We click the relay correctly: switching powerful loads

Hi Geektimes!

Powerful load management is a fairly popular topic among people one way or another relating to home automation, and in general, regardless of the platform: whether it is Arduino, Rapsberry Pi, Unwired One or another platform, turn on or turn off any heater, boiler or channel fan sooner or later have to.

The traditional dilemma here is how, in fact, to commute. As many have seen in their sad experience, Chinese relays do not have the proper reliability - when switching a powerful inductive load, the contacts spark much, and at one point they can simply stick. I have to set two relays - the second is to secure the trip.

Instead of a relay, you can put a triac or solid-state relay (in fact, the same thyristor or polevik with a logic signal control circuit and opto-isolation in one case), but they have another minus - they heat up. Accordingly, a radiator is needed, which increases the dimensions of the structure.

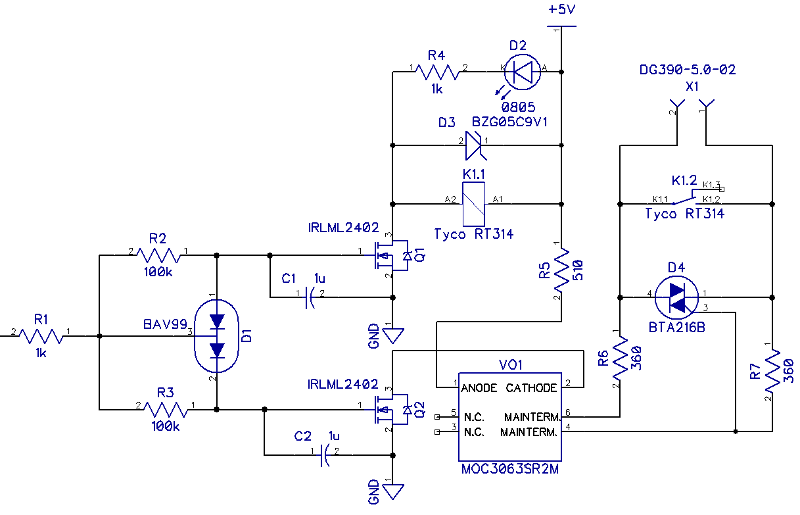

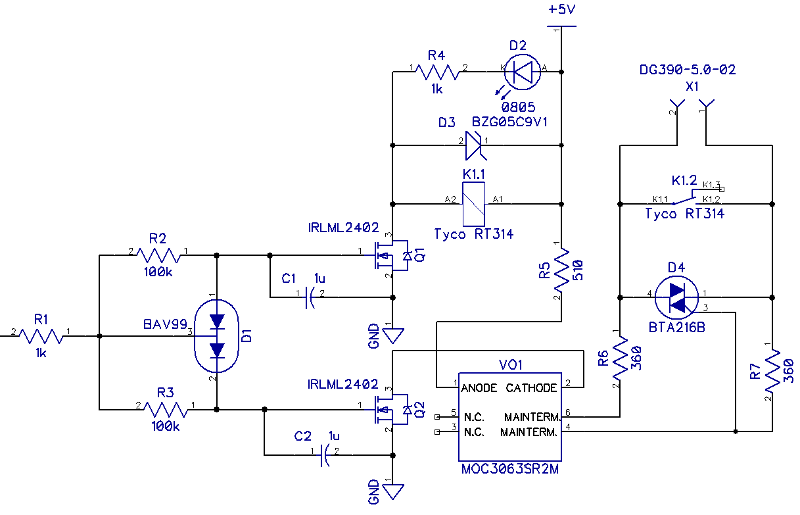

I want to talk about a simple and fairly obvious, but at the same time rare, scheme that can do this:

But first, a little illustration. In all cases, TTI relays of the TRJ and TRIL series were used, and a 650 W vacuum cleaner was used as a load.

The classic scheme - we connect the vacuum cleaner through a conventional relay. Then we connect the oscilloscope to the vacuum cleaner (Caution! Either the oscilloscope or the vacuum cleaner — or better both — must be galvanically isolated from the earth! Do not climb your fingers into the salt shaker with your fingers and eggs! Do not joke with 220 V!) And watch.

We turn it on:

I had to get to a maximum of the mains voltage (trying to tie the electromagnetic relay to going over zero is a daunting task: it is too slow). In both directions it fluttered with a short ejection with almost vertical fronts, interference flew in all directions. Expected.

Turn off:

The sharp loss of voltage at the inductive load does not bode well - the surge flew upwards. In addition, do you see these interference on a sinusoid milliseconds before the actual shutdown? This is the sparking of relay contacts that started to open, because of which they once become stuck.

So, with a “bare” relay, switching an inductive load is bad. What will we do? Let's try to add a snubber - RC-circuit from a 120 Ohm resistor and a 0.15 uF capacitor.

Include:

Better, but not much. The emission slowed down, but generally remained.

Turn off:

The same picture. The garbage remained, moreover, the sparking of the relay contacts remained, albeit greatly reduced.

Conclusion: with a snubber is better than without a snubber, but it does not solve the problem globally. Nevertheless, if you want to switch inductive loads with a conventional relay - put snubber. The ratings should be selected for a specific load, but a 1-W resistor at 100-120 Ohms and a capacitor at 0.1 μF look like a reasonable option for this case.

References: Agilent - Application Note 1399, “ Maximizing the Life Span of Your Relays ”. When the relay operates for the worst type of load - a motor, which, in addition to inductance, also has a very low resistance at startup - kind authors recommend reducing the relay's passport life by five times .

And now let's make a knight's move - we will combine a triac, triac driver with zero detection and relays into one circuit.

What is in this diagram? On the left is the entrance. When “1” is supplied to it, the capacitor C2 is almost instantly charged through R1 and the lower half of D1; The VO1 opto-relay turns on, waits for the next zero crossing (MOC3063 - with an integrated zero detector circuit) and turns on the D4 triac. The load starts.

Capacitor C1 is charged through a chain of R1 and R2, which takes about t = RC ~ 100 ms. These are several periods of mains voltage, that is, during this time the triac will have time to turn on with a guarantee. Then Q1 opens and relay K1 turns on (as well as the D2 LED, which shines with a pleasant emerald light). The relay contacts bypass the triac, therefore further - until it is turned off - it does not take part in the work. And it does not heat up.

Shutdown - in the reverse order. As soon as “0” appears at the input, C1 quickly discharges through the upper arm D1 and R1, the relay turns off. But the triac remains on for about 100 ms, since C2 is discharged through 100-kilo-ohm R3. Moreover, since the triac is held open by current, even after turning off VO1, it will remain open until the load current drops in the next half-cycle below the holding current of the triac.

On:

Off:

Beautiful, isn't it? Moreover, when using modern triacs that are resistant to rapid changes in current and voltage (all major manufacturers have such models - NXP, ST, Onsemi, etc., the names start with "BTA"), the snubber is not needed at all, in any form.

Moreover, if you recall the smart people from Agilent and see how the current consumed by the motor changes, you get the following picture:

The starting current exceeds the working current by more than four times. For the first five periods - the time by which the triac is ahead of the relay in our circuit - the current drops by about half, which also significantly softens the requirements for the relay and prolongs its life.

Yes, the circuit is more complicated and more expensive than a conventional relay or a conventional triac. But often it's worth it.

Powerful load management is a fairly popular topic among people one way or another relating to home automation, and in general, regardless of the platform: whether it is Arduino, Rapsberry Pi, Unwired One or another platform, turn on or turn off any heater, boiler or channel fan sooner or later have to.

The traditional dilemma here is how, in fact, to commute. As many have seen in their sad experience, Chinese relays do not have the proper reliability - when switching a powerful inductive load, the contacts spark much, and at one point they can simply stick. I have to set two relays - the second is to secure the trip.

Instead of a relay, you can put a triac or solid-state relay (in fact, the same thyristor or polevik with a logic signal control circuit and opto-isolation in one case), but they have another minus - they heat up. Accordingly, a radiator is needed, which increases the dimensions of the structure.

I want to talk about a simple and fairly obvious, but at the same time rare, scheme that can do this:

- Galvanic isolation of input and load

- Switching inductive loads without surge current and voltage

- Lack of significant heat dissipation even at maximum power

But first, a little illustration. In all cases, TTI relays of the TRJ and TRIL series were used, and a 650 W vacuum cleaner was used as a load.

The classic scheme - we connect the vacuum cleaner through a conventional relay. Then we connect the oscilloscope to the vacuum cleaner (Caution! Either the oscilloscope or the vacuum cleaner — or better both — must be galvanically isolated from the earth! Do not climb your fingers into the salt shaker with your fingers and eggs! Do not joke with 220 V!) And watch.

We turn it on:

I had to get to a maximum of the mains voltage (trying to tie the electromagnetic relay to going over zero is a daunting task: it is too slow). In both directions it fluttered with a short ejection with almost vertical fronts, interference flew in all directions. Expected.

Turn off:

The sharp loss of voltage at the inductive load does not bode well - the surge flew upwards. In addition, do you see these interference on a sinusoid milliseconds before the actual shutdown? This is the sparking of relay contacts that started to open, because of which they once become stuck.

So, with a “bare” relay, switching an inductive load is bad. What will we do? Let's try to add a snubber - RC-circuit from a 120 Ohm resistor and a 0.15 uF capacitor.

Include:

Better, but not much. The emission slowed down, but generally remained.

Turn off:

The same picture. The garbage remained, moreover, the sparking of the relay contacts remained, albeit greatly reduced.

Conclusion: with a snubber is better than without a snubber, but it does not solve the problem globally. Nevertheless, if you want to switch inductive loads with a conventional relay - put snubber. The ratings should be selected for a specific load, but a 1-W resistor at 100-120 Ohms and a capacitor at 0.1 μF look like a reasonable option for this case.

References: Agilent - Application Note 1399, “ Maximizing the Life Span of Your Relays ”. When the relay operates for the worst type of load - a motor, which, in addition to inductance, also has a very low resistance at startup - kind authors recommend reducing the relay's passport life by five times .

And now let's make a knight's move - we will combine a triac, triac driver with zero detection and relays into one circuit.

What is in this diagram? On the left is the entrance. When “1” is supplied to it, the capacitor C2 is almost instantly charged through R1 and the lower half of D1; The VO1 opto-relay turns on, waits for the next zero crossing (MOC3063 - with an integrated zero detector circuit) and turns on the D4 triac. The load starts.

Capacitor C1 is charged through a chain of R1 and R2, which takes about t = RC ~ 100 ms. These are several periods of mains voltage, that is, during this time the triac will have time to turn on with a guarantee. Then Q1 opens and relay K1 turns on (as well as the D2 LED, which shines with a pleasant emerald light). The relay contacts bypass the triac, therefore further - until it is turned off - it does not take part in the work. And it does not heat up.

Shutdown - in the reverse order. As soon as “0” appears at the input, C1 quickly discharges through the upper arm D1 and R1, the relay turns off. But the triac remains on for about 100 ms, since C2 is discharged through 100-kilo-ohm R3. Moreover, since the triac is held open by current, even after turning off VO1, it will remain open until the load current drops in the next half-cycle below the holding current of the triac.

On:

Off:

Beautiful, isn't it? Moreover, when using modern triacs that are resistant to rapid changes in current and voltage (all major manufacturers have such models - NXP, ST, Onsemi, etc., the names start with "BTA"), the snubber is not needed at all, in any form.

Moreover, if you recall the smart people from Agilent and see how the current consumed by the motor changes, you get the following picture:

The starting current exceeds the working current by more than four times. For the first five periods - the time by which the triac is ahead of the relay in our circuit - the current drops by about half, which also significantly softens the requirements for the relay and prolongs its life.

Yes, the circuit is more complicated and more expensive than a conventional relay or a conventional triac. But often it's worth it.