Airbus takes new heights with Microsoft's mixed reality

Airbus took more than 40 years to build the first 10 thousand aircraft. And over the next two decades, the aerospace giant plans to build another 20 thousand - this is a difficult task, for the solution of which the best innovations are needed.

The key to achieving this ambitious goal will be Microsoft's “holographic” technology, called “mixed reality,” because it combines the real world with a virtual, digital world.

“Our task for the coming years is to produce more aircraft and do it faster. Therefore, we need our employees to be better equipped and work much more efficiently. We need to raise the bar, ”said Jean-Bryce Dumont, Executive Vice President, Engineering, Airbus, which produces planes, helicopters, satellites and launch vehicles.

“In order to cope with this task, we intend to actively use mixed reality, and that’s why we are working with Microsoft,” Dumont explains.

Using Microsoft's mixed reality, Airbus production workers can access information and instructions, even when their hands are busy. This technology also facilitates training, eliminating the need to use expensive equipment and take students to where this equipment is located. And this is just the beginning: Airbus experts have found over 300 mixed reality applications.

Airbus has been exploring mixed reality for several years, and four years ago began developing mixed reality solutions with Microsoft. Now, this work is greatly advanced thanks to the advanced capabilities of Microsoft HoloLens 2 - the latest generation of headsets, as well as a growing family of applications and services of mixed reality from Microsoft and industry partners.

What is mixed reality?

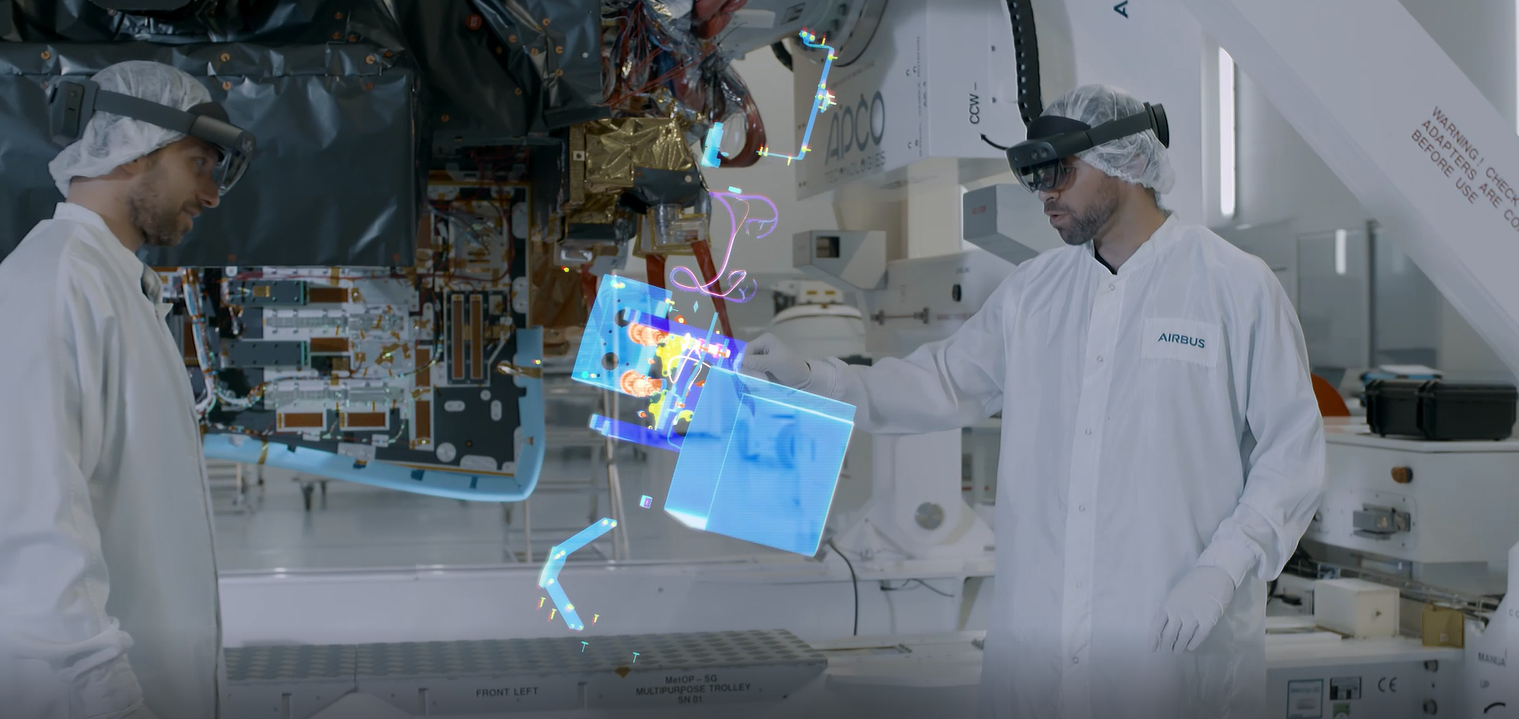

Mixed reality takes digital information beyond the boundaries of two-dimensional screens into a three-dimensional space visible by a person, forming “holograms” - three-dimensional images accompanied by sound.

Microsoft HoloLens headsets are the culmination of advances in artificial intelligence, equipment design, and mixed reality. These headsets give people the opportunity to interact with “holograms” in real space, allowing you to view three-dimensional images and manipulate them in the air or in the context of real-life material objects.

The recent release of the HoloLens 2 model has taken mixed reality one step further, giving users the ability to manipulate “holograms” just like they handle real physical objects. Among other things, the new headset monitors eye movements in order to determine where the user is looking, and generate relevant digital information for him, and also provides automatic scrolling as you read. Users can log in using the iris recognition feature, which makes sharing information between several people simple and safe.

Hololens 2 helps Airbus engineers speed up their product availability test for mass production by 80%.

The practical application of mixed reality

Airbus achieved impressive results during the testing and implementation of Microsoft's mixed-reality technologies in training, design and manufacturing.

“Mixed reality can enhance quality, reliability and security,” says Dumont. “The number of human errors is significantly reduced, and in the aerospace industry, improving quality means improving reliability and, of course, safety.”

Mixed reality allows you to train specialists in aerospace technologies in a virtual environment, eliminating the need to use real aircraft and parts for this. This three-dimensional environment offers opportunities that are not found in traditional training: for example, visualization of parts in three dimensions at any angle.

HoloLens helps Airbus engineers virtually test their designs to see if they are ready for production. Mixed reality speeds up this process significantly, reducing time by 80%.

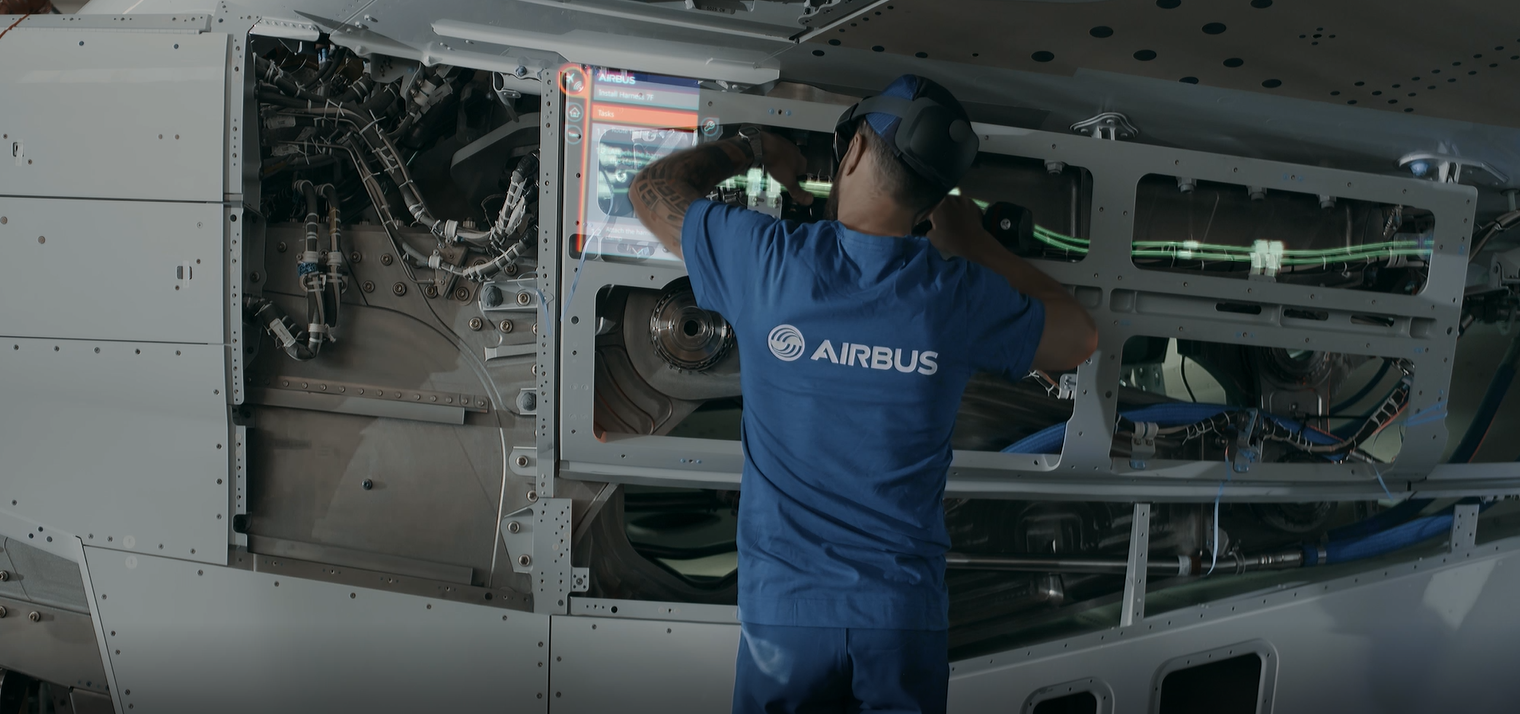

In addition, mixed reality technology will allow workers on the production line to access important information while keeping their hands free. Digital information, such as instructions or diagrams, can be displayed “in the air” on top of real equipment, helping to perform complex tasks and not distract from work. Such mixed reality solutions have already enabled Airbus to cut production times by a third, while improving quality.

Barbara Bergmeier, head of operations at Airbus Defense and Space, says mixed reality empowers workers by letting them perform their tasks very efficiently and ergonomically, and this directly affects productivity gains.

“When employees get the right information at the right time without taking their hands, not only the quality of work, but also the security increases. This is exactly what we need. We cannot think about quality without considering the safety of our employees, ”she says.

Mixed reality technology will allow Airbus production workers to see information and instructions, even when their hands are busy.

Collaboration for the development of mixed reality

Airbus not only creates solutions for employees, but also offers turnkey solutions for customers who can also use Airbus's experience in creating their own mixed reality solutions. Airbus began selling its HoloLens 2 headset solutions with Microsoft at the Paris Air Show .

“At the heart of HoloLens 2 is the idea that this headset is designed for the consumer and with the participation of the consumer,” said Alex Kipman, technical fellow at Microsoft Cloud and AI. - Airbus is our long-standing strategic partner with whom we are creating the future of mixed reality solutions for the industrial environment, and we have learned a lot from them. We are pleased to continue our partnership at the dawn of a new era of computing technology - the era of mixed reality and artificial intelligence. ”

The first new solution created as part of this partnership was a mixed reality training program, first introduced with Japan Airlines (JAL). This program allows maintenance operators and flight attendants to learn in a three-dimensional “holographic” environment, and during work to receive instructions without being distracted and without taking their hands.

In addition, Airbus will launch a joint mapping solution that will enable aerospace and defense professionals to virtually communicate, quickly exchange space data and interact with complex virtual environments during flight planning and preparation.

Airbus also satisfies other customers' needs by providing them with solutions for service, training and remote collaboration in mixed reality.

Over the next 20 years, Airbus plans to build 20,000 aircraft.

Real life leadership

Airbus's partnership with Microsoft in the field of mixed reality not only helps the company solve current problems. These technological innovations are needed by Airbus to achieve the more ambitious goal of becoming the world leader in digital services for the aerospace industry.

“We are very optimistic about the future of working with Microsoft, based on what we have done over the past four years,” says Dumont. “For us, this is a way to go through our own digital transformation.” There are many different aspects, but mixed reality and HoloLens 2 will become one of the main Airbus tools in the future. ”