Waiting for the start of the electric "Electron"

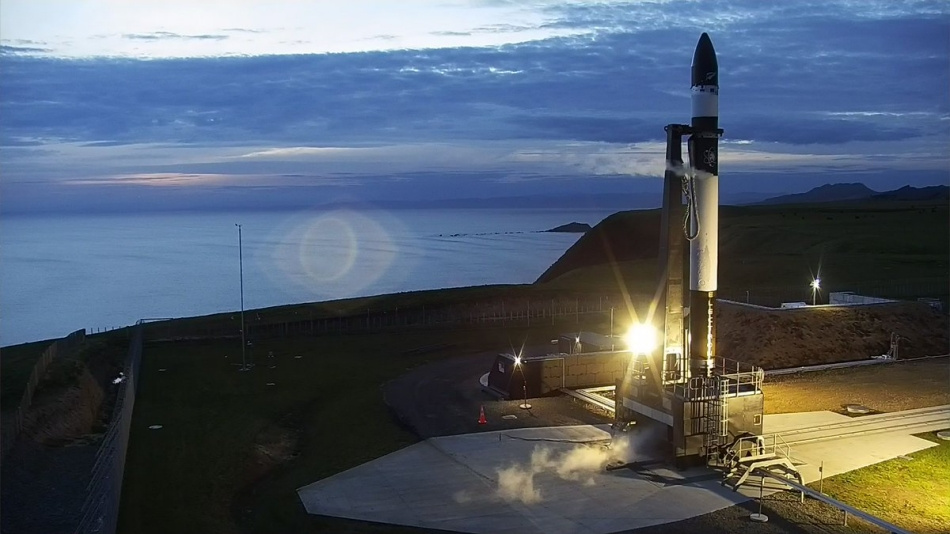

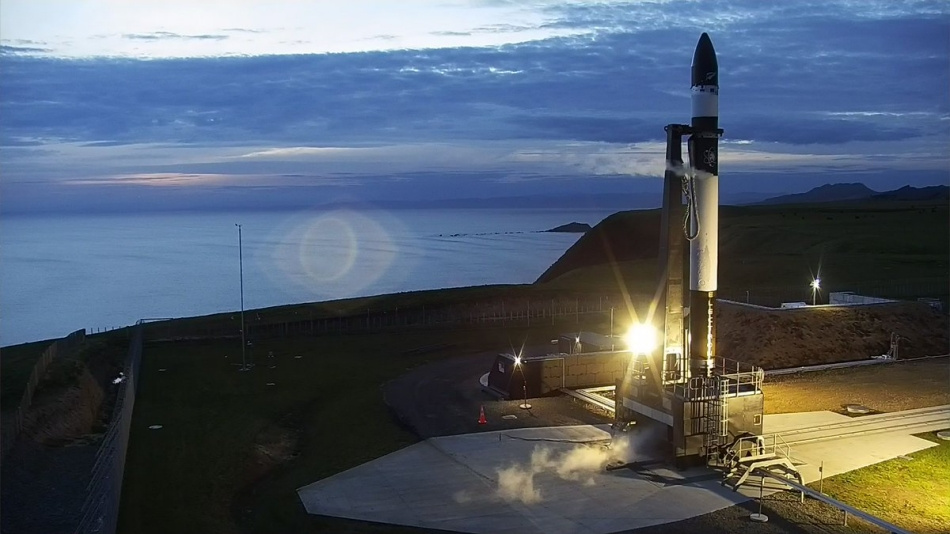

At 9 am Monday to New Zealand time (21:00 GMT, 23:00 MSK) a ten-day launch window opens for the first launch of the Electron light launch vehicle. In New Zealand it is now windy , and the launch of the missile at the launch has already been transferred at least to Tuesday. Despite its low payload, Electron is characterized by a high concentration of modern technologies - composite tanks, 3D printing of engines and a fundamentally new idea of a drive from an electric motor of pumps feeding fuel components.

Electron on the launch pad, photo Rocket Lab

Peter Beck next to the PH Electron rocket and experimental rockets in the background, Rocket Lab photo

The Electron rocket is developed by the Rocket Lab company, which was founded in 2006 by Peter Beck. Legally, this is an American private company with a New Zealand branch. In 2009, they launched a офtea-1 geophysical rocket (in Maori "space") and claim that they became the first private company to reach space in the southern hemisphere. Theoretically, the rocket was supposed to climb 100-120 km, the first stage worked fine, and traces of successful separation were found on it, but the head part was not found after the flight, and the achievement remains questionable.

On the old site, you can find plans to create a Ātea-2 geophysical rocket, but after the success of 2009, the company became interested in DARPA. For the next few years, Rocket Lab developed rocket technology in collaboration with Lockheed Martin, DARPA and the US Department of Defense. In 2010, a new fuel was tested. In the tank it was stored in solid form, but when pressure was applied to the tank, the fuel turned into a viscous liquid and could be fed into the combustion chamber. Thus, it had to combine the advantages of solid fuel (convenient storage of one component) and liquid (the ability to control the engine and restart the engine).

In 2011, the test passed a compact rocket drone. A small rocket could have been fired by a soldier with an arm outstretched, and a picture from a drone descending by parachute was supposed to help fight in conditions of very rough terrain, for example, in a city.

By 2013, the company was at a crossroads. It was possible to continue to earn on defense contracts, but Beck dreamed of commercial space. Having collected additional investments, Rocket Lab has started the development of a new launch vehicle. In 2013, the engine was successfully tested with components supplied with electric motors, and the Electron project was announced. In 2014, a second round of investment collection was held. In 2015, it became known that during the production of the engine, 3D printing would be widely used, and the engine itself was named Rutherford in honor of a New Zealand physicist. Also in the same year, the construction of a cosmodrome on the Mahia Peninsula began (Hawk Bay, North Island of New Zealand)

The location in the eastern part of the island will allow you to easily transfer the payload to the sun-synchronous or low near-earth orbit - in the southern and eastern direction for many hundreds of kilometers stretch the ocean, into which you can, with no one agreeing, drop the spent steps.

In 2016, the rocket passed ground tests, and the spaceport was completed. The first flight of the Electron launch vehicle was scheduled for 2017. And over the past 4.5 months, Rocket Lab has managed to conduct another round of investment collection and has already started receiving orders for commercial launches.

Electron rocket, photo Rocket Lab

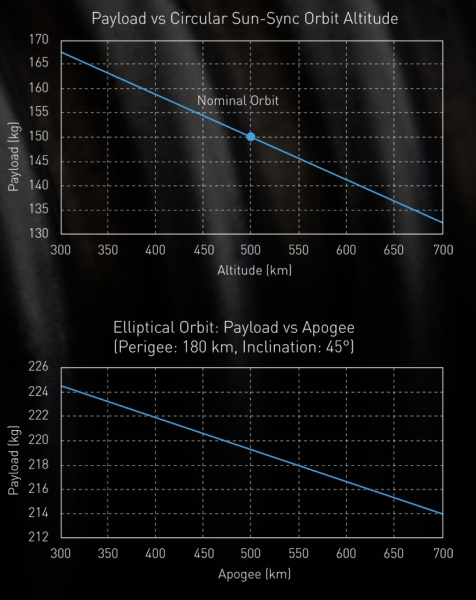

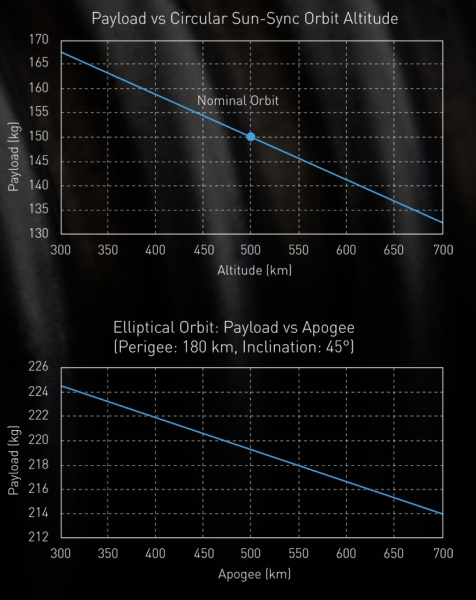

Electron - a two-stage booster with a height of 17 meters and a diameter of 1.2 meters. With an initial mass of around 12.5 tons, it will be able to bring 150 kg into a polar orbit 500 km high. A typical solar-synchronous orbit is usually higher, 600-800 km, where the carrying capacity will be lower. Also, if necessary, the rocket can put 225 kg into orbit 180x300 km with an inclination of 45 °.

Screenshot of the official site Rocket Lab The

tail of the first stage with the engine cover removed, photo Rocket Lab

The first stage with a height of 12.1 meters has a dry weight of 950 kg and carries 9250 kg of fuel. There are nine Rutherford engines (more on them below) with a total of 16.5 tons at the start. Maximum thrust in flight should reach 19.5 tons, and the specific impulse of engines at sea level will be 303 seconds. According to the flight plan, the first stage will have to work for 2.5 minutes. At the stage near the engines, 13 battery packs with a total capacity of more than a megawatt are installed.

The second step. At the edge of the step to the left of the engine, a block of orientation engines is visible. Photo Rocket Lab

The second stage with a height of 2.1 meters has a dry weight of 250 kg and carries 2150 kg of fuel. It is equipped with one Rutherford engine with a high-altitude nozzle, a 2.2 tonne load and a specific impulse of 333 seconds. The engine of the second stage according to the plan should work a little less than five minutes. The stage has three battery packs, two of which will be discharged in flight as it is exhausted in order to ease the stage.

The design of the launch vehicle is distinguished by the following features:

Rutherford engine, photo Rocket Lab

Electric motor drive. This is the first engine to drive the fuel and oxidizer pumps of which the electric motor and lithium polymer batteries are used. In existing engines there is a turbopump - a pump with a turbine, which is usually driven by a separate small combustion chamber (gas generator), where the same components of fuel are burned as in the main engine. A separate combustion chamber and a turbine that runs on its exhaust is a very complicated thing, and more affordable alternatives are attractive to private rocket companies. Rutherford pump has two valve motorsDC "the size of a can of soda", which rotate at a speed of 40,000 revolutions per minute and develop a power of 37 kW each. One engine pumps liquid oxygen, the other kerosene. The specific energy density of modern lithium-ion batteries has reached such a level that the kilos saved on the failure of the gas generator, turbines and fuel for their work become comparable to the weight of the batteries.

According to Peter Beck, they managed to raise the efficiency of the pumps from 50% of the gas generator to 95%, but this is clearly a marketing move, because the efficiency of only part of the engine is given. At the same time, the engine as a whole was efficient. There is some confusion with the specific impulse in the Rocket Lab, because it is not clear that 303 seconds of the specific impulse of the first-stage engines are indicated for sea level or vacuum. More likely, this is data for vacuum, where MD is higher, but even in this case, Rutherford (303 seconds in a vacuum (?) / 333 with a high-altitude nozzle) takes a good place, almost not yielding to SpaceX Merlin 1D (311 seconds in a vacuum / 348 with high-altitude nozzle) and the Soviet / Russian tops of the oxygen-kerosene engine-building RD-180 (338 seconds in vacuum) and RD-0124 (359 seconds with high-altitude nozzle).

3D printing . As stated in the Rocket Lab, the Rutherford engine is the first one in which all the main components are printed on a 3D printer. Laser and electronic sintering printers use titanium and Inconel (a nickel-chromium heat resistant alloy). As a result, one engine is printed in 24 hours.

Test filling May 16, photo Rocket Lab

Composite materials . Tanks of both steps are composite. Considering that one of the tanks holds very cold liquid oxygen under pressure, and low temperatures tend to make the material brittle, this is a considerable achievement. Composite tanks are noticeably lighter and cheaper than metal ones; other rocket planners are now trying to switch to them.

Adapter payload and half head fairing, photo Rocket Lab

Fairing with delivery. An interesting innovation offers Rocket Lab in the field of satellite preparation for launch. Usually, satellites are brought to the launch company’s workshop, installed on the payload adapter and covered with a fairing. Rocket Lab proposes the delivery of a single unit of the payload adapter and the fairing flaps to the customer’s workshop so that it can install the satellite on the adapter in conditions that are convenient for it. Then the closed or air-conditioned modules are transported to the Rocket Lab assembly and test complex and installed on the rocket.

The purpose of the Rocket Lab is the cost of one launch of $ 5 million. Given that the cost of launching “adult” rockets starts from about $ 60 million ($ 62 million from SpaceX for 2018), the Rocket Lab offer will be potentially beneficial for those who have a small satellite, a low-Earth or polar target orbit, and There is no time to wait for fellow travelers to a medium-capacity launch vehicle.

The first launch is an exciting event. Despite all the preparation there is no absolute guarantee of success. But Rocket Lab has demonstrated a very serious approach for a rocket startup, has conducted many tests, including fully assembled stages ( first , second ), and their future seems promising.

Electron on the launch pad, photo Rocket Lab

How did the rockets grow

Peter Beck next to the PH Electron rocket and experimental rockets in the background, Rocket Lab photo

The Electron rocket is developed by the Rocket Lab company, which was founded in 2006 by Peter Beck. Legally, this is an American private company with a New Zealand branch. In 2009, they launched a офtea-1 geophysical rocket (in Maori "space") and claim that they became the first private company to reach space in the southern hemisphere. Theoretically, the rocket was supposed to climb 100-120 km, the first stage worked fine, and traces of successful separation were found on it, but the head part was not found after the flight, and the achievement remains questionable.

On the old site, you can find plans to create a Ātea-2 geophysical rocket, but after the success of 2009, the company became interested in DARPA. For the next few years, Rocket Lab developed rocket technology in collaboration with Lockheed Martin, DARPA and the US Department of Defense. In 2010, a new fuel was tested. In the tank it was stored in solid form, but when pressure was applied to the tank, the fuel turned into a viscous liquid and could be fed into the combustion chamber. Thus, it had to combine the advantages of solid fuel (convenient storage of one component) and liquid (the ability to control the engine and restart the engine).

In 2011, the test passed a compact rocket drone. A small rocket could have been fired by a soldier with an arm outstretched, and a picture from a drone descending by parachute was supposed to help fight in conditions of very rough terrain, for example, in a city.

By 2013, the company was at a crossroads. It was possible to continue to earn on defense contracts, but Beck dreamed of commercial space. Having collected additional investments, Rocket Lab has started the development of a new launch vehicle. In 2013, the engine was successfully tested with components supplied with electric motors, and the Electron project was announced. In 2014, a second round of investment collection was held. In 2015, it became known that during the production of the engine, 3D printing would be widely used, and the engine itself was named Rutherford in honor of a New Zealand physicist. Also in the same year, the construction of a cosmodrome on the Mahia Peninsula began (Hawk Bay, North Island of New Zealand)

An animation of the location of the cosmodrome

Planetary.org animation

Planetary.org animation

The location in the eastern part of the island will allow you to easily transfer the payload to the sun-synchronous or low near-earth orbit - in the southern and eastern direction for many hundreds of kilometers stretch the ocean, into which you can, with no one agreeing, drop the spent steps.

In 2016, the rocket passed ground tests, and the spaceport was completed. The first flight of the Electron launch vehicle was scheduled for 2017. And over the past 4.5 months, Rocket Lab has managed to conduct another round of investment collection and has already started receiving orders for commercial launches.

Composite electroracket

Electron rocket, photo Rocket Lab

Electron - a two-stage booster with a height of 17 meters and a diameter of 1.2 meters. With an initial mass of around 12.5 tons, it will be able to bring 150 kg into a polar orbit 500 km high. A typical solar-synchronous orbit is usually higher, 600-800 km, where the carrying capacity will be lower. Also, if necessary, the rocket can put 225 kg into orbit 180x300 km with an inclination of 45 °.

Screenshot of the official site Rocket Lab The

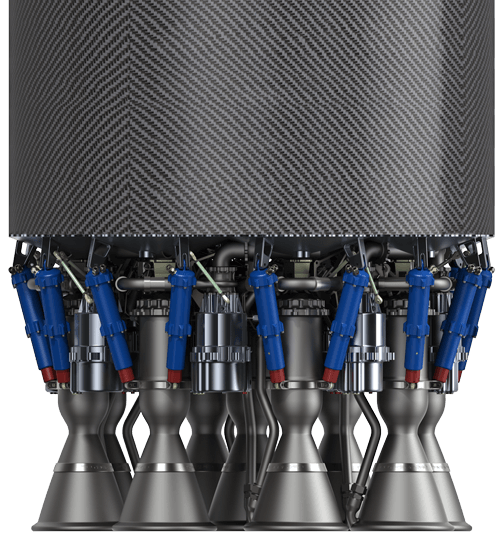

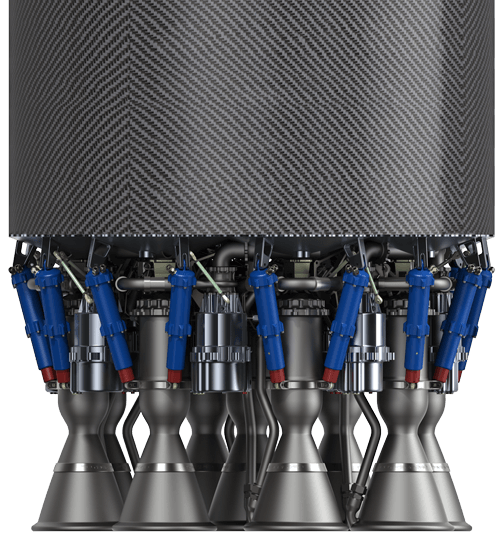

tail of the first stage with the engine cover removed, photo Rocket Lab

The first stage with a height of 12.1 meters has a dry weight of 950 kg and carries 9250 kg of fuel. There are nine Rutherford engines (more on them below) with a total of 16.5 tons at the start. Maximum thrust in flight should reach 19.5 tons, and the specific impulse of engines at sea level will be 303 seconds. According to the flight plan, the first stage will have to work for 2.5 minutes. At the stage near the engines, 13 battery packs with a total capacity of more than a megawatt are installed.

The second step. At the edge of the step to the left of the engine, a block of orientation engines is visible. Photo Rocket Lab

The second stage with a height of 2.1 meters has a dry weight of 250 kg and carries 2150 kg of fuel. It is equipped with one Rutherford engine with a high-altitude nozzle, a 2.2 tonne load and a specific impulse of 333 seconds. The engine of the second stage according to the plan should work a little less than five minutes. The stage has three battery packs, two of which will be discharged in flight as it is exhausted in order to ease the stage.

The design of the launch vehicle is distinguished by the following features:

Rutherford engine, photo Rocket Lab

Electric motor drive. This is the first engine to drive the fuel and oxidizer pumps of which the electric motor and lithium polymer batteries are used. In existing engines there is a turbopump - a pump with a turbine, which is usually driven by a separate small combustion chamber (gas generator), where the same components of fuel are burned as in the main engine. A separate combustion chamber and a turbine that runs on its exhaust is a very complicated thing, and more affordable alternatives are attractive to private rocket companies. Rutherford pump has two valve motorsDC "the size of a can of soda", which rotate at a speed of 40,000 revolutions per minute and develop a power of 37 kW each. One engine pumps liquid oxygen, the other kerosene. The specific energy density of modern lithium-ion batteries has reached such a level that the kilos saved on the failure of the gas generator, turbines and fuel for their work become comparable to the weight of the batteries.

According to Peter Beck, they managed to raise the efficiency of the pumps from 50% of the gas generator to 95%, but this is clearly a marketing move, because the efficiency of only part of the engine is given. At the same time, the engine as a whole was efficient. There is some confusion with the specific impulse in the Rocket Lab, because it is not clear that 303 seconds of the specific impulse of the first-stage engines are indicated for sea level or vacuum. More likely, this is data for vacuum, where MD is higher, but even in this case, Rutherford (303 seconds in a vacuum (?) / 333 with a high-altitude nozzle) takes a good place, almost not yielding to SpaceX Merlin 1D (311 seconds in a vacuum / 348 with high-altitude nozzle) and the Soviet / Russian tops of the oxygen-kerosene engine-building RD-180 (338 seconds in vacuum) and RD-0124 (359 seconds with high-altitude nozzle).

3D printing . As stated in the Rocket Lab, the Rutherford engine is the first one in which all the main components are printed on a 3D printer. Laser and electronic sintering printers use titanium and Inconel (a nickel-chromium heat resistant alloy). As a result, one engine is printed in 24 hours.

Test filling May 16, photo Rocket Lab

Composite materials . Tanks of both steps are composite. Considering that one of the tanks holds very cold liquid oxygen under pressure, and low temperatures tend to make the material brittle, this is a considerable achievement. Composite tanks are noticeably lighter and cheaper than metal ones; other rocket planners are now trying to switch to them.

Adapter payload and half head fairing, photo Rocket Lab

Fairing with delivery. An interesting innovation offers Rocket Lab in the field of satellite preparation for launch. Usually, satellites are brought to the launch company’s workshop, installed on the payload adapter and covered with a fairing. Rocket Lab proposes the delivery of a single unit of the payload adapter and the fairing flaps to the customer’s workshop so that it can install the satellite on the adapter in conditions that are convenient for it. Then the closed or air-conditioned modules are transported to the Rocket Lab assembly and test complex and installed on the rocket.

Conclusion

The purpose of the Rocket Lab is the cost of one launch of $ 5 million. Given that the cost of launching “adult” rockets starts from about $ 60 million ($ 62 million from SpaceX for 2018), the Rocket Lab offer will be potentially beneficial for those who have a small satellite, a low-Earth or polar target orbit, and There is no time to wait for fellow travelers to a medium-capacity launch vehicle.

The first launch is an exciting event. Despite all the preparation there is no absolute guarantee of success. But Rocket Lab has demonstrated a very serious approach for a rocket startup, has conducted many tests, including fully assembled stages ( first , second ), and their future seems promising.