Work on carriers around the globe

Recent days have stood out very peppy in the field of news about work on various media. Fresh photos of the components of the central block of the superheavy rocket SLS appeared, SpaceX brought to the test the final modification of the Falcon 9 - Block 5, in China tests of the Great March 5 engine began as part of the correction of the cause of last year’s accident, and the wording “above the launch vehicles” was replaced in the heading more general due to continued taxiing of the Stratolaunch carrier aircraft.

Photo: Stratolaunch

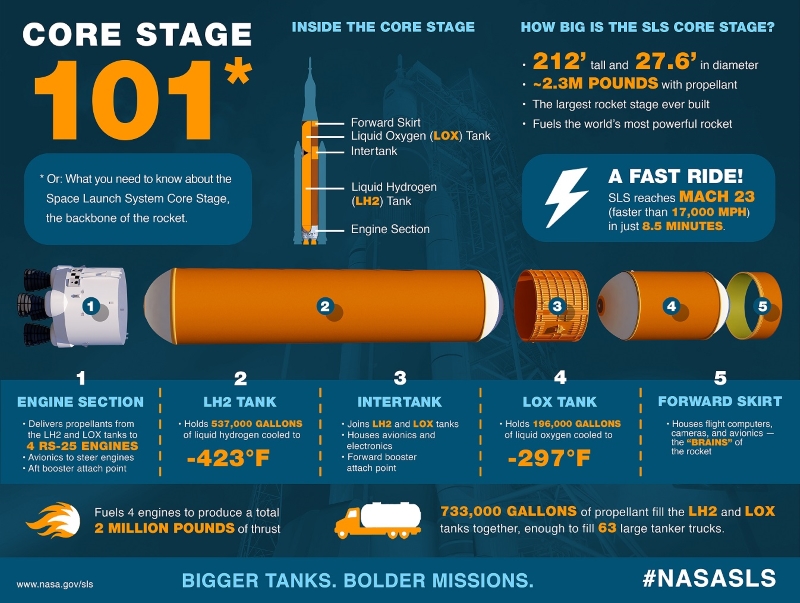

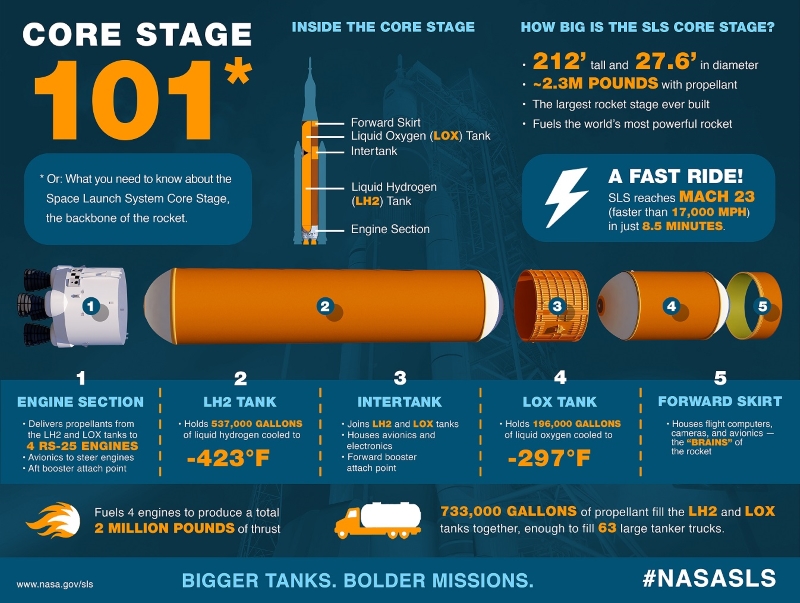

The central unit (second stage according to the Russian classification) of the SLS launch vehicle consists of five large parts: the engine compartment, the hydrogen tank, the inter-tank compartment, the oxygen tank and the transition compartment.

Scheme of the central unit SLS, drawing NASA

The most advanced work on the transition compartment. Its strength is considered excessive, so they did not begin to make an understudy for strength tests. The flight instance has already been equipped with interface connectors with the launch complex and thermal protection has been applied.

Transition compartment SLS, photo Philip Sloss / NSF

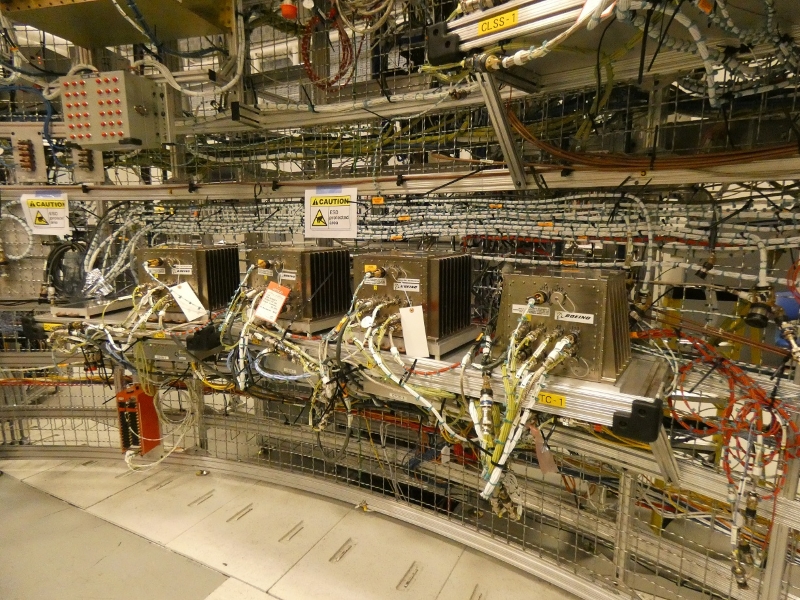

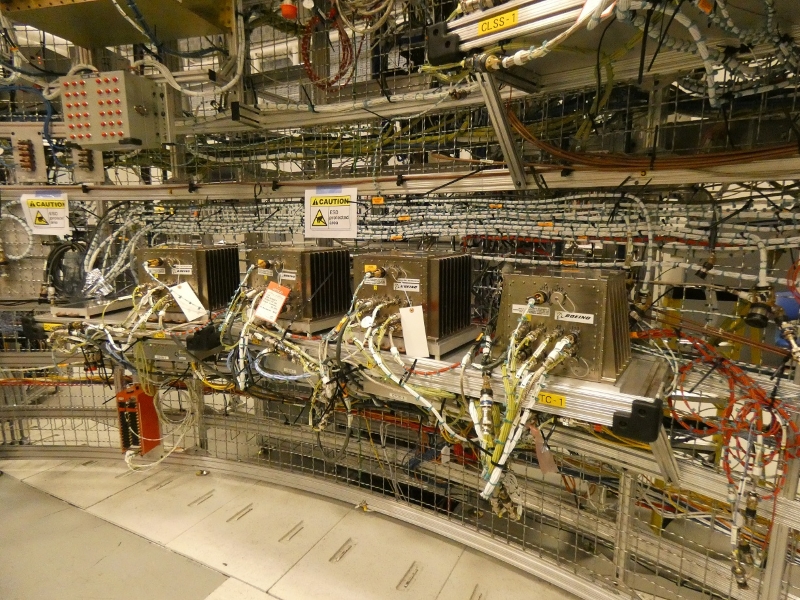

Now the cable network is being installed, the electronics are separately tested. Three on-board computers, an inertial navigation system, and one of the telemetry system transmitters with an antenna will be installed in the transition compartment.

Electronics on tests, photo Philip Sloss / NSF

At the same time, flight specimens and technological models for the strength tests of the remaining elements of the launch vehicle are manufactured.

The inter-tank compartment performs several tasks at once. First of all, it must withstand loads and vibration in flight. The situation is further complicated by the fact that side accelerators will be attached to it. Electronics, telemetry devices, batteries, sensors and controllers are also located there. And finally, through it the pipelines of the upper (oxygen) tank. Due to production features, the hull of the flight instance of the inter-tank compartment was assembled earlier than the layout. Therefore, the former has already been coated with a primer and thermal protection, and the latter is only being driven for testing.

Flight copy of the inter-tank compartment, photo Philip Sloss / NSF

Technological model, photo Philip Sloss / NSF

The flight instance of the oxygen tank also overtook its model - they had already managed to conduct it through non-destructive tests and rinse. The next stage is the coating with anti-corrosion primer and heat-protective foam.

Hydrogen tanks (long) and oxygen (short) in the workshop, NASA photo

Technological layout of the oxygen tank, NASA photo

The flight instance of the hydrogen tank managed to pass only pneumatic tests.

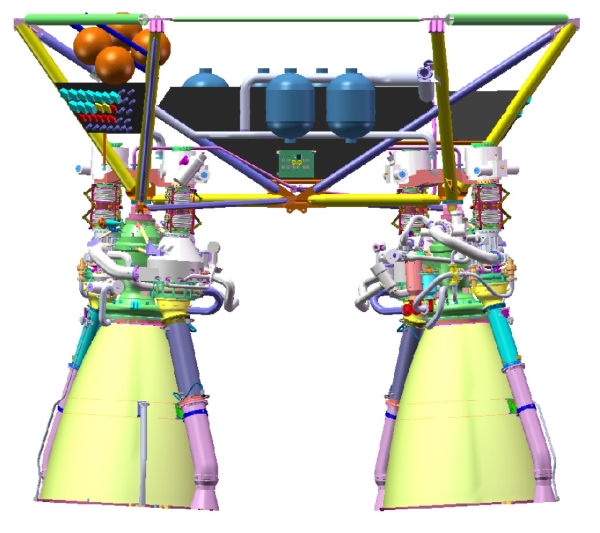

The engine compartment has not yet been assembled in two parts. But his understudy has already passed strength tests. Engines, their hydraulic drives, various controllers and other equipment will be installed here.

The tail section of the engine compartment, photo Philip Sloss / NSF

Work in the assembly shops Mishoud (Michoud Assembly Facility, MAF) in New Orleans are literally around the clock. The assembled central unit for the first SLS flight should leave the workshop at the end of this or the beginning of next year.

Falcon 9 Block 5, photo by Gary Blair / NSF, also in large size

The final version of the Falcon 9 launch vehicle, Block 5, arrived for testing at the SpaceX test bench in McGregor. It is going to implement several changes at once. First of all, inter-flight maintenance is simplified. Musk said that this version will be ready for flight only a day after landing. The new landing bearings can be added up by the efforts of the maintenance team (before that they had to be removed entirely), the stage will receive thermal protection to facilitate braking in the atmosphere, and the aluminum steering wheels will be replaced with titanium ones. New steering wheels have already been tested at the launch of the Iridium NEXT-2 in the summer of 2017.

New steering wheels, photo SpaceX

Further, NASA's stringent safety requirements are being implemented - the design of boost tanks and engine turbopumps is being changed - a study of flying and tested engines found cracks in the turbopumps. At the request of NASA, before flying with the crew, the “frozen” version of the rocket, without new changes, will have to make seven successful flights.

The second launch of the Great Campaign 5 launch vehicle last summer was an accident . The version expressed then on the analysis of translation seemed to be correct - in November anonymous sources said that the cause of the accident was the shutdown of the fuel path of one of the engines with a torn-off rotor pump shaft cover.

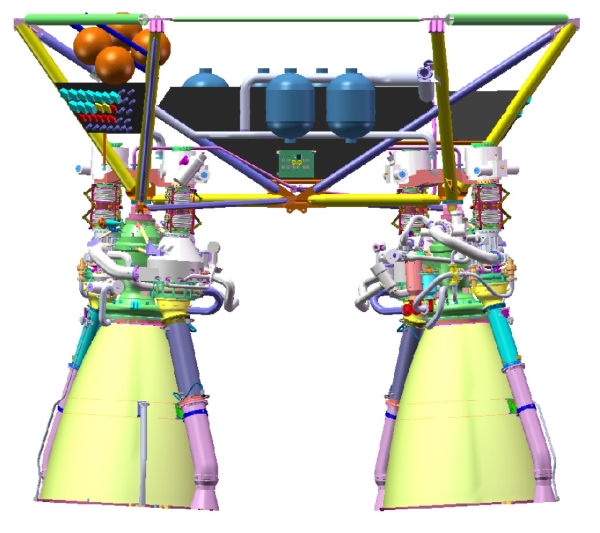

Assembling two YF-77 engines, CALT scheme

As expected, the localization and elimination of the problem took six months already, and work has not yet been completed. According to official information, the revised engine began fire tests in mid-February. The date of the next flight of the Great Campaign 5 is still unknown, and this continues to shift to the right the interesting Chinese mission Chang'e-5 with the return of lunar soil to Earth.

Test engine YF-77, photo CASC

Beginning in December, taxi tests of the Stratolaunch carrier aircraft were continued on February 25 and 26. They reached a speed of 74 km / h. Obviously, soon we will have the first flight of the largest aircraft to date. The first launch of the launch vehicle from it is expected in 2019, according to today's plans, it will be the Pegasus rocket many times already.

Photo: Stratolaunch

SLS assembly

The central unit (second stage according to the Russian classification) of the SLS launch vehicle consists of five large parts: the engine compartment, the hydrogen tank, the inter-tank compartment, the oxygen tank and the transition compartment.

Scheme of the central unit SLS, drawing NASA

The most advanced work on the transition compartment. Its strength is considered excessive, so they did not begin to make an understudy for strength tests. The flight instance has already been equipped with interface connectors with the launch complex and thermal protection has been applied.

Transition compartment SLS, photo Philip Sloss / NSF

Now the cable network is being installed, the electronics are separately tested. Three on-board computers, an inertial navigation system, and one of the telemetry system transmitters with an antenna will be installed in the transition compartment.

Electronics on tests, photo Philip Sloss / NSF

At the same time, flight specimens and technological models for the strength tests of the remaining elements of the launch vehicle are manufactured.

The inter-tank compartment performs several tasks at once. First of all, it must withstand loads and vibration in flight. The situation is further complicated by the fact that side accelerators will be attached to it. Electronics, telemetry devices, batteries, sensors and controllers are also located there. And finally, through it the pipelines of the upper (oxygen) tank. Due to production features, the hull of the flight instance of the inter-tank compartment was assembled earlier than the layout. Therefore, the former has already been coated with a primer and thermal protection, and the latter is only being driven for testing.

Flight copy of the inter-tank compartment, photo Philip Sloss / NSF

Technological model, photo Philip Sloss / NSF

The flight instance of the oxygen tank also overtook its model - they had already managed to conduct it through non-destructive tests and rinse. The next stage is the coating with anti-corrosion primer and heat-protective foam.

Hydrogen tanks (long) and oxygen (short) in the workshop, NASA photo

Technological layout of the oxygen tank, NASA photo

The flight instance of the hydrogen tank managed to pass only pneumatic tests.

The engine compartment has not yet been assembled in two parts. But his understudy has already passed strength tests. Engines, their hydraulic drives, various controllers and other equipment will be installed here.

The tail section of the engine compartment, photo Philip Sloss / NSF

Work in the assembly shops Mishoud (Michoud Assembly Facility, MAF) in New Orleans are literally around the clock. The assembled central unit for the first SLS flight should leave the workshop at the end of this or the beginning of next year.

Block 5 at McGregor

Falcon 9 Block 5, photo by Gary Blair / NSF, also in large size

The final version of the Falcon 9 launch vehicle, Block 5, arrived for testing at the SpaceX test bench in McGregor. It is going to implement several changes at once. First of all, inter-flight maintenance is simplified. Musk said that this version will be ready for flight only a day after landing. The new landing bearings can be added up by the efforts of the maintenance team (before that they had to be removed entirely), the stage will receive thermal protection to facilitate braking in the atmosphere, and the aluminum steering wheels will be replaced with titanium ones. New steering wheels have already been tested at the launch of the Iridium NEXT-2 in the summer of 2017.

New steering wheels, photo SpaceX

Further, NASA's stringent safety requirements are being implemented - the design of boost tanks and engine turbopumps is being changed - a study of flying and tested engines found cracks in the turbopumps. At the request of NASA, before flying with the crew, the “frozen” version of the rocket, without new changes, will have to make seven successful flights.

Corrected Engines for the Great Campaign 5

The second launch of the Great Campaign 5 launch vehicle last summer was an accident . The version expressed then on the analysis of translation seemed to be correct - in November anonymous sources said that the cause of the accident was the shutdown of the fuel path of one of the engines with a torn-off rotor pump shaft cover.

Assembling two YF-77 engines, CALT scheme

As expected, the localization and elimination of the problem took six months already, and work has not yet been completed. According to official information, the revised engine began fire tests in mid-February. The date of the next flight of the Great Campaign 5 is still unknown, and this continues to shift to the right the interesting Chinese mission Chang'e-5 with the return of lunar soil to Earth.

Test engine YF-77, photo CASC

New Stratolaunch Speed

Beginning in December, taxi tests of the Stratolaunch carrier aircraft were continued on February 25 and 26. They reached a speed of 74 km / h. Obviously, soon we will have the first flight of the largest aircraft to date. The first launch of the launch vehicle from it is expected in 2019, according to today's plans, it will be the Pegasus rocket many times already.