UVgel Technology

In a previous post, we mentioned our new UVgel printing technology. Today we offer to talk in more detail about its specifics and prerequisites for its occurrence.

But first, let's step back a little from the topic and find out what is going on in the wide format printing market.

In the future, by 2020, a number of research marketing companies forecast annual growth in printing volumes by an average of 3%. It is expected that the bulk will be on signs, banners, posters and, of course, packaging products. But in addition to the growth in print volumes, the rhythm of modern business requires minimizing the lead time. According to the InfoTrends study, the actual demand for print dates was distributed as follows:

We see that the bulk of orders falls on printing, completed as soon as possible. This means that the winner will be the company that can offer the most expeditious service delivery, all other things being equal. Not the last role in this is played by the used printing equipment.

Today, two main types of printing are traditionally used:

The most common is the first form. This is due to the relatively low cost of equipment and ease of maintenance. However, obtaining satisfactory results, due to the technology used, is a constant compromise between quality and performance. In addition, this equipment works with a limited range of materials due to the presence of high temperature printing processes.

One way to increase productivity is to expand the equipment fleet, which requires additional production facilities and staff expansion. This is justified only during periods of peak loads and unprofitable during periods of recession.

UV curable inks are of good quality at high productivity. But its widespread use is limited due to serious start-up investments, which often turn out to be unbearable for small and medium-sized companies. However, even ownership of such equipment must be ensured by a continuous flow of orders in large volumes so that investments remain in the profitability zone.

Thus, the segment of large format printing has two extreme positions. On the one hand, low starting investments with low productivity or quality, and on the other hand, good quality and speed, but at a high cost. The new UVgel technology is focused on occupying an empty niche and giving high-quality printing with a relatively small investment.

Consider the main problems that affect print speed and quality. Since we accept printing with UV-curable ink as a kind of standard, we will consider printing with latex and eco-solvent ink. It has a number of weaknesses associated with a feature of technology. That is, it is impossible to completely get rid of the flaws, and modernization does not give the desired results. Of the main disadvantages, we highlight:

Let us dwell on each in more detail.

The difference in print area between a digital file and a finished print is called Dot Gain. In domestic polygraphy, this term corresponds to the term “dot gain”. This phenomenon is based on several components:

Base

Each material used as a base has individual characteristics. These include:

The first three characteristics give optical dot gain, which will invariably appear with any type of printing. Due to the propagation of light in the layer of the carrier in its depth creates a shadow from the contours of the print. Moreover, visually the size of the print is perceived more than it actually is.

Depth and area of penetration of paint depends on the porosity of the substrate. This parameter is closely related to the physical and mechanical properties of the ink.

Ink

The main contributor to the spreading phenomenon is ink. It matters density, adhesive properties, curing time, transparency and much more. When printing, equipment settings are made to compensate for dot gain. But this does not always give the desired effect.

In some cases, repeatability of the print is key. For example, when printing wallpapers, when prints made at different times are in direct contact. The quality of such printing is possible, but this is achieved by a significant reduction in speed. So on a latex printer with maximum quality, performance drops to 6 m2 / h. It is clear that large volumes of high-quality printing on equipment of this type cannot be completed in a short time.

Feeding and processing mode of the sealed material

To a lesser extent, but still affects the spread, the feed and drying speeds of the substrate. This affects the shape of the drop print and the degree of ink flowability.

The fixing of latex and eco-solvent inks occurs under the influence of temperature due to evaporation of the solvent (solvent). The prints are dried at a relatively high temperature. Because of this, the range of materials used as a basis is limited. For latex and eco-solvent printing, thermoplastic materials cannot be used.

Taking into account the nuances described above, a new UVgel technology was developed. Simplified printing process can be described in the following stages:

What printing problems does UVgel solve? Liquid ink, leaving the print head, turns into gel directly on the media. They immediately form a point, not spreading over the surface. The size and positioning of the points are fixed, and the merging and mixing of neighboring points is completely eliminated. Thus, we can control mechanical dot gain with high accuracy - and this gives an additional plus.

When printing with latex and eco-solvent ink, in order to reduce dot gain, a single ink supply is reduced, but the number of passes of the print head increases, which significantly reduces the productivity of the equipment. UVgel technology allows you to apply the maximum amount of ink in one go without compromising print quality. That is, we excluded the dependence of print speed on this factor.

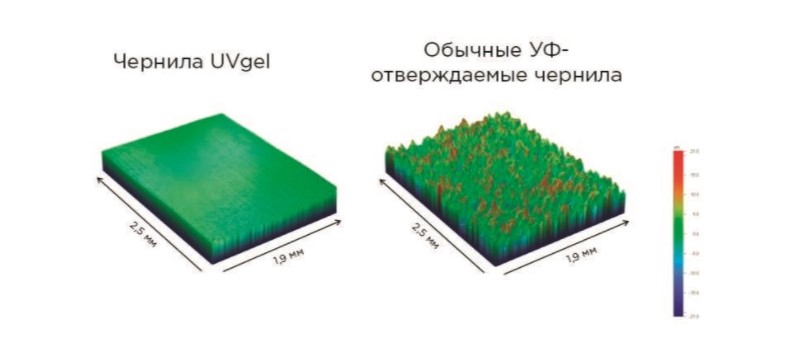

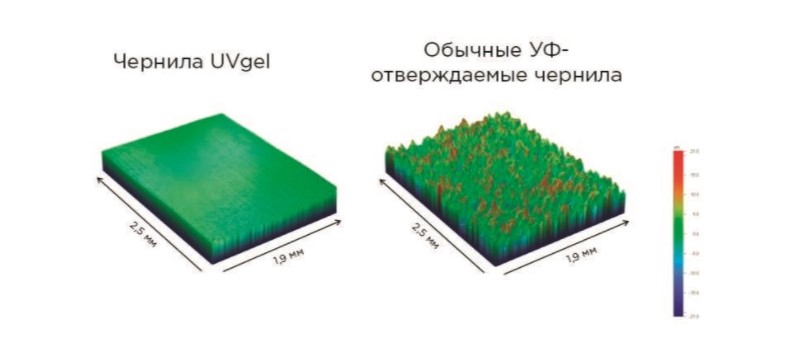

It is worth noting that our new technology has a predominant difference from traditional UV printing. This applies to surface quality when sealing. So, with UV printing in several passes, each ink layer is dried immediately after printing due to the fact that UV curing lamps move with the print head. As a result, a microrelief is formed on the surface of the imprint. In UVgel technology, this process is slightly different. The gel state of the ink does not require instant curing. There is a small time interval between the moment of their application and UV exposure. During this time, a drop of ink gel has time to settle, and surface tension forces to form its smooth surface. Only then can ink be cured with UV light. There is no fundamental difference between these two types of surface,

UVgel technology has the added benefit of ink composition. When curing the print, there is no need for thermal evaporation of the solvent. In addition, the technology requires printing at a stable temperature of +28 0C. And this allows you to significantly expand the range of materials used as a basis. This is especially true for thermoplastic materials that cannot be used with latex and eco-solvent printing. Also, when using materials with increased porosity and high absorbency, this technology will not impair the quality of the print. Unlike latex and eco-solvent inks, which are absorbed and spread out until they are completely dry, UVgel-ink simply sticks to the surface, forming stable points.

Today, the technology is implemented in the Océ Colorado 1640 wide format printer , the first roll printer of its kind. In our next reviews, we will definitely tell you about the characteristics of the machine and the hardware solutions used to implement UVgel-technology - stay tuned so as not to miss.

But first, let's step back a little from the topic and find out what is going on in the wide format printing market.

The modern market for large format printing: trends and problems

In the future, by 2020, a number of research marketing companies forecast annual growth in printing volumes by an average of 3%. It is expected that the bulk will be on signs, banners, posters and, of course, packaging products. But in addition to the growth in print volumes, the rhythm of modern business requires minimizing the lead time. According to the InfoTrends study, the actual demand for print dates was distributed as follows:

- fulfillment of the order during the day - 41%

- from one day to two - 21%

- more than two days - 38%.

We see that the bulk of orders falls on printing, completed as soon as possible. This means that the winner will be the company that can offer the most expeditious service delivery, all other things being equal. Not the last role in this is played by the used printing equipment.

Today, two main types of printing are traditionally used:

- with latex or eco-solvent ink;

- with UV curable ink.

The most common is the first form. This is due to the relatively low cost of equipment and ease of maintenance. However, obtaining satisfactory results, due to the technology used, is a constant compromise between quality and performance. In addition, this equipment works with a limited range of materials due to the presence of high temperature printing processes.

One way to increase productivity is to expand the equipment fleet, which requires additional production facilities and staff expansion. This is justified only during periods of peak loads and unprofitable during periods of recession.

UV curable inks are of good quality at high productivity. But its widespread use is limited due to serious start-up investments, which often turn out to be unbearable for small and medium-sized companies. However, even ownership of such equipment must be ensured by a continuous flow of orders in large volumes so that investments remain in the profitability zone.

Thus, the segment of large format printing has two extreme positions. On the one hand, low starting investments with low productivity or quality, and on the other hand, good quality and speed, but at a high cost. The new UVgel technology is focused on occupying an empty niche and giving high-quality printing with a relatively small investment.

Printing Problems of Large Format Printing Machines

Consider the main problems that affect print speed and quality. Since we accept printing with UV-curable ink as a kind of standard, we will consider printing with latex and eco-solvent ink. It has a number of weaknesses associated with a feature of technology. That is, it is impossible to completely get rid of the flaws, and modernization does not give the desired results. Of the main disadvantages, we highlight:

- Dot gain or dot gain;

- thermal drying of a print.

Let us dwell on each in more detail.

Dot gain

The difference in print area between a digital file and a finished print is called Dot Gain. In domestic polygraphy, this term corresponds to the term “dot gain”. This phenomenon is based on several components:

- optical and diffusion properties of the base;

- physico-mechanical and optical properties of ink;

- feeding and processing mode of the sealed base;

- dimensions and shape of the imprint elements.

Base

Each material used as a base has individual characteristics. These include:

- color;

- reflective ability;

- transparency;

- porosity and much more.

The first three characteristics give optical dot gain, which will invariably appear with any type of printing. Due to the propagation of light in the layer of the carrier in its depth creates a shadow from the contours of the print. Moreover, visually the size of the print is perceived more than it actually is.

Depth and area of penetration of paint depends on the porosity of the substrate. This parameter is closely related to the physical and mechanical properties of the ink.

Ink

The main contributor to the spreading phenomenon is ink. It matters density, adhesive properties, curing time, transparency and much more. When printing, equipment settings are made to compensate for dot gain. But this does not always give the desired effect.

In some cases, repeatability of the print is key. For example, when printing wallpapers, when prints made at different times are in direct contact. The quality of such printing is possible, but this is achieved by a significant reduction in speed. So on a latex printer with maximum quality, performance drops to 6 m2 / h. It is clear that large volumes of high-quality printing on equipment of this type cannot be completed in a short time.

Feeding and processing mode of the sealed material

To a lesser extent, but still affects the spread, the feed and drying speeds of the substrate. This affects the shape of the drop print and the degree of ink flowability.

Thermal drying

The fixing of latex and eco-solvent inks occurs under the influence of temperature due to evaporation of the solvent (solvent). The prints are dried at a relatively high temperature. Because of this, the range of materials used as a basis is limited. For latex and eco-solvent printing, thermoplastic materials cannot be used.

UVgel Printing Technology: Features and Benefits

Taking into account the nuances described above, a new UVgel technology was developed. Simplified printing process can be described in the following stages:

- Warming up the UVgel ink in the print head until they transition from a gel state to a liquid state.

- Application of ink to a medium whose temperature is automatically maintained at +28 0C.

- Due to the maintenance of the set temperature, ink, getting on the carrier, instantly turns from liquid into gel.

- In the gel state, the drops are immediately fixed on the carrier and do not spread.

- After ink is applied to the substrate, they are cured by LED UV light.

What printing problems does UVgel solve? Liquid ink, leaving the print head, turns into gel directly on the media. They immediately form a point, not spreading over the surface. The size and positioning of the points are fixed, and the merging and mixing of neighboring points is completely eliminated. Thus, we can control mechanical dot gain with high accuracy - and this gives an additional plus.

When printing with latex and eco-solvent ink, in order to reduce dot gain, a single ink supply is reduced, but the number of passes of the print head increases, which significantly reduces the productivity of the equipment. UVgel technology allows you to apply the maximum amount of ink in one go without compromising print quality. That is, we excluded the dependence of print speed on this factor.

It is worth noting that our new technology has a predominant difference from traditional UV printing. This applies to surface quality when sealing. So, with UV printing in several passes, each ink layer is dried immediately after printing due to the fact that UV curing lamps move with the print head. As a result, a microrelief is formed on the surface of the imprint. In UVgel technology, this process is slightly different. The gel state of the ink does not require instant curing. There is a small time interval between the moment of their application and UV exposure. During this time, a drop of ink gel has time to settle, and surface tension forces to form its smooth surface. Only then can ink be cured with UV light. There is no fundamental difference between these two types of surface,

UVgel technology has the added benefit of ink composition. When curing the print, there is no need for thermal evaporation of the solvent. In addition, the technology requires printing at a stable temperature of +28 0C. And this allows you to significantly expand the range of materials used as a basis. This is especially true for thermoplastic materials that cannot be used with latex and eco-solvent printing. Also, when using materials with increased porosity and high absorbency, this technology will not impair the quality of the print. Unlike latex and eco-solvent inks, which are absorbed and spread out until they are completely dry, UVgel-ink simply sticks to the surface, forming stable points.

Today, the technology is implemented in the Océ Colorado 1640 wide format printer , the first roll printer of its kind. In our next reviews, we will definitely tell you about the characteristics of the machine and the hardware solutions used to implement UVgel-technology - stay tuned so as not to miss.