Multilevel lighting control based on KTS NPL

Multi-site lighting control and multi-level residential lighting control is becoming increasingly popular. Standard solutions are the use of pulse relays or PLCs, but there is another solution - the Complex of Technological Tools of Non-Programmable Logic (CCL NPL) based on contactors , here I want to show what is the difference and features of such a solution.

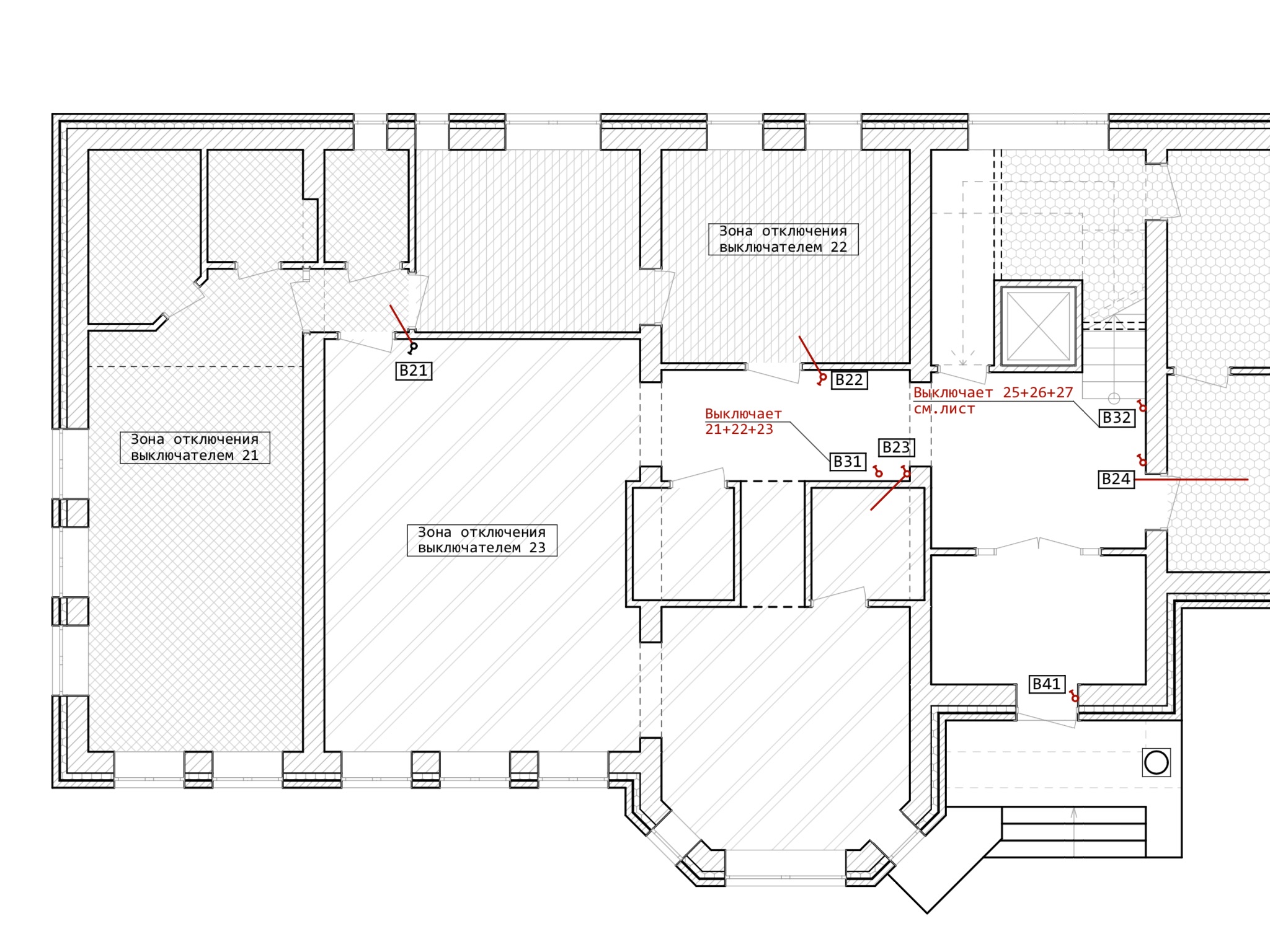

Technical task

All of the above makes sense for multi-level load management without remote access and without creating scripts, because for such tasks the choice is obvious to everyone. Functionality of the systems under consideration: centralized multi-level sectional management, with the preservation of local management. Here is a fragment of what the customer wants and what the designer drew:

Calculation of the total cost of equipment

For a more revealing analysis, below I have indicated the average cost of equipment for each of the systems, I also give a formula by which you can calculate the total cost of equipment for the system. Naturally, the price does not include protection devices, a cabinet, etc.

Total equipment cost = average equipment cost x (number of light sources + number of control sections).

Entry-level PLC lighting control system

The composition of the system:

Logic module, logic module expansion unit, intermediate relays, modular contactors.

System Features:

In the event of a malfunction of the logic module - complete absence of lighting until the malfunction is resolved.

Electrical durability: 100 thousand cycles for AC-1.

Limit the maximum switching frequency to 2 Hz.

Limit the number of relay outputs and the number of control levels.

The average cost of equipment is $ 72.

Lighting control system based on pulse relays

The composition of the system:

Impulse relays, central control modules, group control modules.

System Features:

In the event of a malfunction, the elements of the system fail one at a time.

Electrical durability: 100 thousand cycles for AC-1.

Switching limit: 5-15 shifts per minute / 100 shifts per day.

Pulse duration limitation: 50 ms - 1 s.

Load power limitation.

Vibrations can lead to spontaneous switching, that is, if necessary, it will not be possible to install contactors in such a control cabinet.

As the number of control levels increases, the complexity of constructing a circuit increases.

The average cost of equipment is $ 73.

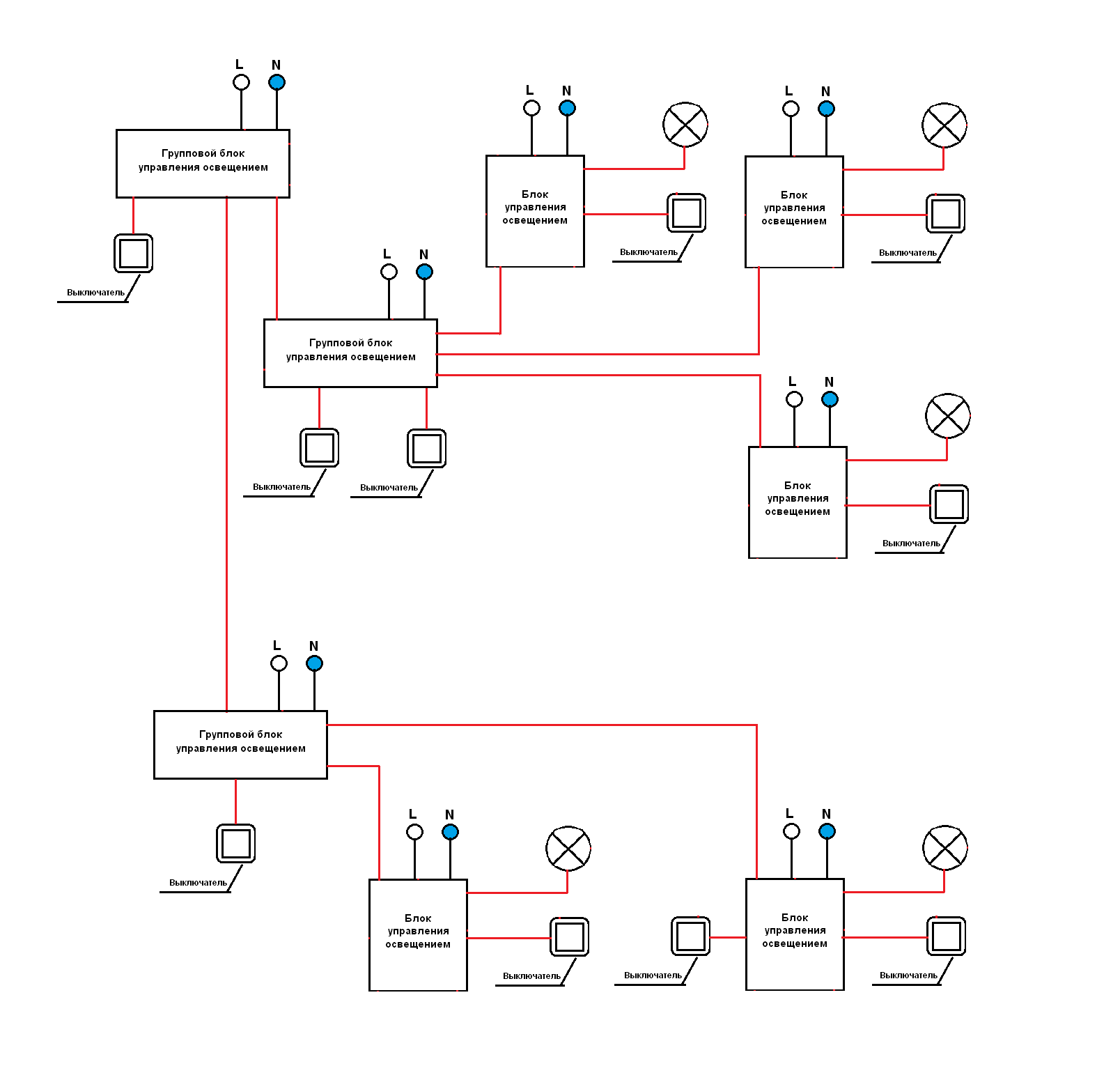

Contactor-based lighting control system

The composition of the system:

Contactors - each lighting control unit consists of two contactors: the first to turn on the load, the second to turn off.

System Features:

Electrical durability: 1.4 million cycles for AC-3, 150 thousand cycles for AC-1.

Number of switching per hour: 1800 cycles.

In the event of a malfunction, the elements of the system fail one at a time.

Unlimited connected load power.

Unlimited levels of control.

With an increase in the number of control levels of the system, the scheme does not become complicated.

The average cost of equipment is $ 53.

Comparison

PLC vs. Impulse relays

Comparability of cost and resource switching load. When using a PLC, if it fails, the entire lighting system will be de-energized until troubleshooting, but despite this, pulse relays have too many disadvantages for such a cost: restrictions on pulse duration, limit on the number of switching per minute, load limits, and the complexity of building a large number of levels, restrictions on the level of vibration.

PLC vs. KTS NPL based on contactors

KTS NPL has a greater load switching resource, the ability to build a circuit with any number of light sources, any number of control levels, without complicating the circuit, and at a lower cost, if one of the system elements fails, the rest of the system will continue to work, unlike PLC