CNC Burning Machine Selection Guide

If you are only exploring the possibilities of pyrography and do not have experience in this area, the choice of a CNC machine for burning out may confuse you in terms of choosing a CNC burner.

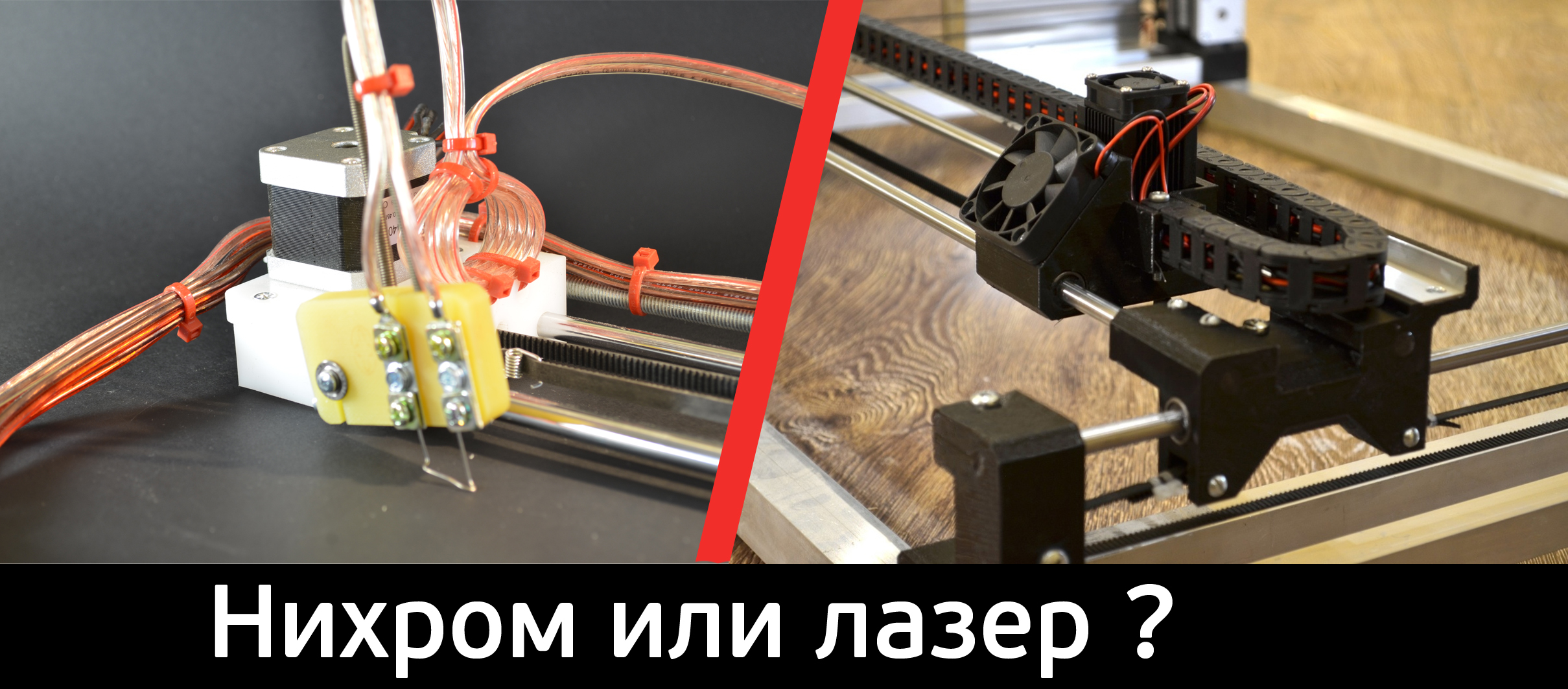

Two CNC options are suitable for burning - a laser machine and a nichrome pyroprinter. In this case, we consider laser ones with a diode solid-state laser, because the CO2 tube goes for other tasks, costs times more and is difficult to maintain. The pyroprinter works with nichrome thread, exactly the same as hand burners from childhood.

Where to start choosing a burner?

It depends on what you want and what task you will set for the machine. These machines are sharpened for different purposes. As if you look at a drill and a screwdriver, which to some extent can cope with each other's tasks, but it will not be convenient and not the best way out. Therefore, we will examine in turn for what tasks this equipment was created.

Laser Tasks

To begin with, the laser burns out using the non-contact method, so it doesn’t care about the thickness, surface roughness and edges of the workpiece. Another advantage of the laser is a large selection of materials for burning. The laser works with materials such as: wood, plywood, veneer, leather, aniline, eco leather, paper, cardboard, felt, jeans, ceramics, glass, etc.

Moreover, some materials can only be engraved, and some can even be cut. Looks especially interesting for scrapbooking.

An example of work done on a laser:

A laser machine is sharpened for applying a vector image and text to a large number of materials. Using a laser from the common one, they engrave on phone cases. He quickly and easily copes with very small text, similar to what is used for business cards.

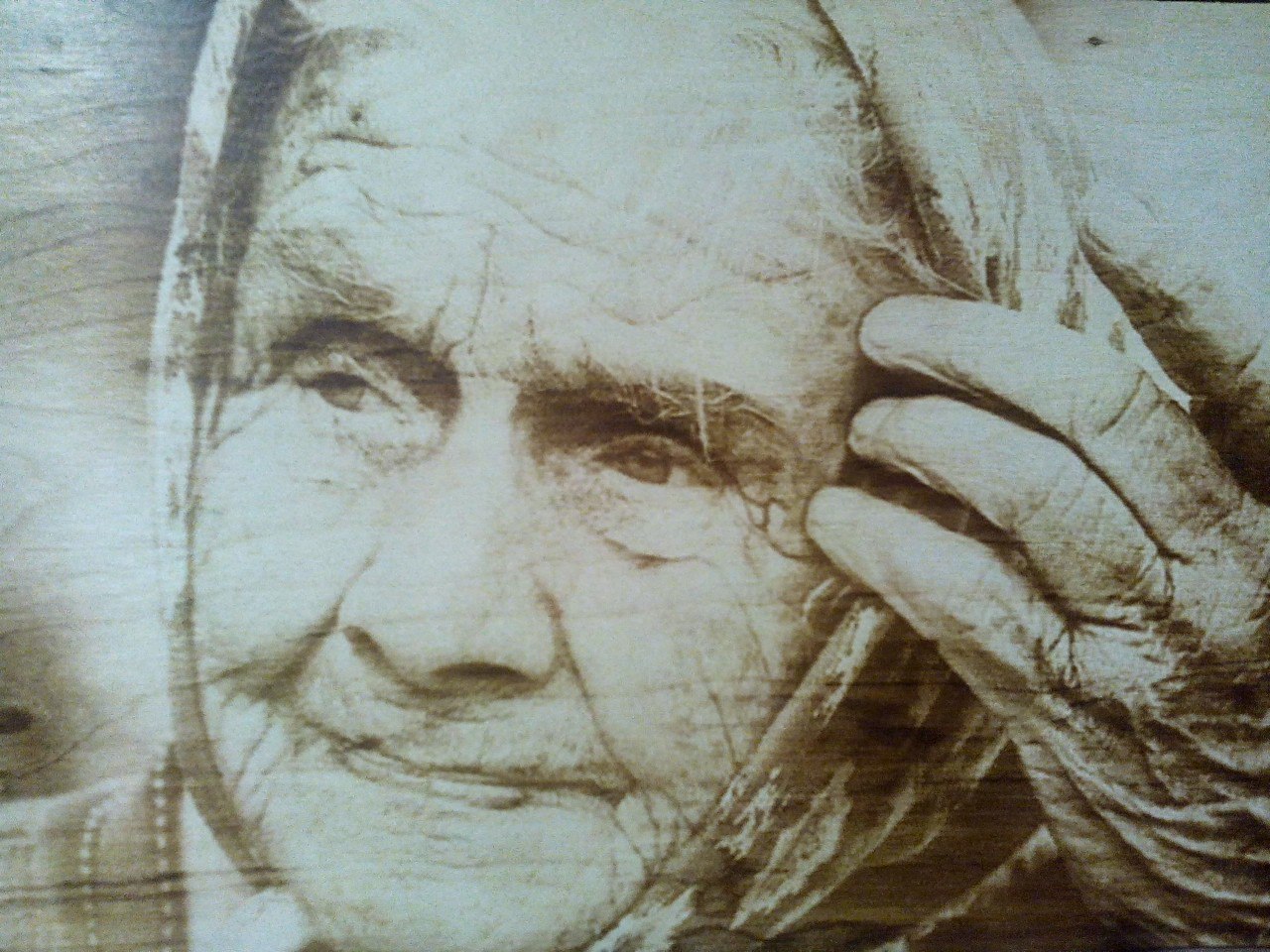

The laser does not cope well with burning portraits, because he has a way of applying the image in dots. This method creates penumbra poorly, and where without penumbra in the portrait. On closer inspection, the portrait becomes like a printout in a cheap newspaper.

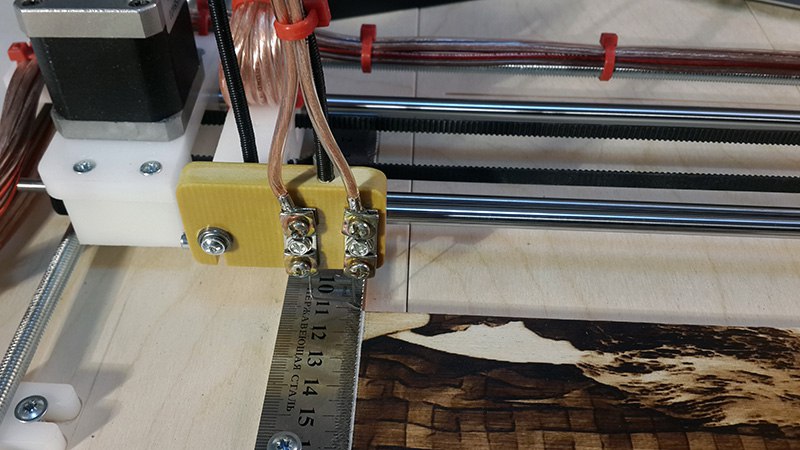

Tasks for Nichrome

The pirinterinter works with nichrome wire and applies the image by the contact method, so for this machine it is important that the flat surface on which the image is applied is even. It is also important for the machine that the surface is rectangular or square. The machine will not be able to apply the image to the round surface, due to the cleaning of the sting.

The machine was created to burn portraits and other raster images, such as landscapes, still lifes, animals. The pyroprinter copes with burning text, but not too small. Those. this machine will be able to sign the work with the phrases “Happy Anniversary”, but it will not be able to burn out a business card.

We figured out the purpose of the machines. But besides the tasks of the machines, there are other characteristics that your choice may depend on. For example, this is an opportunity to deliver equipment at home or in the office.

CNC installation at home

Why do we immediately raise this question about the choice of a machine, as we are interested in such small machines for the home business. And often it arises about installing the machine for the first time home, or maybe they are constantly going to keep the machine at home.

In this regard, the pyroprinter wins, since this CNC works almost without smoke. A barely caught smoke can come from it with a black background of the image, but this smoke will be less than from a match. Such a machine does not require a separate room and almost without noise.

Of course, it is advisable to put the laser in a separate room, because the glow can press on the eyes with a constant presence. Be sure to wear glasses - without them, no matter how. Smoke from the laser is much larger, especially when working with the skin there is still an unpleasant odor.

Conclusion

Choose a machine based on your tasks and possibilities of the place. The software for both machines is not difficult to work with, so you should not pay attention to this.