Inventors of a new type of rotor engine contracted with DARPA

Company LiquidPiston received to finance their project funding from the DARPA . The project is an improved rotary type internal combustion engine called the X1 . Connecticut's Bloomfield company is led by engineers, father and son, Nikolai and Alexander Shkolniki.

Inventors declare many unique properties of their product. For example, the thermal efficiency of their motor is 50% (compared with 20-30% of a conventional gasoline ICE). However, if we take a diesel engine, add turbocharging and intermediate cooling to it, we will also get an efficiency of about 50%. But at the same time, the diesel engine will weigh a lot.

According to Alexander Shkolnik, a typical 3 kW diesel generator has dimensions of 100x60x60 cm and weighs more than 70 kg. In this case, a generator based on an X1 engine of similar power will weigh 15 kg (the engine itself - 4 kg), and its size will be 30x30 cm. In fact, such a generator will fit in a backpack.

The inventors tried to take the best from different thermal cycles and reduce engine energy loss. The theoretical limit of the efficiency of the new engine is 75%, but so far the engineers are working to achieve a real rate of 57%.

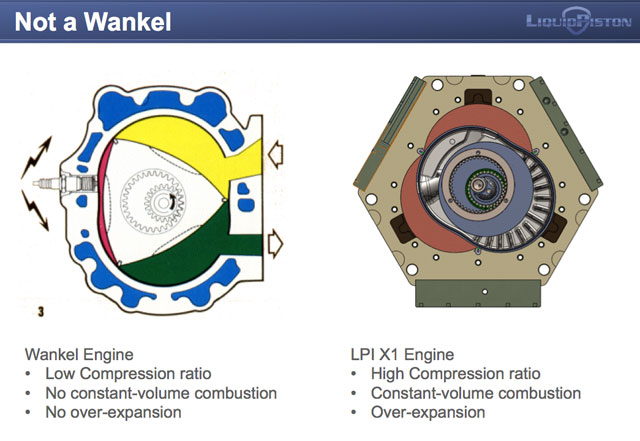

The operation of the X1 engine is reminiscent of the operation of the famous Wankel rotary engine , turned inside out. The rotor is mounted on an eccentric shaft, and contains channels for the inlet of the gas mixture and exhaust gas. The candles located at the corners of an equilateral triangle work out once for one revolution of the shaft.

The engine runs on direct injection and provides a high compression ratio of 18: 1. The chamber volume that does not change during combustion allows you to burn fuel longer and more fully. The exhaust gases reach almost atmospheric pressure before leaving, and therefore manage to give up almost all of their energy to the rotor.

High efficiency also eliminates the need for water cooling of the engine. When operating under load, the engine can skip ignition cycles and suck in air that will cool it. Even the option of injecting water into the combustion chamber is considered, which will cool the engine, reduce exhaust emissions and at the same time turn into steam pushing the rotor.

On the left is the Wankel engine, on the right is the X1. The

compactness and power of the engine interested the military, who require portable energy systems. In the event of a successful implementation, the engine will find many uses - a portable electric generator, an engine for unmanned aerial vehicles, and much more.

Engineers came up with a new engine back in 2003. By 2012, the first prototype was built, which was written in the journal Popular Mechanics . In 2015, the company not only signed a contract with DARPA, but also started developing a mini version of the engine.