Implementation of LoRaWAN in an agricultural enterprise. Part 2. Fuel accounting

Hello dear readers! Since the publication of the first article, we have grown, our beloved vendors and developers of LoThings , have done a lot of painstaking work, and the day has come when there is something to tell and show!

By launching our first LoRaWaN, we immediately determined which tasks we want to close through its capabilities. One of them was the control of fuel metering at gas stations.

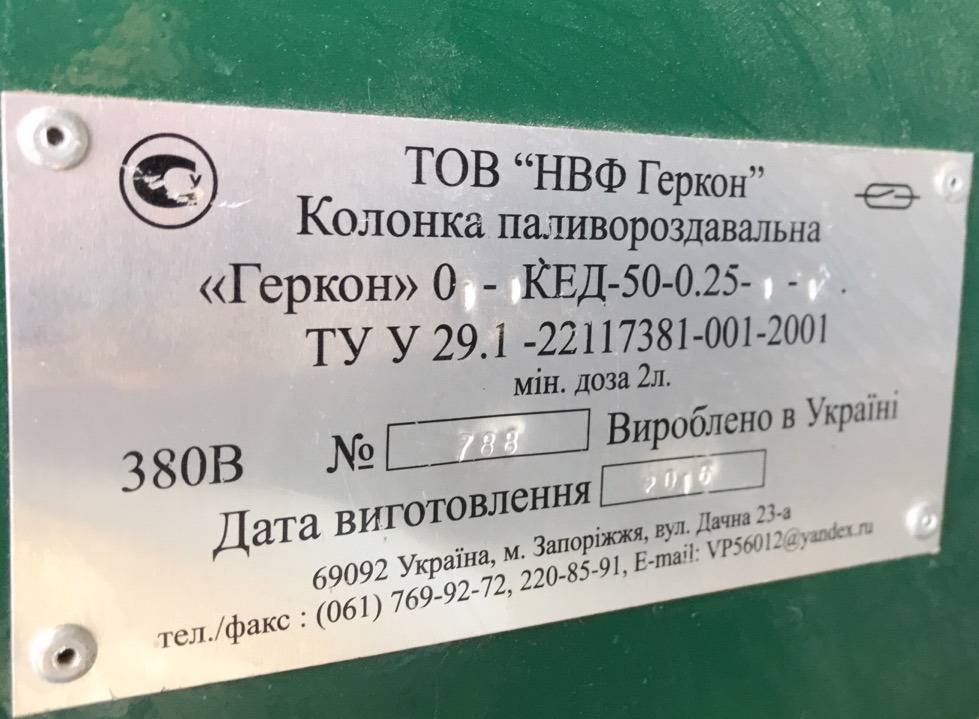

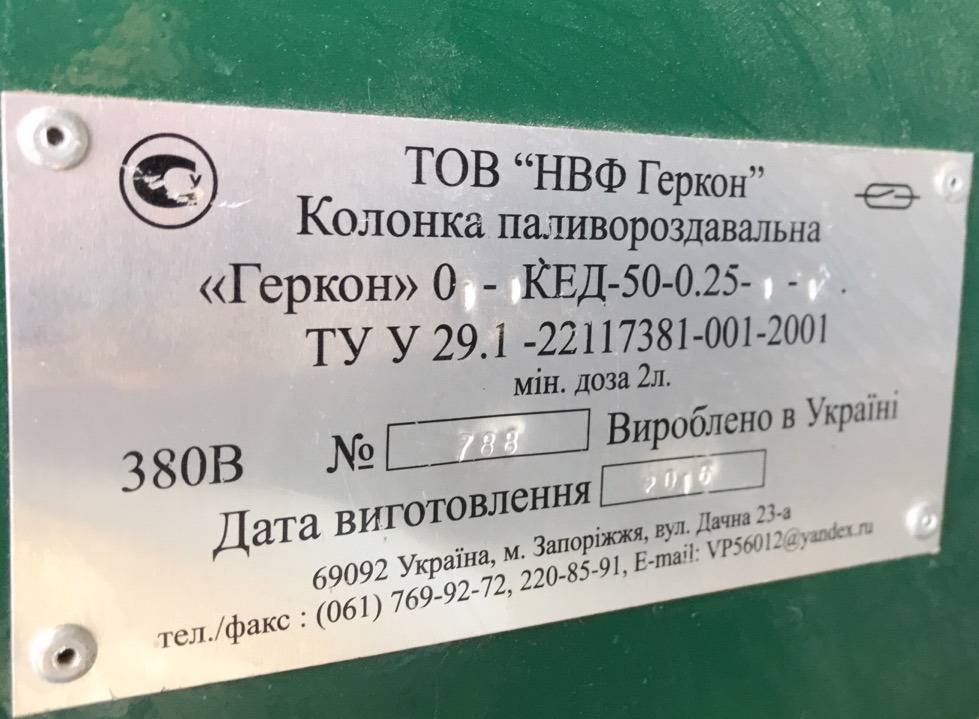

In general, we have 2 tanks in which fuel is stored, and a Gerkon column from a domestic manufacturer.

We solve the problem by measuring the fuel level in the tanks, and by taking data on the number of spilled liters through the column.

In tanks installed FLS BI FLSensor

Now about the connection. The brains of the existing speakers are on board the RS-485. I've already meta post about LoRaWAN and RS-485 and perhaps I won’t repeat it, the author of this post described everything wonderfully before me!

Protocols are uploaded to the device and all processing takes place on board. A packet with dry data flies to the LoRaWaN network for processing on the server. Setting up the process of obtaining data from the column was tedious, due to troubles with the logic of the column, with FLSs, everything is simple.

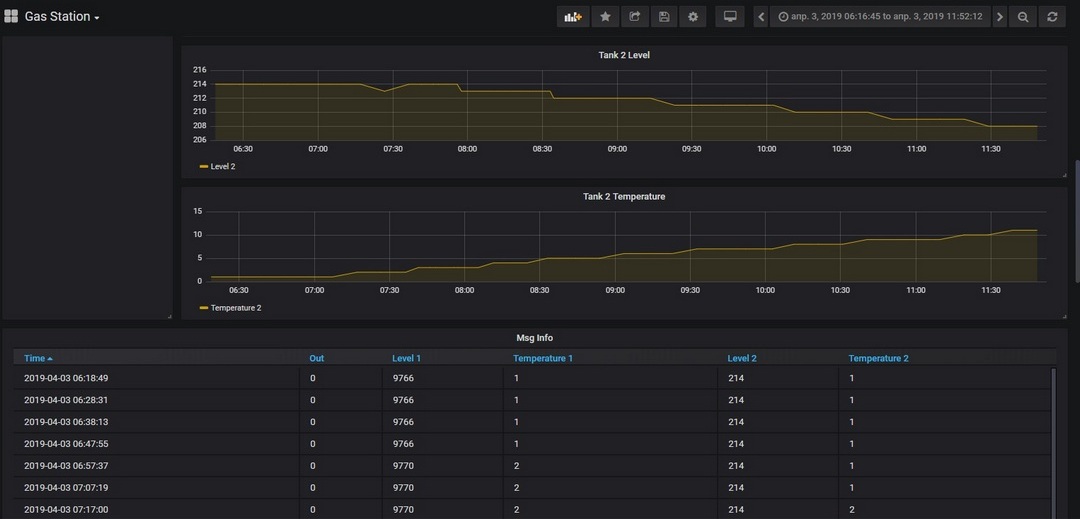

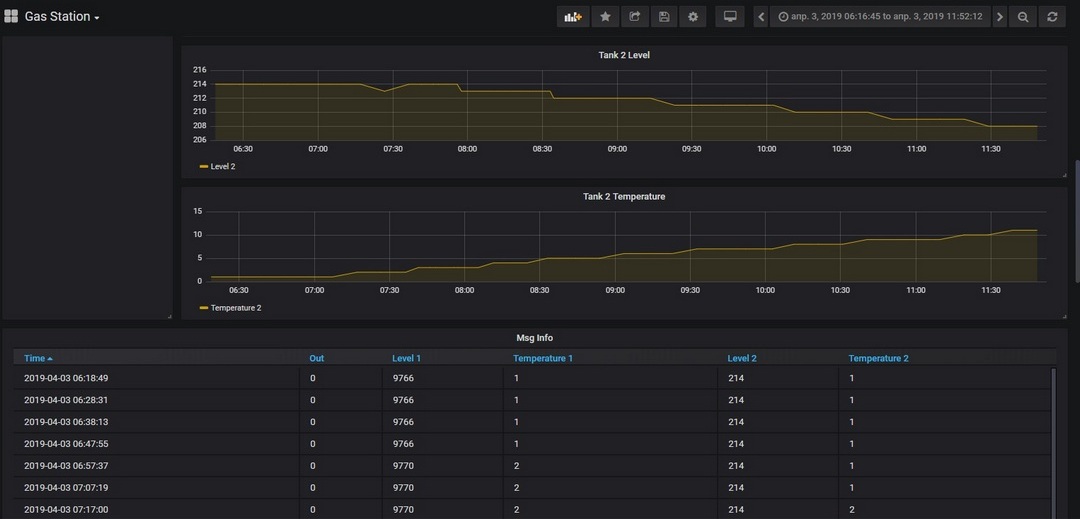

As a result, we receive every 10 minutes a packet with data on the amount of fuel in tanks and temperatures at the moment. In the case of a perfect refueling, at its end a packet arrives with the same data, but supplemented with information about the number of refilled liters.

All information received is collected on the server and displayed in a form convenient for us.

That’s probably all, I’ll be happy to answer all questions in comments or PM.

In the following posts, new tasks, new victories :-)

By launching our first LoRaWaN, we immediately determined which tasks we want to close through its capabilities. One of them was the control of fuel metering at gas stations.

In general, we have 2 tanks in which fuel is stored, and a Gerkon column from a domestic manufacturer.

We solve the problem by measuring the fuel level in the tanks, and by taking data on the number of spilled liters through the column.

In tanks installed FLS BI FLSensor

Now about the connection. The brains of the existing speakers are on board the RS-485. I've already meta post about LoRaWAN and RS-485 and perhaps I won’t repeat it, the author of this post described everything wonderfully before me!

Protocols are uploaded to the device and all processing takes place on board. A packet with dry data flies to the LoRaWaN network for processing on the server. Setting up the process of obtaining data from the column was tedious, due to troubles with the logic of the column, with FLSs, everything is simple.

As a result, we receive every 10 minutes a packet with data on the amount of fuel in tanks and temperatures at the moment. In the case of a perfect refueling, at its end a packet arrives with the same data, but supplemented with information about the number of refilled liters.

All information received is collected on the server and displayed in a form convenient for us.

That’s probably all, I’ll be happy to answer all questions in comments or PM.

In the following posts, new tasks, new victories :-)