Experts: “A 3D scanner will cost 10 times cheaper than a mistake with traditional quality control”

The Canadian company Creaform is one of the manufacturers who create the future before our eyes. Creaform portable 3D metrology solutions are already changing the rules of the game in production, increasing the effectiveness of quality control and optimizing the process. iQB Technologies is the exclusive distributor in Russia of such innovative products of the company as HandySCAN 3D and Go! SCAN 3D 3D scanners, as well as MaxSHOT 3D photogrammetry.

In an exclusive interview with Creafrom representatives - regional manager Damien Plowastel and sales channel manager Marc-Antoine Schneider - we discussed why a modern company needs 3D scanning, what trends will prevail in the 3D market in the coming years and how the role of a person in a business model will change Industry 4.0.

Creaform visiting iQB Technologies

- Which Creaform concept would you name the most successful and why?

Marc-Antoine Schneider: No doubt, this is HandySCAN - the most successful Creafrom product to date. This is the first 3D scanner developed by our company in 2005 and became a real breakthrough in the field of metrology. He determined the success of the company as a whole and today remains the most innovative scanner on the market.

Damien Plowastel: In addition, HandySCAN is our best-selling system.

- Is there any new “breakthrough” product in your plans, like the HandySCAN 3D scanner?

P .: No at the moment. Of course, we are developing new devices, but HandySCAN in its current form is an extremely competitive product, and there is no need to replace it.

Sh .: It should be noted that every year Creafrom invests from 7 to 10 million dollars in R&D, in our industry we are the most innovative company. We release a new product on average every two years. In 2017, it was MaxSHOT , which, like HandySCAN, is distributed in Russia by iQB Technologies. This year we plan to update the software. And there is one interesting novelty that you will learn about in the very near future.

- You gave figures on Creafrom investments in production. Can you share your sales statistics?

Ш .: According to our estimates, Creafrom's turnover in 2018 will be approximately 150 million euros, and the annual growth of the company - on average 20% per year over the past five years.

P .: The goal is to bring the turnover to 200 million by 2020, that is, we are developing very actively.

- And how do you assess the development of the global market for 3D scanners?

Sh.: As such, we do not have published statistics, since this market is not studied in detail, this is a rather difficult task. We turn to third-party services that conduct market assessments.

P .: But we can definitely say that the metrology market is growing: measurement capabilities are expanding, requirements and quality standards are becoming more stringent. And besides, optical devices play an increasingly important role in metrology (namely, Creaform specializes in them), the non-contact method displaces physical measurements. This is a good trend for us.

Sh .: I will add that now they are talking more and more about Industry 4.0, and Creaform is contributing to its approximation thanks to its automated and robotic solutions - for example, 3D scanning using robotic manipulators . Such solutions meet the expectations of manufacturers. Creaform plans to take a share of this new Industry 4.0 market, which has enormous potential: its turnover by 2020 is estimated at 3 billion euros.

- What other trends, in your opinion, will develop in the coming years in the 3D world?

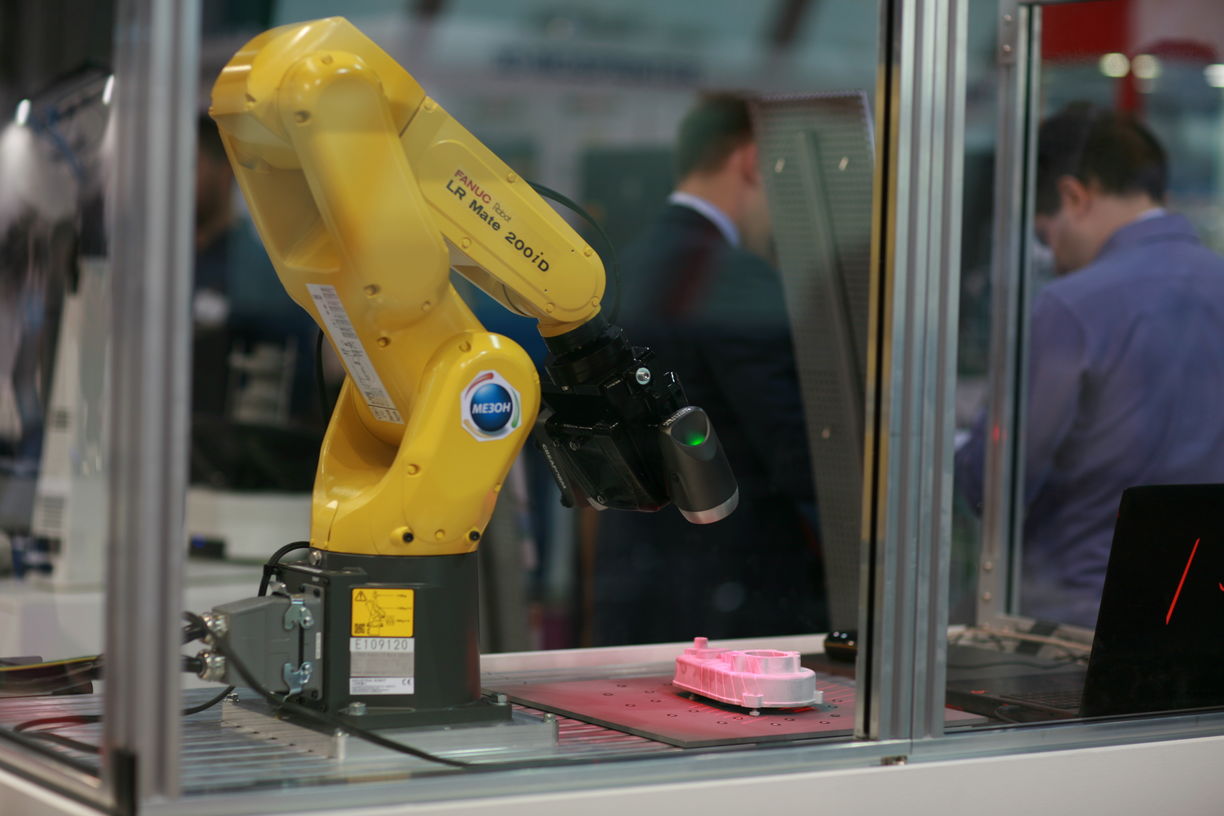

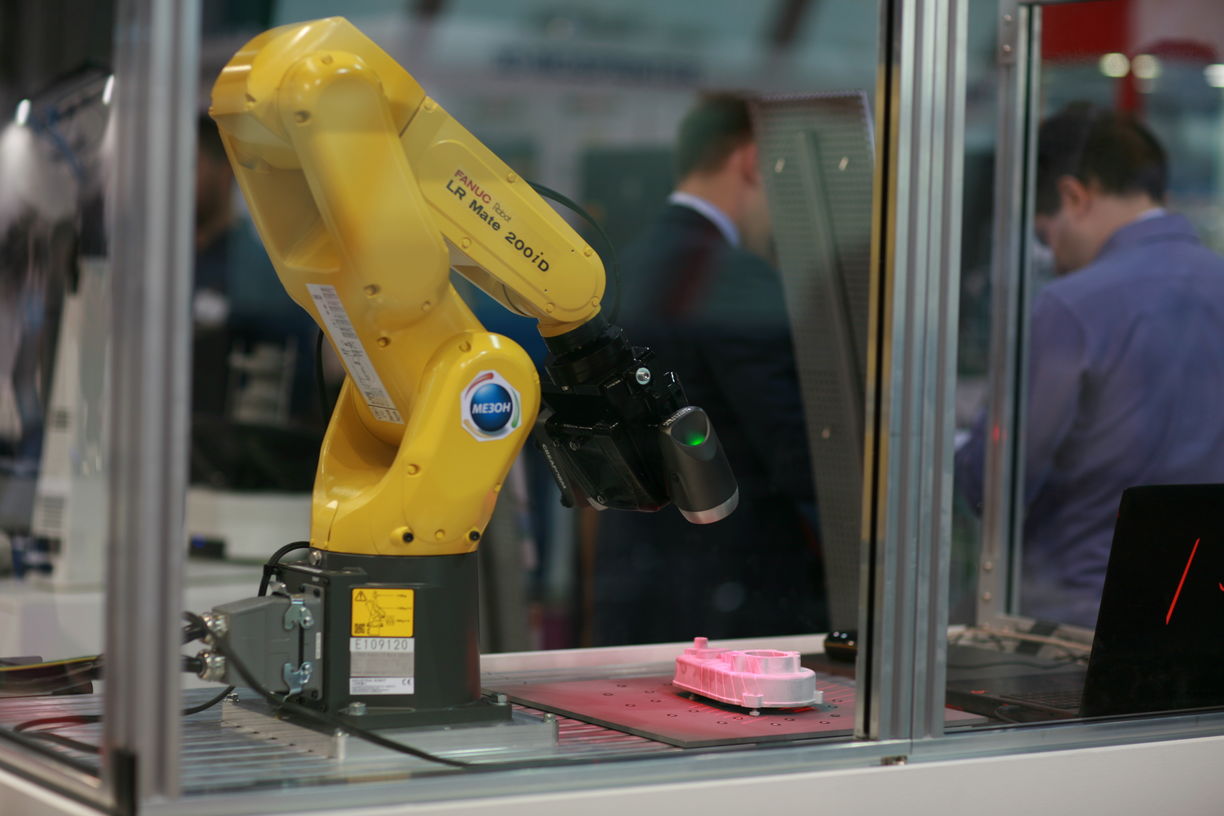

P .: There will be further robotization of the industry, including in the field of quality control, and Creaform has very competitive solutions for this. Any of our 3D scanners can be installed on robots for automated control. As we know, such a system was presented at the iQB Technologies booth at the Metalworking-2018 exhibition.

Sh .: I think that all economic powers are interested in producing better quality goods - this is a global need. And today, every manufacturer can stand out due to both the quality of their products and the ratio of price and quality. For this reason, industries should pay much more attention to control issues, and Creaform offers solutions that are an important link in the production quality control chain. In general, it can be stated that any industry has an interest in introducing 3D technologies to improve the quality control of its products.

Automated quality control system at the Metalworking exhibition: HandySCAN 700 handheld 3D scanner and Fanuc LR Mate 200iD robotic arm

I want to say one more thing. 3D printing, an industry that is now on the rise and will evolve, has opened up incredible prospects. Creaform is one of the largest players in the 3D industry, and although we do not produce printers, 3D models based on scans can be printed on a 3D printer. The real revolution will happen when 3D printers are used as full-fledged production tools and the quality of printed products will need to be checked. The industry will need the solutions Creaform offers in order to control parts printed on 3D printers.

- In which industries are Creaform 3D scanners used the most?

P .: Firstly, in the automotive industry. This industry, which is often ahead of many others in terms of technology, actively uses innovations - including those offered by our company. The largest global manufacturers today are customers of Creaform. Secondly, it is the aerospace industry. In fact, Creaform products are indispensable in all industries related to the production of transport equipment, because it requires particularly strict quality control of parts.

- Please tell us about some interesting project using Creaform 3D scanners.

P .: We were contacted by the Swiss company Jet Aviations, which buys old aircraft and makes their complete re-modeling, for example, to create private jet aircraft. Our company has completed the complete digitization of the huge Boeing 185, then to completely recreate the interior. The team worked on the spot, made scans and measurements. It was a colossal job that lasted several months.

Sh .: It took two weeks to digitize, and it seems that it took two weeks to reconstruct the CAD file.

- Let's talk about Russia. What do you think is the specifics of the Russian market?

Sh .: Russia is a country with a growing economy. When we developed the development plan until 2020, we analyzed the markets for investment. And Russia, as one of the twenty largest world economic powers, is included in this list. We see in Russia the same industrial potential as in France, and France is the second market Creaform entered after Canada, it is well known to us. We have been in France since 2003 and now we sell equipment worth several million euros there.

- But there are also difficulties in the Russian market. The problem of certification, for example.

P .: This is so, but this year we are certifying all the equipment for the Russian market .

Ш .: Half of the assortment is already certified, several recently released products remain(range of Handyscan 3D is included in the State Register of measuring RF metrological class - Ed.) . Indeed, this is an obstacle for foreign manufacturers. With logistics in Russia, things are more complicated than in other countries. To export goods to Russia, you need to consider many formalities. We will not forget about the restrictions caused by international sanctions against Russia, which also create certain difficulties for us. But despite this, we will continue to work with your country. Over the past year, we have quadrupled our sales in Russia, and our Russian partner iQB Technologies plans to double Creaform sales this year.

Typical Applications for the HandySCAN 3D Handheld 3D Scanner - Automotive

I add that many foreign companies work in Russia - such as Renault and Mercedes, which are very important clients of Creaform on a global scale. In Russia, huge opportunities are opening up for us to attract these customers, since we already have experience of successful cooperation with them in other countries. We see great potential here.

- In Russia, there is a certain skepticism among engineers and technical experts who say that 3D scanners are very expensive and inefficient toys. How could you dissuade them?

P .: The numbers speak for themselves: Creaform today has sold about ten thousand 3D scanners all over the world, and the annual sales rhythm remains at the level of 2-3 thousand. There is real demand, and the largest enterprises - BMW, Mercedes, Airbus, Boeing, which trust Creaform, acquire new systems and implement them in production every year as examples. Here is evidence that this equipment is in demand.

Sh .: I would answer these people that any investment requires an assessment of its return on investment. Today, 3D scanners are available on the market at prices ranging from 25 thousand to 150 thousand euros. When developing and manufacturing a product, it is necessary to take into account not only the cost of production, but also the cost of production errors. Suppose a manufacturer made a mold for creating plastic parts. If the form proves to be defective, it will cost ten times more as a result than a 3D scanner. Because the scanner will allow you to check the shape and avoid marriage before the part is put into production.

Thus, it is more profitable to invest in a 3D scanner, which guarantees quality, and eliminate the costs of culling a large number of parts. And I also think that from the point of view of sustainable development, which is now being talked about more and more, it is more profitable for enterprises to improve the quality of production, care about the environment and better control the production process. Quickly producing a quality product is more profitable for everyone - not only for their own business.

- Of course, many are scared away by large investments. But also, perhaps, a conservative view of things plays a role, hence skepticism.

Sh .: People in general are mostly conservative. When you get used to a certain method of work, you are hardly ready to switch to something new. This is inherent in human nature - the desire to preserve what seems good and familiar. Over the past fifty years, it has become apparent that technological innovations - including the 3D industry - have significantly improved, people's lives, made it more convenient. 3D technologies help treat patients through the creation of prostheses and new devices, increase the safety of airplanes and cars - in general, their impact affects each of us.

P .: Creaform presentations also help convince skeptics of the benefits of 3D scanning. We demonstrate the technology with concrete examples, convince people that this equipment can bring real benefits, and thus we have managed to sell ten thousand 3D scanners.

- How do you think the business models of enterprises using 3D technology will change?

Sh .: As for Industry 4.0, it will change the very model of the plant’s functioning and the role of man in production: the implementation of particularly complex, dangerous or routine tasks will be entrusted to specialized robots.

Thus, in the industry of the future, man will play a more advanced role, managing, installing and maintaining these robots. This will contribute to the growth of professional level and self-realization of factory specialists. And it is obvious that the 3D industry, as one of the driving forces of Industry 4.0, will make a significant contribution to a radical change in the production model, including through the development of automation and quality control processes.

In an exclusive interview with Creafrom representatives - regional manager Damien Plowastel and sales channel manager Marc-Antoine Schneider - we discussed why a modern company needs 3D scanning, what trends will prevail in the 3D market in the coming years and how the role of a person in a business model will change Industry 4.0.

Creaform visiting iQB Technologies

- Which Creaform concept would you name the most successful and why?

Marc-Antoine Schneider: No doubt, this is HandySCAN - the most successful Creafrom product to date. This is the first 3D scanner developed by our company in 2005 and became a real breakthrough in the field of metrology. He determined the success of the company as a whole and today remains the most innovative scanner on the market.

Damien Plowastel: In addition, HandySCAN is our best-selling system.

- Is there any new “breakthrough” product in your plans, like the HandySCAN 3D scanner?

P .: No at the moment. Of course, we are developing new devices, but HandySCAN in its current form is an extremely competitive product, and there is no need to replace it.

Sh .: It should be noted that every year Creafrom invests from 7 to 10 million dollars in R&D, in our industry we are the most innovative company. We release a new product on average every two years. In 2017, it was MaxSHOT , which, like HandySCAN, is distributed in Russia by iQB Technologies. This year we plan to update the software. And there is one interesting novelty that you will learn about in the very near future.

- You gave figures on Creafrom investments in production. Can you share your sales statistics?

Ш .: According to our estimates, Creafrom's turnover in 2018 will be approximately 150 million euros, and the annual growth of the company - on average 20% per year over the past five years.

P .: The goal is to bring the turnover to 200 million by 2020, that is, we are developing very actively.

- And how do you assess the development of the global market for 3D scanners?

Sh.: As such, we do not have published statistics, since this market is not studied in detail, this is a rather difficult task. We turn to third-party services that conduct market assessments.

P .: But we can definitely say that the metrology market is growing: measurement capabilities are expanding, requirements and quality standards are becoming more stringent. And besides, optical devices play an increasingly important role in metrology (namely, Creaform specializes in them), the non-contact method displaces physical measurements. This is a good trend for us.

Sh .: I will add that now they are talking more and more about Industry 4.0, and Creaform is contributing to its approximation thanks to its automated and robotic solutions - for example, 3D scanning using robotic manipulators . Such solutions meet the expectations of manufacturers. Creaform plans to take a share of this new Industry 4.0 market, which has enormous potential: its turnover by 2020 is estimated at 3 billion euros.

- What other trends, in your opinion, will develop in the coming years in the 3D world?

P .: There will be further robotization of the industry, including in the field of quality control, and Creaform has very competitive solutions for this. Any of our 3D scanners can be installed on robots for automated control. As we know, such a system was presented at the iQB Technologies booth at the Metalworking-2018 exhibition.

Sh .: I think that all economic powers are interested in producing better quality goods - this is a global need. And today, every manufacturer can stand out due to both the quality of their products and the ratio of price and quality. For this reason, industries should pay much more attention to control issues, and Creaform offers solutions that are an important link in the production quality control chain. In general, it can be stated that any industry has an interest in introducing 3D technologies to improve the quality control of its products.

Automated quality control system at the Metalworking exhibition: HandySCAN 700 handheld 3D scanner and Fanuc LR Mate 200iD robotic arm

I want to say one more thing. 3D printing, an industry that is now on the rise and will evolve, has opened up incredible prospects. Creaform is one of the largest players in the 3D industry, and although we do not produce printers, 3D models based on scans can be printed on a 3D printer. The real revolution will happen when 3D printers are used as full-fledged production tools and the quality of printed products will need to be checked. The industry will need the solutions Creaform offers in order to control parts printed on 3D printers.

- In which industries are Creaform 3D scanners used the most?

P .: Firstly, in the automotive industry. This industry, which is often ahead of many others in terms of technology, actively uses innovations - including those offered by our company. The largest global manufacturers today are customers of Creaform. Secondly, it is the aerospace industry. In fact, Creaform products are indispensable in all industries related to the production of transport equipment, because it requires particularly strict quality control of parts.

- Please tell us about some interesting project using Creaform 3D scanners.

P .: We were contacted by the Swiss company Jet Aviations, which buys old aircraft and makes their complete re-modeling, for example, to create private jet aircraft. Our company has completed the complete digitization of the huge Boeing 185, then to completely recreate the interior. The team worked on the spot, made scans and measurements. It was a colossal job that lasted several months.

Sh .: It took two weeks to digitize, and it seems that it took two weeks to reconstruct the CAD file.

- Let's talk about Russia. What do you think is the specifics of the Russian market?

Sh .: Russia is a country with a growing economy. When we developed the development plan until 2020, we analyzed the markets for investment. And Russia, as one of the twenty largest world economic powers, is included in this list. We see in Russia the same industrial potential as in France, and France is the second market Creaform entered after Canada, it is well known to us. We have been in France since 2003 and now we sell equipment worth several million euros there.

- But there are also difficulties in the Russian market. The problem of certification, for example.

P .: This is so, but this year we are certifying all the equipment for the Russian market .

Ш .: Half of the assortment is already certified, several recently released products remain(range of Handyscan 3D is included in the State Register of measuring RF metrological class - Ed.) . Indeed, this is an obstacle for foreign manufacturers. With logistics in Russia, things are more complicated than in other countries. To export goods to Russia, you need to consider many formalities. We will not forget about the restrictions caused by international sanctions against Russia, which also create certain difficulties for us. But despite this, we will continue to work with your country. Over the past year, we have quadrupled our sales in Russia, and our Russian partner iQB Technologies plans to double Creaform sales this year.

Typical Applications for the HandySCAN 3D Handheld 3D Scanner - Automotive

I add that many foreign companies work in Russia - such as Renault and Mercedes, which are very important clients of Creaform on a global scale. In Russia, huge opportunities are opening up for us to attract these customers, since we already have experience of successful cooperation with them in other countries. We see great potential here.

- In Russia, there is a certain skepticism among engineers and technical experts who say that 3D scanners are very expensive and inefficient toys. How could you dissuade them?

P .: The numbers speak for themselves: Creaform today has sold about ten thousand 3D scanners all over the world, and the annual sales rhythm remains at the level of 2-3 thousand. There is real demand, and the largest enterprises - BMW, Mercedes, Airbus, Boeing, which trust Creaform, acquire new systems and implement them in production every year as examples. Here is evidence that this equipment is in demand.

Sh .: I would answer these people that any investment requires an assessment of its return on investment. Today, 3D scanners are available on the market at prices ranging from 25 thousand to 150 thousand euros. When developing and manufacturing a product, it is necessary to take into account not only the cost of production, but also the cost of production errors. Suppose a manufacturer made a mold for creating plastic parts. If the form proves to be defective, it will cost ten times more as a result than a 3D scanner. Because the scanner will allow you to check the shape and avoid marriage before the part is put into production.

Thus, it is more profitable to invest in a 3D scanner, which guarantees quality, and eliminate the costs of culling a large number of parts. And I also think that from the point of view of sustainable development, which is now being talked about more and more, it is more profitable for enterprises to improve the quality of production, care about the environment and better control the production process. Quickly producing a quality product is more profitable for everyone - not only for their own business.

- Of course, many are scared away by large investments. But also, perhaps, a conservative view of things plays a role, hence skepticism.

Sh .: People in general are mostly conservative. When you get used to a certain method of work, you are hardly ready to switch to something new. This is inherent in human nature - the desire to preserve what seems good and familiar. Over the past fifty years, it has become apparent that technological innovations - including the 3D industry - have significantly improved, people's lives, made it more convenient. 3D technologies help treat patients through the creation of prostheses and new devices, increase the safety of airplanes and cars - in general, their impact affects each of us.

P .: Creaform presentations also help convince skeptics of the benefits of 3D scanning. We demonstrate the technology with concrete examples, convince people that this equipment can bring real benefits, and thus we have managed to sell ten thousand 3D scanners.

- How do you think the business models of enterprises using 3D technology will change?

Sh .: As for Industry 4.0, it will change the very model of the plant’s functioning and the role of man in production: the implementation of particularly complex, dangerous or routine tasks will be entrusted to specialized robots.

Thus, in the industry of the future, man will play a more advanced role, managing, installing and maintaining these robots. This will contribute to the growth of professional level and self-realization of factory specialists. And it is obvious that the 3D industry, as one of the driving forces of Industry 4.0, will make a significant contribution to a radical change in the production model, including through the development of automation and quality control processes.