Electron microscope in the garage

Once a friend called me and said: I found an interesting thing, I need to bring it to you, it weighs half a ton. So I got a column from a JEOL JSM-50A scanning electron microscope. It has long been written off from some research institute and taken to scrap. The electronics were lost, but the electron-optical column, together with the vacuum part, was saved.

Up to this point I have not dealt with such scientific equipment, not to mention knowing how to use it and how it works. To restore this microscope at least to the state of "we draw an electron beam on a fluorescent screen" will require:

Up to this point I have not dealt with such scientific equipment, not to mention knowing how to use it and how it works. To restore this microscope at least to the state of "we draw an electron beam on a fluorescent screen" will require:- Understand the basics of electron microscopes

- Understand what vacuum is

- How vacuum is measured, how it is obtained

- How high vacuum pumps work

- Minimally understand chemistry (what solvents to use to clean the vacuum chamber, what kind of oil to use for lubricating vacuum parts)

- To master metalworking (turning and milling work) for the manufacture of various adapters and tools

- Deal with microcontrollers, their connection circuitry

Having a scientific method in service, I will try to master completely new areas that I have never studied before. I invite you to do this with me.

Microscope recovery after at least a decade - under the cut.

DISCLAIMER: Remember, safety is paramount! I do not bear any responsibility for the fact that you accidentally harm your health or create a black hole, using the knowledge from this article.

It is interesting not only to launch the old piece of iron into working condition, but also to check whether it is possible to master completely new areas using the scientific method.

Therefore, before doing something, it is always helpful to understand how it works.

Principles of operation of electron microscopes

There are two types of electron microscopes:

Transmission electron microscope

TEM is very similar to an ordinary optical, only the sample under study is irradiated not by light (photons), as in an optical microscope, but by electrons.

The length of the electron beam wavelength is much smaller than the photon, so you can get much used to proc eed resolution.

Focusing and control of the electron beam is carried out using electromagnetic or electrostatic lenses. They even have the same distortions (chromatic aberrations) as optical lenses, although the nature of the physical interaction is completely different. By the way, it also adds new distortions (spinning of electrons in the lens along the electron beam axis, which is not the case with photons in an optical microscope).

TEM has drawbacks: the test samples must be very thin, thinner than 1 micron, which is not always convenient at home. For example, to see your hair in the light, it must be cut along at least 50 layers. This is due to the fact that the penetrating ability of the electron beam is much worse than the photon one. In addition, PEM with rare exceptions is rather cumbersome. This device, shown below, seems to be not so big (although taller than a man, and has a solid cast-iron bed), but there is also a power unit the size of a large wardrobe, which takes up a whole room.

But the resolution of FEM is the highest. With it (if you try hard) you can see the individual atoms of the substance. (Photo from here ).

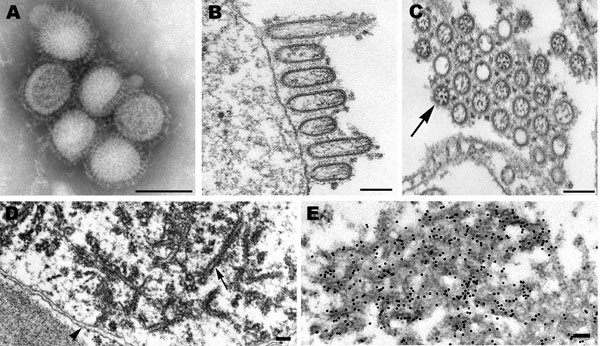

Such permission is particularly useful for identifying the causative agent of a viral disease. All virus analytics of the 20th century were built on the basis of PEM, and only with the advent of cheaper methods for diagnosing popular viruses (for example, PCR ), the routine use of PEMs for this purpose is no longer encountered.

For example, this is how the H1N1 flu is “in the gap”: (photo from here )

Scanning electron microscope

SEM is mainly used to study the surface of samples with very high resolution (an increase of a million times, against 2 thousand for optical ones). And this is much more useful in the household :)

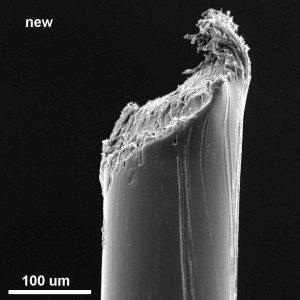

For example, someone is looking at a new toothbrush:

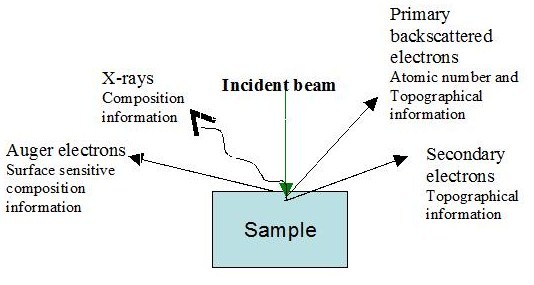

In a scanning microscope, a narrowly focused electron beam “scans” the sample surface point-by-point, and all sorts of sensors pick up what flies out of the sample after being hit by electrons.

The following can fly out:

- electrons with different energies

- optical radiation of the visible, infrared, ultraviolet range

- X-rays

-

The principle of the scanning electron microscope is a bit similar to the operation of the cathode-ray tube of the TV set system of focusing and deflecting lenses). Here, by the way, how it works when shooting 1000 fps:

The same should occur in the electron-optical column of the microscope, only the sample is irradiated, but not the screen phosphor, and the image is formed on the basis of information from the sensors (secondary electrons, elastically-reflected electrons, and others).

Both the television tube and the electron-optical column of the microscope work only under vacuum.

Inspired by the pictures , we proceed to work.

Electron-optical column

The electron-optical column of a microscope is a vacuum chamber in which are located:

- electron beam emitting electron beam

- system of electromagnetic lenses focusing, shifting, unwinding and moving the beam

- holder for the sample, with the possibility of moving and tilting along different axes

- radiation detectors of various nature - electrons, x-rays, light ranges

- ports for connecting additional devices

- vacuum control system

Electron gun (with the Wenelt cylinder removed ):

Managed object stage (located inside the column, access to it through a special gateway, outside its location can be recognized by the abundance of handles for moving and tilting)

I. Disassembly, cleaning, painting

The very first thing that I wanted to do was to thoroughly clean and paint all the rusted parts. The protective covers on the top and sides were removed, there was even more dust under them, and the steel managed to rust in places from the action of moisture and air. It is good that the column itself is made of stainless steel and is not easily oxidized.

During disassembly, the vacuum part (under the column) looked something like this:

Remove all vacuum fittings from the bottom, the remains of the vacuum control unit, the diffusion pump, clean and paint the bottom with semi-matt black paint to make it beautiful. From above we remove protective covers, we see thirty-year-old dust, everything is mine, skins and dye. That was / was for comparison:

Having dealt with the pieces of iron, I unlocked the anti-vibration spring suspension of the column and tried to hang the column into the working position (a two-centimeter steel sheet and several weighting materials ensure solidity of wiggling).

All parts of the project:

- 2. “About Vacuum” - what it is, how it is obtained and measured

- 3. Equip the garage with metalworking machines.

- 4. Pump down the column to the fore vacuum

- 5. Restoring the diffusion pump and get a high vacuum.

- 6. Put the cathode and prepare the column for launch

- 7. We deal with the high-voltage block.

- 8. We accelerate electrons

- 9. Image Capture

- 10. Detectors of secondary electrons,

history of their development.

And also watch the video on my channel .

I look forward to your comments and questions, see you in the next series!