Powder coating of metal surfaces using an oven grill

Painting metal products with powder paints is a fairly popular alternative to conventional painting methods using liquid paints for parts that can be heat treated. Wikipedia describes this method as follows: Powder paint is sprayed onto a cleaned metal product. During the spraying process, powder paint particles are electrically charged from an external source or by electrification during friction. By electric field, the particles of paint are transferred to the product to be painted, which has the opposite charge. Particles of powder paint that have not settled on the product are captured in the spray booth and can be used for re-spraying, which is not possible with conventional liquid paints.

In the process of coating formation from the applied powder layer, a monolithic high-quality coating is created on the surface of the product. As it turned out, to use this type of painting does not need any industrial equipment. Enough mini-ovens, a tool for applying powder paint, as well as a high voltage source. As an example, one of YouTube users is powder coating the metal part of his skateboard.

At the very beginning, it is necessary to degrease the part, and if there is already paint on it, then remove it (here you will need a sandblast or something like that). It is easiest to take a part without coating so that you do not have to clean the surface.

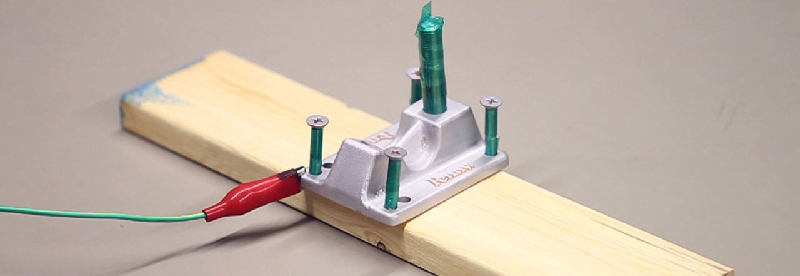

Next, apply powder paint using a powder “gun” or any other suitable equipment. We bring current to the metal and apply paint. Surfaces that do not need to be painted are covered with a high-temperature film. Immediately after this, you can place the part in a mini-furnace, with a temperature of 230C. If the part is large, you should use a homemade thermal furnace, it can be made from an old safe or a metal cabinet for documents.

Of course, a fair amount of time will be needed to make such a furnace, so it’s better to use ready-made solutions and small metal parts :)

The video shows how metal parts (aluminum) are cleaned of paint using sandblasting, powder dye is applied and heated in mini-furnaces. Pretty simple, fast and efficient. Powder polymer protects the metal better, and holds very tightly, unlike many varieties of liquid paints. After application to the metal, the powder dye melts, representing a monolithic protective surface.