Cable marking

In this article:

Marking makes sense when there are many wires and it is not immediately clear which one leads to where. It may not only be that there are too many of them.

As a rule, in the server (or data center - data center) some external channels (Internet, direct cables to other data centers, company branches, etc.) are connected, and local equipment is located in telecommunication cabinets.

The photo shows the top of such a cabinet. Cables from other devices in the rack are suitable from the bottom left, and cables that go to other racks or to external channels go up. Above the racks there is a special cable organizer.

Inside the rack, active and passive equipment are separated. Passive serves solely for switching purposes. For example, the patch panel:

Such a panel has 24 or more ports; it has a height of 1 U or 2U. On the back of the panel, all cables are bundled into a bundle that goes up to the rack. As a rule, all ports of one patch panel correspond to ports of another panel in another rack.

Thus, ports in active and passive equipment in various racks are subject to switching.

This table indicates:

It is clear that for equipment in the same rack passive patch panels may be absent. In addition, with different types of connectors adapters may be present, or passive equipment itself may be more complicated than a simple panel with ports. If all ports are the same, you can omit this.

In order to effectively label equipment, it is necessary to introduce some designation rules.

Firstly, all cabinets / racks within the data center or within the framework of several sites created for a common, but geographically spaced, are numbered. Since such a cabinet is called a rack, it is designated: R01, R02, etc.

Further, it is convenient to number active equipment from the bottom up with numbers, and passive equipment from top to bottom with the letters A, B, C, etc. Appropriate stickers are applied to the equipment itself or to the side of the rack.

Inside the equipment, you also need to enter the numbering. Many complex devices have modules in themselves, so to use the numbering applied to them, you must first specify the module number (always 1 if there are no modules there), and then the port number in it. Ports are numbered from left to right, from top to bottom. The port numbering should be transparent, for each type of equipment you need a picture with the numbering in the documentation, because when you plug in a lot of cables it’s not convenient to look at the numbers. And recently I met Cisco with the signs turned upside down, thanks to the Chinese.

Thus, to designate a specific port, we have something like:R01: 2 \ 1 \ 14 .

For passive equipment, it is enough:R03: E-21 , since for one device the numbering will probably be end-to-end.

Thus, we have a connection table from which it is absolutely clear how many cables are needed and which, as well as where to stick them.

Marking is necessary in order to be able to remove and plug any cable back. In addition, looking at the cable, it is possible to understand where it is going (or at least should go).

What to apply to the cable is a matter of taste.

Possible options:

For example, I chose the third option, when on each end of each cable it says:123 R01: 1 \ 2 \ 12: E-15 , where 123 is the connection number.

Then you can mark the required number of cables and then take them one at a time and insert them into the equipment, looking at the markings.

In principle, anything can be used, but it must be borne in mind that ordinary adhesive paper deteriorates from the "weather conditions" of the server, and also does not tolerate excesses in wires. Therefore, a film is better suited, and even better is a special one. I will consider this option below, but for now - what other options are there?

For example, I chose a method with marking on special paper.

On such paper there are separate stickers that are easy to peel off and stick well to the cable. They are called self-laminating, because gluing the cable begins with the paper part, and then the film (transparent) part is wrapped around the cable and covers the inscription itself, thereby ensuring its durability. Also, such paper withstands bending of the cable, but it is better to glue it on a straight cut, it will be smoother.

You can print on such paper using a conventional laser printer. One sheet in Russian stores, unfortunately, costs from 600 rubles (from 49 to ~ 200 stickers on the sheet, depending on which ones are needed). When ordering in the United States, prices will be 3-5 times lower.

For printing, you need to make a template, most conveniently - in the form of a table in Excel. For paper with 13x10 stickers, here is the template: link .

It is necessary to adjust the fields in the template to fit your printer, since differences of 1-2 mm affect significantly. You can scan and print this sheet on plain paper and try on it. You can print only on one sticker until it matches, but there is a danger that an offset will still come out somewhere below.

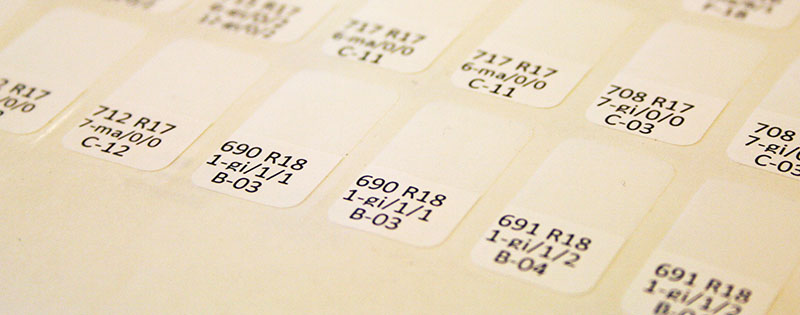

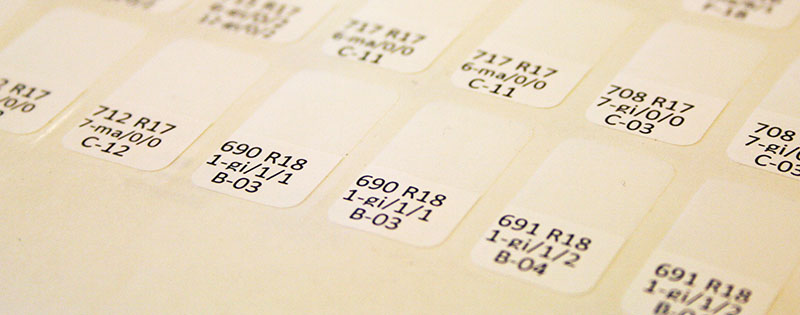

For printing, you must prepare a table with the inscriptions for cables. Columns: connection number, inscription on one end, inscription on the other. The inscription may match. In my case, I made the breakdown of the inscription into three lines: the number of the connection and the cabinet, the source equipment, the final equipment. It turned out a larger font, but there is a big minus: you need to look at the cable from almost 270-degrees-sides, which is not always easy.

The table is transferred to the template using the VBA macro. The specific macro will vary depending on the template and table.

R - sheet template, S - tables with source data.

The result of printing on the very first photo of the article. In 8 hours, you can glue 500-1000 cables.

Materials used:

About patch panels

About errors, please write in PM.

I also accept offers about what you would be interested in reading from a series of servers and server, telecommunication equipment (Cisco, EMC), servers and blade centers of HP, IBM, Hitachi, etc.

- preparation of the switching table;

- labeling options (what to put on cables);

- overview of labeling methods;

- An example of working with one of the methods, including a macro and a template for printing.

What are we going to commute with?

Marking makes sense when there are many wires and it is not immediately clear which one leads to where. It may not only be that there are too many of them.

As a rule, in the server (or data center - data center) some external channels (Internet, direct cables to other data centers, company branches, etc.) are connected, and local equipment is located in telecommunication cabinets.

The photo shows the top of such a cabinet. Cables from other devices in the rack are suitable from the bottom left, and cables that go to other racks or to external channels go up. Above the racks there is a special cable organizer.

Inside the rack, active and passive equipment are separated. Passive serves solely for switching purposes. For example, the patch panel:

Such a panel has 24 or more ports; it has a height of 1 U or 2U. On the back of the panel, all cables are bundled into a bundle that goes up to the rack. As a rule, all ports of one patch panel correspond to ports of another panel in another rack.

Thus, ports in active and passive equipment in various racks are subject to switching.

Switching table preparation

This table indicates:

- connection number;

- source active equipment;

- type of connector on the original equipment;

- passive equipment in the same rack;

- end active equipment;

- connector type on end equipment;

- active equipment in the same rack;

It is clear that for equipment in the same rack passive patch panels may be absent. In addition, with different types of connectors adapters may be present, or passive equipment itself may be more complicated than a simple panel with ports. If all ports are the same, you can omit this.

In order to effectively label equipment, it is necessary to introduce some designation rules.

Firstly, all cabinets / racks within the data center or within the framework of several sites created for a common, but geographically spaced, are numbered. Since such a cabinet is called a rack, it is designated: R01, R02, etc.

Further, it is convenient to number active equipment from the bottom up with numbers, and passive equipment from top to bottom with the letters A, B, C, etc. Appropriate stickers are applied to the equipment itself or to the side of the rack.

Inside the equipment, you also need to enter the numbering. Many complex devices have modules in themselves, so to use the numbering applied to them, you must first specify the module number (always 1 if there are no modules there), and then the port number in it. Ports are numbered from left to right, from top to bottom. The port numbering should be transparent, for each type of equipment you need a picture with the numbering in the documentation, because when you plug in a lot of cables it’s not convenient to look at the numbers. And recently I met Cisco with the signs turned upside down, thanks to the Chinese.

Thus, to designate a specific port, we have something like:

For passive equipment, it is enough:

Thus, we have a connection table from which it is absolutely clear how many cables are needed and which, as well as where to stick them.

What to put on a cable?

Marking is necessary in order to be able to remove and plug any cable back. In addition, looking at the cable, it is possible to understand where it is going (or at least should go).

What to apply to the cable is a matter of taste.

Possible options:

- connection number;

- indicate active (in the same rack) at the passive equipment port, and active in the same rack at the active port. It is convenient for the concept of where this cable leads, but it is impossible to insert it into the desired port without a table, it can be used for marking after switching;

- write the same thing at both ends: the number of the rack and which two ports the cable connects to it is convenient for preliminary marking, but without a table it’s not clear where this cable leads, especially if the correspondence of the patch panels is not indicated;

- others.

For example, I chose the third option, when on each end of each cable it says:

Then you can mark the required number of cables and then take them one at a time and insert them into the equipment, looking at the markings.

Overview of Labeling Methods

In principle, anything can be used, but it must be borne in mind that ordinary adhesive paper deteriorates from the "weather conditions" of the server, and also does not tolerate excesses in wires. Therefore, a film is better suited, and even better is a special one. I will consider this option below, but for now - what other options are there?

- Special tags ;

- ordinary marker, the number can be written directly on the cable;

- you may be asked to label cable manufacturers if the order goes directly from the factory;

- equipment that prints marking itself (video of work by reference);

- typesetting rings .

Example

For example, I chose a method with marking on special paper.

On such paper there are separate stickers that are easy to peel off and stick well to the cable. They are called self-laminating, because gluing the cable begins with the paper part, and then the film (transparent) part is wrapped around the cable and covers the inscription itself, thereby ensuring its durability. Also, such paper withstands bending of the cable, but it is better to glue it on a straight cut, it will be smoother.

You can print on such paper using a conventional laser printer. One sheet in Russian stores, unfortunately, costs from 600 rubles (from 49 to ~ 200 stickers on the sheet, depending on which ones are needed). When ordering in the United States, prices will be 3-5 times lower.

For printing, you need to make a template, most conveniently - in the form of a table in Excel. For paper with 13x10 stickers, here is the template: link .

It is necessary to adjust the fields in the template to fit your printer, since differences of 1-2 mm affect significantly. You can scan and print this sheet on plain paper and try on it. You can print only on one sticker until it matches, but there is a danger that an offset will still come out somewhere below.

For printing, you must prepare a table with the inscriptions for cables. Columns: connection number, inscription on one end, inscription on the other. The inscription may match. In my case, I made the breakdown of the inscription into three lines: the number of the connection and the cabinet, the source equipment, the final equipment. It turned out a larger font, but there is a big minus: you need to look at the cable from almost 270-degrees-sides, which is not always easy.

The table is transferred to the template using the VBA macro. The specific macro will vary depending on the template and table.

Public Sub CopyToExcel()

' Параметры шаблона '

Dim StepV As Long

Dim StepH As Long

Dim CountH As Long

' Текущее положение в шаблоне '

Dim CurrentH As Long

Dim CurrentV As Long

' Текущая строчка таблицы маркировки '

Dim currentL As Long

' Элементы текста маркировки '

Dim Say As String

Dim Rack As String

Dim Patch As String

Dim Active As String

' Начальные параметры '

StepV = 4

StepH = 2

CountH = 12

currentL = 2

CurrentH = 1

CurrentV = 1

With Sheets("R")

While Sheets("S").Cells(currentL, 1) <> ""

If Len(Sheets("S").Cells(currentL, 2)) > 0 Then

Say = Sheets("S").Cells(currentL, 2)

' Link number '

Rack = Left(Say, 3)

Say = Replace(Say, Rack & "=", "")

.Cells(CurrentV, CurrentH).Value = Val(Replace(Sheets("S").Cells(currentL, 1), ".", "")) & " " & Rack

.Cells(CurrentV, CurrentH + StepH).Value = Val(Replace(Sheets("S").Cells(currentL, 1), ".", "")) & " " & Rack

Active = Replace(Left(Say, InStr(Say, "=")), "=", "")

Patch = Replace(Say, Active & "=", "")

' First link '

.Cells(CurrentV + 1, CurrentH).Value = Active

.Cells(CurrentV + 2, CurrentH).Value = Patch

' Second link '

.Cells(CurrentV + 1, CurrentH + StepH).Value = Active

.Cells(CurrentV + 2, CurrentH + StepH).Value = Patch

' New coordinates '

CurrentH = CurrentH + 2 * StepH

If CurrentH >= (CountH - 0) * StepH - 1 Then

CurrentH = 1

CurrentV = CurrentV + StepV

End If

' Если нужно два и более одинаковых кабеля, где-то тут нужно добавить на это проверку и скопировать. '

End If

currentL = currentL + 1

Wend

End With

End Sub

R - sheet template, S - tables with source data.

The result of printing on the very first photo of the article. In 8 hours, you can glue 500-1000 cables.

Materials used:

About patch panels

About errors, please write in PM.

I also accept offers about what you would be interested in reading from a series of servers and server, telecommunication equipment (Cisco, EMC), servers and blade centers of HP, IBM, Hitachi, etc.