Flying Bear Tornado 2 - the new bear flew

Last October, the Flying Bear company , known to Russian users as Flying Bear, announced a new version of the popular Tornado 3D printer - today Flying Bear Tornado 2 is available for purchase at Top 3D Shop as a set for self-assembly.

Video

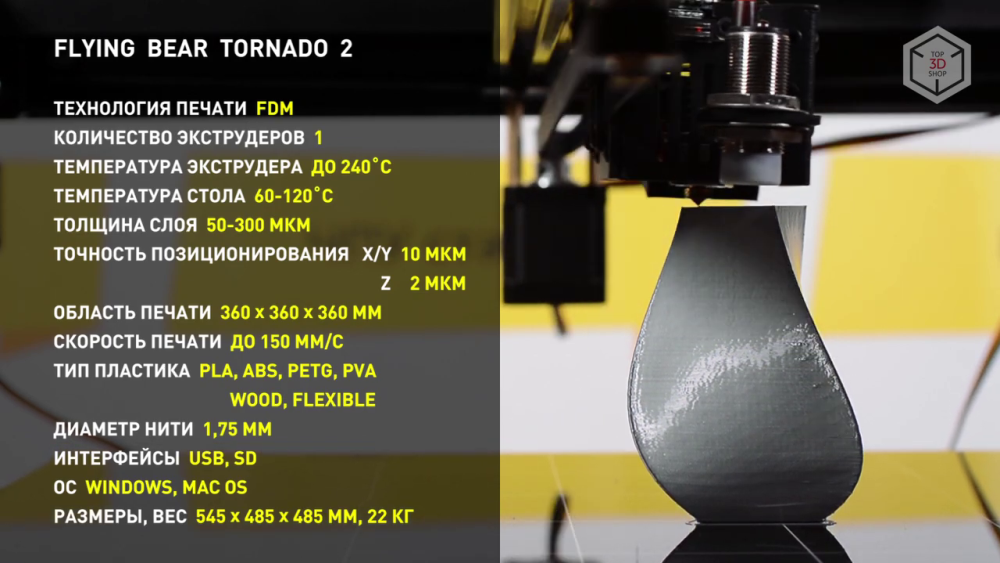

Flying bear tornado 2

- Power supply: 110V / 220V, 450W;

- Dimensions, mm: 545x485x485;

- Weight, kg: 20;

- Software: Repetier-host, Cura;

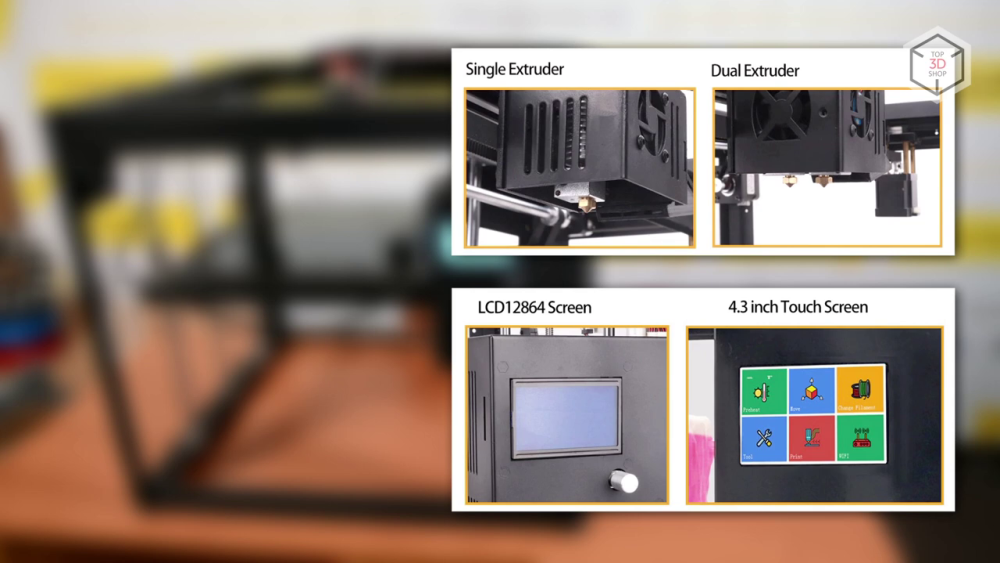

- Number of extruders: 1 (optional 2);

- Size of print area, mm: 360x360x360;

- Compatibility with operating systems: Windows, OsX;

- Temperature of the heating table, ° C: 60-120;

- Extruder temperature, ° C: 240;

- Printing technology: FDM;

- Layer thickness, microns: from 50;

- Positioning accuracy, µm: Z-2, XY-10;

- File format: STL, G-Code;

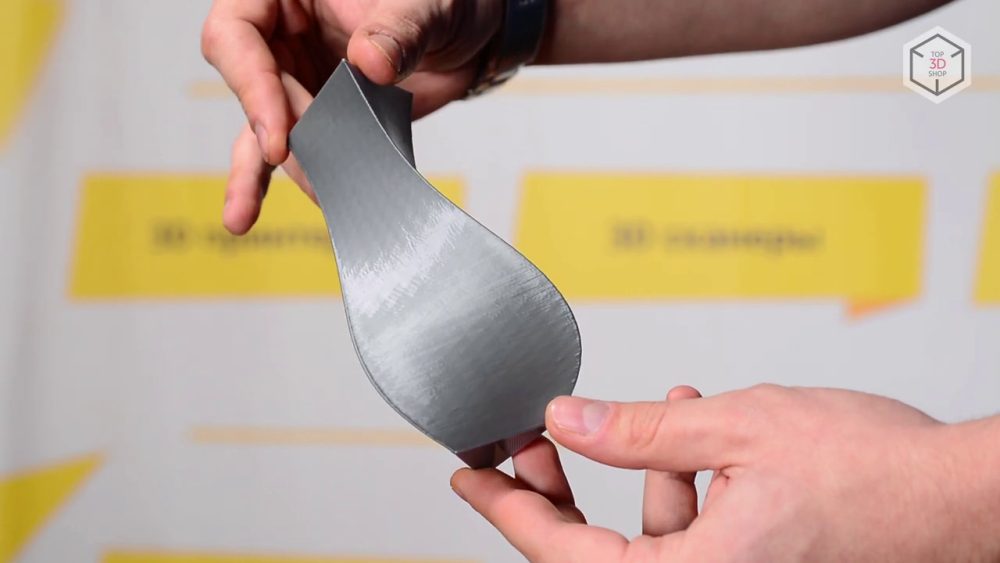

- Поддерживаемые материалы: PLA, ABS, PETG, Wood, PVA, Flex;

- Диаметр нити, мм: 1,75;

- Диаметр сопла, мм: 0,4 (опционально 0,2, 0,3 мм);

- Интерфейсы: SD, USB;

- Скорость печати, мм/сек: до 150;

- Цена, руб: 59 506 (ориентировочная, точную цену узнавайте на сайте).

Описание

The novelty is a solid frame structure. The first version of Tornado was based on the kinematics known as H-Bot. The new version uses a different kinematics, similar to that used in earlier versions of Makerbot 3D printers. The X axis motor is now located on the axis itself, which has reduced the load on the processor when the printer is running.

In addition to this major change, about a dozen improvements have been made to Tornado 2 - perhaps not as noticeable, but at the same time having a positive effect on print results.

Innovations

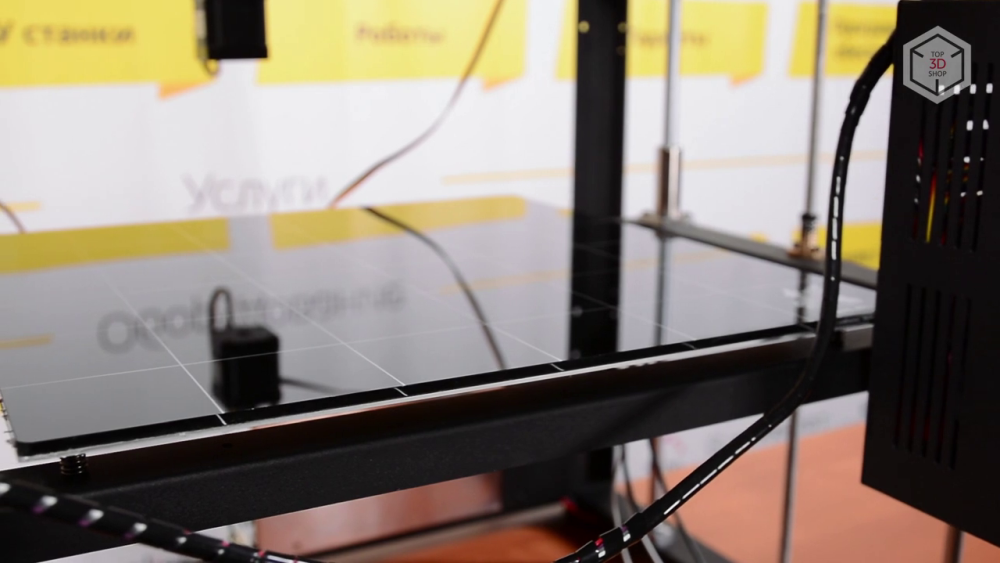

Flying Bear engineers installed a second engine on the Y axis, some steel components were replaced by milled aluminum, and the 3D printer was equipped with a more powerful, 600-watt power supply. Instead of an aluminum printing table, a glass work surface was installed.

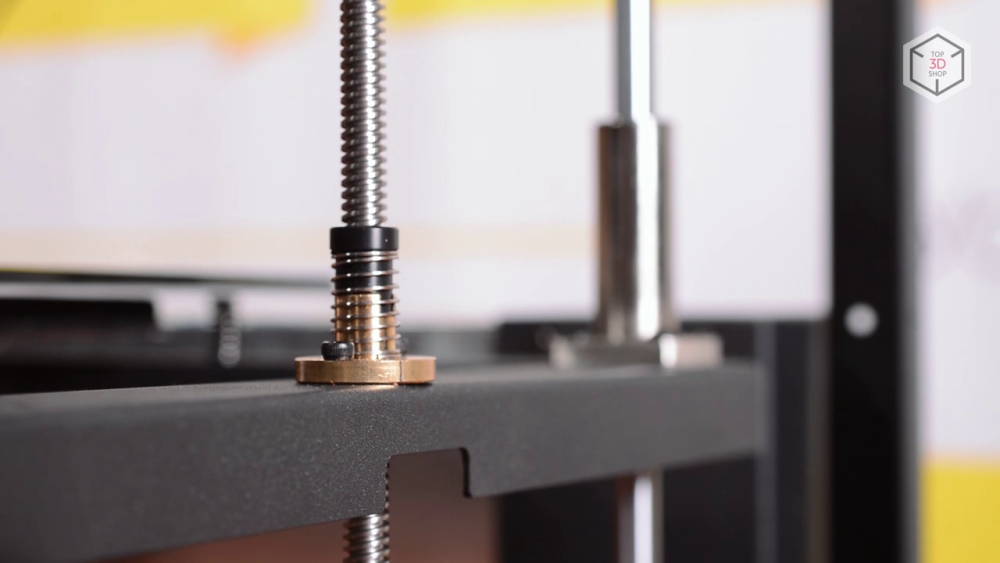

And also added anti-backlash springs, thrust bearings and holes for the installation of a protective casing. It is now easier to close the working volume of a 3D printer - earlier for this purpose it was necessary to drill a frame or use ties.

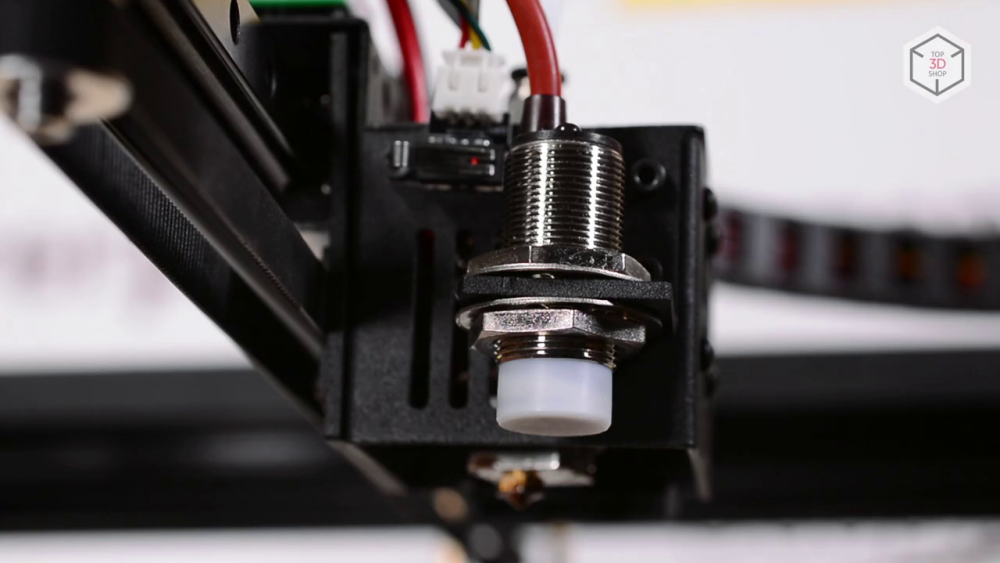

Using an inductive sensor improves the calibration accuracy to hundredths of a millimeter: set the required clearance, and then adjust using the screws located at the corners of the desktop.

Holder for the coil with plastic in the first version of the printer was placed behind, now - from the side. In terms of ease of filament replacement - heaven and earth.

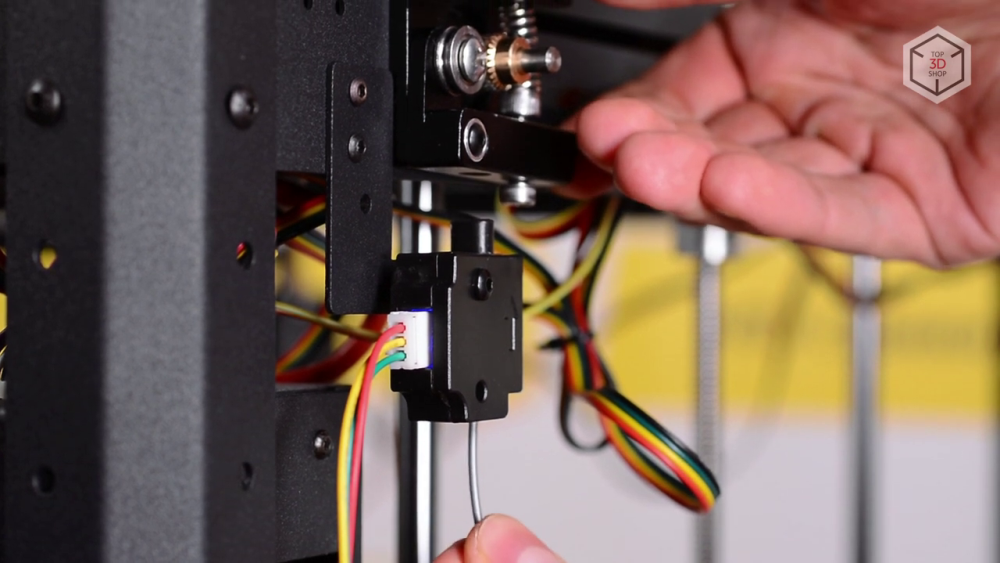

In the second Tornado, a filament termination sensor appeared - a convenient thing, but still rare in the budget printer segment.

Software

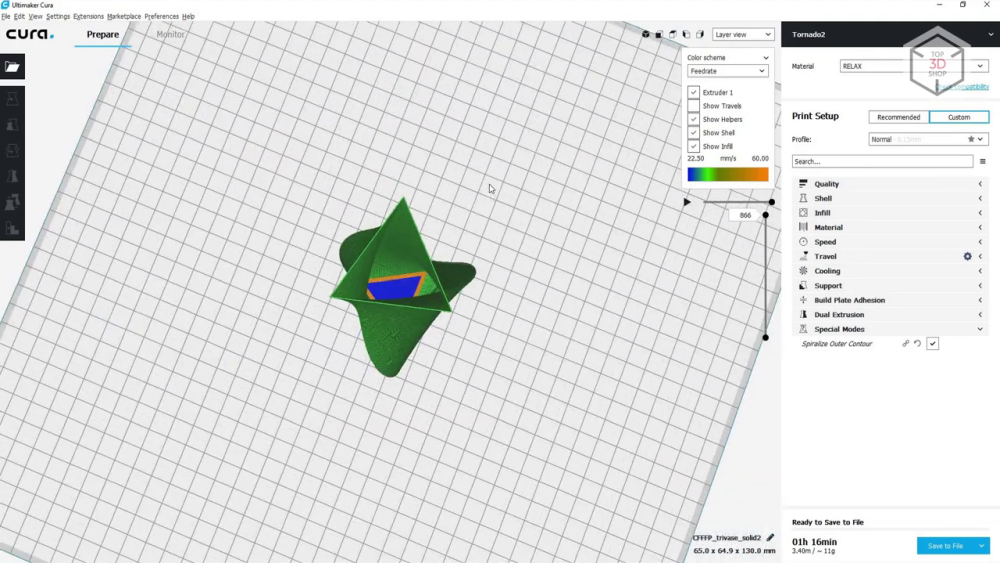

Preparation of 3D models for printing is recommended using the Cura program. Working with this slicer, we got the highest quality printouts. You can use another, more familiar to you software.

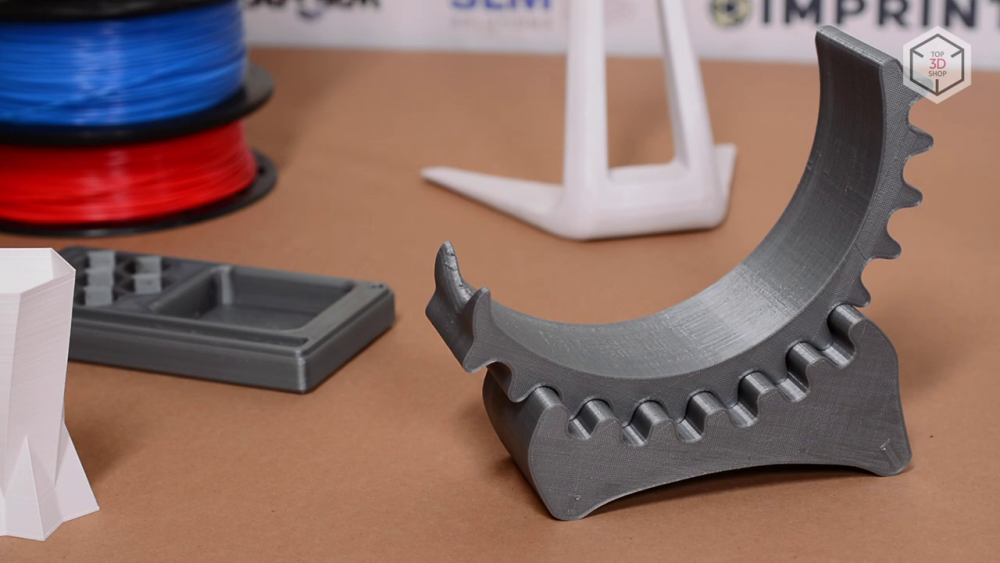

About brand

The Flying Bear Chinese brand , Flying Bear, has gained popularity among 3D print enthusiasts due to its good price-performance ratio, the results of the test print are excellent proof of that.

Modifications

In addition to the basic configuration, the second "Tornado" can also be supplied with two extruders or with a color touch screen.

Assembly

Tornado 2, despite all the positive differences from the first version, is still designed primarily for the “experienced users” category - self-assembly and configuration is a nontrivial task, and further upgrading a 3D printer requires minimal engineering and electrical engineering experience.

However, the buyer can order in the Top 3D Shop assembly and pre-configuration of a 3D printer.

You have read the review of the Flying Bear Tornado 2 FDM Printer , prepared by Top 3D Shop.

Need an inexpensive FDM 3D printer? Write to sales@top3dshop.ru and we will find the best option for your tasks and opportunities.

Subscribe to us in the social. networks: