following links also produce less output. But what will happen if the first link exceeds the plan?

Table 4. Actual production chain production (Fragment 3).

As you can see from the table, nothing will change. In general, the whole chain will work only with normal output. Even Nikolai’s intention to overfulfill the plan will not help either. Here's what it looks like in practice:

Basil, catching up with the backlog, speeds up his work, making 7 blanks. But at the same time, Peter is ready to do only his norm - Vasily’s problems are not of interest to him (and after the conflicts at the beginning of his work, he is even a little happy with his difficulties). Peter works with the normal production of 5 units. Where to Vasily put the extra two blanks? As a rule, they are placed next to the workplace, giving rise to a huge heap of work in progress. Each time the previous link does more than it can accept the next, the surplus goes into reserves. In general, it’s not so scary when it comes to stocks of steel bars, which for years can lie in the aisle between the machines. And if we are talking about perishable blanks that can now be processed, but after an hour they are no longer suitable?

The first time we encountered a change in flow direction in the example of tanks and water. From this example, the following conclusion can be drawn:

When one of the departments tries to do more work than the following can take, the surplus goes into stock.

The second example with the production chain confirms our conclusion and gives us another one, which looks like this:

Fluctuations in link productivity reduce the productivity of the entire system, creating stocks.

Both of these findings (or systemic laws) "excellently" work side by side. I leave you the task for an independent solution:

Figure 10. The effect of two laws on the system.

Question:

What is the productivity of the system shown in Figure 10?

I will not give an answer to this question here, but I will ask a few more. Imagine that Vasily is our salesman. The figure shows that his performance is higher than that of Peter. (I’m not going to say now that this is actually the case, this is just a model.) Do you think, colleagues, can Vasily transfer the incoming customer flow “to the reserve”? No, he can not! The client is a very quickly deteriorating billet, spitting of which even for several minutes can make it unsuitable for further use.

Now that we’ve figured out flow systems and some of the laws that apply to them, I’m ready to clarify my point in the first chapter on performance and 100% load. If we force Vasily, Peter and Nikolai to work at full capacity, we will achieve an increase in the number of unfinished work, the departure of dissatisfied customers and conflicts between employees, but in no way increase the efficiency of the entire system.

The approach “everyone works 100%” is local optimization, and from all of the above, one important conclusion can be made:

Local optimization is bad!

I will give typical problems for “locally optimized” companies explaining why this is bad:

Problem No. 1: Inefficient use of resources. The head of each of the departments, striving to increase the effectiveness of his department, invests forces, money and other resources. Salesmen spend their energy on attracting new customers with whom there is no one to work with, production buys materials that will be needed very soon, buyers buy goods that are “interesting” in price but unnecessary in the market, etc.

Problem number 2 : Permanent conflicts in the team. I have already described several conflict situations above, and they all have a common nature of occurrence: within the framework of each department, each employee works in the best way (or at least not badly), and from the point of view of employees of other departments, he creates problems.

Problem number 3: Lagging behind the work plan and delaying employees at the workplace at the end of the working day. Incomplete work stocks must be raked. In factories, this is due to the fact that blanks in the aisle at some point block it completely, and in our work it looks like a manager’s plan, in which there is not enough space. And this causes the following problem.

Problem No. 4 : General decrease in work efficiency. An employee who, in terms of tasks, has more than should be forced to constantly switch between them. Switching between tasks takes extra time. Moreover, time is wasted both directly plunging into a previously left task, and trying to explain to a colleague who needs it to be completed, that another, more important problem for the company is currently being solved.

Problem number 5: Cash gaps. This problem should be described in the "Finance" section, but its causes are found, including here. The chaotic spending of funds (both tasks are performed and resources spent on them) negates the possibility of planning. And situations constantly arise in which the tasks that need to be solved in a week have already been paid, and there’s nothing to buy materials for today's work.

It should be noted here that not only problems No. 3 and No. 4 are related. Since the problems are systemic, they are also interlinked into the system. Figure 11 shows a fragment of the problem system that haunts us day after day:

Figure 11. A fragment of the company's problem system.

In order not to make me sad, I brought only part of a network of problems. If you do not believe me, answer the question: “How does systematic non-fulfillment of plans affect customer relations?” Or "How does labor efficiency affect employee wages?"

Effective managers in this place should say: “So let's list all the problems and solve them!” Great offer, but unfortunately completely useless. Solving each of these problems individually and even in small groups is nothing but another local optimization.

UPD`17:

I still can not get together to publish the material. If someone really needs or is just interested, then here is the link to the original. There is only one request: indicate full or partial use of the link to the author. All coordinates are inprofile .

But, let's leave for a while complex schemes and return to simple examples. A streamlined approach to organizing a business allows us to apply simple technical laws to our company, drawing from this many useful lessons.

Previous chapters

For example, consider a simple system of three tanks and connecting pipes:

Figure 6. The simplest flow system with limited throughput.

Suppose that water must be driven through this system. And the more water we drive, the better. As we see, each of the reservoirs has its own limitation. Tank A only allows 10 liters per hour, B 7 liters per hour, and C 18 liters per hour. Assume that at the beginning of the experiment all the tanks are empty. We deliver water to the IN pipe at a pressure of 18 l / h. Attention, question:

At what speed will water flow out of the OUT pipe?

There are several ways to get the answer: calculate the average of all tanks, take the largest number, take the smallest number, and other arithmetic operations. There is only one correct answer - 7 liters per hour. An old saying goes, “A chain is as strong as its weakest link.” (Remember the conclusion about the laws that are common to all systems?) Water will pass through the system at the speed with which the slowest tank can pass it, which means 7 liters per hour. What do you think will happen if you continue to supply water with a pressure greater than 7 l / h? If you have never "drowned" the neighbors, then I inform you: either it will break the pipe, or it will break the tank.

To avoid tragedy, we add a branch pipe, which will discharge excess water. In the diagram, we denote the actual speed of water passage through the system:

Figure 7. Actual speed of water passage.

The diagram shows that 11 liters per hour flows from the system to nowhere. I think, colleagues, you have already drawn analogies between this simple picture and our company flow chart. Imagine that this diagram depicts three departments of our company: "Sales - Production Managers - Workshop". No matter how much effort sellers spend on strengthening the incoming stream, the more “slowest” of the departments will work more than will not go through the company.

Let's look at another simple example. We will build a flow diagram of the assembly of a certain product, consisting of three posts and a conveyor belt between them.

Figure 8. Production flow.

5 billets are fed to the production line, which must be processed to obtain 5 finished products. But at the same time, it should be remembered that living people are at the posts and sometimes they are distracted, tired or just lazy. In such cases, they process up to 3 in an hour instead of 5 blanks. But then they realize that they are behind the plan and quickly catch up, making up to 7 blanks. To be fair, we distribute the probability of processing so that the average output remains at level 5:

Figure 9. The probability of processing a different number of blanks.

And, of course, the question:

How many units of finished products will be produced in a forty-hour working week?

Production managers are required to consider this every day in the mind and very quickly. Try it and you, first count, and then look back.

Table 1. Actual production chain production.

Let me remind you that the production plan for all is five, and the table shows what the employee planned for himself. Apparently, we lost 10% of productivity only on the fact that workers sometimes deviate from the norm of production! Let’s see how it turned out

Table 2. Actual production chain production (Fragment 1).

For example, in the first hour, Vasily processed four instead of the prescribed five pieces. Of course, after two hours, he caught up with the backlog, having made six instead of five, but in the first hour he transferred only four to the next post. What was happening at the second post at this time? Peter, acting in normal mode, was forced to periodically wait for work, because Vasily did not give it fast enough. Thus, from Peter to Nicholas also took four blanks instead of five, and the output in the first hour amounted to four units of production.

Table 3. Actual production chain production (Fragment 2).

I remind you again that live people are standing at the conveyor. All of them want to get paid, to please their children and live comfortably. Therefore, at the third hour, the situation may well look like this:

Peter, remembers that he is already lagging behind the norm of production, and decided to catch up with the lag, and also do a little for the future. For this reason, he planned to work as fast as possible and make 7 blanks. But Vasily had important things to do and, thinking about them, he did even less than the first hour. What do you think, how polite will Peter be with Vasily for the whole hour, which he will be forced to work under intense conditions, but at the same time systematically lose his work? And given that this is not the first time?

Every time you see conflicts in the company on the topic “What the hell is it for so long !?”, you observe the local Vasily and Peter.

In both examples considered, the first link performs less than planned, so the following links also produce less output. But what will happen if the first link exceeds the plan?

Table 4. Actual production chain production (Fragment 3).

As you can see from the table, nothing will change. In general, the whole chain will work only with normal output. Even Nikolai’s intention to overfulfill the plan will not help either. Here's what it looks like in practice:

Basil, catching up with the backlog, speeds up his work, making 7 blanks. But at the same time, Peter is ready to do only his norm - Vasily’s problems are not of interest to him (and after the conflicts at the beginning of his work, he is even a little happy with his difficulties). Peter works with the normal production of 5 units. Where to Vasily put the extra two blanks? As a rule, they are placed next to the workplace, giving rise to a huge heap of work in progress. Each time the previous link does more than it can accept the next, the surplus goes into reserves. In general, it’s not so scary when it comes to stocks of steel bars, which for years can lie in the aisle between the machines. And if we are talking about perishable blanks that can now be processed, but after an hour they are no longer suitable?

The first time we encountered a change in flow direction in the example of tanks and water. From this example, the following conclusion can be drawn:

When one of the departments tries to do more work than the following can take, the surplus goes into stock.

The second example with the production chain confirms our conclusion and gives us another one, which looks like this:

Fluctuations in link productivity reduce the productivity of the entire system, creating stocks.

Both of these findings (or systemic laws) "excellently" work side by side. I leave you the task for an independent solution:

Figure 10. The effect of two laws on the system.

Question:

What is the productivity of the system shown in Figure 10?

I will not give an answer to this question here, but I will ask a few more. Imagine that Vasily is our salesman. The figure shows that his performance is higher than that of Peter. (I’m not going to say now that this is actually the case, this is just a model.) Do you think, colleagues, can Vasily transfer the incoming customer flow “to the reserve”? No, he can not! The client is a very quickly deteriorating billet, spitting of which even for several minutes can make it unsuitable for further use.

Now that we’ve figured out flow systems and some of the laws that apply to them, I’m ready to clarify my point in the first chapter on performance and 100% load. If we force Vasily, Peter and Nikolai to work at full capacity, we will achieve an increase in the number of unfinished work, the departure of dissatisfied customers and conflicts between employees, but in no way increase the efficiency of the entire system.

The approach “everyone works 100%” is local optimization, and from all of the above, one important conclusion can be made:

Local optimization is bad!

I will give typical problems for “locally optimized” companies explaining why this is bad:

Problem No. 1: Inefficient use of resources. The head of each of the departments, striving to increase the effectiveness of his department, invests forces, money and other resources. Salesmen spend their energy on attracting new customers with whom there is no one to work with, production buys materials that will be needed very soon, buyers buy goods that are “interesting” in price but unnecessary in the market, etc.

Problem number 2 : Permanent conflicts in the team. I have already described several conflict situations above, and they all have a common nature of occurrence: within the framework of each department, each employee works in the best way (or at least not badly), and from the point of view of employees of other departments, he creates problems.

Problem number 3: Lagging behind the work plan and delaying employees at the workplace at the end of the working day. Incomplete work stocks must be raked. In factories, this is due to the fact that blanks in the aisle at some point block it completely, and in our work it looks like a manager’s plan, in which there is not enough space. And this causes the following problem.

Problem No. 4 : General decrease in work efficiency. An employee who, in terms of tasks, has more than should be forced to constantly switch between them. Switching between tasks takes extra time. Moreover, time is wasted both directly plunging into a previously left task, and trying to explain to a colleague who needs it to be completed, that another, more important problem for the company is currently being solved.

Problem number 5: Cash gaps. This problem should be described in the "Finance" section, but its causes are found, including here. The chaotic spending of funds (both tasks are performed and resources spent on them) negates the possibility of planning. And situations constantly arise in which the tasks that need to be solved in a week have already been paid, and there’s nothing to buy materials for today's work.

It should be noted here that not only problems No. 3 and No. 4 are related. Since the problems are systemic, they are also interlinked into the system. Figure 11 shows a fragment of the problem system that haunts us day after day:

Figure 11. A fragment of the company's problem system.

- Lagging behind the plan gives rise to conflicts between employees, because people who can and want to fulfill the plan constantly require the “guilty” (from their point of view) to hurry up or quit everything and switch to the “hung” task.

- Constant conflicts reduce labor efficiency, because employees spend time on “showdowns” with each other, on breaks after showdowns, on switching between tasks. And all this time they’re not working.

- A decrease in labor efficiency leads to a lag behind the plan.

- Lagging behind the plan makes it unreasonable to spend money. If the task consists of several sub-tasks, and one of them lags behind the plan, then in order to “optimize” the time, materials are often bought in advance, which will be required much later, services that are needed for subsequent tasks are paid. Within one department, this seems to be a completely justified step.

- Unreasonable expenditure of resources leads to a shortage of working capital. The amount of money at the checkout is limited. And the funds are paid to the cash desk, counting on the planned expense and the planned revenues. If, in order to save time, money should be spent earlier than planned, it is very likely that we will be left without funds for current expenses.

- Shortage of working capital gives rise to new conflicts. If there is no money at the checkout, then the employee cannot purchase materials to carry out his task. So, he will not have time to complete it in time (7). Therefore, there will again be problems. Again, you have to work overtime, and over the head someone will constantly complain, demand a hurry. It’s not only that the working conditions are hellish, but also they don’t give an advance.

In order not to make me sad, I brought only part of a network of problems. If you do not believe me, answer the question: “How does systematic non-fulfillment of plans affect customer relations?” Or "How does labor efficiency affect employee wages?"

Effective managers in this place should say: “So let's list all the problems and solve them!” Great offer, but unfortunately completely useless. Solving each of these problems individually and even in small groups is nothing but another local optimization.

UPD`17:

I still can not get together to publish the material. If someone really needs or is just interested, then here is the link to the original. There is only one request: indicate full or partial use of the link to the author. All coordinates are inprofile .