Does not burst and does not freeze

Employees of the Center for Composite Materials NITU "MISiS" and the company Biomimetix showed how a sandwich panel made of ultra high molecular weight polyethylene was holding up the impact.

The impact process is fixed by a special camera that shoots video at a speed of 30,000 frames per second.

“Our plate consists of a porous layer and a continuous layer of ultra-high molecular weight polyethylene,” says one of the founders of the company Biomimetix, an employee of the Center, Ph.D. Fedor Senates. - Layers are not connected to each other, but received immediately as a single product, in one technological operation. Largely due to this, after impact, cracks do not form either in the thickness of the layer, or even on the boundary between the layers. Moreover, the material retains the properties even up to -80 ° C. Moreover, we tried to split it in liquid nitrogen (-196 ° C). It turned out to be almost impossible to do if the plate was not strongly cut in advance. ”

According to Fedor Senatov, the developers not only threw heavy hardware at their development, but even shot at it. True, from pneumatics. However, the result was successful - the material extinguished the force of impact. So for the protection of hockey players or paintball fans (or even hunters), such a panel is ideal - this is complete protection with a reasonable budget.

“One of our first tasks was to create cheap protective material,” says the head of Biomimetix. “It does not reach combat protection in terms of defensive characteristics, but is better and much cheaper than existing sports defenses.”

The porous layer can also become a good sound absorber, said Fedor of the Senates. At the request of one of the business partners, the company is now specifying the optimal sound insulation parameters. As the developer noted, they can be configured by controlled changes in the porosity of the material.

New sandwich plates will be the basis for the creation of heat-insulating shock-resistant coatings. Therefore, the material certainly can be used in the Arctic - it is light, durable, able to protect not only from the Arctic wind, but also from its howling, and, moreover, durable.

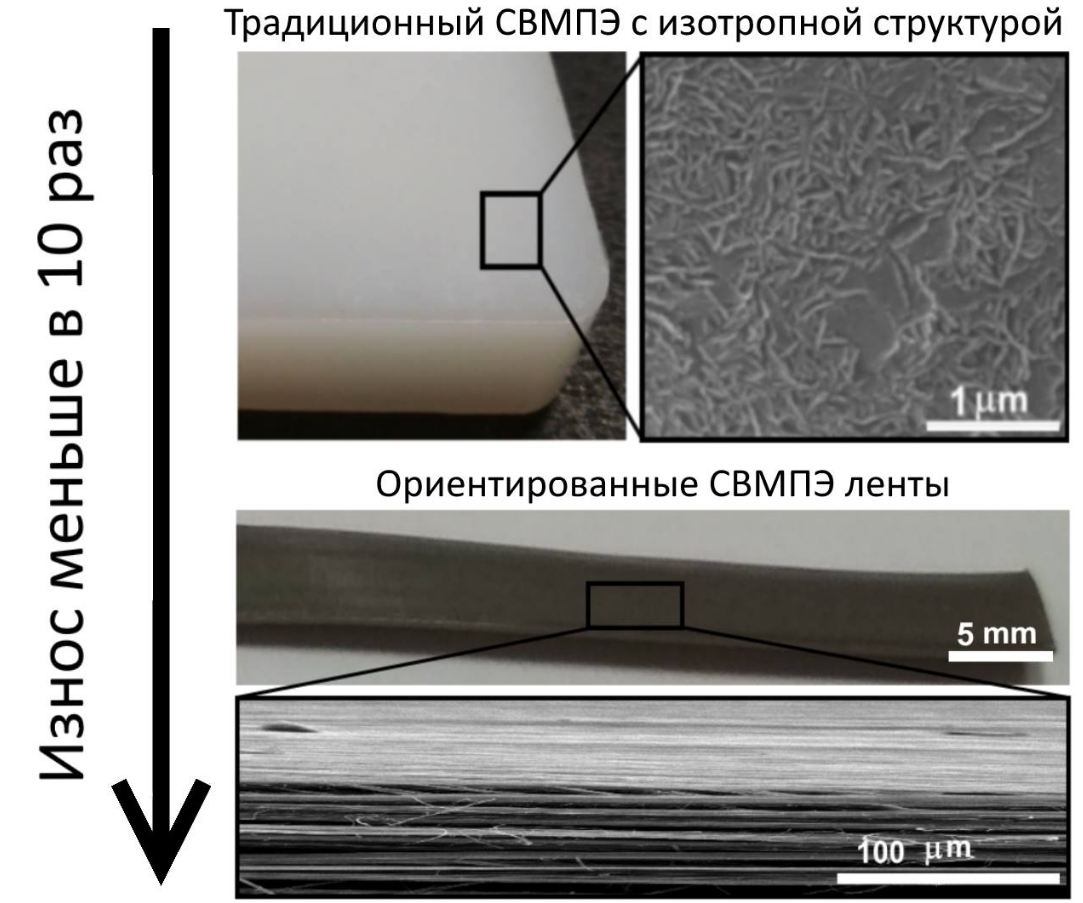

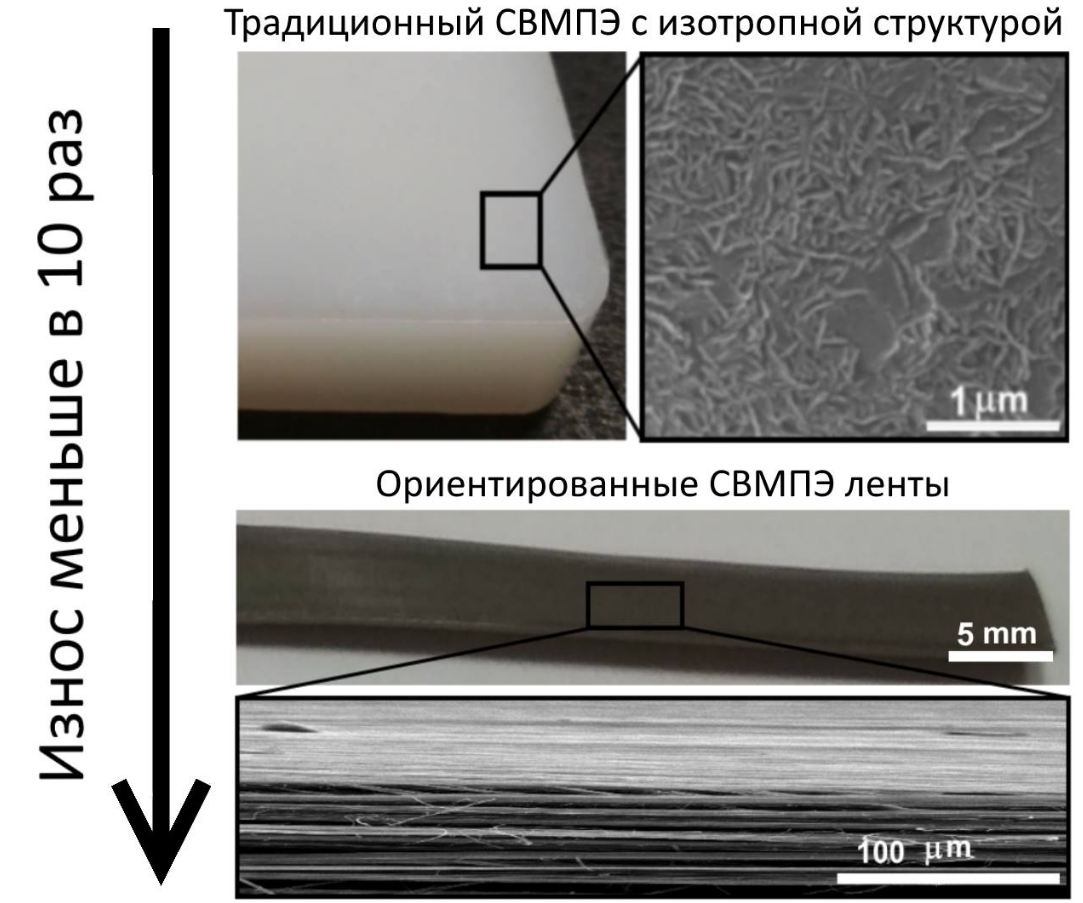

The durability of ultra-high molecular weight polyethylene was checked by employees of the company on another polymer product - bearing belts. Such belts embedded in the inner surface of the bearing are in contact with the balls or rollers. Due to the special technology of manufacturing tapes, they have an extremely low coefficient of sliding friction on steel - 0.04 (for existing bearings made of similar materials on the market, the coefficient of friction under similar conditions is at least twice as large). At the same time, wear resistance is higher by an order of magnitude, especially at low temperatures. The tape, like the sandwich panel, also does not change the characteristics up to -80 ° C.

“We talked to the miners, and they said that transportation belts of enormous length are used to transport the ore. Bearings on which the conveyor belt lies are often broken. Because of this, you have to stop to replace them. I believe that we will be able to reduce the frequency of replacement at least three times, or even more, - said Fedor Senates. “Thus, our development will bring a serious additional profit to companies that will use it.”

The company Biomimetix was a logical continuation of the work that scientists carried out in the NITU "MISiS". On the basis of the university, they opened a small innovative enterprise to bring a number of fundamental, and then applied works to a commercial product.

The impact process is fixed by a special camera that shoots video at a speed of 30,000 frames per second.

“Our plate consists of a porous layer and a continuous layer of ultra-high molecular weight polyethylene,” says one of the founders of the company Biomimetix, an employee of the Center, Ph.D. Fedor Senates. - Layers are not connected to each other, but received immediately as a single product, in one technological operation. Largely due to this, after impact, cracks do not form either in the thickness of the layer, or even on the boundary between the layers. Moreover, the material retains the properties even up to -80 ° C. Moreover, we tried to split it in liquid nitrogen (-196 ° C). It turned out to be almost impossible to do if the plate was not strongly cut in advance. ”

According to Fedor Senatov, the developers not only threw heavy hardware at their development, but even shot at it. True, from pneumatics. However, the result was successful - the material extinguished the force of impact. So for the protection of hockey players or paintball fans (or even hunters), such a panel is ideal - this is complete protection with a reasonable budget.

“One of our first tasks was to create cheap protective material,” says the head of Biomimetix. “It does not reach combat protection in terms of defensive characteristics, but is better and much cheaper than existing sports defenses.”

The porous layer can also become a good sound absorber, said Fedor of the Senates. At the request of one of the business partners, the company is now specifying the optimal sound insulation parameters. As the developer noted, they can be configured by controlled changes in the porosity of the material.

New sandwich plates will be the basis for the creation of heat-insulating shock-resistant coatings. Therefore, the material certainly can be used in the Arctic - it is light, durable, able to protect not only from the Arctic wind, but also from its howling, and, moreover, durable.

The durability of ultra-high molecular weight polyethylene was checked by employees of the company on another polymer product - bearing belts. Such belts embedded in the inner surface of the bearing are in contact with the balls or rollers. Due to the special technology of manufacturing tapes, they have an extremely low coefficient of sliding friction on steel - 0.04 (for existing bearings made of similar materials on the market, the coefficient of friction under similar conditions is at least twice as large). At the same time, wear resistance is higher by an order of magnitude, especially at low temperatures. The tape, like the sandwich panel, also does not change the characteristics up to -80 ° C.

“We talked to the miners, and they said that transportation belts of enormous length are used to transport the ore. Bearings on which the conveyor belt lies are often broken. Because of this, you have to stop to replace them. I believe that we will be able to reduce the frequency of replacement at least three times, or even more, - said Fedor Senates. “Thus, our development will bring a serious additional profit to companies that will use it.”

The company Biomimetix was a logical continuation of the work that scientists carried out in the NITU "MISiS". On the basis of the university, they opened a small innovative enterprise to bring a number of fundamental, and then applied works to a commercial product.